Felt Laser Cutter

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Felt Laser Cutter, We sincerely welcome the two overseas and domestic business enterprise associates, and hope to operate along with you in the around long term!

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for best machine for cutting felt, best machine to cut felt, best way to cut felt, Cnc felt cutting machine, felt cutter, felt cutting machine, Felt cutting tools, felt laser cut, how to cut felt, how to cut felt circles, how to cut thick felt, laser cut felt coasters, laser cut felt panels, laser cutting felt, Laser felt cutting machine, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

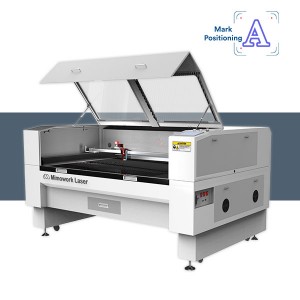

Advantages of Flatbed Laser Cutter

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

R&D for Flexible Material Cutting

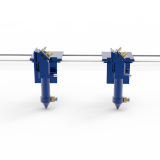

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

2-min Overview of Laser Cutting Felt

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

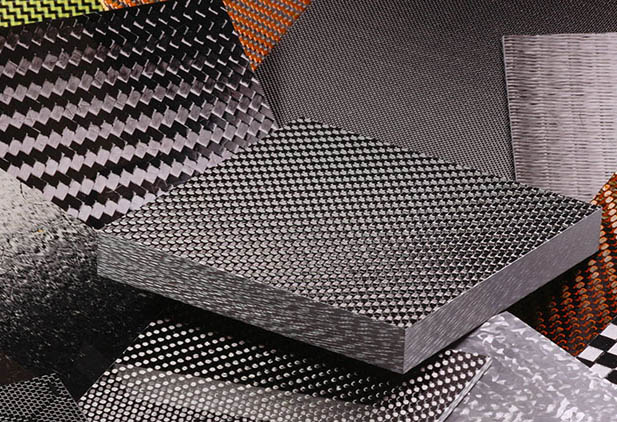

Composite Material

Engraving, marking, and cutting can be realized in single process

Automotive & Aviation

Your popular and wise manufacturing direction

Outdoor Equipment

The secret of exquisite pattern cutting

Common materials and applications

of Flatbed Laser Cutter 160

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Laser Cutting Felt

How to cut felt?

Felt is a non-woven fabric that typically consists of natural fibers and synthetic fibers by the process of heat, moisture, and mechanical action. Compared with regular woven fabrics, felt is much thicker and more compact. For this reason, felt is widely used to make slippers and as a novelty fabric for garments and furniture. Industrial applications include insulation, packaging, and polishing materials for mechanical parts. A flexible and specialized felt laser cutter is the best way to cut felt. Different from the traditional felt cutter, laser cutting machine owns unique and premium features. Thermal cutting can melt the fragmentary fibers and seal the edge of the felt. Precisely because of that, the untight internal structure of the felt will not be damaged and the processing does not accompany by dust and ash.

Laser processing for felt

1. Laser cutting Felt

Fast and neat laser cutting on felt avoids adhesion between material, bringing high quality finished felt with sealing edge while heat cutting. Automated feeding and cutting reduce labor cost in a degree.

2. Laser marking felt

High contrasting in color with laser etching single-layer of the felt can achieve permanent and unfading varieties patterns, customized brand logo images.

3. Laser engraving felt

Thin and fine laser beam can instantly engrave multilayer felt material by setting suitable laser power. Flexible processing method has no limitation for different shapes and patterns.

Application of laser cutting felt

When laser-cut, CO2 laser machine can produce wonderfully precise results on felt placemats and coasters. For house decoration, a thick rug pad can be easily cut.

Felt hat, Felt bag, Self-adhesive felt, Felt craft, Felt pad, Felt mattress, Felt ornament, Felt letter board, Felt Christmas tree, Felt carpet (mat)

Benefits from laser cutting felt panels

• No need for material fixation with vacuum working table

• Contactless and free forceful processing guarantees felt intact stability

• No tool wear and replacing cost

• Clean processing environment

• Free pattern cutting, engraving, marking

• Suitable processing method according to fabric structure