Lokacin da kuka kasance sababbi ga fasahar Laser kuma kuyi la'akari da siyan injin yankan Laser, dole ne ku sami tambayoyi da yawa da kuke son yi.

MimoWork yana farin cikin raba muku ƙarin bayani game da na'urorin Laser CO2 kuma da fatan za ku iya samun na'urar da ta dace da ku, ko daga gare mu ne ko kuma wani mai samar da Laser.

A cikin wannan labarin, za mu ba da taƙaitaccen bayani game da tsarin injin a cikin al'ada kuma muyi nazarin kwatancen kowane sashe. Gabaɗaya, labarin zai ƙunshi batutuwa kamar haka:

>> Tsarin injina na injin Laser

>> CO2 gilashin Laser tubes VS CO2 RF Laser shambura (Synrad, Coherent, Rofin)

>> Tsarin Gudanarwa da Software

>> Zabuka

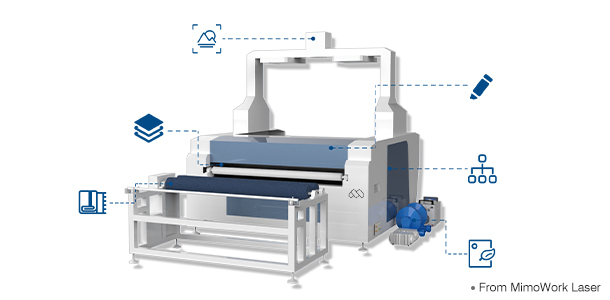

Makanikai na CO2 Laser inji

a. Motar DC mara nauyi, Motar Servo, Motar Mataki

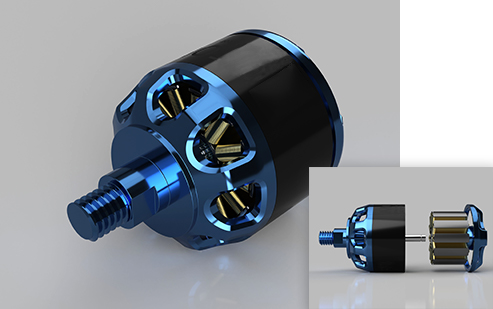

Motar Brushless DC (kai tsaye na yanzu).

Motar DC maras goge tana iya gudu a babban RPM (juyin juya hali a minti daya). Stator na injin DC yana ba da filin maganadisu mai jujjuya wanda ke motsa ƙwanƙwasa don juyawa. Daga cikin dukkan injina, injin dc maras goge zai iya samar da mafi girman kuzarin motsin motsi kuma yana fitar da kan laser don motsawa cikin babban sauri.MimoWork mafi kyawun injin zanen Laser CO2 an sanye shi da injin da ba shi da goga kuma yana iya kaiwa matsakaicin saurin zane na 2000mm/s.Motar dc maras goge ba a cika gani a cikin injin yankan Laser CO2 ba. Wannan shi ne saboda saurin yankewa ta hanyar abu yana iyakance ta kauri daga cikin kayan. Akasin haka, kawai kuna buƙatar ƙaramin ƙarfi don sassaƙa zane akan kayan ku, Motar da ba ta da goga wanda aka sanye da injin injin Laser zai yi. rage lokacin zanen ku da daidaito mafi girma.

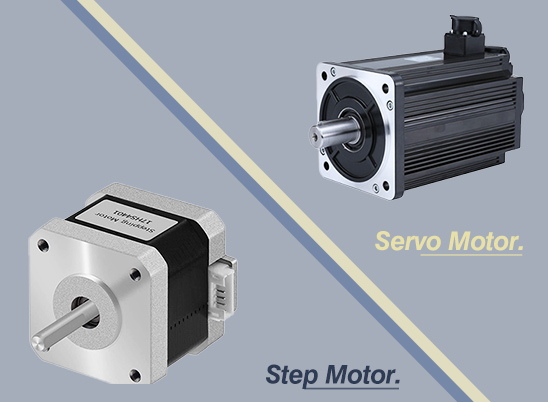

Motar Servo & Motar Mataki

Kamar yadda muka sani duk gaskiyar cewa servo Motors na iya samar da manyan matakan juzu'i a babban gudun kuma sun fi tsada fiye da matakan stepper. Motocin Servo suna buƙatar mai rikodin don daidaita bugun jini don sarrafa matsayi. Buƙatar mai rikodin rikodi da akwatin gear yana sa tsarin ya fi rikitarwa na inji, yana haifar da ƙarin kulawa akai-akai da ƙarin farashi. Hade tare da CO2 Laser inji,Motar servo na iya isar da daidaito mafi girma akan matsayin gantry da shugaban laser fiye da injin stepper yayi. Ganin cewa, magana ta gaskiya, a mafi yawan lokuta, yana da wuya a gane bambancin daidaito lokacin da kuke amfani da injina daban-daban, musamman idan kuna yin kyaututtuka masu sauƙi waɗanda ba sa buƙatar daidaito sosai. Idan kuna sarrafa kayan haɗe-haɗe da aikace-aikacen fasaha, kamar zane mai tacewa don farantin tacewa, labule mai ƙoshin lafiya don abin hawa, murfin insulating don jagorar, to za a nuna iyawar servo Motors daidai.

Kowane motar yana da fa'ida da rashin amfaninsa. Wanda ya dace da ku shine mafi kyau a gare ku.

Tabbas, MimoWork na iya samar da CO2 Laser engraver da abun yanka tare da nau'ikan injin guda uku dangane da bukatu da kasafin ku.

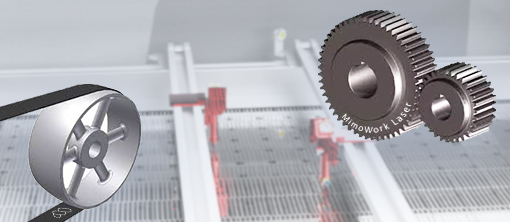

b. Belt Drive VS Gear Drive

A bel Drive tsarin ne na haɗa ƙafafun da bel yayin da wani gear drive ne biyu gears suna da alaka da juna kamar yadda m biyu hakora suna gama interconnected. A cikin inji tsarin na Laser kayan aiki, biyu tafiyarwa ake amfani da susarrafa motsi na gantry Laser da kuma ayyana madaidaicin na'urar Laser.

Mu kwatanta su biyun da tebur mai zuwa:

|

Belt Drive |

Gear Drive |

| Babban kashi Pulleys da Belt | Babban kashi Gears |

| Ana buƙatar ƙarin sarari | Ƙananan sarari da ake buƙata, don haka ana iya tsara na'urar laser don zama ƙarami |

| Babban hasara na gogayya, don haka ƙananan watsawa da ƙarancin inganci | Ƙananan asarar gogayya, don haka mafi girman watsawa da ƙarin inganci |

| Ƙananan tsammanin rayuwa fiye da kayan tuƙi, yawanci yana canzawa kowace shekara 3 | Mafi girman tsammanin rayuwa fiye da bel, yawanci yana canzawa kowace shekara goma |

| Yana buƙatar ƙarin kulawa, amma farashin kulawa yana da ɗan rahusa da dacewa | Yana buƙatar ƙarancin kulawa, amma farashin kulawa ya fi so kuma mai wahala |

| Ba a buƙatar man shafawa | Bukatar man shafawa na yau da kullun |

| Yayi shiru yana aiki | Hayaniyar aiki |

Dukansu gear drive da bel drive tsarin yawanci tsara a cikin Laser sabon na'ura tare da ribobi da fursunoni. A takaice dai,tsarin tuƙi na bel ɗin ya fi fa'ida a cikin ƙananan girman, nau'ikan injuna masu tashi-fitowa; saboda mafi girman watsawa da karko,da gear drive ya fi dace da babban-format Laser abun yanka, kullum tare da matasan Tantancewar zane.

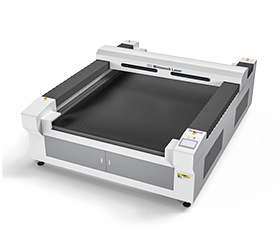

c. Teburin Aiki Na Tsaye VS Teburin Mai Aiki

Don inganta aikin sarrafa Laser, kuna buƙatar fiye da wadatar Laser mai inganci da ingantaccen tsarin tuki don matsar da kan Laser, tebur tallafin kayan dacewa kuma ana buƙatar. Teburin aiki wanda aka keɓance don dacewa da kayan ko aikace-aikacen yana nufin zaku iya haɓaka yuwuwar injin ku.

Gabaɗaya, akwai nau'ikan dandamalin aiki guda biyu: Tsaye da Wayar hannu.

(Don aikace-aikace daban-daban, zaku iya ƙare ta amfani da kowane nau'in kayan, ko dai kayan takarda ko kayan naɗe)

○ Tebur Aiki A tsaye ya dace don sanya kayan takarda kamar acrylic, itace, takarda (kwali).

• Tebur tsiri wuka

• tebur tsefe zuma

○ Teburin Aiki Mai Canjawa ya dace don sanya kayan mirgine kamar masana'anta, fata, kumfa.

• Teburin jirgi

Tebur mai ɗaukar kaya

Amfanin ƙirar tebur aiki mai dacewa

✔ Kyakkyawan hakar fitar da hayaki

✔ Tabbatar da kayan aiki, babu motsi yana faruwa lokacin yankan

✔ Dace don lodawa da sauke kayan aikin

✔ Mafi kyawun jagorar mayar da hankali godiya ga filaye masu lebur

✔ Sauƙaƙan kulawa da tsaftacewa

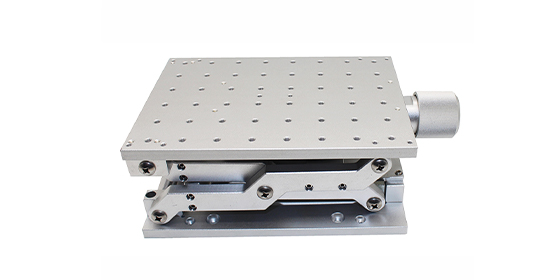

d. Platform na ɗagawa VS Manual dagawa ta atomatik

Lokacin da kuke zana kayan aiki masu ƙarfi, kamar acrylic (PMMA) kuma itace (MDF), kayan sun bambanta da kauri. Madaidaicin tsayin mayar da hankali zai iya inganta tasirin zane. Madaidaicin dandamalin aiki yana da mahimmanci don nemo mafi ƙanƙanta wurin mayar da hankali. Domin CO2 Laser engraving inji, atomatik dagawa da manual dagawa dandamali yawanci kwatanta. Idan kasafin kuɗin ku ya isa, je don dandamalin ɗagawa ta atomatik.Ba wai kawai inganta yankan da zane-zane daidai ba, yana iya ceton ku ton na lokaci da ƙoƙari.

e. Tsarin Sama, Gefe & Kasa

Tsarin iska na ƙasa shine zaɓi na yau da kullun na injin laser CO2, amma MimoWork kuma yana da wasu nau'ikan ƙira don haɓaka ƙwarewar sarrafa laser gabaɗaya. Za amanyan-size Laser sabon na'ura, MimoWork zai yi amfani da haɗin gwiwa na sama da kasa m tsarindon bunkasa sakamakon hakar yayin da yake kiyaye sakamakon yankan Laser mai inganci. Ga yawancin mugalvo marking machine, za mu shigar da tsarin samun iska na gefedon shayar da hayaki. Dukkan bayanan na'urar za a fi dacewa da su don magance matsalolin kowace masana'antu.

An tsarin hakarana samar da shi a ƙarƙashin kayan da ake sarrafa su. Ba wai kawai fitar da hayakin da ake samu ta hanyar maganin zafi ba amma har ma da daidaita kayan, musamman masana'anta mai nauyi. Mafi girman sashin da ake sarrafawa wanda ke rufe da kayan da ake sarrafa shi, mafi girma shine tasirin tsotsawa da sakamakon tsotsawa.

CO2 gilashin Laser tubes VS CO2 RF Laser tubes

a. Motar DC mara nauyi, Motar Servo, Motar Mataki

Ƙarin tambayoyi game da na'urar Laser ko kula da Laser

Lokacin aikawa: Oktoba-12-2021