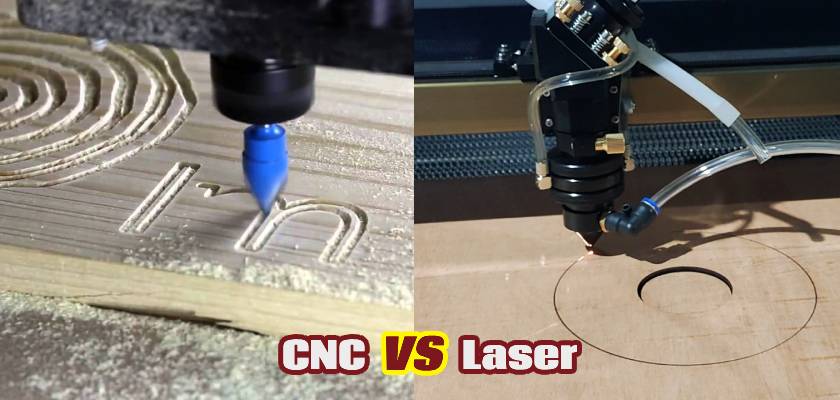

Kodi kusiyana pakati pa cnc rauta ndi laser cutter ndi kotani? Pa kudula ndi kulemba matabwa, okonda ntchito zamatabwa ndi akatswiri nthawi zambiri amakumana ndi vuto losankha chida choyenera ntchito zawo. Njira ziwiri zodziwika bwino ndi ma CNC (Computer Numerical Control) rauta ndi makina a CO2 laser, iliyonse ili ndi ubwino wake wapadera komanso ntchito zake. M'nkhaniyi, tifufuza kusiyana pakati pa zida izi ndikuthandizani kusankha bwino zomwe mukufuna pantchito zamatabwa.

Tengani Mwachangu >>

Mfundo Zofunika:

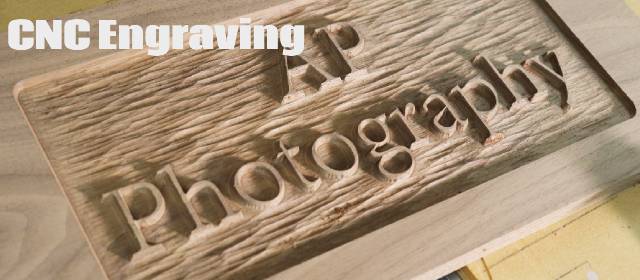

Ma rauta a CNC

Ubwino:

• Pezani kuzama kolondola kwa kudula pogwiritsa ntchito Z-axis control.

• Yothandiza pogwira ntchito yokhota pang'onopang'ono komanso yojambula mogometsa.

• Yoyenera kugwiritsidwa ntchito popanga matabwa a 3D komanso mapangidwe atsatanetsatane.

Zoyipa:

• Kusalondola kwenikweni pogwira ma angles akuthwa chifukwa cha kudula kwa bit radius.

• Zimafunika kukhazikika bwino kwa zinthu, zomwe zingayambitse kupsinjika nthawi zina.

Odulira a Laser

Ubwino:

• Kudula kosakhudzana ndi kutentha kwambiri.

• Kulondola kwapadera kwa kudula kovuta komanso m'mbali zakuthwa.

• Amatseka m'mbali kuti achepetse kukula ndi kupindika kwa matabwa.

Zoyipa:

• Zingayambitse kusintha kwa mtundu wa matabwa, koma zingatheke kupewa ndi njira zoyenera.

• Sizigwira ntchito bwino kwambiri pa ma curve oyenda pang'onopang'ono komanso m'mbali zozungulira.

Kusanthula kwa Gawo ndi Gawo >>

Kutanthauzira konse:

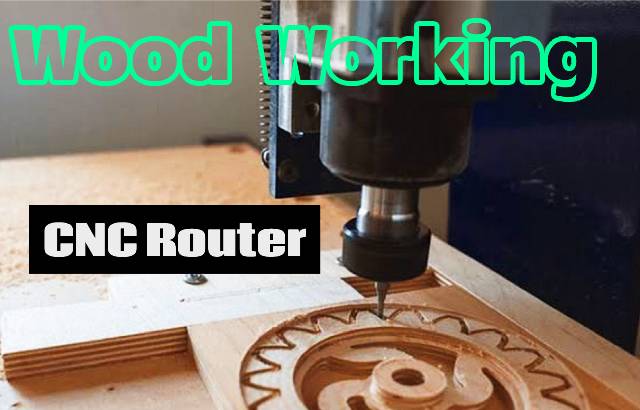

1. Kodi CNC Router ya matabwa ndi chiyani?

Routa ya CNC (Computer Numerical Control) ndi chida chogwiritsidwa ntchito kwambiri popanga matabwa chomwe chasintha dziko la luso la matabwa komanso kukonza matabwa molondola. Motsogozedwa ndi mapulogalamu apakompyuta, ma router a CNC amagwira ntchito molondola kwambiri ndipo amatha kupanga mapangidwe ovuta komanso kudula matabwa. Amagwiritsa ntchito chozungulira chozungulira kuchotsa zinthu kuchokera pa workpiece, zomwe zimapangitsa kuti zikhale zoyenera ntchito zosiyanasiyana, kuyambira zojambula mwatsatanetsatane ndi ntchito zamatabwa za 3D mpaka ma profiles olondola a m'mphepete, komanso zojambula. M'nkhaniyi, tifufuza kuthekera ndi ubwino wa ma router a CNC pankhani ya ntchito zamatabwa, kukuthandizani kumvetsetsa momwe ukadaulo uwu wakhalira chida chofunikira kwambiri kwa okonda ntchito zamatabwa komanso akatswiri.

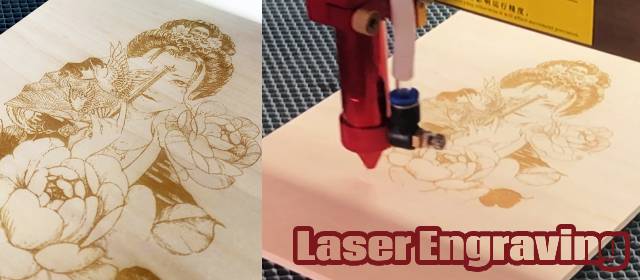

2. Kodi Laser Cutter ndi chiyani pa matabwa?

Makina odulira laser, omwe amayendetsedwa ndi magetsi amphamvu kwambiri, ayamba kukhala chida chosintha kwambiri pantchito yopanga matabwa. Makinawa amagwiritsa ntchito kulondola kwa ma laser popanga kudula kodabwitsa komanso kolondola kwambiri, komanso zojambula, muzinthu zosiyanasiyana, kuphatikiza matabwa. Pokhala ndi kuthekera kopanga m'mbali zabwino komanso zakuthwa, odulira laser atchuka chifukwa cha luso lawo lapadera lodulira bwino komanso luso lodulira bwino pantchito yopanga matabwa, kaya ndi kupanga, kupanga, kapena kujambula pamwamba pa matabwa. M'nkhaniyi, tifufuza dziko la odulira laser a CO2 ndikuwona momwe amagwiritsidwira ntchito pantchito yopanga matabwa, kukuthandizani kumvetsetsa momwe ukadaulo wamakonowu wasinthira malire a luso ndi luso.

3. Kusiyana: CNC vs. Laser Cutter

◼ Dziwani Mozama Mfundo Yogwirira Ntchito - Imagwira ntchito bwanji?

Ma rauta a CNC

Routa ya CNC imagwira ntchito motsatira mfundo yochepetsera kupanga. Ndi makina odulira olamulidwa ndi kompyuta omwe amagwiritsa ntchito chida chodulira chozungulira, monga chodulira cha router kapena mphero yomaliza, kuchotsa zinthu kuchokera pa workpiece. Chodulira cha router chimazungulira mofulumira kwambiri ndipo chimagwirizanitsidwa ndi zinthuzo, zomwe zingakhale matabwa, pulasitiki, kapena zinthu zina. Pamene choduliracho chikulumikizana, pang'onopang'ono chimadula zinthuzo, ndikupanga mawonekedwe, mapangidwe, ndi mapangidwe.

Kuyenda kwa rauta kumayendetsedwa bwino m'magawo atatu (X, Y, ndi Z) ndi pulogalamu ya pakompyuta. Izi zimathandiza kuti chipangizocho chiziyang'anira bwino malo ake komanso kuya kwake. Ma rauta a CNC ndi abwino kwambiri podula, kupanga, kusema, ndi kuchotsa zinthu. Ndi oyenera kwambiri ntchito zomwe zimafuna ntchito zovuta, za 3D, kapena zatsatanetsatane, ndipo angagwiritsidwe ntchito pojambula mwa kuwongolera mosamala kuzama ndi liwiro la choduliracho.

Odulira Laser

Odulira laser amagwiritsa ntchito mfundo ina yodziwika kuti kupanga zithunzi pogwiritsa ntchito njira yochotsera. M'malo mokhudzana ndi zinthuzo, amagwiritsa ntchito kuwala kwa laser komwe kumakhala ndi mphamvu zambiri kuti asungunule, kupsa nthunzi, kapena kutentha zinthu zomwe zili pachogwirira ntchitocho. Odulira laser nthawi zambiri amagwiritsidwa ntchito ndi zinthu zosiyanasiyana, kuphatikizapo matabwa, ndipo amatha kudula molondola. Amakhalanso ndi luso lojambula, kupanga mapangidwe ovuta mwa kusintha mphamvu ndi nthawi ya kuwala kwa laser.

Dongosolo lolamulidwa ndi kompyuta la chodulira laser limatsogolera kuwala kwa laser kuti kutsatire njira zinazake, ndikupanga mabala ovuta komanso zojambula. Kusiyana kwakukulu apa ndikuti ndi njira yosakhudzana. Laser ndi yolondola kwambiri ndipo imatha kupanga tsatanetsatane wochepa komanso m'mbali zakuthwa. Ndi yothandiza kwambiri podula ndi kujambula matabwa, mapulasitiki, ndi zipangizo zina komwe kumafunika kulondola pang'ono komanso kuchotsa zinthu zochepa.

◼ Ngati Mumakonda Kudula Matabwa:

Ma rauta a CNC

Ma router a CNC ndi akatswiri odziwa bwino ntchito yopangira matabwa chifukwa cha luso lawo lophatikiza luso lodula bwino ndi kulamulira kuya. Makina awa ndi osinthika, zomwe zimapangitsa kuti akhale abwino kwambiri popanga mapangidwe ovuta, kusema, ndi kupanga matabwa. Chomwe chimawasiyanitsa ndi kulondola kwawo pakukwaniritsa kuya kosiyanasiyana. Ndi Z-axis control, muli ndi mphamvu yosintha bwino kuya kwa kudula. Kaya ndi zojambula mwatsatanetsatane, 3D woodworking, kapena kupanga ma profiles ovuta, ma router a CNC amapereka njira zosiyanasiyana. Kuzama kwa kudula kumatsimikiziridwa ndi kutalika kwa chida chodulira ndi luso la Z-axis.

Odulira Laser

Odulira a laser, ngakhale kuti amayamikiridwa chifukwa cha kudula kwawo molondola, amagwira ntchito mosiyana pankhani ya kuzama. Amachita bwino kwambiri popanga kudula kolondola, kosaya kwambiri komanso kujambula pamwamba, kugogomezera kuzama kwambiri. Makina awa ndi akatswiri popanga mapangidwe ovuta, tsatanetsatane wochepa, ndi m'mbali zakuthwa. Ngakhale amatha kudula matabwa, cholinga chachikulu ndi pa ubwino wa pamwamba osati kuchotsa zinthu zambiri. Odulira a laser ndi akatswiri pa kulondola, kupanga mapangidwe ovuta kwambiri pamwamba pa matabwa. Komabe, kulamulira kuya kumakhala kochepa poyerekeza ndi ma rauta a CNC, nthawi zambiri kumagwirizana ndi makulidwe a zinthu zomwe akugwira ntchito.

◼ Ngati Mukugwira Ntchito Yojambula Matabwa:

Matabwa ojambulidwa ndi laserNdizabwino kwambiri popanga zojambula mwatsatanetsatane, makamaka pankhani yojambula mozungulira, zomwe zimaphatikizapo mthunzi kapena kusinthasintha kwa kujambulidwa kuti apange mapangidwe ovuta kapena zithunzi. Kulondola komanso kusakhudzana kwa ma laser kumapangitsa kuti akhale abwino kwambiri popanga mapangidwe abwino komanso atsatanetsatane pazinthu zosiyanasiyana, kuphatikizapo matabwa.

Kumbali inayi, ma router a CNC ndi oyenera kwambiri ntchito zomwe zimafuna kudula, kupanga mawonekedwe, ndi ntchito zamatabwa za 3D koma sizingapambane popanga tsatanetsatane wofanana ndi ma laser cutters. Ma router a CNC ndi ofunika popanga malo okhala ndi mawonekedwe ndi ma profiles ovuta, zomwe zimapangitsa kuti akhale zida zogwiritsidwa ntchito popanga matabwa.

Ena Akupereka Malangizo:

Zipangizo zodulira laser ndi zabwino kwambiri popanga zojambula mwatsatanetsatane, makamaka pankhani yojambula raster, zomwe zimaphatikizapo mthunzi kapena kusinthasintha kwa kuzama kwa zojambula kuti apange mapangidwe ovuta kapena zithunzi. Kulondola komanso kusakhudzana kwa ma laser kumapangitsa kuti akhale abwino kwambiri popanga mapangidwe abwino komanso atsatanetsatane pazinthu zosiyanasiyana, kuphatikizapo matabwa.

◼ Ganizirani za Kuchita Bwino ndi Kuthamanga kwa Ntchito Yopangira Matabwa

Mukasankha pakati pa ma rauta a CNC ndi odulira laser pa ntchito yanu yopangira matabwa, kumvetsetsa liwiro lawo lodulira ndi kulemba n'kofunika kwambiri. Ma rauta a CNC amagwira ntchito pokhudza zinthuzo, zomwe zimayambitsa kukangana ndipo zingayambitse nthawi yayitali yodulira. Nthawi zina, ma passion angapo angafunike kuti amalize kudula. Mosiyana ndi zimenezi, odulira laser amadziwika ndi liwiro lawo komanso luso lawo. Amatha kudutsa mwachangu m'zinthuzo, nthawi zambiri kumaliza ntchito imodzi.

Mwachitsanzo, kudula MDF ya 6mm, cnc router imatha kudula pa liwiro la 25mm pa sekondi, koma laser ndi yachangu, imatha kudula pa 50mm pa sekondi ya laser ya 300W. Komabe, ndikofunikira kudziwa kuti pamene makulidwe a zinthu akuwonjezeka, liwiro ndi magwiridwe antchito a kudula kwa laser zitha kuchepa. Pa matabwa okhuthala kwambiri, cnc router ndi yamphamvu kwambiri. Koma ngati liwiro ndi tsatanetsatane wovuta ndizo zomwe mukufuna, chodulira cha laser chingakhale chisankho chomwe mumakonda. Zambiri mwatsatanetsatane kuti mugwiritse ntchitofunsani ife >>

NGATI muli ndi zofunikira zapadera pakupanga matabwa mwamakonda,

Kupita kukalandira upangiri kwa katswiri wa laser!

◼ Ntchito ndi yosavuta kapena ayi?

Mukasankha pakati pa ma rauta a CNC ndi odulira laser pa ntchito yanu yopangira matabwa, kumvetsetsa liwiro lawo lodulira ndi kulemba n'kofunika kwambiri. Ma rauta a CNC amagwira ntchito pokhudza zinthuzo, zomwe zimayambitsa kukangana ndipo zingayambitse nthawi yayitali yodulira. Nthawi zina, ma passion angapo angafunike kuti amalize kudula. Mosiyana ndi zimenezi, odulira laser amadziwika ndi liwiro lawo komanso luso lawo. Amatha kudutsa mwachangu m'zinthuzo, nthawi zambiri kumaliza ntchito imodzi.

Mosiyana kwambiri, makina a CNC ali ndi njira yophunzirira yovuta kwambiri. Kuti muwadziwe bwino, muyenera kufufuza zovuta zake, zomwe zimaphatikizapo kumvetsetsa magawo osiyanasiyana a rauta ndi momwe amagwiritsidwira ntchito, komanso kusintha magawo osiyanasiyana kuti mupeze zotsatira zabwino. Ngati mukuganiza zogwiritsa ntchito makina a CNC, yembekezerani njira yophunzirira yayikulu, yomwe imafuna nthawi yambiri kuti mumvetse chidacho ndi tsatanetsatane wake wovuta.

◼ Ndi iti yomwe ili yosamalira chilengedwe?

• Phokoso

CNC Rauta:

Ma rauta a CNC nthawi zambiri amapanga phokoso lalikulu poyerekeza ndi odulira a laser. Kuchuluka kwa phokoso kumatha kusiyana kutengera mtundu wa rauta, chida chodulira, ndi zinthu zomwe zikukonzedwa. Nthawi zambiri ndibwino kugwiritsa ntchito zoteteza kumva mukamagwiritsa ntchito rauta ya CNC, makamaka kwa nthawi yayitali.

Chodulira cha Laser:

Zodulira za laser zimakhala chete kwambiri zikagwira ntchito. Ngakhale kuti zimapanga phokoso, nthawi zambiri zimakhala pamlingo wotsika wa decibel kuposa ma rauta a CNC. Komabe, ndikofunikira kudziwa kuti mafani otulutsa utsi ndi makina osefera mpweya, omwe nthawi zambiri amagwiritsidwa ntchito ndi zodulira za laser kuchotsa utsi, angathandize pamlingo wonse wa phokoso.

• Chitetezo

CNC Rauta:

Ma router a CNC amaonedwa kuti ndi otetezeka kwambiri pankhani yochepetsa chiopsezo chopuma utsi kapena fumbi lopangidwa panthawi yodula. Komabe, njira zotetezera ziyenera kukhazikitsidwabe, monga njira zosonkhanitsira fumbi ndi mpweya wabwino, kuti muchepetse zoopsa zokhudzana ndi fumbi la matabwa paumoyo.

Chodulira cha Laser:

Zodulira za laser zitha kukhala vuto lalikulu chifukwa cha kutulutsa utsi ndi tinthu tating'onoting'ono tomwe timadula kapena kugoba matabwa. Zipangizo monga MDF ndi plywood zimatha kutulutsa mpweya woipa, ndipo mpweya wabwino ndi makina otulutsa utsi ndizofunikira kuti malo ogwirira ntchito akhale otetezeka. Malangizo achitetezo a laser ayenera kutsatiridwa mosamala kuti ateteze ku kuwala kwa laser.

4. Kodi Mungasankhe Bwanji CNC kapena Laser?

Ganizirani Zofunikira pa Pulojekiti Yanu:

Pa zojambula zovuta, ntchito zamatabwa za 3D, ndi ntchito zopanga mawonekedwe, ma rauta a CNC ndi chisankho chabwino.

Ngati kulondola, kufotokozera bwino, ndi kulemba zinthu zovuta kwambiri ndizo zinthu zofunika kwambiri kwa inu, sankhani chodulira cha laser.

Liwiro ndi Kuchita Bwino:

Ma router a CNC amachita bwino kwambiri pochotsa zinthu ndi kupanga mawonekedwe, zomwe zimapangitsa kuti zikhale zosavuta kugwira ntchito izi.

Zodulira za laser zimakhala zachangu komanso zogwira mtima kwambiri pankhani yodula molondola komanso ntchito zovuta.

Phokoso ndi Chitetezo:

Ma rauta a CNC amakhala ndi phokoso kwambiri akamagwira ntchito, choncho ganizirani zolekerera phokoso ndipo gwiritsani ntchito zoteteza kumva.

Zodulira za laser zimakhala chete koma zimafuna njira zodzitetezera kwambiri chifukwa cha utsi ndi kuwala kwa laser.

Mzere Wophunzirira:

Ma rauta a CNC ali ndi njira yophunzirira yozama, yomwe imafuna kumvetsetsa bwino momwe zida zimagwirira ntchito komanso magawo ake.

Zodulira za laser zimapereka njira yophunzirira mwachangu kwa iwo omwe akufuna njira yolumikizira ndi kusewera.

Kuchotsa Zinthu ndi Kufotokozera Zinthu:

Ma rauta a CNC ndi abwino kwambiri pochotsa zinthu zambiri ndikupanga malo okhala ndi mawonekedwe.

Zodulira za laser ndi zabwino kwambiri pokonza molondola komanso mofatsa pamwamba pa chinthucho.

Kukhuthala kwa Zinthu:

Ma router a CNC amatha kugwiritsa ntchito bwino zipangizo zokhuthala chifukwa cha luso lawo lodula mozama.

Zodulira za laser ndizoyenera kwambiri pazinthu zopyapyala makamaka pamtundu wa pamwamba.

Muli ndi vuto lililonse lokhudza cnc vs laser mpaka pano? Bwanji osafunsa mayankho athu!

Ngati mukufuna chodulira cha laser cha matabwa

Onani makina ogwirizana >>

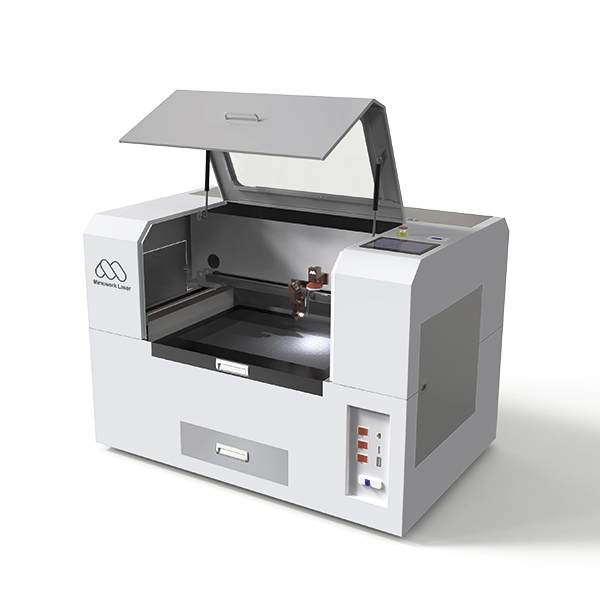

Kukula kwa Tebulo Logwira Ntchito:600mm * 400mm (23.6” * 15.7”)

Zosankha za Mphamvu ya Laser:65W

Chidule cha Desktop Laser Cutter 60

Flatbed Laser Cutter 60 ndi chitsanzo cha pakompyuta. Kapangidwe kake kakang'ono kamachepetsa kufunika kwa malo m'chipinda chanu. Mutha kuyika mosavuta patebulo kuti mugwiritse ntchito, zomwe zimapangitsa kuti ikhale njira yabwino kwambiri yoyambira kwa makampani atsopano omwe amachita zinthu zazing'ono zomwe mwasankha.

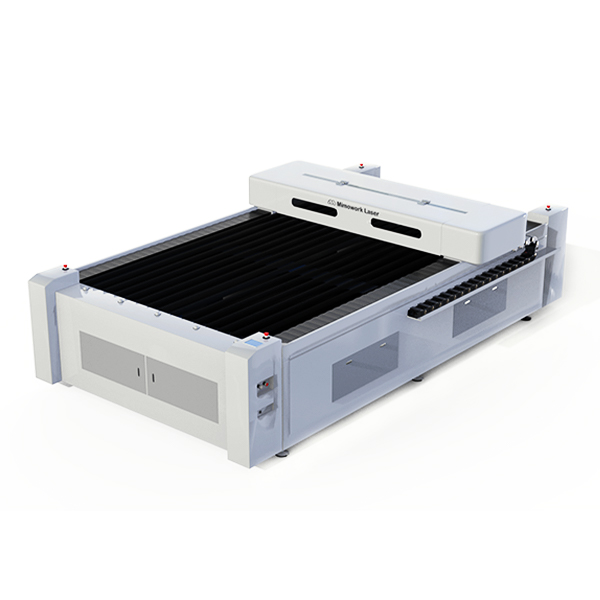

Kukula kwa Tebulo Logwira Ntchito:1300mm * 900mm (51.2” * 35.4”)

Zosankha za Mphamvu ya Laser:100W/150W/300W

Chidule cha Flatbed Laser Cutter 130

Flatbed Laser Cutter 130 ndiye chisankho chodziwika kwambiri pakudula matabwa. Kapangidwe kake ka tebulo logwirira ntchito lochokera kutsogolo kupita kumbuyo kamakupatsani mwayi wodula matabwa amatabwa motalika kuposa malo ogwirira ntchito. Kuphatikiza apo, imapereka kusinthasintha popereka machubu a laser a mphamvu iliyonse kuti akwaniritse zosowa zodula matabwa okhala ndi makulidwe osiyanasiyana.

Kukula kwa Tebulo Logwira Ntchito:1300mm * 2500mm (51.2” * 98.4”)

Zosankha za Mphamvu ya Laser:150W/300W/500W

Chidule cha Flatbed Laser Cutter 130L

Flatbed Laser Cutter 130L ndi makina akuluakulu. Ndi oyenera kudula matabwa akuluakulu, monga matabwa a 4ft x 8ft omwe amapezeka pamsika. Amagwiritsidwa ntchito makamaka pazinthu zazikulu, zomwe zimapangitsa kuti ikhale chisankho chokondedwa m'mafakitale monga malonda ndi mipando.

Mukufuna kuyambitsa bizinesi yanu yodula/kujambula laser?

▶Chidziwitso Cham'mbaliKupatula matabwa, zinthu mongaplywoodndiMapanelo a MDFamagwiritsidwanso ntchito kwambiri mumakampani.

Nthawi yotumizira: Okutobala-18-2023