Tekinoroji yekubatanidza nelaser inzira itsva uye iri kutsvakwa zvikuru mumusika, ine kudiwa kuri kukura kwemuchina wekubatanidza nelaser wemhando yepamusoro wekutengeswa kuti ugutse zvinodiwa zvakasiyana-siyana zvemaindasitiri.

Mawelder eLaser, anonziwo michina yekuwachisa laser, kana kuti maturusi ekuwachisa laser, anoshandiswa pakugadzirisa zvinhu kuburikidza nekushandisa malaser.

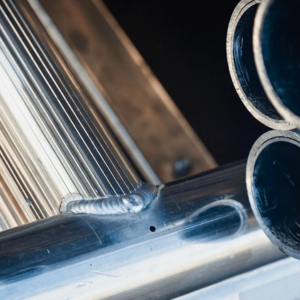

Nzira iyi itsva yekuwedera yakanyatsokodzera pakuwedera simbi dzine madziro matete uye zvikamu zvakanyatsonaka. Haina deformation yakawanda uye haipe hunhu hwakanaka hwekuvharira simbi.

Nekunge nzvimbo diki yekutarisa uye kunyatsorongeka kwepamusoro, welding yelaser inoitwa otomatiki zviri nyore, izvo zvinoita kuti ive sarudzo yakakurumbira kune akawanda maindasitiri.

Saka, chii chinoita kuti welder inobatwa neruoko isiyane nemamwe kana tichienzanisa nemuchina we welder unogadzirwa nemaoko? Chinyorwa chino chicharatidza musiyano nezvakanaka zvewelder inobatwa nemaoko, zvichikubatsira kuita sarudzo ine ruzivo pakusarudza muchina wakakodzera.

1. Mabhenefiti ekushandisa Laser Welder inobatwa nemaoko

Chishandiso che laser chinobatirwa nemaoko chinoshandiswa ne laser chinoda kushandiswa nemaoko.Chishandiso ichi chekuwedera nelaser chinotakurika chakagadzirirwa kuwedera zvinhu zvikuru nezvigadzirwa munzvimbo refu.

1. Iyomaitiro ekunamirainoratidzwa nenzvimbo diki inokanganiswa nekupisa, izvo zvinoderedza zvakanyanya njodzi yekushanduka kwezvinhu, kuchinja kweruvara, uye mavanga ari kuseri kwechinhu chebasa.

2.Izvoudzamu hwekunamiraZvakakosha, zvichiita kuti pave nekusanganiswa kwakasimba uye kwakakwana pasina maburi panzvimbo inoungana zvinhu zvakanyungudutswa nechigadziko.

3.Iyokumhanya kwekushongedzainokurumidza, mhando yacho yakanaka kwazvo, uye ma welds acho akasimba, akatsetseka, uye anoyevedza.

4. Iyomisono yeweldmadiki, haana maburi, uye anogona kudzorwa nemazvo.

Hapana kugadziriswa kwechipiri kunodiwa, uye laser welder inobatwa nemaoko inokwanisa kuita mhando dzakasiyana dzeweld, kusanganisira spot welding, butt welding, stack welding, seal welding, uye corner weldin.g.

Kubata Laser Welder Welding Aluminium Inobatwa Nemaoko

Simbi Yekushongedza Inobatwa Nemaoko YeLaser

2. Kusiyana Kunoenzaniswa Nekushandisa Laser Welder Yega

Michina yekuisa simbi yelaser inogadzirwa otomatiki uchishandisa software kuti iite mabasa ekuisa simbi otomatiki.

Kusiyana neizvi, sisitimu yekuisa laser inobatwa nemaoko, inozivikanwawo sekuisa laser nemaoko, inoshandiswa nemaoko, uye mushandisi anoshandisa display yakakura kuti aronge uye adzore zvakanyatsonaka.

1. Chinhu chikuru chinobatsira kubata ruokomuchina wekuwedera nelaser, zvichienzaniswa ne zvizereSisitimu ye laser inongoerekana yagadzirwa, iri mukuchinjika kwayo uye nyore kwayo, kunyanya pakugadzira zvinhu zvidiki kana zvinodiwa zvekunamira zvisina mwero.

2. Laser welder inobatwa nemaoko yakanakira maworkshop anoda mhinduro dzinochinjikazvekushandisa pakusondera zvinhu zvemhando dzakasiyana-siyana uye saizi.

3. Kusiyana nemuchina wekuisa welaser unoshanda otomatiki, muchina wekuisa welaser nemaokohazvidi kugadziriswa kwakawanda kana kugadziriswa kwemamiriro ezvinhu, zvichiita kuti zvikodzere mabhizinesi ane zvinodiwa zvakasiyana-siyana zvekugadzira.

Webhusaiti yedu inopa welder inobatwa nemaoko, kana uchifarira unogona kudzvanya pano kuti udzidze zvakawanda:>>CHINHU CHEKUWEDZERA CHELASER CHINOBATWA NERUOKO<

Unoda Kutenga Laser Welder?

3. Mhedziso

Mukupedzisa, welder yeruoko inopa mhinduro inoshanda zvakasiyana-siyana uye inoshanda zvikuru kune akasiyana-siyana mashandisirwo ewelding, kunyanya pakugadzira zvinhu zvidiki kana zvakagadzirwa.

Kushanda kwayo kuri nyore kushandisa, kumhanya kwayo kwekunamira nekukurumidza, mhedzisiro yepamusoro, uye njodzi shoma yekukuvadzwa kwezvinhu zvinoita kuti ive sarudzo inokwezva maindasitiri mazhinji.

Kunyange zvazvo michina ye laser welding inoshanda neunyanzvi uye otomatiki pakugadzira zvinhu zvakakura,Laser welder inobatwa nemaoko inonyatsoonekwa nekuchinjika kwayo uye kuchinjika kwayo, zvichiita kuti ive sarudzo yakanaka yekubata zvinhu zvakasiyana-siyana uye maumbirwo asina kurongeka.

Ungave uri kufunga nezvekushandisa laser welder iri kutengeswa kana kutsvaga nzira dzakasiyana siyana mu tekinoroji ye laser welding,welder inobatwa nemaoko inopa chiyero chakakwana chekushanda, mhando, uye kuchinjika, zvichiratidza kuti chishandiso chakakosha pakugadzira zvinhu zvemazuva ano.

Unoda Kuziva Zvakawanda NezveMuchina weLaser Welding?

Muchina Wakafanana: Laser Welders

Iyi modular handheld unit inobvumira kushanduka kwebasa nekukurumidza kuburikidza nemisoro inochinjika.

Gadzira welding ne laser nemazvo, kuchenesa nzvimbo isina kubatwa (isina makemikari), uye kucheka simbi inotakurika uchishandisa puratifomu imwe chete.

Deredza mari inoshandiswa pakushandisa michina ne70%, deredza zvinodiwa pakushanda, uye gadzirisa mashandiro emumunda.

Yakagadzirwa kuti igadzirise, igadzirise, uye ishandise nzvimbo dzakamanikana.

Wedzera kuchinjika kwekushanda uye ROI nehunyanzvi hwakabatana.

Ichishandisa simba rayo uye kugona kwayo kuchinjika, iyi welder inobatwa nemaoko inosanganisira kabhineti kadiki, fiber laser source, system inotonhodza mvura yakatenderera, laser control system, uye ergonomic welding gun.

Chimiro chayo chiri nyore asi chakasimba chinoita kuti zvive nyore kufamba. Izvi zvinoita kuti vashandisi vakwanise kufambisa mudziyo wacho vakasununguka pakusanganisa simbi kana vachida.

Yakanakira kushandiswa kwakadai sekugadzira mabhanhire esimbi, kubatana kwesimbi isingatsvi, kubatanidza makabati esimbi, uye kusanganisa simbi yakakura. Inoita kuti kushanda kwemumunda kuve nyore uye nyore.

Mibvunzo Inowanzo bvunzwa

Mawelder elaser anobata nemaoko anogona kushandiswa pakugadzira simbi dzakadai sesimbi isingatsvedzeri, aruminiyamu, nezvimwe zvinhu zvakasiyana-siyana. Anobata simbi dzakatetepa dzine madziro, zvinhu zvakanyatsonaka, uye kunyange zvinhu zvisina kurongeka. Akanakira mabhanhire esimbi, zvigadzirwa zvesimbi isingatsvedzeri, makabati esimbi, nezvimwewo. Ingave jira diki kana jira guru, anochinjika zvakanaka, achipa jira rakasimba uye rinoyevedza.

Vagadziri vema laser vanobatwa nemaoko vanochengetedza mari. Vanoderedza mari inoshandiswa mumidziyo (semuenzaniso, 3 - mu - 1 modhi inoderedza mari inoshandiswa ne70%). Kudiwa kwenzvimbo yekushandira kwakaderera uye kusave nepurogiramu yakaoma kunoderedza mari yekushandisa. Kune akasiyana-siyana, madiki ekugadzira, vanopa ROI iri nani pane vanogadzirisa otomatiki vanoda kugadzwa kwakawanda kwemabasa makuru.

Inopa ma weld emhando yepamusoro. Nzvimbo ine kupisa kudiki, welding yakadzika, misono yakasimba uye yakatsetseka isina maburi. Weld haidi kugadziriswa kwechipiri. Inoita kutonga kwakarurama, ichivimbisa runako uye majoini akasimba, ichisangana nezvinodiwa zveindasitiri zvekushandiswa kwakasiyana-siyana kubva pakugadzira simbi kusvika pakugadzirisa.

Nguva yekutumira: Ndira-07-2025