Kushongedza neLaserTekinoroji yakachinja maindasitiri ekugadzira nekugadzira, ichipa kunyatsorongeka, kumhanya, uye kushanduka-shanduka kusingaenzaniswi. Nzira iyi yepamusoro yekushongedza inoshandisa matanda elaser akaomeswa kunyungudutsa nekubatanidza zvinhu, zvichiita kuti zvikwanise kushandiswa zvakasiyana-siyana.

Chimwe chezvakanakira zvikuru zve laser welding kugona kwayo kushanda nezvinhu zvakasiyana-siyana, zvichigonesa vagadziri kugadzira majoini akasimba uye anogara kwenguva refu muzvigadzirwa zvakasiyana-siyana.

Muchinyorwa chino, tichaongorora zvinhu zvakakosha zvinogona kusungirirwa uchishandisa michina ye laser welding, tichiratidza hunhu hwayo hwakasiyana uye mashandisirwo ayo.

1. Simbi dzeLaser Machine Welding

a. Simbi Isina Chinovhara

Simbi isina ngura ndeimwe yesimbi dzinonyanya kusungirirwa uchishandisa tekinoroji yelaser. Inozivikanwa nekudzivirira ngura uye kusimba kwayo, simbi isina ngura inoshandiswa zvakanyanya mumaindasitiri akadai sekugadzira chikafu, mishonga, kugadzira mota, uye kuvaka.

Kuwedera neLaser kunopa maweld emhando yepamusoro, akachena ane nzvimbo shoma dzinobatwa nekupisa (HAZ), zvichiita kuti chimiro chechinhu chacho chirambe chakasimba. Kugona kudzora simba reLaser nemazvoinobvumira kusungirirwa kwezvikamu zvitete nezvikobvu zvakafanana, zvichiita kuti zvikodzere magadzirirwo akaomarara uye magungano akaomarara.

b. Simbi yeKabhoni

Simbi yekabhoni ndeimwe simbi inoshanda zvakanaka pakuwelda nelaser. Chinhu ichi chinowanikwa zvakanyanya mukuvaka nekugadzira, uko chinoshandiswa muzvikamu zvemaumbirwo nemichina.Kupinza neLaser kunowedzera simba uye kugara kwenguva refu kwe carbon steel welds ukuwo kuchichengetedza kupedzisa kwemhando yepamusoro.

Maitiro acho anoshanda zvakanaka, zvichideredza njodzi yekukombama uye kukanganiswa kunowanzobatanidzwa nenzira dzechinyakare dzekunamira. Pamusoro pezvo, kumhanya kwenamira yelaser kunobvumira vagadziri kuwedzera kugona kwavo pasina kukanganisa mhando.

c. Aruminiyamu neAruminiyamu Alloys

Aruminiyamu inokosheswa nekuda kwehunhu hwayo hwakareruka uye hunodzivirira ngura, zvichiita kuti ive chinhu chinodiwa zvikuru muindasitiri yendege nemotokari. Zvisinei, aruminiyamu yekushongedza inogona kuva yakaoma nekuda kwekupisa kwayo kwakanyanya uye inogona kukanganiswa nematambudziko ane chekuita nekupisa.

Kupinza neLaser kunobatsira kugadzirisa matambudziko aya nekupa nzvimbo inodziya yakananga inoderedza kupisa uye inoderedza kukanganiswa.Maitiro aya anobvumira kubatana kwakanyatsojeka kwezvikamu zvearuminiyamu, zvichigonesa kugadzirwa kwezvivakwa zvakareruka zvine hunhu hwakanaka hwemakanika.

d. MaAlloys emhangura nemhangura

Mhangura inozivikanwa nekugona kwayo kupinza magetsi zvakanaka, zvichiita kuti ive yakakosha mukushandiswa kwemagetsi akadai sewaya dzemagetsi nemabhodhi edunhu.

Kunyange zvazvo kupinza mhangura kuchigona kuoma nekuda kwekukwira kwayo kwekupisa uye pamusoro pechiedza, michina yekupinza nelaser ine zvigadziriso zvepamusoro inogona kuwana mhedzisiro inobudirira.

Tekinoroji iyi inoita kuti mhangura nesimbi dzayo zvibatanidzwe zvakanaka, zvichiita kuti pave nekubatana kwakasimba uye kwakavimbika kunokosha pakushandiswa kwemagetsi.

e. Nickel neNickel Alloys

Nickel nesimbi dzayo dzinowanzoshandiswa munzvimbo dzinopisa zvakanyanya uye dzine ngura, dzakadai semumaindasitiri emakemikari nemafuta.

Kupinza neLaser kunopa mhinduro inoshanda uye inoshanda yekubatanidza zvinhu izvi, zvichiita kuti ma weld arambe akasimba mumamiriro ezvinhu akaoma.

Kunyatsorongeka kwe laser welding kunobatsira zvikuru mukushandiswa uko kushanda kwejoin yakasungirirwa kwakakosha.

2. Kushandisa Plastiki Yekushongedza NeLaser

Pamusoro pesimbi,Kukwesha ne laser kunoshandawo kune mapurasitiki akasiyana-siyana, kuwedzera kushanda kwayo mumaindasitiri akasiyana-siyana.

Muchina wesimbi weLaser Welding Aluminium

a. Polypropylene (PP)

Polypropylene inoshandiswa zvakanyanya mukupakata, muzvikamu zvemotokari, uye muzvinhu zvinotengeswa nevatengi. Kubatanidza nelaser kunobvumira majoini akasimba, asina musono anogona kuwedzera kushanda kwezvigadzirwa zvepolypropylene.

Maitiro acho akachena uye anoshanda zvakanaka, zvichideredza kudiwa kwemamwe manamati kana zvisungo zvemakanika, izvo zvinogona kuchengetedza nguva nekuderedza mari.

b. Polyethylene (PE)

Polyethylene imwe yepurasitiki inowanzo shandiswa inogona kusungirirwa uchishandisa tekinoroji yelaser. Inoshandiswa mukushandiswa kubva mumidziyo kusvika kumapombi. Kusungirirwa kwepolyethylene nelaser kunopa nzira yakasimba yekubatanidza iyo inogona kutsungirira mamiriro akasiyana-siyana ezvakatipoteredza.Kunyatsorongeka kwemaitiro aya kunoita kuti ma weld arambe akasimba uye akavimbika, achizadzisa zvinodiwa pakushandiswa kwakakosha.

c. Polycarbonate (PC)

Polycarbonate inokosheswa nekuda kwekusasimba kwayo uye kujeka kwayo, zvichiita kuti ive sarudzo yakakodzera kune zvishandiso zvakaita semagirazi ekuchengetedza uye magirazi emagetsi. Kushongedza nelaser kunopa nzira yekubatanidza zvikamu zvepolycarbonate pasina kukanganisa kunaka kwechimiro chazvo.Kugona uku kunobatsira zvikuru mumaindasitiri uko kujekesa uye kugara kwenguva refu zvakakosha.

d. Polyamide (Nylon)

Nylon, inozivikanwa nekusimba kwayo uye kuchinjika kwayo, inowanzoshandiswa mumotokari, machira, uye zvigadzirwa zvevatengi. Kubatanidza nelaser kunogona kushandiswa kubatanidza zvikamu zvenylon zvinobudirira, zvichipa zvisungo zvakasimba zvinogona kutsungirira kushushikana kwemakanika.Kugona kusundira naironi uchishandisa lasers kunovhura mikana mitsva mukugadzira zvigadzirwa neinjiniya.

Unoda Kutenga Laser Welder?

3. Zvinhu Zvakasanganiswa zveLaser Welding

Sezvo maindasitiri achiwedzera kushandisa zvinhu zvakasanganiswa nekuda kwehunhu hwazvo hwakasiyana,Tekinoroji yekucheka nelaser iri kuchinja kuti ienderane nezvinodiwa izvi.

a. Zvikamu zveSimbi-Purasitiki

Zvinhu zvakagadzirwa nesimbi nepurasitiki zvinosanganisa mabhenefiti ezvinhu zvese zviri zviviri, zvichipa mhinduro dzakareruka asi dzakasimba dzekushandisa zvakasiyana-siyana.

Kushongedza nelaser kunogona kubatanidza zvinhu izvi zvinosanganiswa, zvichiita kuti ive nzira inokosha mukugadzira mota nemagetsi.

Kukwanisa kugadzira majoini akasimba pasina kuwedzera huremu hwakakosha mukana mukuru mumaindasitiri aya.

b. Zvinhu Zvinosanganiswa Nefibre

Zvinhu izvi, zvinosanganisa fibers mu resin matrix, zvinozivikanwa nekusimba kwazvo kusvika pakurema.

Tekinoroji ye laser welding inogona kushandiswa kune mamwe marudzi ema composites akasimbiswa nefiber, zvichibvumira kubatana kwakanyatsojeka kunochengetedza kuvimbika kwema fibers.

Kugona uku kunobatsira zvikuru mukushandiswa kwemuchadenga nemotokari, uko zvivakwa zvakareruka zvakakosha pakushanda zvakanaka.

4. Mashandisirwo Ekugadzira Welding Machine Ekutanga neLaser Welding

Kushandiswa kwakasiyana-siyana kwetekinoroji ye laser welding kuri kuita kuti ishandiswe muzvishandiso zvitsva uye zvitsva.

Maindasitiri akadai sesimba rinogona kushandiswazve ari kutsvaga kushandiswa kwelaser welding pakugadzira solar panel, uko kugona kubatanidza zvinhu zvakasiyana kwakakosha.

Pamusoro pezvo,Kufambira mberi mune tekinoroji yelaser kuri kuita kuti zvinhu zvakaoma zvikuru zvibatanidzwe, zvichiwedzera kuwedzera kwekushandiswa kwelaser welding.

5. Mhedziso

Michina ye laser welding inokwanisa kubatanazvinhu zvakasiyana-siyana, kusanganisira simbi, mapurasitiki, uye zvinhu zvakasanganiswa.

Kunyatsojeka uye kushanda zvakanaka kwe laser welding kunoita kuti ive sarudzo yakanakayemakambani akasiyana-siyana, anosanganisira mota, ndege, zvemagetsi, uye zvekurapa.

Sezvo tekinoroji ichiramba ichifambira mberi, huwandu hwezvinhu zvinogona kusungirirwa zvinobudirira uchishandisa lasers hunogona kuwedzera, zvichiwedzera kushanduka-shanduka uye kushanda kwayo mukugadzira kwemazuva ano.

Kuchinjika uku kunoita kuti welding yelaser ive chinhu chakakosha pakugadzira zvigadzirwa zvemhando yepamusoro uye zvinogara kwenguva refu mumusika uri kuramba uchikwikwidzana.

Kuwedera Simbi neLaser Welder

Unoda Kuziva Zvakawanda NezveMuchina weLaser Welding?

Muchina Wakafanana: Laser Welders

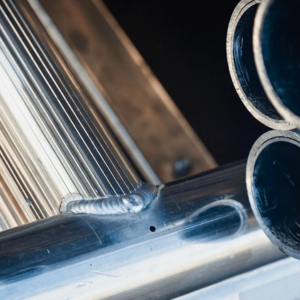

Chishandiso che fiber laser chinoiswa neruoko chakagadzirwa nezvikamu zvishanu: kabhineti, chitubu che fiber laser, sisitimu inotonhodza mvura yakatenderera, sisitimu yekudzora laser, uye pfuti yekuwedera inobatwa nemaoko.

Maumbirwo emuchina ari nyore asi akasimba anoita kuti zvive nyore kuti mushandisi afambise muchina we laser welding uye asundire simbi zvakasununguka.

Muchina wekukwevera welaser unotakurika unoshandiswa zvakanyanya mukukwevera simbi pabhodhibhodhi, kukwevera simbi isingatsvi, kukwevera makabati esimbi, uye kukwevera simbi hombe.

Muchina wekuwedera wefiber laser une pfuti inochinjika yelaser welding iyo inokubatsira kuita basa racho nemaoko.

Zvichienderana netambo yefiber ine urefu hwakati, danda re laser rakasimba uye remhando yepamusoro rinotumirwa kubva kunobva fiber laser kuenda kumuromo we laser welding.

Izvi zvinovandudza kuchengetedzeka uye zvine hushamwari kune anotanga kushandisa laser welder inobatwa nemaoko.

Nguva yekutumira: Ndira-06-2025