Ma Laser-ka Goynta Doorashada ugu Fiican ee Maro Shaandheeye ah?

Noocyada, Faa'iidooyinka, iyo Codsiyada

Hordhac:

Waxyaabaha Muhiimka ah ee ay tahay inaad ogaato kahor intaadan quusin

Tiknoolajiyadda jarista laysarka ayaa kacaan ku samaysay habaynta agabka warshado kala duwan. Kuwaas waxaa ka mid ah, isticmaalka jarista laysarka ee maro shaandheyn ah ayaa ka muuqata saxnaanteeda, waxtarkeeda, iyo kala duwanaanshaheeda. Maro shaandheyn ah, oo lagama maarmaan u ah warshadaha sida daaweynta biyaha, shaandheynta hawada, daawooyinka, iyo habaynta cuntada, waxay u baahan tahay habab jaris tayo sare leh si loo ilaaliyo shaqadeeda.

Maqaalkani wuxuu baarayaa in jarista laysarka ay ku habboon tahay maro shaandheyn ah, wuxuu barbar dhigayaa hababka kale ee jarista, wuxuuna iftiiminayaa faa'iidooyinka maro shaandheyn ah oo laysarka lagu jaro. Waxaan sidoo kale kugula talin doonnaa mashiinnada jarista laysarka ee ugu fiican ee loogu talagalay baahiyahaaga.

Maaddooyinka shaandhaynta sida polyester, nayloon, iyo polypropylene waxaa loogu talagalay in lagu isticmaalo meelaha ay ku qabtaan walxaha iyagoo u oggolaanaya dareerayaasha ama gaasaska inay dhex maraan. Goynta laysarka ayaa ku fiican farsamaynta agabkan sababtoo ah waxay bixisaa:

1. Cidhifyada Nadiifi

Maro shaandhada goynta laysarka waxay bixisaa geeso xiran, taasoo ka hortagaysa jajabka waxayna kor u qaadaysaa cimriga dharka shaandhada.

2. Saxnaan Sare

Mashiinka jarista laysarka ee maro shaandhada leh wuxuu leeyahay leysar fiican laakiin awood badan oo jari kara qaabab sax ah iyo naqshado gaar ah. Waxay ku habboon tahay agabka shaandhada ee la habeeyey ama qiimaha sare leh.

3. Habayn

Qalabka laysarka jarjara wuxuu qaban karaa naqshado adag iyo qaabab gaar ah, kuwaas oo lagama maarmaan u ah baahiyaha shaandhaynta gaarka ah.

4. Waxtar Sare

Nidaamyada goynta laser-ka maro shaandheeye waxay ku shaqeeyaan xawaare sare, taasoo ka dhigaysa kuwo ku habboon wax soo saarka badan.

5. Qashinka Agabka Ugu Yar

Si ka duwan hababka dhaqameed, goynta laser waxay yareysaa qashinka agabka iyada oo loo marayo qaabab la hagaajiyay iyo goynta saxda ah.

6. Otomaatig Sare

Nidaamka jarista laysarka ee maro shaandhada ah waa mid fudud in la shaqeeyo, taas oo ay ugu wacan tahay nidaamka CNC iyo software-ka goynta laysarka ee caqliga badan. Hal qof ayaa xakamayn kara mashiinka laysarka oo gaari kara wax soo saar badan waqti gaaban gudaheed.

In kasta oo jarista laysarka ay si aad ah waxtar ugu leedahay maro shaandheyn ah, haddana waxaa jira dhowr hab oo kale oo badanaa loo isticmaalo jarista dharka. Aan si kooban u sahaminno:

1. Jaritaanka Farsamada:

Qalabka caadiga ah sida jarista wareegtada ah waa kuwo dhaqaale ahaan wanaagsan laakiin waxay u nugul yihiin geesaha jajaban iyo natiijooyinka aan iswaafaqsanayn, gaar ahaan naqshadaha faahfaahsan.

Hababka jarista dhaqameed sida jarista wareegta ama mindiyaha dharka ayaa badanaa loo isticmaalaa jarista maro shaandheyn ah. Si kastaba ha ahaatee, hababkani waxay sababi karaan jajab ka dhaca geesaha, taas oo saameyn karta hufnaanta dharka, gaar ahaan codsiyada saxda ah sida shaandhaynta.

2. Jaritaanka Die:

Ku habboon qaababka fudud ee soo noqnoqda ee wax soo saarka ballaaran laakiin ma laha dabacsanaan naqshado gaar ah ama kuwa adag.

Jarjaridda timaha waxaa badanaa loo isticmaalaa soo saarista qaybaha maro shaandhada leh, gaar ahaan marka loo baahdo qaabab fudud. In kasta oo jarista timaha ay waxtar yeelan karto, haddana ma bixiso heer sax ah ama dabacsanaan la mid ah jarista laysarka, gaar ahaan marka la macaamilayo naqshado aad u adag.

3. Goynta Ultrasonic:

Wax ku ool u ah dharka qaarkood laakiin way xaddidan tahay marka la barbar dhigo gooyayaasha laser-ka ee maro shaandhaynta, gaar ahaan shaqooyinka adag ama kuwa waaweyn.

Goynta Ultrasonic waxay isticmaashaa hirarka dhawaaqa ee soo noqnoqda sare si loo jaro walxaha. Waa mid waxtar u leh codsiyada qaarkood laakiin waxaa laga yaabaa inaysan u badnayn mid la mid ah jarista laysarka ee dhammaan noocyada maro shaandhada.

Gunaanad:

Jarista laysarka ayaa ka wanaagsan hababkan iyadoo la bixinayo saxnaan, kala duwanaansho, iyo hufnaan, dhammaantoodna iyada oo aan la taabanayn ama la xirin qalabka.

Jarista laysarka waxay bixisaa gees sax ah oo xiran oo ka hortagaya jajabka. Tani waxay si gaar ah muhiim ugu tahay agabka sida polyester ama nayloon, kuwaas oo si fudud u furfuri kara haddii aan si habboon loo jarin. Kulaylka laysarka ayaa sidoo kale nadiifiya geesaha la jaray, taasoo yaraynaysa khatarta wasakhowga, taas oo muhiim u ah codsiyada caafimaadka ama warshadaha cuntada.

Hadday tahay inaad jarto daloolo adag, qaabab gaar ah, ama naqshado gaar ah, jarista laysarka waxaa loo habeyn karaa si ay u daboolaan baahiyahaaga. Saxnaanta waxay u oggolaanaysaa jarista adag ee hababka dhaqameedku aysan soo koobi karin.

Si ka duwan qalabka jarjara ama daabyada farsamada, laysarka ma la kulmaan duug iyo jeex. Taas macnaheedu waa inaan loo baahnayn in la beddelo daabyada, taasoo horseedi karta keydin kharash iyo hoos u dhac waqtiga shaqada.

Maro shaandhada goynta laserWaxay ku shaqeysaa iyadoo diiradda saareysa fallaadho laysar oo awood sare leh oo ku dul yaal walxaha, kuwaas oo dhalaaliya ama uumi geliya walxaha meesha ay taabtaan. Fallaadhaha laysarka waxaa si sax ah u xakameeya nidaamka CNC (Kontoroolka Tirada Kombuyuutarka), taasoo u oggolaanaysa inay jarto ama ku qorto agabyo kala duwan oo maro shaandho ah oo leh saxnaan gaar ah.

Nooc kasta oo maro shaandho ah wuxuu u baahan yahay dejimo gaar ah si loo hubiyo natiijooyinka ugu wanaagsan ee jarista. Waa kan eeg sidamaro shaandhada goynta laser-kawaxay u shaqeysaa qaar ka mid ah agabka maro shaandhada ugu badan:

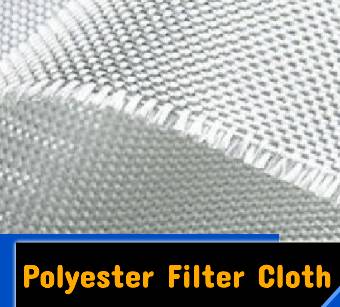

Polyester-ka La Jarayo ee Laser-ka:

Polyesterwaa maro macmal ah oo si fiican uga falcelisamaro shaandhada goynta laser-ka.

Laser-ku si habsami leh ayuu u dhex maraa walxaha, kulaylka ka imanaya iftiinka laser-kana wuxuu xiraa geesaha, taasoo ka hortagaysa in wax furfuran ama jajabaan.

Tani waxay si gaar ah muhiim ugu tahay codsiyada shaandhaynta halkaas oo geesaha nadiifka ah ay muhiim u yihiin ilaalinta hufnaanta shaandhada.

Dharka aan la tolin ee Laser-ka laga jaray:

Dhar aan la tolaynwaa kuwo fudud oo jilicsan, taasoo ka dhigaysa kuwo ku habboonmaro shaandhada goynta laser-ka. Laysarku si dhakhso ah ayuu u jari karaa agabkan isagoon waxyeello u geysanayn qaab-dhismeedkooda, taasoo siinaysa jaritaanno nadiif ah oo lagama maarmaan u ah soo saarista qaababka shaandhada saxda ah.Maro shaandhada goynta lasersi gaar ah ayay faa'iido ugu leedahay dharka aan tolnayn ee loo isticmaalo codsiyada shaandhaynta caafimaadka ama baabuurta.

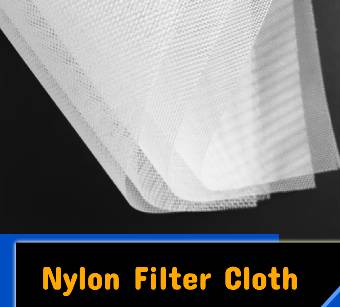

Nayloonka La Jarayo ee Laser-ka:

Nayloonwaa walxo xooggan oo dabacsan oo ku habboonmaro shaandhada goynta laser-kaLaydhka laysarka si fudud ayuu u dhex maraa nayloon wuxuuna abuuraa geeso siman oo shaabadaysan. Intaa waxaa dheer,maro shaandhada goynta laser-kasaxnaanta sare ee habka jarista ma keento qallooc ama kala-goyn, taas oo inta badan dhibaato ku ah hababka jarista dhaqameed.maro shaandhada goynta laser-kawaxay hubisaa in badeecada kama dambaysta ahi ay ilaaliso waxqabadka shaandhaynta ee lagama maarmaanka ah.

Xumbo Goynta Laser-ka:

Xumboagabka shaandhada ayaa sidoo kale ku habboonmaro shaandhada goynta laser-ka, gaar ahaan marka loo baahdo daloolo sax ah ama jaritaan.Maro shaandhada goynta laserSida xumbo oo kale waxay u oggolaanaysaa naqshado adag waxayna hubisaa in geesaha la shaabadeeyey, taas oo ka hortagaysa in xumbodu ay hoos u dhigto ama lumiso sifooyinkeeda qaab-dhismeedka. Si kastaba ha ahaatee, waa in taxaddar laga muujiyaa goobaha si looga hortago kulaylka xad-dhaafka ah, kaas oo sababi kara gubasho ama dhalaalid.

Nidaamyada Jarida Laser-ka ee lagu taliyay ee Filter-ka

Si loo gaaro natiijooyinka ugu fiican marka la jarayo maro shaandheeye ah, doorashada saxda ahmashiinka goynta laser maro shaandheynwaa muhiim. MimoWork Laser waxay bixisaa mashiinno kala duwan oo ku habboonmaro shaandhada goynta laser-ka, oo ay ku jiraan:

• Goobta Shaqada (W *L): 1000mm * 600mm

• Awoodda laysarka: 60W/80W/100W

• Goobta Shaqada (W *L): 1300mm * 900mm

• Awoodda laysarka: 100W/150W/300W

• Goobta Shaqada (W *L): 1800mm * 1000mm

• Awoodda laysarka: 100W/150W/300W

Gunaanad

Jarista laysarka shaki la'aan waa hab aad waxtar u leh oo hufan oo lagu jaro maro shaandho leh. Saxnimadeeda, xawaaraheeda, iyo kala duwanaanshaheeda ayaa ka dhigaya doorasho sare warshadaha u baahan jaritaan tayo sare leh oo gaar ah. Haddii aad u baahan tahay mashiin goyn laysar oo la isku halleyn karo oo hufan oo loogu talagalay maro shaandho leh, noocyada kala duwan ee mashiinnada goynta laysarka ee MimoWork waxay bixiyaan ikhtiyaarro aad u fiican oo ku habboon baahiyaha wax soo saarka yar iyo kuwa waaweynba.

Nala soo xiriir maanta si aad wax badan uga barato mashiinnadayada jarista laysarka iyo sida ay u hagaajin karaan habka wax soo saarkaaga maro shaandhaynta.

A: Alaabada sida polyester, polypropylene, iyo nayloonku waa kuwo ku habboon. Nidaamku wuxuu sidoo kale u shaqeeyaa dharka mesh-ka iyo xumbo.

A: Iyadoo la otomaatig gareynayo habka jarista iyo bixinta jarista saxda ah oo nadiif ah iyada oo aan la faragelin gacanta, taasoo horseedaysa wareegyo wax soo saar oo degdeg ah.

J: Dabcan. Nidaamyada laysarka ayaa ku fiican abuurista qaabab faahfaahsan iyo qaabab gaar ah oo hababka dhaqameedku aysan gaari karin.

J: Haa, inta badan mashiinnada waxay leeyihiin barnaamijyo iyo otomaatig u fudud, taasoo u baahan tababar yar oo loogu talagalay hawl wadeennada.

Waxaa laga yaabaa inaad xiisaynayso

Fikrado kasta oo ku saabsan Maro Shaandhada Goynta Laser-ka, Kusoo dhawoow inaad nagala hadasho!

Su'aalo ma qabtaa oo ku saabsan Mashiinka Goynta Laser-ka ee Shaandheeyaha?

Cusbooneysiintii ugu dambeysay: Oktoobar 9, 2025

Waqtiga boostada: Noofambar-18-2024