Uma umusha kubuchwepheshe be-laser futhi ucabangela ukuthenga umshini wokusika i-laser, kufanele kube nemibuzo eminingi ofuna ukuyibuza.

MimoWork iyajabula ukwabelana nawe ngolwazi olwengeziwe mayelana nemishini ye-laser ye-CO2 futhi ngethemba, ungathola idivayisi ekufanele ngempela, kungakhathaliseki ukuthi ivela kithi noma omunye umhlinzeki we-laser.

Kulesi sihloko, sizonikeza ukubuka okufushane kokucushwa komshini endaweni evamile futhi senze ukuhlaziya okuqhathanisayo komkhakha ngamunye. Ngokuvamile, i-athikili izohlanganisa amaphuzu alandelayo:

>> Isakhiwo sikaMechanical somshini we-laser

>> I-CO2 glass laser tubes VS CO2 RF laser tubes (Synrad, Coherent, Rofin)

>> Lawula Isistimu neSofthiwe

>> Izinketho

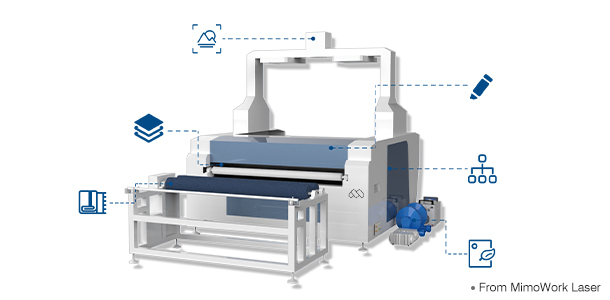

Imishini yomshini we-CO2 laser

a. Brushless DC Motor, Servo Motor, Step Motor

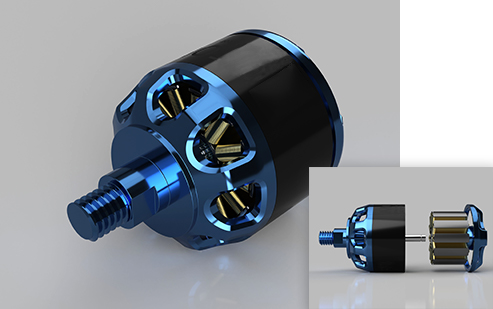

I-Brushless DC (i-direct current) motor

I-Brushless DC motor ingasebenza nge-RPM ephezulu (izinguquko ngomzuzu). I-stator ye-DC motor inikeza inkambu kazibuthe ezungezayo eshayela i-armature ukuze ijikeleze. Kuzo zonke izinjini, i-brushless dc motor inganikeza amandla e-kinetic anamandla futhi ishayele ikhanda le-laser ukuthi lihambe ngesivinini esikhulu.Umshini wokuqopha we-laser we-MimoWork ongcono kakhulu we-CO2 ifakwe injini ye-brushless futhi ingafinyelela isivinini esiphezulu sokuqopha esingu-2000mm/s.I-brushless dc motor ayivamile ukubonakala emshinini wokusika we-CO2 laser. Lokhu kungenxa yokuthi ijubane lokusika ngempahla lilinganiselwe ubukhulu bezinto. Ngokuphambene nalokho, udinga kuphela amandla amancane ukuze uqophe ihluzo ezintweni zakho, I-brushless motor efakwe umqophi we-laser izokwazi finyeza isikhathi sakho sokuqopha ngokunemba okukhulu.

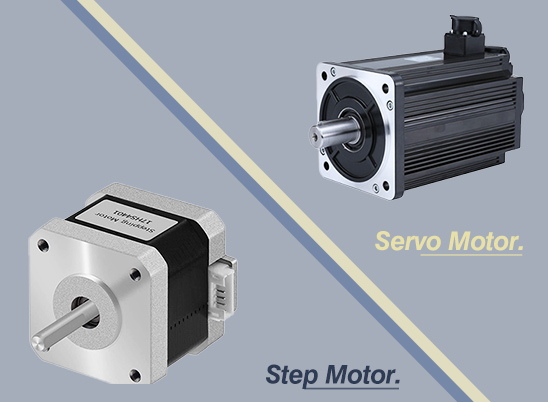

I-Servo motor & Isinyathelo motor

Njengoba sonke sazi iqiniso lokuthi ama-servo motors anganikeza amazinga aphezulu we-torque ngesivinini esikhulu futhi abiza kakhulu kunama-stepper motors. Ama-Servo motors adinga isifaki khodi ukuze silungise ama-pulse ukulawula indawo. Isidingo se-encoder kanye ne-gearbox senza isistimu ibe yinkimbinkimbi ngokwengeziwe, okuholela ekunakekeleni njalo kanye nezindleko eziphezulu. Ihlanganiswe nomshini we-laser CO2,i-servo motor ingaletha ukunemba okuphezulu ekumiseni i-gantry nekhanda le-laser kune-stepper motor. Nakuba, uma sikhuluma iqiniso, ezikhathini eziningi, kunzima ukusho umehluko ngokunemba lapho usebenzisa amamotho ahlukene, ikakhulukazi uma wenza izipho ezilula zobuciko ezingadingi ukunemba okuningi. Uma ucubungula izinto eziyinhlanganisela kanye nezinhlelo zokusebenza zobuchwepheshe, njengendwangu yokuhlunga yepuleti lokuhlunga, ikhethini lokuphepha eline-inflatable lemoto, ikhava evikelayo yomqhubi, khona-ke amandla ama-servo motors azoboniswa kahle.

Injini ngayinye inezinzuzo nezingozi zayo. Leyo evumelana nawe iyona engcono kakhulu kuwe.

Impela, iMimoWork ingahlinzeka nge I-CO2 laser engraver kanye nomsiki ngezinhlobo ezintathu zenjini ngokusekelwe kwimfuneko yakho kanye nesabelomali.

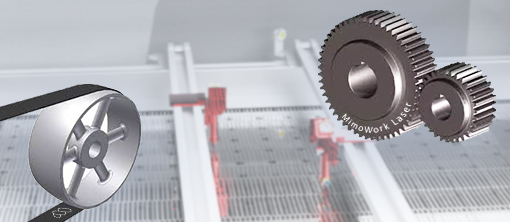

b. I-Belt Drive VS Gear Drive

I-belt drive wuhlelo lokuxhuma amasondo ngebhande kanti igiya drive ngamagiya amabili axhumene namanye njengoba ahambisana nawo womabili amazinyo exhumene. Ekwakhekeni kwemishini yemishini ye-laser, womabili amadrayivu asetshenziselwalawula ukunyakaza kwe-laser gantry futhi uchaze ukunemba komshini we-laser.

Ake siqhathanise lezi ezimbili nethebula elilandelayo:

|

I-Belt Drive |

Gear Drive |

| Isici esiyinhloko Ama-Pulleys kanye nebhande | Isici esiyinhloko Amagiya |

| Kudingeka isikhala esengeziwe | Isikhala esincane esidingekayo, ngakho-ke umshini we-laser ungaklanywa ube mncane |

| Ukulahleka kwe-friction ephezulu, ngakho-ke ukudluliselwa kuphansi nokusebenza kahle okuncane | Ukulahleka kokungqubuzana okuphansi, ngakho-ke ukudluliswa okuphezulu nokusebenza kahle okwengeziwe |

| Impilo elindelekile ephansi kunemishini yokushayela, imvamisa ishintsha njalo eminyakeni emi-3 | Iminyaka yokuphila inkulu kakhulu kunokushayela amabhande, ngokuvamile ishintsha njalo eminyakeni eyishumi |

| Idinga ukunakekelwa okwengeziwe, kodwa izindleko zokunakekela zishibhile futhi zilula | Idinga ukulungiswa okuncane, kodwa izindleko zokuyilungisa ziyathandeka futhi zinzima |

| Ukugcotshwa akudingeki | Idinga ukugcotshwa okuvamile |

| Kuthuleke kakhulu ekusebenzeni | Kunomsindo osebenzayo |

Zombili izinhlelo zokushayela igiya nebhande zivame ukuklanywa emshinini wokusika we-laser onezinzuzo nobubi. Ngamafuphi nje,uhlelo lokushayela ibhande lunenzuzo kakhulu kusayizi omncane, izinhlobo zemishini endizayo; ngenxa yokudluliselwa okuphezulu nokuqina,idrayivu yegiya ifaneleka kakhulu kumsiki we-laser enefomethi enkulu, ngokuvamile enomklamo we-hybrid optical.

c. Ithebula Lokusebenza Elinganyakazi VS Ithebula Lokusebenza Lokuthutha

Ukuze wenze kahle ukucutshungulwa kwe-laser, udinga okungaphezu kokuhlinzekwa nge-laser yekhwalithi ephezulu kanye nesistimu yokushayela evelele ukuze uhambise ikhanda le-laser, itafula elifanele lokusekela impahla liyadingeka. Ithebula elisebenzayo elenzelwe ukufanisa impahla noma uhlelo lokusebenza lisho ukuthi ungakwazi ukwandisa amandla omshini wakho we-laser.

Ngokuvamile, kunezigaba ezimbili zamapulatifomu asebenzayo: I-Stationary ne-Mobile.

(Ezinhlelo zokusebenza ezahlukahlukene, ungagcina ususebenzisa zonke izinhlobo zezinto, noma impahla yeshidi noma impahla ehlanganisiwe)

○ Ithebula Lokusebenza Elinganyakazi ilungele ukubeka izinto zeshidi njenge-acrylic, izinkuni, iphepha (amakhadibhodi).

• ithebula lokuhlubula ummese

• Itafula lekhekhe lezinyosi

○ Ithebula Lokusebenza Le-Conveyor ilungele ukubeka izinto zokugoqa njengendwangu, isikhumba, igwebu.

• itafula le-shuttle

• ithebula lokuthutha

Izinzuzo zokuklama itafula lokusebenza elifanele

✔ Ukukhishwa okuhle kakhulu kwe-cut emissions

✔ Zinzisa okokusebenza, akukho kususwa okwenzekayo lapho usikwa

✔ Kulula ukulayisha nokulayisha ama-workpieces

✔ Isiqondiso sokugxila esiphezulu sibonga izindawo eziyisicaba

✔ Ukunakekelwa okulula nokuhlanza

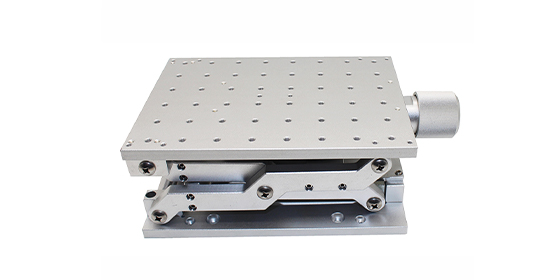

d. I-Automatic Lifting VS Manual Lifting Platform

Uma uqopha izinto eziqinile, njenge i-acrylic (PMMA) futhi ukhuni (MDF), izinto zokwakha ziyahlukahluka ngobukhulu. Ubude bokugxila obufanelekile bungakhulisa umphumela wokuqopha. Inkundla yokusebenza elungisekayo iyadingeka ukuze uthole indawo encane okugxilwe kuyo. Ngomshini wokuqopha we-laser we-CO2, amapulatifomu okuphakamisa okuzenzakalelayo kanye namapulatifomu okuphakamisa okwenziwa ngesandla kuvame ukuqhathaniswa. Uma ibhajethi yakho yanele, vakashela izinkundla zokuziphakamisa ezizenzakalelayo.Akukona nje ukuthuthukisa ukunemba kokusika nokuqopha, kungakongela amathani esikhathi nomzamo.

e. Upper, Side & Down Ventilation System

Isistimu yokungenisa umoya ephansi iwukukhetha okuvame kakhulu komshini we-laser CO2, kodwa i-MimoWork futhi inezinye izinhlobo zomklamo ukuze kuthuthukiswe isipiliyoni sokucubungula i-laser. Okweumshini omkhulu wokusika we-laser, i-MimoWork izosebenzisa okuhlanganisiwe uhlelo lokuqeda phezulu naphansiukukhulisa umphumela wokukhipha ngenkathi ugcina imiphumela yekhwalithi ephezulu yokusika i-laser. Kwabaningi bethuumshini wokumaka we-galvo, sizofaka i uhlelo lwe-ventilation ohlangothiniukuqeda intuthu. Yonke imininingwane yomshini kufanele iqondiswe kangcono ukuxazulula izinkinga zemboni ngayinye.

An uhlelo lokukhiphaikhiqizwa ngaphansi kwento eyenziwa ngomshini. Akukhiphi nje intuthu ekhiqizwe ukwelapha okushisayo kodwa futhi kuzinzisa okokusebenza, ikakhulukazi indwangu enesisindo esincane. Ingxenye yendawo yokucubungula embozwe into ecutshungulwayo iba nkulu, iba nkulu umphumela wokumunca kanye ne-vacuum ewumphumela yokumuncwa.

CO2 ingilazi laser amashubhu VS CO2 RF laser amashubhu

a. Brushless DC Motor, Servo Motor, Step Motor

Imibuzo eyengeziwe mayelana nomshini we-laser noma ukulungiswa kwe-laser

Isikhathi sokuthumela: Oct-12-2021