Jaket ɗin Yankan Laser mai laushi

Ku nisanci sanyi, ruwan sama, ku kula da yanayin jikinku da kyau da sutura ɗaya kawai?!

Da tufafin masana'anta masu laushi za ku iya!

Bayani na Jaket ɗin Yanke Laser mai laushi

A Turanci ana kiran harsashi mai laushi "Jaket mai laushi", don haka sunan ba za a iya tunaninsa ba ne "jaket mai laushi", yana nufin masana'anta ta fasaha da aka tsara don tabbatar da kwanciyar hankali mafi girma a cikin yanayin yanayi mai canzawa. Yawanci laushin yadi ya fi harsashi mai tauri kyau, kuma wasu yadi kuma suna da ɗan sassauci. Yana haɗa wasu ayyuka na jaket ɗin hardshell da ulu na baya, kumaYana la'akari da juriyar ruwa yayin yin kariya daga iska, ɗumi da kuma numfashi- harsashi mai laushi yana da murfin maganin hana ruwa shiga DWR. Yadin tufafi da ya dace da hawa dutse da kuma dogon lokaci na aikin jiki.

Ba Ruwan Raincoat bane

Gabaɗaya, yawan ruwan da tufafi ke sha shi ne yake hana ruwa shiga, haka nan kuma yawan iskar da ke sha shi ke hana ruwa shiga. Babbar matsalar da masoyan wasanni na waje suka samu ta hanyar amfani da kayan da ke hana ruwa shiga ita ce danshi da ke cikin jaket da wando. Amfanin kayan da ke hana ruwa shiga shi ne a daina sha a yanayin ruwan sama da sanyi, kuma idan ka tsaya ka huta, jin daɗin ba zai yi daɗi ba.

A gefe guda kuma, an ƙirƙiri jaket ɗin mai laushi musamman don sauƙaƙe fitar da danshi da kuma daidaita zafin jiki.Saboda wannan dalili, layin waje na softshell ba zai iya zama mai hana ruwa ba, amma mai hana ruwa, don haka yana tabbatar da cewa sanya shi ya kasance bushe da kariya.

Yadda Ake Yinsa

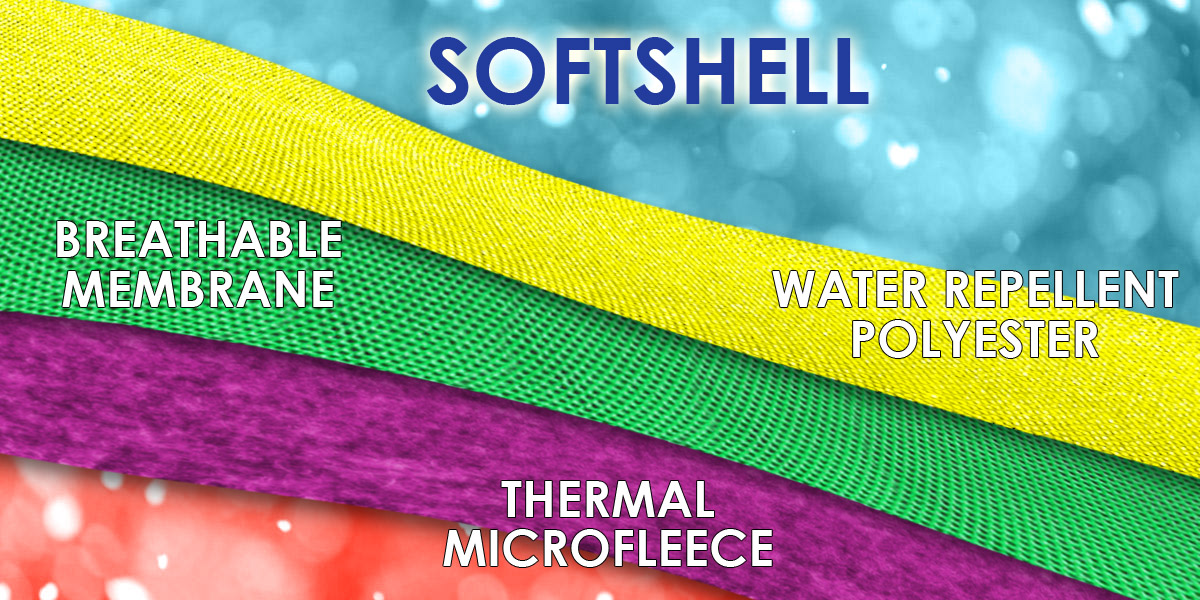

Jaket ɗin softshell ya ƙunshi yadudduka uku na kayan aiki daban-daban, waɗanda ke tabbatar da kyakkyawan aiki:

• Tsarin waje yana cikin polyester mai yawan ruwa, wanda ke ba rigar damar jure wa abubuwan da ke waje, tare da ruwan sama ko dusar ƙanƙara.

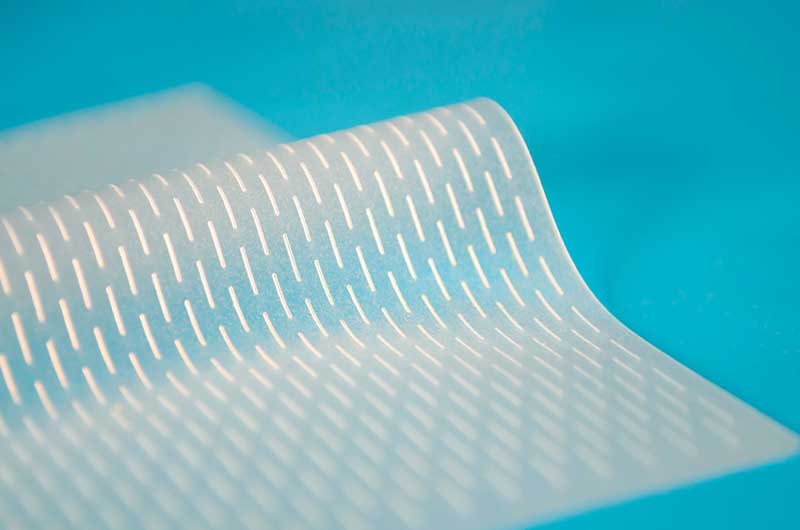

• Tsakiyar tsakiya ta zama membrane mai numfashi, don haka tana barin danshi ya fita, ba tare da tsayawa ko jika cikin ba.

• An yi layin ciki da microfleece, wanda ke tabbatar da ingantaccen kariya daga zafi kuma yana da daɗi a taɓa fata.

An haɗa layuka uku, don haka suka zama abu mai sauƙi, mai laushi da laushi, wanda ke ba da juriya ga iska da yanayi, yana kiyaye iska mai kyau da 'yancin motsi.

Shin duk Softshells iri ɗaya ne?

Amsar, ba shakka, a'a ce.

Akwai ƙananan shells waɗanda ke tabbatar da aiki daban-daban kuma yana da mahimmanci a san su kafin siyan tufafi da aka yi da wannan kayan. Abubuwa uku masu mahimmanci, waɗanda ke auna su.Ingancin samfurin jaket mai laushi, sune hana ruwa shiga, juriyar iska da kuma iska mai ƙarfi.

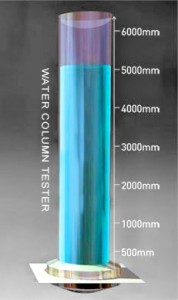

Mai Gwaji na Ginshiƙin Ruwa

Ta hanyar sanya ginshiƙi mai zurfi a kan masakar, ana cika shi da ruwa don tantance matsin lambar da kayan ke shiga. Saboda wannan dalili, ana bayyana rashin shigar da ruwa a cikin milimita. A cikin yanayi na yau da kullun, matsin ruwan sama yana tsakanin milimita 1000 zuwa 2000. Sama da milimita 5000 masakar tana ba da kyakkyawan matakan juriya ga ruwa, kodayake ba ta da cikakken hana ruwa shiga.

Gwajin Dawwama a Iska

Ya ƙunshi auna adadin iskar da ke ratsa samfurin masana'anta, ta amfani da kayan aiki na musamman. Kashi na iskar da ke ratsawa yawanci ana auna shi da CFM (ƙafa mai siffar cubic/minti), inda 0 ke wakiltar cikakken rufin. Saboda haka, ya kamata a yi la'akari da shi dangane da yadda ake iya numfashin masana'anta.

Gwajin Numfashi

Yana auna adadin tururin ruwa da ke ratsawa ta cikin wani yanki na murabba'in mita 1 na masaka a cikin awanni 24, sannan a bayyana shi a cikin MVTR (ƙimar watsa tururin danshi). Saboda haka, ƙimar 4000 g/M2/awa 24 ta fi 1000 g/M2/awa 24 kuma ya riga ya zama kyakkyawan matakin fitar da ruwa.

MimoWorkyana bayar da hanyoyi daban-dabanTeburan aikikuma zaɓi netsarin gane ganisuna ba da gudummawa ga nau'ikan kayan yankan laser, ko da kuwa girmansu ne, ko kuma siffarsu, ko kuma kowane tsari da aka buga. Ba wai kawai haka ba, kowanneInjin yanke laserAn daidaita shi daidai da ƙwararrun MimoWork kafin barin masana'anta don ku sami injin laser mafi kyau.

Yadda ake Yanke Jakar Softshell tare da Injin Yanke Laser na Yankewa?

Laser ɗin CO₂, mai tsawon tsayin microns 9.3 da 10.6, yana da tasiri wajen yanke masaka masu laushi kamar nailan da polyester. Bugu da ƙari,yanke da sassaka na Laseryana ba wa masu zane damar ƙirƙirar keɓancewa. Wannan fasaha tana ci gaba da ƙirƙira, tana biyan buƙatun da ke ƙaruwa na ƙirar kayan aiki na waje dalla-dalla da aiki.

Fa'idodi daga Jaket ɗin Yanke Laser Softshell

An gwada & An tabbatar ta MimoWork

Tsaftace gefuna a kowane kusurwa

Barga da kuma sake maimaita ingancin yankan

Babban yanke tsari yana yiwuwa

✔ Babu yankewa nakasa

Babban fa'idar yanke laser shineyankewa mara lamba, wanda hakan ya sa babu kayan aiki da zai taɓa masakar lokacin yankewa kamar wukake. Yana haifar da cewa babu kurakuran yankewa da matsin lamba ke haifarwa a kan masakar, wanda hakan ke inganta dabarun inganci a samarwa.

✔ Babban gefen

Sabodamagungunan zafiTsarin laser, masana'anta mai laushi za ta narke ta hanyar laser. Fa'idar ita ce cewa za a narkar da shi cikin wannan yanki.Ana magance gefunan da aka yanke kuma an rufe su da zafin jiki mai yawa, ba tare da wani lahani ko lahani ba, wanda ke ƙayyade samun mafi kyawun inganci a cikin sarrafawa ɗaya, babu buƙatar sake yin aiki don ɓatar da ƙarin lokacin sarrafawa.

✔ Babban mataki na daidaito

Masu yanke Laser kayan aikin injin CNC ne, kowane mataki na aikin kan laser ana ƙididdige shi ta hanyar kwamfutar motherboard, wanda ke sa yanke ya fi daidai. Daidaita da zaɓitsarin gane kyamara, ana iya gano zane-zanen yankewar yadin jaket mai laushi ta hanyar laser don cimmawamafi girman daidaitofiye da hanyar yankewa ta gargajiya.

Kayan Yanke Ski na Laser

Wannan bidiyon yana nuna yadda za a iya amfani da yanke laser don ƙirƙirar kayan wasan kankara tare da tsare-tsare masu rikitarwa da ƙira na musamman don tabbatar da dacewa da aiki mafi kyau a kan gangaren kankara. Tsarin ya ƙunshi yanke harsashi mai laushi da sauran masaku na fasaha ta amfani da laser mai ƙarfi na CO₂, wanda ke haifar da gefuna marasa matsala da ƙarancin sharar kayan aiki.

Bidiyon ya kuma nuna fa'idodin yanke laser, kamar ingantaccen juriyar ruwa, iska mai shiga da kuma sassauci, waɗanda suke da mahimmanci ga masu tsere a kan dusar ƙanƙara waɗanda ke fuskantar ƙalubalen yanayin hunturu.

Auto Ciyar Laser Yankan Machine

Wannan bidiyon yana nuna sassaucin da injin yanke laser ke da shi musamman wanda aka tsara don yadi da tufafi. Injin yanke laser da sassaka yana ba da daidaito da sauƙin amfani, wanda hakan ya sa ya dace da nau'ikan yadi iri-iri.

Idan ana maganar ƙalubalen yankan dogon yadi ko na birgima, injin yanke laser na CO2 (mai yanke laser na CO2 1610) ya yi fice a matsayin mafita mafi dacewa. Ƙarfin ciyarwa da yankewa ta atomatik yana ƙara ingancin samarwa sosai, yana ba da ƙwarewa mai santsi da inganci ga kowa, tun daga masu farawa zuwa masu zanen kaya da masu samar da masana'antu.

Na'urar Yanke CNC da Aka Ba da Shawara don Jaket ɗin Softshell

Mai Yanke Laser Mai Kwanto 160L

Na'urar yanke Laser ta Contour 160L tana da kyamarar HD a samanta wacce zata iya gano siffar da kuma canja wurin bayanan yankewa zuwa laser kai tsaye....

Mai Yanke Laser Mai Kwanto 160

An sanye shi da kyamarar CCD, Contour Laser Cutter 160 ya dace da sarrafa haruffan twill masu inganci, lambobi, da lakabi…

Flatbed Laser Cutter 160 tare da tebur mai tsawo

Musamman don yadi da fata da sauran kayan laushi. Kuna iya zaɓar dandamali daban-daban na aiki don kayan daban-daban...

Tsarin Laser don Jaket ɗin Shortshell

1. Jaket ɗin Yankan Laser Shotshell

•Tabbatar da masana'anta:Sanya yadin mai laushi a kan teburin aiki kuma a ɗaure shi da maƙalli.

•Shigo da zane:A ɗora fayil ɗin zane a kan na'urar yanke laser kuma a daidaita matsayin tsarin.

•Fara yankewa:Saita sigogi bisa ga nau'in yadi kuma fara injin don kammala yankewa.

2. Zane-zanen Laser akan Jaket ɗin Shotshell

•Daidaita tsarin:Gyara jaket ɗin a kan teburin aiki kuma yi amfani da kyamarar don daidaita tsarin ƙira.

•Saita sigogi:Shigo da fayil ɗin sassaka kuma daidaita sigogin laser bisa ga masana'anta.

•Aiwatar da sassaka:Fara shirin, kuma laser ɗin zai zana tsarin da ake so a saman jaket ɗin.

3. Fuskantar Laser akan Jakar Shotshell

Fasahar haƙa Laser na iya ƙirƙirar ramuka masu yawa da yawa a cikin yadudduka masu laushi don ƙira masu rikitarwa. Bayan daidaita yadi da tsari, shigo da fayil ɗin kuma saita sigogi, sannan fara injin don cimma haƙa mai tsabta ba tare da an sarrafa shi ba.

Aikace-aikace na yau da kullun don Yanke Laser Softshell Yadi

Saboda kyawun halayensa na hana ruwa shiga, iska, iska, roba, dorewa da kuma sauƙin amfani, ana amfani da yadin da aka yi da harsashi mai laushi sosai a cikin kayan sawa na waje ko kayan aiki na waje.