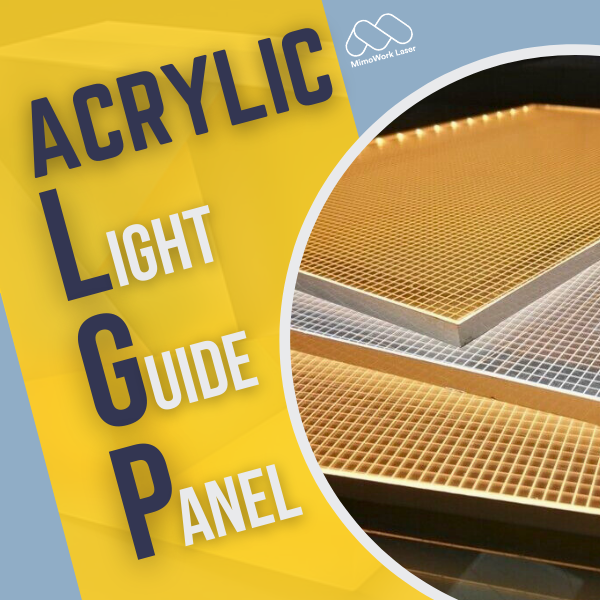

Acrylic LGP (Jagorar Haske)

Acrylic LGP: Mai Sauƙi, Tsabta da Dorewa

Duk da cewa acrylic galibi ana danganta shi da yankewa, mutane da yawa suna mamakin ko za a iya yin amfani da laser a kansa.

Labari mai daɗi shine cewaeh, hakika yana yiwuwa a goge fenti acrylic ta laser!

Teburin Abubuwan da ke Ciki:

1. Za ku iya yin Laser Etch Acrylic?

Laser na CO2 zai iya tururi da kuma cire siririn yadudduka na acrylic don barin alamun da aka zana ko aka sassaka.

Yana aiki a cikin kewayon raƙuman infrared na 10.6 μm, wanda ke ba da damarsha sosai ba tare da tunani mai yawa ba.

Tsarin etching yana aiki ta hanyar jagorantar hasken laser CO2 mai da hankali akan saman acrylic.

Zafin da ke fitowa daga hasken yana sa kayan acrylic da ke wurin da aka nufa su lalace su kuma yi tururi.

Wannan yana kawar da ƙaramin adadin filastik, yana barin zane, rubutu, ko tsari mai laushi.

Ana iya samar da laser CO2 na ƙwararru cikin sauƙibabban ƙudurin ƙiraa kan zanen acrylic da sanduna.

2. Wane Acrylic ne ya fi kyau ga Laser Etching?

Ba dukkan zanen acrylic ake ƙirƙira su iri ɗaya ba idan aka yi musu fenti da laser. Tsarin da kauri na kayan yana shafar ingancin da saurin yin zane.

Ga wasu abubuwa da ya kamata a yi la'akari da su yayin zabar mafi kyawun acrylic don fenti laser:

1. Zane-zanen Acrylic da aka yi da simintisuna da sauƙin tsaftace fenti kuma suna da juriya ga narkewa ko ƙonewa idan aka kwatanta da acrylic da aka fitar.

2. Takardun Acrylic Masu Sirarakamar 3-5mm kyakkyawan tsari ne na kauri. Duk da haka, kauri ƙasa da 2mm yana iya narkewa ko ƙonewa.

3. A bayyane yake, Acrylic mara launiyana samar da layuka da rubutu mafi kaifi. Guji acrylic masu launin shuɗi, masu launi, ko masu madubi waɗanda zasu iya haifar da sassaka mara daidaito.

4. Acrylic Mai Kyau Ba Tare da Ƙari Bakamar masu kare UV ko kuma shafan antistatic zai haifar da gefuna masu tsabta fiye da ƙananan maki.

5. Fafuka masu santsi, masu sheƙian fi son su fiye da ƙarewar rubutu ko matte wanda zai iya haifar da gefuna masu kauri bayan an yi musu fenti.

Bin waɗannan ƙa'idodin kayan aiki zai tabbatar da cewa ayyukan gyaran laser na acrylic ɗinku suna da cikakken bayani kuma suna da kyau a kowane lokaci.

KOYAUSHE a gwada samfuran farko don a saita saitunan laser daidai.

3. Fitar Laser/Ƙararrawa a Faifan Jagorar Haske

Ɗaya daga cikin aikace-aikacen da aka saba amfani da shi don ƙirƙirar acrylic na laser shine:bangarorin jagora masu haske, wanda kuma ake kirabangarorin matrix masu digo.

Wannan zanen acrylic yana da siffar da ta dacejerin ƙananan ɗigo ko makian zana su daidai don ƙirƙirar alamu, zane-zane, ko hotuna masu cikakken launi lokacin dahaske na baya tare da LEDs.

Jagorar haskoki na acrylic na Laser Dottingfa'idodi da yawata hanyar amfani da fasahar buga allo ko kuma fasahar buga pad.

Yana bayar daƙuduri mai kaifi har zuwa girman digo 0.1mmkuma yana iya sanya ɗigo a cikin tsare-tsare masu rikitarwa ko kuma matakai masu sauƙi.

Hakanan yana ba da damarSaurin canje-canje na ƙira da kuma samar da kayayyaki na ɗan gajeren lokaci.

Don nuna alamar laser a cikin jagorar hasken acrylic, an tsara tsarin laser CO2 don yin raster a fadin takardar a cikin daidaitattun XY, yana harbawa.bugun gajere a kowane wuri na "pixel" da aka yi niyya.

Makamashin Laser mai mayar da hankaliyana haƙa ramuka ko ramuka masu girman micrometerta hanyarkauri kaɗanna acrylic.

Ta hanyar sarrafa ƙarfin laser, tsawon bugun jini da kuma haɗuwar digo, za a iya cimma zurfin digo daban-daban don samar da matakai daban-daban na ƙarfin hasken da aka watsa.

Bayan an sarrafa shi, allon zai kasance a shirye don haskakawa da kuma haskaka tsarin da aka saka.

Ana samun amfani da dot matrix acrylic a cikin alamun rubutu, hasken gine-gine, har ma da nunin na'urorin lantarki.

Tare da saurinsa da daidaitonsa, sarrafa laser yana buɗe sabbin damar ƙirƙira don ƙira da kera allon jagora mai haske.

Ana amfani da Laser Etching don amfani da sigina, nuni, da sauran aikace-aikace

Muna farin cikin fara muku nan take

4. Fa'idodin Laser Etching Acrylic

Akwai fa'idodi da yawa na amfani da laser don zana zane da rubutu akan acrylic idan aka kwatanta da sauran hanyoyin alamar saman:

1. Daidaito da ƙuduri

Laser na CO2 yana ba da damar yin zane-zane masu kyau da cikakkun bayanai, layuka, haruffa, da tambari tare da ƙudurin ƙasa da 0.1 mm ko ƙasa da haka,ba za a iya cimmawa bata wasu hanyoyin.

2. Tsarin Rashin Saduwa

Domin gyaran laser abu ne mai sauƙihanyar da ba ta hulɗa ba, yana kawar da buƙatar rufe fuska, wanka mai sinadarai, ko matsin lamba wanda zai iya lalata sassa masu laushi.

3. Dorewa

Alamun acrylic da aka zana da laser suna jure wa muhalli kuma suna da matuƙar ɗorewa.Kada a goge, a goge, ko a sake amfani da shikamar saman da aka buga ko aka fenti.

4. Sauƙin Zane

Tare da gyaran laser, ana iya yin canje-canje a cikin ƙira a cikin minti na ƙarshecikin sauƙi ta hanyar gyaran fayiloli na dijitalWannan yana ba da damar yin gyare-gyare cikin sauri da kuma yin gajerun shirye-shiryen samarwa akan buƙata.

5. Daidaita Kayan Aiki

Laser na CO2 na iya yin fenti iri-iri na acrylic masu haske da kauri.yana buɗe damar ƙirƙiraidan aka kwatanta da sauran hanyoyin da ke da ƙuntatawa na kayan aiki.

6. Gudu

Tsarin laser na zamani na iya yin zane mai rikitarwa a cikin sauri har zuwa 1000 mm/s, yana yin alamar acrylicinganci sosaidon samar da kayayyaki da yawa da kuma amfani da su a manyan yawa.

Don Laser Etching Acrylic (Yankewa & sassaka)

Bayan jagororin haske da alamun rubutu, gyaran laser yana ba da damar amfani da acrylic da yawa:

1. Nunin Na'urorin Lantarki

2. Siffofin Gine-gine

3. Motoci/Sufuri

4. Kula da Lafiya/Kiwon Lafiya

5. Hasken Ado

6. Kayan aikin masana'antu

Laser Processing Acrylic Yana Bukatar Wasu Kulawa Mai Kyau

Har da Saita Daidaito don Tabbatar da Inganci Mai Kyau, Ba Tare da Burr Ba.

5. Mafi kyawun Ayyuka don Gyaran Laser Acrylic

1. Shiri na Kayan Aiki

Koyaushe fara da acrylic mai tsabta, mara ƙura.Ko da ƙananan ƙwayoyin cuta na iya haifar da wargajewar bishiyoyi kuma su bar tarkace a wuraren da aka yi wa fenti.

2. Cire Tururi

Samun iska mai kyau yana da mahimmancilokacin da ake yin fenti da laser. Acrylic yana samar da hayaki mai guba wanda ke buƙatar ingantaccen shaye-shaye kai tsaye a yankin aiki.

3. Mayar da Hankali Kan Hasken

Ɗauki lokaci don mayar da hankali sosai kan hasken laser a kan saman acrylic.Ko da ƙaramin cire hankali yana haifar da ƙarancin ingancin gefen ko kuma cire kayan da ba a cika yi ba.

4. Gwaji Kayan Samfura

Gwada samfurin da farkoamfani da saitunan da aka tsara don duba sakamako kafin sarrafa manyan ayyuka ko ayyuka masu tsada. Yi gyare-gyare kamar yadda ake buƙata.

5. Matsewa da Daidaita Daidaito

Acrylic ɗindole ne a ɗaure shi da kyau ko kuma a sanya shi a wuri mai aminciAn saka shi don hana motsi ko zamewa yayin sarrafawa. Tef ɗin bai isa ba.

6. Inganta Wutar Lantarki & Sauri

Daidaita saitunan wutar lantarki, mita, da saurin laser don cire kayan acrylic gaba ɗaya ba tare danarkewar abinci mai yawa, ƙonewa ko fashewa.

7. Bayan Sarrafawa

Yi ɗan yashi kaɗan da takarda mai laushiBayan yin etching, yana cire ƙananan tarkace ko lahani don kammalawa mai santsi sosai.

Bin waɗannan mafi kyawun hanyoyin etching na laser yana haifar da alamun acrylic na ƙwararru, waɗanda ba su da burr a kowane lokaci.

Ingantaccen tsarin saiti yana da mahimmanci don samun sakamako mai kyau.

6. Tambayoyi da Amsoshi kan Etching na Laser Acrylic

1. Har yaushe ake ɗaukar aikin gyaran laser?

Lokacin yin zane ya dogara ne da sarkakiyar ƙira, kauri na kayan aiki, da saitunan wutar lantarki/gudun laser. Rubutu mai sauƙi yawanci yana ɗaukar mintuna 1-3 yayin da zane mai rikitarwa na iya ɗaukar mintuna 15-30 don takardar 12x12".Ana buƙatar gwaji mai kyau.

2. Shin laser zai iya yin fenti da launuka zuwa acrylic?

A'a, gyaran laser yana cire kayan acrylic ne kawai don bayyana filastik mai haske a ƙasa. Don ƙara launi, dole ne a fara fenti ko a rina acrylic kafin a sarrafa laser.Yin feshi ba zai canza launi ba.

3. Waɗanne irin ƙira ne za a iya yi wa fenti da laser?

Kusan kowace tsarin fayil ɗin hoton vector ko rasterya dace da yin amfani da laser etching a kan acrylic. Wannan ya haɗa da tambari masu rikitarwa, zane-zane, tsarin lambobi/alphanumeric jere, lambobin QR, da hotuna ko zane-zane masu cikakken launi.

4. Shin aikin gyaran fuska na dindindin ne?

Ee, alamun acrylic da aka yi da laser da kyau suna ba da zane mai ɗorewa wanda zai iya zama na dindindinba ya gogewa, ya goge, ko kuma ya buƙaci sake amfani da shi.Saƙar tana jure wa yanayin muhalli sosai don a gane ta na dogon lokaci.

5. Zan iya yin aikin gyaran laser da kaina?

Duk da cewa aikin gyaran laser yana buƙatar kayan aiki na musamman, wasu masu yanke laser na tebur da masu sassaka yanzu sun isa ga masu sha'awar sha'awa da ƙananan kasuwanci don yin ayyukan alamar acrylic na asali a cikin gida.Koyaushe a bi matakan kariya.

6. Ta yaya zan tsaftace fenti mai laushi?

Don tsaftacewa ta yau da kullun, yi amfani da mai tsabtace gilashi mai laushi ko sabulu da ruwa.Kada a yi amfani da sinadarai masu tsauriwanda zai iya lalata filastik akan lokaci. A guji yin zafi sosai lokacin tsaftacewa. Yadi mai laushi yana taimakawa wajen cire yatsan hannu da ƙura.

7. Menene matsakaicin girman acrylic don etching na laser?

Yawancin tsarin laser na CO2 na kasuwanci na iya ɗaukar girman zanen acrylic har zuwa ƙafa 4x8, kodayake ƙananan girman tebur suma sun zama ruwan dare. Ainihin wurin aiki ya dogara da samfurin laser na kowane mutum - koyaushe a dubaƙayyadaddun bayanai na masana'anta don iyakokin girman.