Tsaftace Mold na Laser

Tsaftace mold ɗin Laser wata fasaha ce ta zamani da ake amfani da ita don cire gurɓatattun abubuwadaga ƙirar masana'antumusamman a fannin kera kayayyakifilastikkumarobasassan. Yana inganta ingancin masana'antu yayin da yake tabbatar da sakamako mai inganci. Daidaitonsa da kuma kyawun muhallinsa sun sa ya zamazaɓi mafi soyuwa a aikace-aikacen masana'antu na zamani.

Yadda Tsaftace Mold na Laser ke Aiki

Inganci, Inganci Mai Inganci, da Kulawa Mai Inganci

Man shafawa daban-daban da masana'antu daban-daban ke amfani da su

Lasers masu ƙarfi suna fitar da haskemai da hankalihasken da zai iya kai hari daidai da kuma cire gurɓatattun abubuwa ba tare da lalata saman ƙasa ba. Nau'ikan laser da aka saba amfani da su sun haɗa da CO2 dana'urorin laser na fiber.

Matakan Tsarin Aikidon Tsaftace Fuskar Laser

Ana duba mold ɗin kuma ana cire duk wani tarkace da ya ɓace. Ana mayar da laser ɗin zuwa saman mold ɗin.

Ƙarfin da ke fitowa daga laser yana sa gurɓatattun abubuwa (kamar resin, mai, ko tsatsa) su shiga ko dai cikin ɗayansu.tururiko kuma zamaan rusa shita hanyar ƙarfin hasken laser. Masu aiki suna sa ido kan tsarin tsaftacewa don tabbatar da inganci da daidaita sigogi kamar yadda ake buƙata.

Fa'idodidon Tsaftace Fuskar Laser:

Ba kamar hanyoyin tsaftacewa na gargajiya ba (kamar shafa yashi), tsaftace laser ba ya lalata saman mold. Lasers na iya tsaftace ƙira masu rikitarwa.ba tare da shafar yanayin mold ba.

Tsaftace Mold na Laseryana rage buƙatadon sinadarai masu ƙarfi da sinadarai masu narkewa.

Fa'idodin Tsaftace Mold na Laser

Tsaftace Mold na Laser yana Ba da Fa'idodi Da Dama Da Ya Sa Ya Zama Zabi Mafi Kyau

Tsaftace Mold na Laser

Tsaftace mold na Laser mafita ce ta zamani wacce ke haɗuwainganci,daidaito, kumafa'idodin muhalli, wanda hakan ya sanya shi zaɓi mai mahimmanci ga masana'antu masu mai da hankali kan inganci da dorewa.

Ba Ya Lalacewa, Daidaito da kuma Yana da Kyau ga Muhalli

Yanayin tsaftacewar laser mara abrasionyana hana lalacewa da tsagewaa saman mold.

Kula da siffarsu ta asali da kuma aikinsu.

Na'urorin laser za su iya mai da hankali kan takamaiman wurare, wanda hakan zai sa su dace da ƙirar mold mai rikitarwa da wuraren da ba a iya isa gare su ba. Wannan hanyarrage buƙatardon sinadarai masu ƙarfi da sinadarai masu narkewa, suna haɓaka ingantaccen tsari na tsaftacewa mai ɗorewa.

Inganci, Sauƙin Amfani da Tsaro

Ta hanyar tsawaita tsawon rayuwar molds da rage buƙatar kayan aiki da tsaftacewa da hannu, tsaftacewar laser na iya haifar dababban tanadin farashi.

Mai tasiriakan gurɓatattun abubuwa daban-daban, ciki har da mai, mai, tsatsa, da ragowar filastik, wanda hakan ya sa ya dace da masana'antu daban-daban. Kamar yadda yake buƙataƙarancin sarrafa hannuna kayan tsaftacewa masu nauyi da sinadarai, yana ƙara aminci a wurin aiki.

Tsaftace Laser na Mold: Aikace-aikace

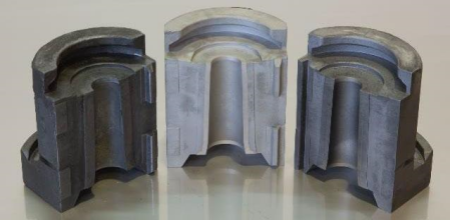

RobaMould

Tsaftace mold na Laser don molds na roba hanya ce mai inganci kuma mai inganci wacce aka tsara musamman donkadarori na musammanna kayan roba.

Wannan tsari ba wai kawaiyana inganta tsawon raina molds amma kuma yana inganta ingancin samfura ta hanyar hana lahani a cikin samfuran roba na ƙarshe.

Ya dace da masana'antu waɗanda suka dogara da daidaito da inganci mai kyau, tsaftace mold na laser mafita ce mai ɗorewa wacce ke rage lokacin aiki da kuma haɓaka ingancin aiki.

RobaMould

Tsaftace mold ɗin Laser don mold ɗin filastik yana cire datti, ragowar abubuwa, da sauran gurɓatattun abubuwa daga saman mold ba tare da haifar da wata illa ta zahiri ba.

Sabanin dabarun tsaftacewa na gargajiya, wanda zai iya haifar dakarce ko lalacewaTsaftace laser daidai ne kuma ba ya gogewa,kiyaye mutuncina mold.

Ya dace da masana'antun da ke da niyyaringanci mafi kyaukumadorewawannan sabuwar hanyar tana ƙara tsawon rayuwar molds na filastik yayin dainganta yawan aiki gaba ɗaya.

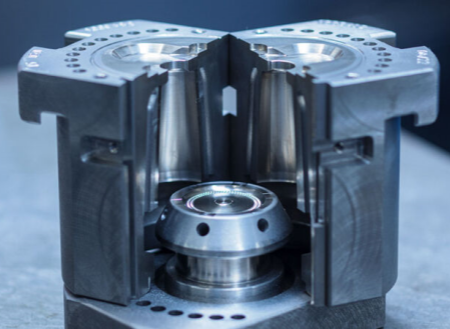

Tsaftace Mold na Laser:Allura Mould

AlluraMould

Tsaftace mold ɗin Laser don mold yana da fa'idodi na musamman waɗanda ke da mahimmanci don kiyayewa da kiyayewadaidaitokumaaikidaga cikin waɗannan kayan aikin masu rikitarwa.

Tsaftace Laser yana tabbatar da cewa yana da kyauhaƙuri mai kyaumahimmanci don ƙera alluraan kiyaye su, hana lahani a cikin samfuran ƙarshe.

Ta hanyar inganta tsaftar molds, wannan tsari yana ingantamafi kyawun canja wurin zafikumakwararar kayan aiki mai daidaito, wanda ya haifar daingantattun lokutan zagayowarkumakammalawa mafi kyau.

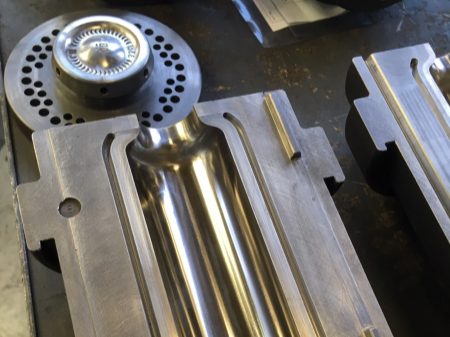

Haɗaɗɗun kayan haɗinMould

Tsaftace mold na Laser don molds masu haɗawa yana ba da damarfa'idodi na musammanwanda aka tsara shi da sarkakiyar kayan haɗin kai.

Wannan sabuwar hanyar tsaftacewa tana cire resin da aka warke, gel ɗin gashi, da sauran ragowar da suka taurare yadda ya kamata.ba tare da cutarwa basaman mai laushi na mold.

Ya dace da masana'antun da ke cikin masana'antar sararin samaniya da motoci, wannan hanyar tana haɓaka inganci kuma tana tabbatar da sakamako mai kyau a cikin samar da kayayyaki iri-iri.

Tsaftace Mold na Laser:Haɗaɗɗun Mold

Ina son sanin yadda ake yiTsaftace Mold na LaserAiki?

Za Mu Iya Taimakawa!

Shin Injinan Tsaftace Laser Suna Aiki Da Gaske?

Menene Tsaftace Laser kuma Ta Yaya Yana Aiki?

Shin injinan tsaftacewa na laser suna aiki da gaske?Hakika!

Waɗannan na'urori masu ci gaba suna da matuƙar tasiri gatsaftacewa mai yawamolds a cikin masana'antu daban-daban.

Masu tsabtace laser suna amfani da hasken da aka mayar da hankali a kai don cire gurɓatattun abubuwa, ragowar abubuwa, da taruwar abubuwa daidai.ba tare da cutarwa basaman mold.

A cikin manyan ayyuka, ingancin tsaftacewar laser yana fassara zuwarage lokacin hutukumaƙarancin farashin aiki, domin ana iya tsaftace ƙwayaye da yawa a lokaci guda ba tare da kulawa sosai ba. Bugu da ƙari, tsaftace laser yana da kyau ga muhalli, yana rage buƙatar sinadarai masu tsauri da zubar da shara.

Don Tsaftace Mold na Laser?

Mai Tsaftace Laser Mai Tura(100W, 200W, 300W, 400W)

Ga masana'antun da ke neman kulawamanyan ƙa'idodinatsaftakumainganciyayin da suke inganta layukan samar da su, injunan tsaftacewa na laser suna ba da mafita mai ƙarfi wanda ke haɓaka duka biyunaikikumadorewa.

Ƙarfin Laser:100-500W

Daidaita Tsawon Pulse:10-350ns

Tsawon Kebul na Fiber:3-10m

Tsawon Raƙuman Ruwa:1064nm

Tushen Laser:Laser ɗin Fiber Mai Ƙarfi