Jagorar Ƙarshe ga Zane na Yankan Laser:

Nau'i, Fa'idodi, da Aikace-aikace

Gabatarwa:

Muhimman Abubuwa da Ya Kamata Ku Sani Kafin Ku Shiga Cikin Ruwa

Zane-zanen tacewa suna taka muhimmiyar rawa a fannoni daban-daban na masana'antu, tun daga tace ruwa da iska zuwa sarrafa magunguna da abinci. Yayin da kamfanoni ke neman inganta inganci, daidaito, da kuma keɓancewa wajen samar da zane-zanen tacewa, zane-zanen tacewa na laser ya fito a matsayin mafita mafi kyau. Ba kamar hanyoyin yankewa na gargajiya ba, zane-zanen tacewa na laser yana ba da babban matakin daidaito, gudu, da ƙarancin sharar kayan aiki, wanda hakan ya sa ya zama zaɓi mafi kyau don yanke zane-zanen tacewa da aka yi da kayayyaki daban-daban kamarpolyester, nailan, kumayadi marasa saka.

A cikin wannan labarin, za mu yi nazari sosai kan nau'ikan zane-zanen tacewa daban-daban da kuma yadda zane-zanen yanke laser ke aiki a kan kayayyaki daban-daban. Za ku ga dalilin da ya sa ya zamamafita mafi dacewa don samar da inganci mai kyau, samfuran tacewa na musammanZa mu kuma raba bayanai daga gwaje-gwajenmu na baya-bayan nan da kayan aiki kamar kumfa da polyester, wanda zai ba ku misalai na gaske na yadda zane na laser zai iya haɓaka inganci da daidaito a cikin samarwa.

Yadda ake Yanke Laser Tace Yadi | Injin Yanke Laser don Masana'antar Tacewa

Ku zo bidiyon don bincika tsarin yanke zanen laser. Bukatar yankewa mai yawa ta shahara da injin yanke laser a masana'antar tacewa.

Kawuna biyu na laser suna ƙara haɓaka samarwa, suna haɓaka saurin yankewa yayin da suke tabbatar da inganci.

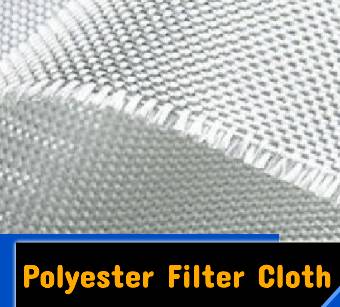

1. Zane na Tace Polyester:

• Amfani:Zane na matattarar polyester yana ɗaya daga cikin kayan da aka fi amfani da su wajen tacewa saboda dorewarsa, juriyarsa ga sinadarai, da kuma ikonsa na jure yanayin zafi mai yawa.

•Aikace-aikace:Sau da yawa ana amfani da shi a tsarin tace iska, sarrafa ruwa, da tsarin tacewa na masana'antu.

•Amfanin Yanke Laser:Polyester yana da kyau sosai tare dazane na matatar tace Laserdomin yana samar da gefuna masu tsabta da daidaito. Hakanan laser yana rufe gefuna, yana hana lalacewa da kuma ƙara ƙarfin zane gaba ɗaya.

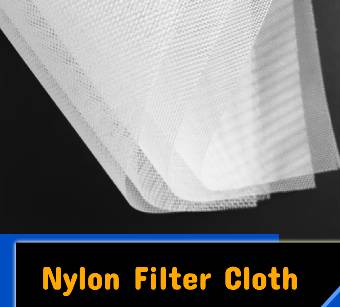

2. Zane na Tace Nailan:

• Amfani:An san shi da sassauci da tauri, zanen matattarar nailan ya dace da aikace-aikacen tacewa mai wahala, kamar a masana'antar sinadarai ko a fannin abinci da abin sha.

•Aikace-aikace:Ana amfani da shi sosai wajen tace sinadarai, tsaftace ruwa, da kuma tace abinci.

•Amfanin Yanke Laser:Ƙarfin nailan da juriyarsa ga sawa sun sa ya zama kyakkyawan zaɓi gazane na matatar tace LaserLaser ɗin yana tabbatar da gefuna masu santsi da aka rufe waɗanda ke kiyaye dorewar kayan da kuma halayen tacewa.

3. Zane na Matatar Polypropylene:

• Amfani:An san Polypropylene saboda kyawun juriyarsa ga sinadarai, wanda hakan ya sa ya dace da tace sinadarai masu ƙarfi ko abubuwan da ke da zafi sosai.

•Aikace-aikace:Ana amfani da shi a cikin tace magunguna, tace masana'antu, da tace ruwa.

•Amfanin Yanke Laser: Laser yanke tace zaneKamar polypropylene, yana ba da damar yankewa daidai da ƙira mai rikitarwa ba tare da lalata kayan ba. Gefunan da aka rufe suna ba da ingantaccen tsari, wanda hakan ya sa ya dace da aikace-aikace masu mahimmanci.

4. Zane mara sakawa:

• Amfani:Zane mara sakawa mara nauyi ne, mai sassauƙa, kuma mai araha. Ana amfani da shi a aikace-aikace inda sauƙin amfani da ƙarancin matsi yake da mahimmanci.

•Aikace-aikace:Ana amfani da shi a tacewa ta mota, iska, da ƙura, da kuma a cikin kayayyakin tacewa da ake zubarwa.

•Amfanin Yanke Laser:Ana iya yin yadin da ba a saka bayankewar laserda sauri da inganci.Laser yanke tace zaneyana da matuƙar amfani ga buƙatun tacewa daban-daban, yana ba da damar yin ramuka masu kyau da kuma yanke manyan yankuna.

Zane mai tace laser yana amfani da hasken laser mai ƙarfi wanda ke narke ko tururi a daidai wurin da aka taɓa masa. Tare da jagorancin tsarin CNC (Na'urar Kula da Lambobin Kwamfuta), laser ɗin yana motsawa da daidaito mai ban mamaki, wanda ke ba da damar yanke ko ma sassaka nau'ikan zane daban-daban tare da daidaito mai ban mamaki.

Ba shakka, ba duk kayan zane-zanen matattara iri ɗaya ba ne. Kowannensu yana buƙatar saitunan da aka gyara don cimma mafi kyawun sakamakon yankewa. Bari mu bayyana yadda zanen matattara na yanke laser ke aiki akan wasu daga cikin kayan da aka fi amfani da su.

Polyester na Laser:

Zane mai tacewa na polyester yana da ɗorewa kuma yana jure wa shimfiɗawa, wanda wani lokacin yakan sa ya yi wuya a yanke shi da kayan aikin gargajiya. Yanke laser yana ba da fa'ida a nan, domin yana ba da gefuna masu santsi da aka rufe waɗanda ke hana lalacewa yayin da yake kiyaye ƙarfin masana'anta. Wannan daidaito yana da mahimmanci musamman a masana'antu kamar sarrafa ruwa ko sarrafa abinci, inda ake buƙatar aikin tacewa mai daidaito.

Yadin Laser Nonwoven Yadi:

Yadudduka marasa saka suna da sauƙi kuma masu laushi, wanda hakan ya sa suka dace da yanke laser. Da wannan fasaha, ana iya sarrafa kayan cikin sauri ba tare da lalata tsarinsa ba, wanda ke haifar da yankewa masu tsabta da daidaito waɗanda suke da mahimmanci don tsara matatun. Wannan hanyar tana da matuƙar amfani musamman lokacin aiki da yadudduka marasa saka a cikin tacewa na likita ko na mota, inda daidaito da daidaito suke da mahimmanci.

Nailan Yanke Laser:

An san masaku na nailan da sassauci da tauri, amma suna iya zama da wahala a iya jurewa ta hanyar amfani da hanyoyin yankewa na inji. Sarrafa laser yana magance wannan ƙalubalen ta hanyar samar da yankewa masu kaifi da daidaito ba tare da haifar da karkacewa ba. Sakamakon haka shine matattara waɗanda ke riƙe siffarsu kuma suna ba da ingantaccen aiki, wanda yake da mahimmanci a cikin yanayi mai wahala kamar aikace-aikacen sinadarai ko magunguna.

Kumfa Yanke Laser:

Kumfa abu ne mai laushi da ramuka wanda zai iya yagewa ko lalacewa cikin sauƙi idan aka yanke shi da ruwan wukake. Fasahar Laser tana ba da mafita mai tsabta da aminci, domin tana yanke kumfa cikin sauƙi ba tare da murƙushe ƙwayoyin ba ko kuma ta lalata tsarinta. Wannan yana tabbatar da cewa matatun da aka yi da kumfa suna kiyaye porosity da aikinsu, wanda hakan ke sa su zama masu amfani musamman a aikace-aikace kamar tsarkake iska da kuma rufewar sauti.

Me Yasa Zabi Laser Yankan Don Tace Zane?

Laser yanke tace zaneyana ba da fa'idodi da yawa fiye da hanyoyin yanke gargajiya, musamman ga kayan zane na tacewa. Ga wasu daga cikin manyan fa'idodi:

1. Daidaito da Tsabtace Gefen

Laser yanke tace zaneyana tabbatar da yankewa daidai tare da gefuna masu tsabta da aka rufe, wanda yake da mahimmanci don kiyaye daidaiton tsarin zanen matatar. Wannan yana da mahimmanci musamman a tsarin tacewa inda kayan dole ne su kula da ikon tacewa yadda ya kamata.

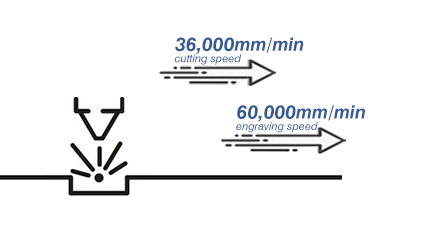

2. Saurin Sauri & Ingantaccen Aiki

Laser yanke tace zaneya fi sauri da inganci fiye da hanyoyin yankewa na inji ko na mutu, musamman ga ƙira masu rikitarwa ko na musamman.tsarin yanke zane na Laserana iya sarrafa shi ta atomatik, yana rage buƙatar shiga tsakani da hannu da kuma hanzarta lokacin samarwa.

3. Ƙananan Sharar Kayan Aiki

Hanyoyin yankewa na gargajiya galibi suna haifar da asarar kayan da suka wuce kima, musamman lokacin yanke siffofi masu rikitarwa.Laser yanke tace zaneyana ba da daidaito mai kyau da ƙarancin ɓarnar kayan aiki, wanda hakan ya sa ya zama zaɓi mai araha ga ƙananan da manyan masana'antu.

4. Keɓancewa da Sauƙin Sauƙi

Laser yanke tace zaneyana ba da damar yin gyare-gyare ga zane-zanen tacewa gaba ɗaya. Ko kuna buƙatar ƙananan ramuka, takamaiman siffofi, ko zane-zane dalla-dalla,zane na matatar tace Laserzai iya biyan buƙatunku cikin sauƙi, yana ba ku sassauci don samar da nau'ikan samfuran zane masu tacewa iri-iri.

5. Babu Kayan aiki da ake sakawa

Ba kamar yankewa ko yankewa na inji ba,zane na matatar tace Laserba ya haɗa da taɓawa ta jiki da kayan, ma'ana babu lalacewa a kan ruwan wukake ko kayan aiki. Wannan yana rage farashin gyara da lokacin hutu, wanda hakan ya sa ya zama mafita mafi aminci na dogon lokaci.

• Wurin Aiki (W *L): 1300mm * 900mm

• Ƙarfin Laser: 100W/150W/300W

A Kammalawa

Laser yanke tace zaneya tabbatar da cewa hanya ce mai kyau ta yanke kyallen tacewa, tana ba da fa'idodi da yawa kamar daidaito, gudu, da ƙarancin sharar gida. Ko kuna yanke polyester, kumfa, nailan, ko yadudduka marasa sakawa, kyallen tacewa na laser yana tabbatar da sakamako mai inganci tare da gefuna da aka rufe da ƙira na musamman. Tsarin yankewa na laser na zane-zanen matattara na MimoWork Laser yana ba da mafita mafi kyau ga kasuwanci na kowane girma da ke neman inganta tsarin samar da kyallen tacewa.

Tuntube mu a yau don ƙarin bayani game da yadda muke aikiinjin yanke laser zanezai iya inganta ayyukan yanke zane na tacewa da kuma inganta ingancin samfuran ku.

Idan ana maganar zaɓen waniinjin yanke zane na Laser, yi la'akari da waɗannan:

Nau'ikan Injina:

Ana ba da shawarar a yi amfani da na'urorin yanke laser na CO2 don yanke zane mai tacewa domin na'urar laser na iya yanke siffofi da girma dabam-dabam. Kuna buƙatar zaɓar injin laser mai dacewa da girmansa da ƙarfinsa bisa ga nau'ikan kayan ku da fasalulluka. Tuntuɓi ƙwararren laser don neman shawarar laser na ƙwararru.

Gwaji shine Farko:

Kafin ka saka hannun jari a injin yanke laser, hanya mafi kyau ita ce yin gwajin kayan aiki ta amfani da laser. Za ka iya amfani da ɗan ƙaramin zane mai tacewa kuma ka gwada ƙarfin laser da saurinsa daban-daban don duba tasirin yankewa.

Duk wani Ra'ayi game da Laser Yankan Tace Zane, Barka da zuwa Tattaunawa da Mu!

Duk wani Tambayoyi game da Injin Yanke Laser don Zane Mai Tace?

An sabunta shi na ƙarshe: Satumba 9, 2025

Lokacin Saƙo: Nuwamba-14-2024