Kuwelda neLaser vs TIG: Chii Chakachinja muna 2024

Chii chinonzi Handheld Laser Welding?

Kukwesha kweLaser Yemaoko Simbi Isina Kusimba

Kushongedza nelaser inobatwa nemaokoinoshandisa mudziyo welaser unotakurika kubatanidza zvinhu, kazhinji simbi.

Kukwesha ne laser kunobvumirachikurukugona kufamba uye kurongeka,

Uye inogadzira weld yemhando yepamusoro uye yakachena inezvishomakuisa kupisa,

Kuderedzakukanganisa uye kudiwa kwekugadzirisa kwakakura mushure mekusveta.

Vashandi vanogona kugadzirisa simba nekumhanya kwelaser zviri nyore,

Kugonesamarongero akagadzirirwazvezvinhu zvakasiyana uye ukobvu.

Tafura yezviri Mukati:

Chii chinonzi Laser Weld Cleaning?

Kukosha kweKuchena mukuWelding

Kuchenesa Kwepamberi Pekushongedza KweTIG

Kana zvasvika pakunamira,

Kuchena kunoita basa guru mukuita kutiyepamusoro-soromhedzisiro.

Nheyo iyi inoshanda kune ese ari maviri TIG welding uye handheld laser welding,

Asi nzira dzekugadzirira zvinhu zvakasiyana zvikuru.

Kune chero nzira yekushongedza,

Kuvapo kwezvinhu zvinosvibisa zvakaita sengura, pendi, uye mafuta

Chinogonakubvumirana zvakanyanyakuvimbika kwe weld.

Tsvina iyi inogona kukonzera kusasimba kwemajoini, maburi, nezvimwe zvikanganiso

Izvozvo zvinoderedza simba rechigadzirwa chekupedzisira.

Izvi ndizvo zvaunoitaZVINOFANIRA KUTIBata Nezvinhu Izvi Zvinosvibisa:Kuchenesa NeLaser Weld.

Kuchenesa neLaser vs TIG Welding: Kuchenesa neLaser Weld

Nzvimbo Dzakacheneswa Dzinogadzira Welds dzemhando yepamusoro

Kuchenesa Kwesimbi NeLaser Kwekuchenesa Nemaoko NeLaser

Kunyange zvazvo TIG welding ichivimba nebhuku rekushandisanzira dzekuchenesa dzakadai sekukuya makona uye kupukuta acetone,

Kukwesha kwe laser nemaoko kunopa zvakawandazviri nyoreimwe nzira ine hunyanzvi hwayo hwekuchenesa hwakabatana.

Unyanzvi uhwu hahungobatsiri chete pakushanda zvakanaka

Asi zvakare inoita kuti maitiro ekunamira ashande zvakanaka sezvinobvira,

Pakupedzisira zvichitungamira kumhedzisiro iri nani.

Kugadzirira Kusonwa kweTIG:

MuTIG (Gasi Risina Kushanda reTungsten) kusona, kugadzirira kwakanyatsonaka kwakakosha.

Usati watanga maitiro ekunamira,

Zvakajairika kushandisamagrinder ekonakubvisa ngura kana machira pamusoro pechinhu chacho.

Kuchenesa uku kwemuchina kunobatsira kuona kuti pamusoro payo hapana tsvina.

Mushure meizvi, pukuta zvakakwana neacetoneinowanzoitwa.

Acetone chinhu chinonyungudutsa chine simba guruinobvisa zvinobudirirachero mafuta asara kana zvimwe zvinosvibisa,

Kusiya nzvimbo yakachena yekunamira.

Maitiro aya ekuchenesa ane matanho maviri anogona kutora nguva,

Asi zvakakosha kuti pave ne weld yakasimba uye inogara kwenguva refu.

Kugadzirira Kukwevera KweLaser Nemaoko

Kusiyana neizvi, welding yelaser inobatwa nemaoko inopa

Zvimwenzira yakarongekakugadzirira pamusoro.

Ne3-mu-1Nekushandisa laser welder, maitiro acho anova nyore zvikuru.

Michina iyi yepamusoro inowanzo shongedzerwa nemaburi anochinjika

Izvi zvinoita kuti pave nekucheneswa kwenzvimbo usati wabatanidza.

Kusiyana nenzira dzechinyakare, uko maturusi akasiyana nemishonga yekuchenesa zvinodiwa,

Vagadziri vemachira eLaser vanogona kuchenesa pamusoro pasina dambudziko nemwaranzi weLaser wakanangana.

Izvi hazvingochengetedzi nguva chete asi zvinoderedzawohuwandu hwemidziyozvinodiwa panzvimbo yacho.

Kuwelda neLaser vs TIG Kwachinja muna 2024

Taura Nesu Kuti Uwane Zvimwe Nezve Handheld Laser Welding System

Sei Uchifanira Kushandisa Gasi Rekudzivirira Mukugadzira Welding?

Kusarudzwa kweGasi Rinodzivirira Kunoita Basa Rakakosha

Gasi rekudzivirira reTIG Welding: Argon

Kana zvasvika pakunamira,

Kusarudza gasi rekudzivirira kwakakosha pakuona kuti mhedzisiro yacho yakanaka.

Kunyanya, TIG welding uye handheld laser welding zvine zvinodiwa zvakasiyana uye sarudzo.

Kana zvasvika pakudzivirira magasi, zvinokanganisa mashandiro uye mutengo.

Kudzivirira Gasi mukatiKushongedza kweTIG

MuTIG (Tungsten Inert Gasi) welding,

Gasi guru rekudzivirira rinoshandiswa ndirokuchena kwakanyanyaargon.

Gasi rakanaka iri rinosarudzwa nekuda kwekugona kwaro kukuruchengetedza dziva rekunamira weld

Kubva pakusvibiswa kwemhepo, kunyanya oxidation.

Kuoxidation kunogona kutungamira kuzvikanganisomune weld, senge maburi uye majoini asina simba,

Ndeipikubvumiranakuvimbika kwese kwesimbi.

Nekuda kwekushanda kwayo,

Kubatanidza TIG kunowanzo dachinoenderera mberikuwanikwa kweargon panguva yese yekushongedza.

Zvisinei, argon inogona kudhura zvakanyanya, zvichikonzera kudhura kwakanyanya kwekushanda,

Kunyanya mumapurojekiti anoda kusungirirwa kwakawanda.

Kudzivirira Gasi mukatiKukwevera neLaser Inobatwa Nemaoko

Gasi Rinovharidzira Rinoshandiswa Pakushongedza NeLaser: Nitrogen

Kune rumwe rutivi, kupinza ne laser nemaoko kunowanzo shandisa nitrogen segasi rekudzivirira.

Nitrogen haisi cheteinoshandakudzivirira oxidation

Asi zvakare zvakanyanya kukoshaisingadhurikupfuura argon.

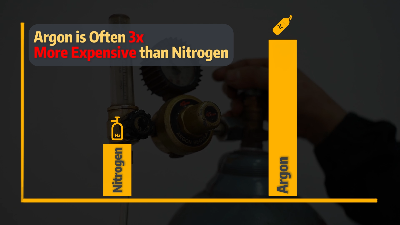

Musiyano wemutengo unogona kuva mukuru;

Nitrogen inogona kunge irikatatuyakachipa pane argon ine purity yakawanda.

Izvi zvinoita kuti nitrogen ive sarudzo inokwezva mabhizinesi ari kutsvaga kuderedza mitengopasina kuzvipiramhando.

TIG vs Laser Welding: Sarudzo dzeGasi rekudzivirira

Wana Mari Yekuchengetedza Uchichengetedza Hunhu Hwakanaka

Kuenzanisa Mutengo Pakati peArgon neNitrogen

Kuchinja kushandisa nitrogen mukushandisa laser welding nemaoko zvinopaakati wandeizvakanakira

Kuchengetedza Mari:

Nekukoshamusiyano wemutengo pakati peargon nenitrogen,

Kushandisa nitrogen kunogona kuchengetedza mari yakawanda nekufamba kwenguva.

Ichi chizvinobatsira zvikurukumapurojekiti makuru kana mabhizinesi

Izvo zvinoita mabasa ekusonta kakawanda.

Dziviriro Inoshanda:

Nitrogen inopadziviriro yakakwanakurwisa oxidation,

Kuve nechokwadi chekuti weld inoramba iripokuchena uye kwakasimba.

Kunyange zvazvo argon ichizivikanwa nekudzivirira kwayo kwakanyanya,

Nitrogen ichiriposarudzo inoshandaizvo zvinogutsa zvinobudirira zvinodiwa nemabasa akawanda ekuwelda.

Enzanisa Maitiro Ekubatanidza: Kubatanidza Laser vs TIG

Kunyatsoteerera Matekiniki Kunowana Mhedzisiro Yakanakisisa

Angle Yakakodzera Yekushongedza NeLaser: 45 Degree

Kana gasi rekudzivirira rava kuyerera zvakanaka,

Yasvika nguva yekutarisa pakuita kwewelding chaiyo.

Kubatanidza TIG (Tungsten Inert Gas) uye kusanganisa nelaser nemaoko

Zvinodamatekiniki chaiwokuti uwane mhedzisiro yepamusoro-soro,

Zvisinei, zvakasiyana muzvinodiwa zvavo uye nzira dzavanoshandisa.

Kushongedza kweTIGMaitiro ekugadzira

Chinangwa chekuchengetedza electrode panguva imwe chetedaro rakakwana uye kumhanyakugadzira nekutungamira dziva rekuwedera.

Daro iri rinogona kusiyana zvichienderana nechinhu chacho uye ukobvu hwacho.

Kuchengetedza kona chaiyo, kazhinji yakatenderedzaTembiricha iri pakati pe15 ne20 degrees,

Inobatsira pakuwana weld yakagadzikana uye yakachena.

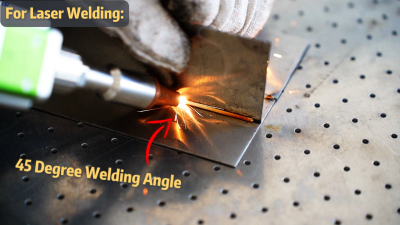

Kukwevera neLaser Inobatwa NemaokoMaitiro ekugadzira

Chimwe chezvakanakira zve laser welding kugona kuisa angle yakafanana

Kazhinji kutenderedzamadhigirii makumi mana nemashanu, zvichiita kuti kuve nyore kutarisira maitiro ekunamira.

Kana kona yangoiswa, chengetedzakumhanya kwakasimbandicho chinhu chikuru.

Kuwedera neruoko nelaser kunowanzo gadzirakupisa kushomazvichienzaniswa nekusonwa kweTIG.

Izvi zvinoreva kuti panenjodzi shoma yekukombama kana kukanganiswa,

Kuzviita kuti zvive zvakanaka pakushanda nemazvo pazvinhu zvakatetepa.

Simba reLaser Weld vs TIG: Kubvisa Ngano

Mafungiro Asiri Akajairika Nezve Kushongedza NeLaser

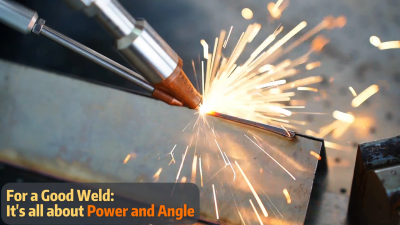

Kwekushongedza Kwakanaka KweLaser Kunobatwa Nemaoko: Simba & Angle

Chimwe chezvakanakira zvikuru zvekushandisa laser welding nemaoko ndiko kugona kwayo kupa simba rakawanda.chaizvokwazvinodiwa.

Nemarongero esimba rerudyiuyekona yakakwana

Kazhinji kutenderedzamadhigirii makumi mana nemashanu, laser welding inogona kuwana kupinda kwakanaka uye simba.

Simba Rakakodzera Rinobuda

Kugadzika kwesimba remuchina we laser welder kwakakosha.

Kushomeka kwesimba remagetsi kunogona kukonzerakupinda kwakakwana, zvichikonzera kusveta kusina simba.

Kusiyana neizvi, simba rakakodzera rinobvumira laser kunyungudutsa chinhu zvinobudirira, zvichiita kuti pave nemajoini akasimba.

Kushandisa michina isina simba rakawanda hakuzobudisi mhedzisiro yaunoda.

Kukwesha kweTIG neHandheld Laser kwese kunoshanda zvakanaka

Unoda Kudzidza Zvakawanda Nezvekushandisa Laser Welding Nemaoko?

Kukwesha KweLaser Kunobatwa Nemaoko: Maitiro Ekuchengetedza Midziyo

Kutarisira Kwakakodzera uye Kunyatsoteerera Zvinhu Zvidiki Zvichavimbisa Kubudirira uye Kuvimbika

Waizviziva here kuti welding yeTIG (Tungsten Inert Gas) uye welding yelaser inobatwa nemaoko inorongwa se

Nzira dzekunamira dzisingashandisike?

Izvi zvinoreva kuti, mumamiriro ezvinhu akanaka uye nekutarisirwa kwakakodzera,

Zvinhu zvakakosha zvinoshandiswa mukuita izvi zvinogona kugara kwenguva yakareba

Pasina kuda kuchinjwa nguva nenguva.

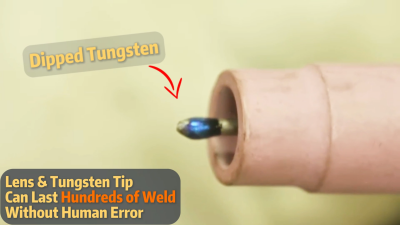

Zvikamu Zvisingashandisike

Chikanganiso cheTungsten chakanyikwa cheTIG Welding

Tungsten electrode chinhu chakakosha mukushongedza TIG.

Kusiyana nemaelectrode anodyiwa anoshandiswa mune dzimwe nzira dzekushongedza,

senge MIG welding, iyo tungsten electrodehainyungudikepanguva yekunamira.

Pane kudaro, inochengetedza kunaka kwayo, zvichibvumira kushandiswa kwenguva refu.

Zvisinei, electrode inogona kusvibiswa kana "kunyikwa" kana ikawanikwapedyo zvakanyanya nedziva re weld rakanyungudutswa.

Muzviitiko zvakadaro, inofanira kuchekwa yogayiwa kuti idzorere painopinza uye ishande zvakanaka.

Kugadziriswa nguva dzoseKuumbwa kwe electrode ye tungsten kwakakosha pakugadzira welds dzakachena uye dzemhando yepamusoro.

Kugadzirira Kukwevera KweLaser Nemaoko

Lenzi yeLaser yekugadzirisa kusungirirwa kweLaser inobatwa nemaoko

Mukushongedza nelaser nemaoko, lenzi yelaser inoshanda senzvimbo yekutarisa danda relaser.

Lenzi yakaiswa zvakanaka inogona kugara kwenguva yakareba, ichipa kushanda kwakasimba.

Zvisinei, kana lenzi ikatsemuka nekuda kwekusaiswa zvakanaka kana kupiswa zvakanyanya

Ichada kutsiviwa.

Kuchengetedza lenzi iri mumamiriro akanaka kwakakosha,

Kunyangwe kukuvara kudiki kunogona kukanganisa kururama uye kushanda kwelaser, zvichikonzera ma welds asina kunaka.

Unoda Gwaro Rakazara Rekunongedzera reKubata Nemaoko NeLaser Welding?

Kukwesha nelaser nemaoko kune mabhenefiti akawanda,

Asi zvinodawo kunyatsoteerera mitemo yekuchengetedza.

Chinyorwa chino chichaongorora zvinhu zvakakosha zvekuchengetedza pakushongedza nelaser nemaoko.

Pamwe nekupa mazano ekusarudza gasi rekudzivirira uye sarudzo dzewaya dzekuzadza dzemhando dzesimbi dzakajairika.

Kukwesha neLaser Kwakasimba Sekukwesha neTIG Here?

Kushongedza neLaseruye TIG (Tungsten Inert Gas) welding zvese zvinozivikanwa nekunyatsorongeka uye kunaka kwazvo mukubatanidza simbi.

Asi vanobatana sei panyaya yesimba?

Muvhidhiyo iyi, tichaongorora musiyano mukuru uripo pakati pemashandiro ekuwelda,kuenderana kwezvinhuuyekugara kwenguva refupakati pe laser neTIG welding.

Kukwesha Fiber Laser Inobatwa Nemaoko (Kukwesha Laser Inobatwa Nemaoko)

Kuwedzera Kunokosha Kunzvimbo Yekushandisa Laser Weld Inobatwa Nemaoko

Kuwedera KweLaser Kudiki Kunoita Kuti Kuwedera Kuve Kusingadhuri Uye Kusadhure

Ine chitarisiko chemuchina mudiki uye mudiki.

Muchina we laser welder unotakurika une pfuti ye laser welder inotakurika inotakurika iyoyakareruka.

Uye zviri nyore kushandisa multi-laser welding applications pachero konauyepamusoro.

Mhando dzakasiyana dzema nozzles e laser welder dzinosarudzwa.

Sisitimu yekudyisa waya otomatiki inoita kuti kushanda kwe laser welding kuve nyore uye izvi zvine hushamwari kune vanotanga.

Zvinhu zvishanu nezveLaser Welding (Zvawakarasikirwa nazvo)

Kana wakafarira vhidhiyo iyi, wadii kufunga nezvayoUri kunyoresa kuYoutube Channel yedu here?

Mapurogiramu Akafanana Aungade Kufarira:

Kukwesha Laser nemaoko isarudzo yakanaka kwazvo pamabasa ekukwesha nemaoko

Uye Remangwana Rinotanga Nemi!

Nguva yekutumira: Gunyana-14-2024