Maitiro ekutanga ekubatanidza nelaser anosanganisira kuisa danda relaser panzvimbo yakabatana pakati pezvinhu zviviri uchishandisa sisitimu yekuendesa optical. Kana danda rikabatana nezvinhu, rinotamisa simba raro, richikurumidza kupisa nekunyungudutsa nzvimbo diki.

Tafura yeZviri Mukati

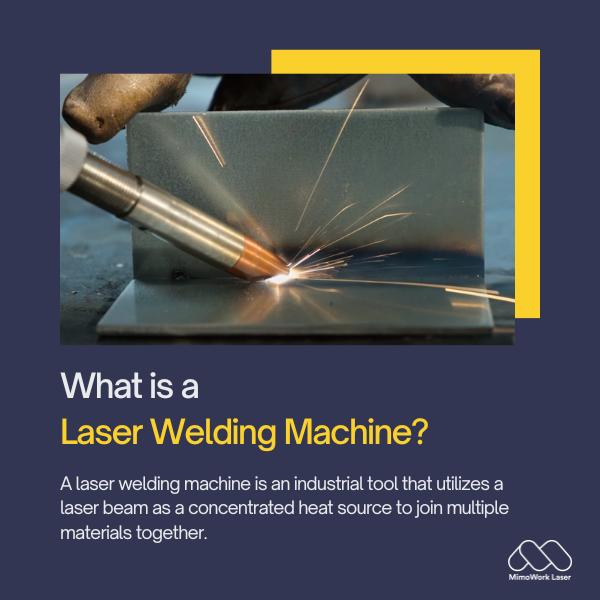

1. Chii chinonzi Laser Welding Machine?

Muchina we laser welding chishandiso cheindasitiri chinoshandisa laser beam senzvimbo yekupisa yakawanda kubatanidza zvinhu zvakawanda pamwe chete.

Zvimwe zvinhu zvakakosha zvemichina ye laser welding zvinosanganisira:

1. Kunobva Laser:Vazhinji vemazuva ano vanoshandisa ma laser diode e solid-state anogadzira laser beam ine simba guru mu infrared spectrum. Manyuko e laser anowanzo sanganisira CO2, fiber, uye diode lasers.

2. Optics:Benzi relaser rinofamba nepakati pezvinhu zvakasiyana-siyana zve optical zvakaita semagirazi, ma lenses, uye ma nozzles zvinotarisa uye zvinotungamira benzi kunzvimbo ye weld nemazvo. Maoko e telescoping kana ma gantries anoisa benzi panzvimbo yacho.

3. Kuzvigadzira otomatiki:Mazhinji ma laser welders ane computer numeral control (CNC) integration uye robotics kuti aite otomatiki maitiro akaomarara ekuwelda. Nzira dzinorongwa uye masensa emhinduro zvinovimbisa kururama.

4. Kutarisa Maitiro:Makamera akabatanidzwa, maspectrometer, nemamwe masensa anotarisa maitiro ekuwelda panguva chaiyo. Chero matambudziko ane chekuita nekugadziriswa kwebeam, kupinda mukati, kana mhando anogona kuonekwa nekukurumidza uye kugadziriswa.

5. Zvivharo zvekuchengetedza:Dziviriro, magonhi, uye mabhatani e e-stop anodzivirira vanoisa mawaya kubva kuchiedza che laser chine simba guru. Makiyi anovhara laser kana mitemo yekuchengetedza ikatyorwa.

Saka muchidimbu, muchina wekuisa laser chishandiso chinoshandiswa nekombiyuta, chakanyatsogadzirwa nemaindasitiri chinoshandisa danda re laser rakanangana nekushandisa otomatiki uye zvinodzokororwa.

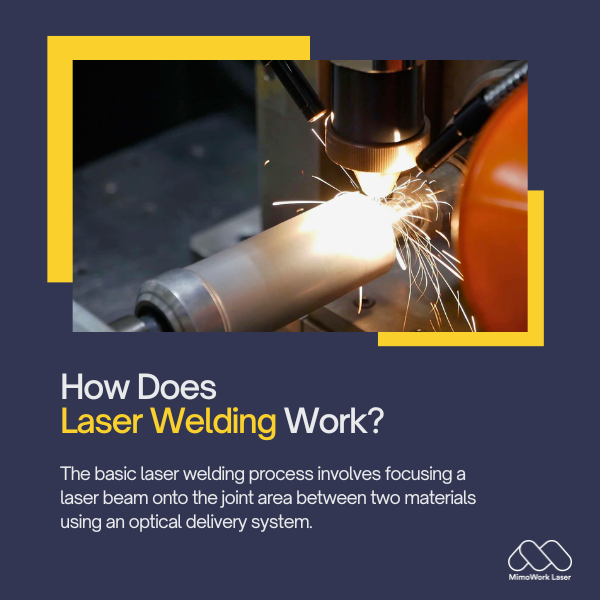

2. Kushanda Sei Kucheka NeLaser?

Mamwe matanho akakosha mukuita kwe laser welding anosanganisira:

1. Kugadzirwa kweLaser Beam:Solid-state laser diode kana chimwe chinhu chinoburitsa dayamondi ye infrared.

2. Kutumirwa kweMatanda: Magirazi, magirazi, uye muromo wemuromo zvinonyatsotarisa danda panzvimbo yakasimba pane workpiece.

3. Kupisa Zvinhu:Danda rinopisa zvinhu nekukurumidza, nehuwandu hwaro hunosvika 106 W/cm2.

4. Kunyungudutsa uye Kubatanidza:Dziva diki rinonyunguduka rinoumbwa apo zvinhu zvinobatana. Dziva parinosimba, panogadzirwa weld joint.

5. Kutonhodza uye Kusimbisazve: Nzvimbo yesimbi inotonhorera pakupisa kwakanyanya kupfuura 104°C/sekondi, zvichiita kuti pave nechimiro chakasimba uye chakanyatsogadzirwa zvakanaka.

6. Kufambira Mberi:Danda rinofamba kana kuti zvikamu zvinoiswa panzvimbo imwe chete uye maitiro acho anodzokororwa kuti apedzise musono we weld. Gasi rekudzivirira risina simba rinogona kushandiswawo.

Saka muchidimbu, kupinza nelaser kunoshandisa laser beam yakanyatsotarisa uye thermal cycling inodzorwa kuti igadzire welds dzemhando yepamusoro, dzisinganyanyi kukanganiswa nekupisa.

Takapa Ruzivo Runobatsira Pamichina Yekushongedza NeLaser

Pamwe nemhinduro dzakagadzirirwa bhizinesi rako

3. Kuwelda neLaser kuri nani pane MIG here?

Kana tichienzanisa nemaitiro echinyakare esimbi inert gas (MIG) welding...

Kucheka ne laser kune zvakawanda zvakanakira:

1. Kunyatsorongeka: Matanda eLaser anogona kunangidzirwa panzvimbo diki ye 0.1-1mm, zvichiita kuti zvive nyore kupinza ma welds akanyatsojeka uye anodzokororwa. Izvi zvakanaka kune zvikamu zvidiki, zvinoshivirira zvakanyanya.

2. Kumhanya:Mwero wekuwedera we laser unokurumidza kupfuura MIG, kunyanya pamagauge akatetepa. Izvi zvinovandudza kugona uye zvinoderedza nguva yekutenderera.

3. Hunhu:Kupisa kwakasimba kunoita kuti pave nekukanganisika kushoma uye nzvimbo dzakamanikana dzinokanganiswa nekupisa. Izvi zvinoita kuti pave nekupinza kwakasimba uye kwemhando yepamusoro.

4. Kuzvigadzira otomatiki:Kupinza neLaser kunoitwa otomatiki uchishandisa marobhoti neCNC. Izvi zvinoita kuti patani dzakaoma dzivepo uye kuve nekugadzikana kwakanaka kana tichienzanisa nekushandisa manual MIG welding.

5. Zvishandiso:MaLaser anogona kubatanidza zvinhu zvakawanda, kusanganisira weld dzesimbi dzakasiyana-siyana uye dzakasiyana.

Zvisinei, MIG welding inezvimwe zvakanakirapamusoro pe laser mune mamwe mashandisirwo:

1. Mutengo:Midziyo yeMIG ine mutengo wakaderera wekudyara kwekutanga pane masisitimu elaser.

2. Zvinhu zvakakora:MIG yakakodzera zviri nani pakunamira simbi dzakakora kupfuura 3mm, uko kunyudzwa nelaser kunogona kuva nedambudziko.

3. Gasi rekudzivirira:MIG inoshandisa gasi rinodzivirira kuti ridzivirire nzvimbo inopinzwa, nepo laser inowanzoshandisa nzira yedanda rakavharwa.

Saka muchidimbu, laser welding inowanzo kufarirwa kunekunyatsoita zvinhu, otomatiki, uye mhando yekunamira.

Asi MIG inoramba ichikwikwidza mukugadzirwa kwemagauge akakora pabhajeti.

Maitiro akakodzera anoenderana nekushandiswa kwewelding chaiyo uye zvinodiwa nezvikamu.

4. Kucheka neLaser Zviri Nani Pane Kucheka neTIG?

Kubatanidza gasi reTungsten inert gas (TIG) inzira inoshandiswa nemaoko, ine hunyanzvi hwehunyanzvi iyo inogona kuburitsa mhedzisiro yakanaka pazvinhu zvitete.

Zvisinei, laser welding ine zvimwe zvakanakira pamusoro peTIG:

1. Kumhanya:Kupinza kwelaser kunokurumidza kupfuura TIG pakugadzira nekuda kwekunyatsorongeka kwayo. Izvi zvinovandudza kugona kwayo kugadzira zvinhu.

2. Kunyatsorongeka:Beam re laser rakanangana rinobvumira kurongeka kwenzvimbo kusvika mukati mechikamu chezana chemirimita. Izvi hazvigone kuenzaniswa neruoko rwemunhu neTIG.

3. Kudzora:Zvinhu zvinochinja-chinja maitiro zvakaita sekupisa uye weld geometry zvinodzorwa zvakanyanya ne laser, zvichiita kuti mhedzisiro ienderane.

4. Zvinhu:TIG ndiyo yakanakira zvinhu zvinofambisa mhepo zvakatetepa, nepo laser welding ichivhura mhando dzakasiyana dzemisanganiswa yezvinhu zvakawanda.

5. Kuzvigadzira otomatiki: Masisitimu erobhoti elaser anogonesa kuchinjisa otomatiki pasina kuneta, nepo TIG inowanzoda kutarisirwa kwakazara kwemushandisi uye hunyanzvi.

Zvisinei, TIG welding inoramba iine mukana webasa rekuchenesa rakatetepa kana welding ye alloyuko kupisa kunofanira kugadziriswa nokungwarira. Pakushandisa uku, hunyanzvi hwenyanzvi hunobatsira.

5. Chii chakaipa neLaser Welding?

Sezvakaita chero maitiro emaindasitiri, laser welding ine zvimwe zvingangove zvakashata zvekufunga nezvazvo:

1. Mutengo: Kunyange zvazvo zvichiva nyore kutenga, masisitimu elaser ane simba guru anoda mari yakawanda kana tichienzanisa nedzimwe nzira dzekuwedera.

2. Zvinoshandiswa:Manotsi egasi nemagetsi zvinopera nekufamba kwenguva uye zvinofanirwa kutsiviwa, zvichiwedzera mari yekuva muridzi.

3. Kuchengetedzwa:Maitiro akaomarara uye dzimba dzekuchengetedza dzakavharirwa zvinodiwa kudzivirira kusangana nemwaranzi welaser wakasimba.

4. Kudzidziswa:Vashandi vanoda kudzidziswa kuti vashande zvakachengeteka uye vagadzirise michina yekuwelding nelaser nemazvo.

5. Mutsetse wekuona:Benzi relaser rinofamba mumitsara yakatwasuka, saka ma geometri akaomarara angada matanda akawanda kana kuti kuiswazve panzvimbo ye workpiece.

6. Kunwisa:Zvimwe zvinhu zvakaita sesimbi gobvu kana aruminiyamu zvinogona kuoma kusanganisa kana zvikasatora wavelength chaiyo yelaser zvinobudirira.

Zvisinei, nekuchengetedza kwakakodzera, kudzidziswa, uye kugadziriswa kwemaitiro, welding nelaser inopa mabhenefiti ekubudirira, kunyatsojeka, uye emhando yepamusoro kune akawanda mashandisirwo emaindasitiri.

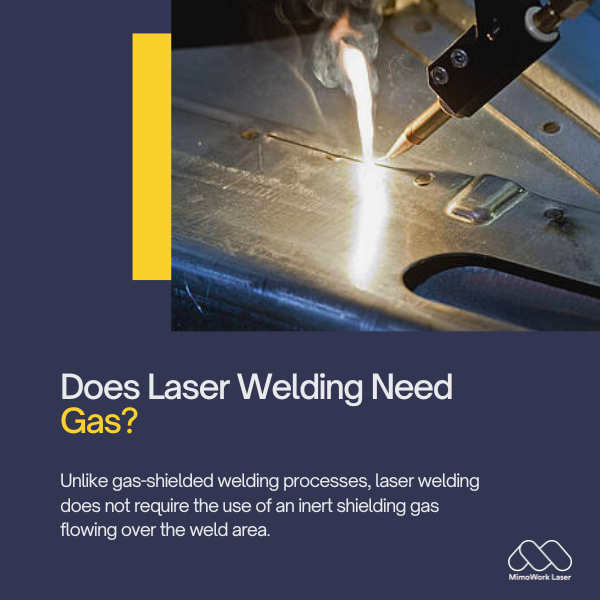

6. Kuwedera neLaser Kunoda Gasi Here?

Kusiyana nemaitiro ekuwelda anodzivirira gasi, welding nelaser haidi kushandiswa kwegasi rinodzivirira risina simba rinoyerera pamusoro penzvimbo yekuwelda. Izvi zvinokonzerwa nekuti:

1. Danda relaser rinonanga rinofamba nemhepo kuti rigadzire dziva diki rine simba guru rinonyunguduka robatanidza zvinhu.

2. Mhepo yakakomberedza haina ionized segasi plasma arc uye haikanganisi danda kana weld formation.

3. Weld inosimba nekukurumidza kubva pakupisa kwakanyanya zvekuti inoumbwa ma oxide asati agadzirwa pamusoro.

Zvisinei, mamwe mashandisirwo e laser welding anogona kubatsirwa nekushandisa assist gas:

1. Pasimbi dzinoshanda searuminiyamu, gasi rinodzivirira dziva rinopisa reweld kubva kuokisijeni iri mumhepo.

2. Pamabasa elaser ane simba guru, gasi rinodzikamisa plasma plume inoumbwa panguva yekucheka kwemvura yakadzika.

3. Magasi anobvisa utsi nemarara kuti mwenje upfuure zvakanaka panzvimbo dzakasviba kana dzakapendwa.

Saka muchidimbu, kunyange zvazvo zvisiri zvekuda, gasi risina simba rinogona kupa zvakanakira kune mamwe mashandisirwo kana zvinhu zvakaoma zve laser welding. Asi maitiro acho anogona kushanda zvakanaka pasina.

Zvinenge simbi dzese dzinogona kusungirirwa ne laser kusanganisirasimbi, aruminiyamu, titanium, nickel alloys, nezvimwewo.

Kunyangwe kusanganiswa kwesimbi dzakasiyana kunogoneka. Chinokosha ndechekutiinofanira kupinza wavelength yelaser zvinobudirira.

Mapepa matete se0.1mm uye ukobvu se25mminogona kusanganiswa nelaser, zvichienderana nekushandiswa kwayo uye simba relaser.

Zvikamu zvakakora zvingada kusungirirwa kwema "multi-pass welding" kana kuti "special optics".

Zvechokwadi. Marobhoti laser welding cells anowanzo shandiswa munzvimbo dzinogadzirwa otomatiki uye dzinomhanya zvakanyanya, dzakadai sekugadzira mota.

Kuburikidza kwehuwandu hwemamita akati wandei paminiti kunogoneka.

Mashandisirwo akajairika e laser welding anowanikwa mumota, zvemagetsi, zvekurapa, zvemuchadenga, zvekushandisa/zvekufa, uye kugadzira zvikamu zvidiki zvine hungwaru.

Tekinoroji iyikuramba kuchiwedzera muzvikamu zvitsva.

Zvinhu zvekufunga nezvazvo zvinosanganisira zvinhu zvebasa, saizi/ukobvu, zvinodiwa pakushanda, bhajeti, uye mhando yeweld inodiwa.

Vatengesi vane mukurumbira vanogona kubatsira kutsanangura mhando yelaser yakakodzera, simba, optics, uye otomatiki yeapp yako chaiyo.

Maitiro akajairika ekushongedza nelaser anosanganisira mabutt, lap, fillet, kuboora, uye cladding welds.

Dzimwe nzira itsva dzakadai sekugadzira zvinhu zvinowedzerwa nelaser dziri kubudawo dzekugadzirisa uye kushandisa mapurojekiti ekugadzira mifananidzo.

Ehe, kukwesha ne laser kwakakodzera kugadzirisa zvinhu zvine mutengo wakakwirira nemazvo.

Kupisa kwakasimba kunoderedza kukuvara kwakawedzerwa kwezvinhu zvepasi panguva yekugadzirisa.

Unoda Kutanga neLaser Welder Machine?

Sei tisingafunge nezvedu?

Nguva yekutumira: Kukadzi-12-2024