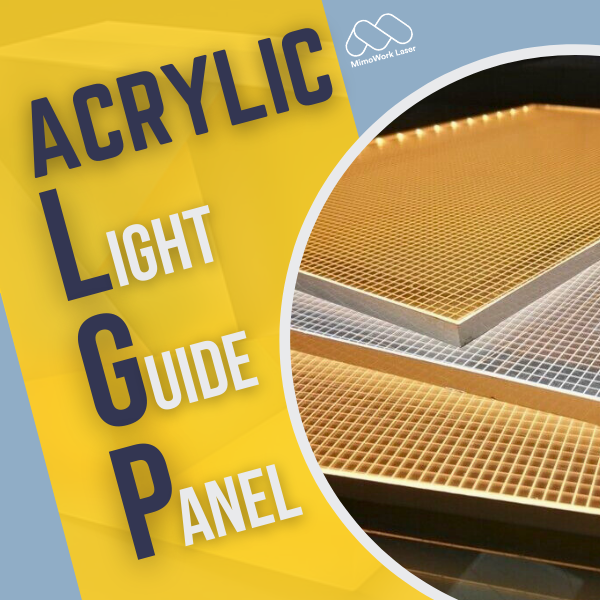

I-Acrylic LGP (Iphaneli yeSikhokelo soKhanya)

I-Acrylic LGP: Iyasebenziseka, Icacile kwaye Ihlala ixesha elide

Nangona i-acrylic idla ngokunxulunyaniswa nokusika, abantu abaninzi bayazibuza ukuba ingaba ingasetyenziswa nge-laser na.

Iindaba ezimnandi zezokubaEwe, kunokwenzeka ngokwenene ukuqhekeza i-acrylic nge-laser!

Uluhlu Lomxholo:

1. Ngaba ungayenza i-Laser Etch Acrylic?

I-laser ye-CO2 inokutshintsha ngokuchanekileyo i-acrylic ize isuse amaleko amancinci ukuze ishiye ngasemva amanqaku aqoshiweyo okanye aqoshiweyo.

Isebenza kuluhlu lwamaza e-infrared lwe-10.6 μm, oluvumelaukufunxwa kakuhle ngaphandle kokucamngca kakhulu.

Inkqubo yokukrola isebenza ngokuyalela umqadi welaser we-CO2 ogxile kumphezulu we-acrylic.

Ubushushu obukhulu obuvela kumqadi bubangela ukuba izinto ze-acrylic kwindawo ekujoliswe kuyo ziqhekeke kwaye zibe ngumphunga.

Oku kususa iplastiki encinci, kushiye uyilo oluqoshweyo, umbhalo, okanye ipateni.

I-laser ye-CO2 yobungcali inokuvelisa ngokululaukukrola okunesisombululo esiphezulukwiimashiti ze-acrylic kunye neentonga.

2. Yeyiphi i-Acrylic efanelekileyo kwi-Laser Etching?

Ayizizo zonke ii-acrylic sheets ezilingana xa zigrunjwa nge-laser. Ukwakheka kunye nobukhulu bezinto ezisetyenzisiweyo kuchaphazela umgangatho kunye nesantya sokugrunjwa.

Nazi ezinye izinto ekufuneka uziqwalasele xa ukhetha i-acrylic engcono kakhulu yokutshiza nge-laser:

1. Amaphepha e-Acrylic axoviweyoithanda ukucoca kwaye iyakwazi ukumelana nokunyibilika okanye ukutsha xa ithelekiswa ne-acrylic ekhutshiweyo.

2. Amaphepha e-Acrylic abhityileyoNjengo-3-5mm, luluhlu oluhle lobukhulu obuqhelekileyo. Nangona kunjalo, ubukhulu obungaphantsi kwe-2mm bunomngcipheko wokunyibilika okanye ukutsha.

3. I-Acrylic ecacileyo, engenambalaivelisa imigca ebukhali kakhulu kunye nombhalo ocacileyo. Ziphephe ii-acrylics ezinombala, ezinemibala, okanye ezibukwayo ezinokubangela ukugruzuka okungalinganiyo.

4. I-Acrylic ekumgangatho ophezulu ngaphandle kwezongezonjengezikhuseli ze-UV okanye ii-antistatic coatings ziya kubangela imiphetho ecocekileyo kunee-grades ezingaphantsi.

5. Iindawo ze-Acrylic ezithambileyo nezikhazimlayozikhethwa kakhulu kunezigqityiweyo okanye ezingacacanga nto leyo enokubangela imiphetho eqinileyo emva kokukrola.

Ukulandela ezi zikhokelo zezinto kuya kuqinisekisa ukuba iiprojekthi zakho zokupeyinta nge-laser ye-acrylic zibonakala zineenkcukacha kwaye zibukeka zingcali ngalo lonke ixesha.

HLALA uvavanya iziqwenga zesampulu kuqala ukuze ucofe useto lwelaser olufanelekileyo.

3. Iphaneli yesikhokelo sokukhanya Ukukrola/ukufaka amachaphaza ngeLaser

Enye indlela eqhelekileyo yokusebenzisa i-acrylic etching nge-laser kukuvelisaiiphaneli zesikhokelo sokukhanya, ikwabizwa ngokubaiiphaneli ze-dot matrix.

La maphepha e-acrylic aneuluhlu lwamachaphaza amancinci okanye amanqakuzikrolwe ngokuchanekileyo kuzo ukuze zenze iipateni, imizobo, okanye imifanekiso enemibala epheleleyo xaizibane ezingasemva ezinee-LED.

Izikhokelo zokukhanya kwe-acrylic ezine-laser dotiingenelo ezininzingaphezu kweendlela zemveli zokuprinta isikrini okanye zokuprinta iiphedi.

Ibonelelaisisombululo esibukhali sehle siye kubungakanani bamachaphaza angama-0.1mmkwaye inokubeka amachaphaza kwiipateni ezintsonkothileyo okanye iigradients.

Ikwavumela ukubautshintsho olukhawulezileyo kuyilo kunye nemveliso yexesha elifutshane ngexesha elifunekayo.

Ukuze i-laser ifumane isikhokelo sokukhanya kwe-acrylic, inkqubo ye-laser ye-CO2 icwangciswe ukuba i-raster kwiphepha kwi-XY coordinates, idubulaiipulses ezimfutshane kakhulu kwindawo nganye "yeepixel" ekujoliswe kuzo.

Amandla e-laser agxileibhoboza imingxunya okanye iidimples ezinobukhulu be-micrometerngokusebenzisaubukhulu obungaphelelangaye-acrylic.

Ngokulawula amandla elaser, ubude be-pulse kunye nokudibana kwamachaphaza, ubunzulu bamachaphaza ahlukeneyo bunokuphunyezwa ukuvelisa amanqanaba ahlukeneyo obunzulu bokukhanya okudlulisiweyo.

Emva kokucubungula, iphaneli ilungele ukukhanyisa ngasemva kwaye ikhanyise ipateni efakwe ngaphakathi.

I-Dot matrix acrylic ifumana ukusetyenziswa okukhulayo kwimiqondiso, izibane zezakhiwo, kwaneziboniso zezixhobo ze-elektroniki.

Ngesantya sayo kunye nokuchaneka kwayo, ukucutshungulwa kwelaser kuvula amathuba amatsha okudala uyilo kunye nokuveliswa kwephaneli yesikhokelo sokukhanya.

Ukukrola ngeLaser kudla ngokusetyenziselwa iMiqondiso, iiDisplays, kunye nezinye izicelo

Siyavuya ukukuqalisa kwangoko

4. Iingenelo zeLaser Etching Acrylic

Kukho iingenelo ezininzi zokusebenzisa i-laser ukukrola uyilo kunye nokubhala umbhalo kwi-acrylic xa kuthelekiswa nezinye iindlela zokuphawula umphezulu:

1. Ukuchaneka kunye nesisombululo

Iilaser ze-CO2 zivumela ukukrola iinkcukacha ezintsonkothileyo, imigca, oonobumba, kunye neelogo ezintle kakhulu ezineresolution engaphantsi kwe-0.1 mm okanye ngaphantsi,akunakwenzekangezinye iinkqubo.

2. Inkqubo yokungaqhagamshelani nabantu

Ekubeni i-laser etching iyinto eqhelekileyoindlela yokungaqhagamshelani, isusa isidingo sokufihla ubuso, iibhafu zamachiza, okanye uxinzelelo olunokonakalisa iindawo ezibuthathaka.

3. Ukuqina

Iimpawu ze-acrylic ezikrolwe nge-laser ziyamelana nokuchatshazelwa kokusingqongileyo kwaye zihlala ixesha elide.ayifiphali, ayikrweli, okanye ayifuni ukuphinda isetyenziswenjengemiphezulu eprintiweyo okanye epeyintiweyo.

4. Ukuguquguquka koyilo

Ngokusika nge-laser, utshintsho kuyilo lomzuzu wokugqibela lunokwenziwangokulula ngokuhlela iifayile zedijithaliOku kuvumela ukwenziwa kwemisebenzi ngokukhawuleza kunye nokuveliswa kwemveliso okufutshane xa kuyimfuneko.

5. Ukuhambelana kwezinto

Iilaser ze-CO2 zinokukrola iintlobo ngeentlobo ze-acrylic ezicacileyo kunye nobukhulu.kuvula amathuba okudalaxa kuthelekiswa nezinye iinkqubo ezinemiqathango yezinto eziphathekayo.

6. Isantya

Iinkqubo ze-laser zanamhlanje zinokukrola iipateni ezintsonkothileyo ngesantya esifikelela kwi-1000 mm/s, zenze uphawu lwe-acrylicisebenza kakuhle kakhuluyemveliso enkulu kunye nokusetyenziswa komthamo omkhulu.

Ukusika ngeLaser, iAcrylic (Ukusika nokukrola)

Ngaphandle kwezikhokelo zokukhanya kunye neempawu, ukukrola nge-laser kwenza ukuba kubekho izicelo ezininzi ezintsha ze-acrylic:

1. Iziboniso zeZixhobo ze-elektroniki

2. Iimpawu zoYilo

3. Iimoto/Ezothutho

4. Ezonyango/Ukhathalelo lwempilo

5. Izibane zokuhombisa

6. Izixhobo Zoshishino

Ukucubungula ngeLaser iAcrylic kufuna ukuphathwa ngononophelo

Kubandakanya Ukuseta Uhlengahlengiso Ukuqinisekisa Umgangatho Ophezulu, Iziphumo EzingenaBurr.

5. Iindlela ezilungileyo zokuGcina i-Acrylic ngeLaser

1. Ukulungiswa kwezinto

Qala rhoqo nge-acrylic ecocekileyo, engenathuli.Kwanamasuntswana amancinci anokubangela ukusasazeka kwemisebe aze ashiye inkunkuma kwiindawo ezikroliweyo.

2. Ukukhupha umsi

Umoya ofanelekileyo ubalulekilexa kugrunjwa nge-laser. I-Acrylic ivelisa umsi onetyhefu ofuna ukukhupha umoya ngokufanelekileyo ngqo kwindawo yokusebenza.

3. Ukujolisa iBeam

Zinike ixesha lokugxila ngokugqibeleleyo umqadi welaser kumphezulu we-acrylic.Nokuba ukungazinzisi kangako kukhokelela ekubeni umgangatho womphetho ungabi semgangathweni okanye ukususwa kwezinto ngokupheleleyo.

4. Ukuvavanya izixhobo zesampulu

Vavanya iqhekeza lesampulu kuqalausebenzisa useto olucwangcisiweyo ukujonga iziphumo ngaphambi kokuba usebenze imisebenzi emikhulu okanye ebiza kakhulu. Yenza uhlengahlengiso njengoko kufuneka.

5. Ukubotshwa nokuLungiswa okufanelekileyo

I-acrylickufuneka ibotshelelwe ngokukhuselekileyo okanye ifakelweifakelwe ukuthintela intshukumo okanye ukutyibilika ngexesha lokucubungula. Iteyiphu ayanelanga.

6. Ukuphucula Amandla kunye nesantya

Lungisa amandla e-laser, i-frequency, kunye ne-speed sets ukuze ususe ngokupheleleyo izinto ze-acrylic ngaphandleukunyibilika kakhulu, ukutsha okanye ukuqhekeka.

7. Ukucutshungulwa emva kokwenziwa

Ukugquma kancinci ngephepha elinongwengwezi oluphezuluemva kokugrumba, kususa inkunkuma encinci okanye ukungapheleli ukuze kugqitywe kakuhle.

Ukunamathela kwezi ndlela zibalaseleyo zokugrumba nge-laser kuphumela kwi-acrylic marks zobungcali, ezingenayo i-burr ngalo lonke ixesha.

Ukulungiswa kokuseta ngokufanelekileyo kubalulekile kwiziphumo ezisemgangathweni.

6. Imibuzo ebuzwa rhoqo malunga nokugrumba nge-laser acrylic

1. Kuthatha ixesha elingakanani ukukrola nge-laser?

Ixesha lokukrola lixhomekeke kubunzima boyilo, ubukhulu bezinto, kunye noseto lwamandla/isantya se-laser. Umbhalo olula uhlala uthatha imizuzu eyi-1-3 ngelixa imifanekiso enzima ingathatha imizuzu eli-15-30 kwiphepha le-12x12".Uvavanyo olufanelekileyo luyafuneka.

2. Ngaba i-laser etch ingafaka umbala ibe yi-acrylic?

Hayi, ukugrumba nge-laser kususa kuphela izinto ze-acrylic ukuze kubonakale iplastiki ecacileyo engaphantsi. Ukuze kongezwe umbala, i-acrylic kufuneka ipeyintwe okanye idaywe kuqala ngaphambi kokuba kusetyenzwe nge-laser.Ukugcaba akuyi kutshintsha umbala.

3. Luhlobo luni loyilo olunokukrolwa nge-laser?

Phantse nayiphi na ifomathi yefayile yomfanekiso wevektha okanye werasteriyahambelana nokukrola nge-laser kwi-acrylic. Oku kuquka iilogo ezintsonkothileyo, imifanekiso, iipateni zamanani/ze-alphanumeric ezilandelelanayo, iikhowudi ze-QR, kunye nemifanekiso okanye imizobo enemibala epheleleyo.

4. Ingaba ukukrola kuhlala kuhleli?

Ewe, iimpawu ze-acrylic ezikrolwe nge-laser zibonelela ngomkrolo osisigxina oyaayifiphali, ayikrweli, okanye ayifuni ukuphinda isetyenziswe.Ukugrumba kumelana kakuhle nokuchatshazelwa bubume bendalo ukuze kubonakale ixesha elide.

5. Ndingenza i-laser etching yam?

Nangona ukugrumba nge-laser kufuna izixhobo ezikhethekileyo, ezinye izixhobo zokusika kunye nabakroli be-laser zedesktop ngoku zifikeleleka ngokwaneleyo kubantu abathanda izinto zokuzonwabisa kunye namashishini amancinci ukwenza iiprojekthi zokumakisha ze-acrylic ezisisiseko ngaphakathi.Landela amanyathelo okhuseleko rhoqo.

6. Ndiyicoca njani i-acrylic eqoshiweyo?

Ukucoca rhoqo, sebenzisa isicoci seglasi esithambileyo okanye isepha namanzi.Musa ukusebenzisa iikhemikhali ezinobungozinto leyo enokuyonakalisa iplastiki ngokuhamba kwexesha. Kuphephe ukuba i-acrylic ishushu kakhulu xa uyicoca. Ilaphu elithambileyo linceda ukususa iminwe kunye nokungcola.

7. Ingakanani ubukhulu be-acrylic obukhulu bokugcada nge-laser?

Uninzi lweenkqubo ze-laser ze-CO2 zorhwebo zinokusingatha ubungakanani beshiti ze-acrylic ukuya kuthi ga kwi-4x8 yeenyawo, nangona ubukhulu beetafile ezincinci nazo ziqhelekile. Indawo yokusebenza ixhomekeke kwimodeli yelaser nganye - soloko ujongaiinkcukacha zomenzi malunga nemida yobukhulu.