Ukususwa kwe-Laser Oxide

Ii-oxides ziikhompawundi eziqhelekileyo ezivela kwiinkqubo ze-oxidation ezichaphazela izinto ezahlukeneyo.

Ukuqonda indlela eyenzeka ngayo i-oxidation kunceda ekulawuleni imiphumo yayo.

Ingakumbi kumashishini apho ukuthembeka kwezinto eziphathekayo kubaluleke kakhulu.

Ukucocwa nge-laser kuvela njengesisombululo esisebenzayo kakhulu sokususa ezi layer ze-oxide ezingafunekiyo.

Ukuqinisekisa ukuba izinto zibuyiselwa kwimeko yazo yokuqala ngaphandle kokwenzakala.

Yintoni i-Oxide kunye ne-Oxidation?

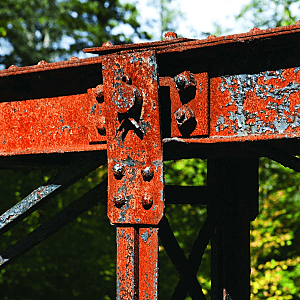

I-Oxidation ifunyenwe kwiindlela zikaloliwe

Ii-Oxides ziikhemikhali eziqulathe ioksijini kunye nenye into.

Zingakhiwa kwizinto ezahlukeneyo, kuquka iintsimbi, iiseramikhi, kwanezinye ezingezizo iintsimbi.

Imizekelo eqhelekileyo ibandakanya:

Umhlwa:

I-iron oxide (Fe₂O₃), eyenzeka kwi-iron nakwintsimbi xa isabela kumswakama kunye ne-oxygen.

I-okside yealuminiyam:

Umaleko okhuselayo owakheka kwi-aluminiyam, othintela ukugqwala okungakumbi.

I-Copper Oxide:

I-patina eluhlaza (Cu₂(OH)₂CO₃) ekhula phezu kobhedu ngokuhamba kwexesha.

Iintsimbi:

Iintsimbi ezifana nentsimbi, ubhedu, kunye ne-aluminium zikhawuleza zinyibilike xa zifakwe kwi-oxygen.

Oku kungenza buthathaka ukwakheka kwesinyithi.

Iiseramikhi:

Ukuxubana kwe-oxidation kunokuchaphazela neeseramikhi, ingakumbi ezo zenziwe ngee-oxide zesinyithi.

Ukutshintsha iimpawu zabo kunye nenkangeleko.

Ezingezizo iiMetals:

Ezinye izinto ezingezizo iimetali, ezifana nekhabhoni, zinokunyibilikisa i-oxidize ukuze zenze ikhabhoni diokside (CO₂) xa zitshiswa.

Kutheni i-Oxidation ifanele icocwe?

I-Oxidation efunyenwe kwiZakhiwo zeBhulorho ingacocwa ngeLaser

I-oxidation inokuchaphazela kakhulu izinto ezahlukeneyo kwiindawo zoshishino.

Oku kukhokelela kwiingxaki ezahlukeneyo ezinokuchaphazela ukusebenza kakuhle, ukhuseleko kunye neendleko.

Nazi izizathu ezininzi zokuba kutheni kubalulekile ukujongana ne-oxidation:

Ukunyaniseka kwesakhiwo seeMetals:Ubuhle kunye nomgangatho osebenzayo

Ukuxinana kwe-oxidation, ngakumbi kwiintsimbi ezifana nentsimbi kunye nentsimbi, kukhokelela ekuboleni.

Oku kunokwenza buthathaka izinto ezakhiweyo.

Iibhulorho:

Umhlwa unokonakalisa ukhuseleko lweebhulorho, nto leyo enokubangela ukuba kufuneke ukulungiswa okubizayo okanye ukutshintshwa kweebhulorho.

Oomatshini:

Iindawo ezibolileyo kumatshini zinokusilela, nto leyo ekhokelela ekubeni zingasebenzi kakuhle kwaye zibe yingozi kukhuseleko.

Ioyile neGesi:

Ukuxinana kwe-oxidation kwimibhobho kunokubangela ukuvuza okanye ukuqhuma, okubangela iingozi zokusingqongileyo kunye nelahleko yemali.

UkwandaIindleko zoLondolozo kunyeKuncitshisiweUkusebenza

Xa i-oxidation ingaqwalaselwanga, inokukhokelela ekwandeni kweendleko zokulungisa nokulungisa.

Nangona kunjalo ithintela ukusebenza kweenkqubo ezahlukeneyo

Ukulungiswa rhoqo:

Ukulungisa okanye ukutshintsha izinto ezifakwe i-oxidized rhoqo kunokubangela ubunzima kwisabelomali.

Izitshintshi zobushushu:

Ukukhupha i-oxidation kunokunciphisa ukusebenza kakuhle kwezixhobo zokutshintshiselana ubushushu, nto leyo ekhokelela kwiindleko eziphezulu zamandla.

Izixhobo Zokuvelisa:

Iindawo ezifakwe i-oxidized zinokuphazamisana neenkqubo zemveliso, zibangele iziphene kunye nenkunkuma.

Ukunyibilika kwe-oksidation kunokubangela iingxaki ezinkulu

Sombulula kwaye Ukhusele Ikamva Ngomatshini Wokususa I-Laser Oxide

Isicelo: Ukususwa kwe-Laser Oxide

Imfuneko yokususwa kwe-okside ifumaneka phantse kuyo yonke indawo

Ukususwa kwe-okside yelaser yindlela ephucukileyo esetyenziswa ekususeni ngempumelelo i-oxidation kwizinto ezahlukeneyo, ingakumbi iintsimbi.

Le ndlela ifumana ukuthandwa kwiindawo ezininzi zoshishino ngenxa yokuchaneka kwayo, ukusebenza kakuhle kwayo, kunye nobuhlobo bayo nendalo.

Nantsi ingqwalasela esondeleyo kwiindlela ezithile zokususa i-oxide nge-laser.

Ngokwendalo i-aluminium yenza umaleko we-oxide okhuselayo xa ibekwe emoyeni.

Nangona kunjalo, le oxide ngamanye amaxesha inokuphazamisana nokuqhubekeka kokusebenza okanye ukubopha.

Kwimizi-mveliso efana neenqwelo-moya kunye neemoto.

Ukususa olu layer lwe-oxide kubalulekile ukuze kufunyanwe ii-welds eziqinileyo kunye nokuqinisekisa ukuba i-glue ibophane ngokufanelekileyo.

Ukucocwa nge-laser kuvumela ukususwa kwe-oxide ngendlela ejolise kuyo ngaphandle kokonakalisa i-aluminium engaphantsi.

Ukuqinisekisa ukuba imiphezulu icocekile kwaye ilungele unyango olongezelelweyo.

Ukususwa kwe-Oxide yeNtsimbi Engagqwaliyo

Intsimbi engagqwaliyo idla ngokusetyenziswa kwiindawo ezinobungozi bokungcoliswa, nto leyo ekhokelela ekwakhiweni komhlwa okanye isikali.

Kwimizi-mveliso yokulungisa ukutya, amayeza, kunye neekhemikhali.

Ukugcina imiphezulu yentsimbi engagqwaliyo icocekile kubalulekile ukuze kubekho ucoceko nokhuseleko.

Ukususwa kwe-okside yelaser kucoca ngokufanelekileyo iindawo zentsimbi engagqwaliyo, ukubuyisela inkangeleko yazo kunye nokuthintela ukugqwala.

Oku kuphucula ixesha elide lezixhobo.

Kwi-welding, ubukho bee-oxides kumphezulu wesinyithi bunokubangela umgangatho ophantsi wamalungu kunye nee-welds ezibuthathaka.

Ngaphambi kokuwelda, kubalulekile ukususa naluphi na uhlobo lwe-oxidation okanye ungcoliseko kumphezulu wesinyithi ukuqinisekisa ukubopha okuqinileyo.

Ukucocwa nge-laser kunika indlela ekhawulezayo nechanekileyo yokulungisa iindawo.

Oku kubangela ukuba kubekho ii-welds eziqinileyo nezithembekileyo kwaye kunciphisa amathuba okuba kubekho iziphene.

Ukulungiswa komphezulu wokuGcoba kunye nokuBopha

Ukulungiswa komphezulu ngokufanelekileyo kubalulekile ngaphambi kokuba ufake iipeyinti okanye iipeyinti ukuqinisekisa ukuba zinamathela kwaye zihlala ixesha elide.

Kwimizi-mveliso yeemoto kunye neyokuvelisa.

Iindawo eziphezulu mazingabi nazi-oxides kunye nezinto ezingcolisayo ukuze kufezekiswe ukusebenza kakuhle kokugquma.

Ukususwa kwe-okside yelaser kucoca kakuhle iindawo.

Ukukhuthaza ukunamathela okungcono kweengubo kunye nokuphucula ukugqitywa kwayo yonke kunye nobude bexesha lemveliso.

Ukususwa kwe-okside yelaser kuyasebenziseka kwaye kunokusetyenziswa kwezinye iindlela ezahlukeneyo:

Iinxalenye zeMoto zokucoca ngeLaser:Ukucoca izinto ezifana neenxalenye zenjini ngaphambi kokuba zihlanganiswe ukuze kuthintelwe ukugqwala.

I-Electronics: Ukulungiselela imiphezulu yesinyithi ukuze ifakelwe okanye igqunywe ukuze kuphuculwe ukuhanjiswa kwegesi kunye nokuthembeka kwayo.

Izixhobo Zokucoca Nge-Laser:Ukugcinwa rhoqo koomatshini ukuze kususwe i-oxidation kwaye kwandise ubomi benkonzo.

Umatshini wokususa i-okside yelaser

Ukususwa kwe-okside yelaser yindlela esebenzayo kakhulu yokujongana ne-oxidation kwizinto ezifana ne-aluminium kunye nentsimbi engagqwaliyo kwiintlobo ngeentlobo zezicelo, kubandakanya ukuwelda, ukulungiswa komphezulu, kunye nokubopha.

Ukuchaneka kwayo, ukusebenza kwayo kakuhle, kunye nobuhlobo nokusingqongileyo kwenza ukuba ibe lukhetho olufanelekileyo kumashishini afuna ukugcina imigangatho ephezulu yomgangatho kunye nokusebenza.

Amandla eLaser:100W - 500W

Uluhlu lweeNqanaba zePulse:20 - 2000 kHz

Ukuguqulwa kobude bePulse:10 - 350 ns

Ukwanda kwe-oxidation kunokubangela iingxaki ezinkulu kwizicelo ezahlukeneyo zoshishino, nto leyo echaphazela ukhuseleko, iindleko kunye nokusebenza kakuhle.

Ngokujongana ne-oxidation ngendlela ekhawulezileyo, ingakumbi ngezisombululo eziphambili ezifana nokucoca nge-laser, amashishini anokukhusela izinto zawo, aphucule ukusebenza kwawo, kwaye agcine ithuba lokukhuphisana.

Amandla eLaser:1000W - 3000W

Ubude beLaser Wave:1070nm

Ukupholisa:Ukupholisa Amanzi