Iiparamitha zokuWelda zoMatshini wokuWelda weLaser Inkcazelo eneenkcukacha

Ukuwelda nge-laser yindlela echanekileyo nesebenzayo yokudibanisa izinto, ingakumbi iintsimbi.

Ukuqonda iiparameters ze-welding kubalulekile ukuze kufezekiswe iziphumo ezilungileyo.

Eli nqaku lichaza imigaqo ebalulekileyo kunye neeparameters ezichaphazela ukusebenza kakuhle kwe-laser welding, kubandakanya ubukhulu bezinto, ububanzi bentambo, useto lwamandla, nokunye.

Imigaqo ephambili yokuWelda ngeLaser

1. Ubukhulu bezinto kunye nobubanzi bentambo:

o Xa kudityaniswa izinto ezijiyileyo, kubalulekile ukusebenzisa ucingo olujiyileyo olujiyileyo kunye noseto lwamandla aphezulu.

Ngokwahlukileyo koko, kwizinto ezincinci, ucingo oluthambileyo kunye namandla aphantsi zifanelekile.

Umzekelo, ukuba ubukhulu bezinto buyanda, ububanzi bentambo bufanele bunyuke ngokulinganayo, kwaye amandla kufuneka alungiswe abe phezulu ngelixa kunciphisa isantya sokutya kwentambo.

Oku kuqinisekisa ukuba amandla aneleyo angena kwizinto ukuze kufakwe i-weld eqinileyo.

2. Useto lwamandla kunye nenkangeleko ye-Weld:

o Useto lwamandla luchaphazela ngokuthe ngqo inkangeleko ye-weld.

Amandla aphantsi adla ngokuvelisa umphezulu we-weld omhlophe, ngelixa amandla aphezulu ebangela umthungo we-weld omnyama nonemibala engakumbi.

Njengoko amandla esanda, i-weld inokutshintsha ukusuka kwimbonakalo enemibala emininzi ukuya kumbala omnyama kakhulu, nto leyo ebonisa ukuba i-weld yenzeka kwicala elinye.

Olu phawu lubalulekile ekuvavanyeni umgangatho we-weld nokuqinisekisa ukuba iyahlangabezana nemigangatho efunekayo.

3. Ukhetho lweDayamitha yeNtambo:

Ukukhetha ububanzi bentambo obufanelekileyo kubalulekile.

Ububanzi bocingo lokuwelda akufuneki budlule ubukhulu bezinto, kwaye kufanele ukuba lube lukhuni ngakumbi kunezinto ezisisiseko.

Olu khetho luchaphazela kakhulu ukugcwala kwe-weld bead.

o Ucingo olutyebileyo lunokuba negalelo ekufakweni kwentsimbi eqinileyo, ngelixa ucingo oluncinci kakhulu lunokubangela ukudibana okunganelanga kunye nokudibana okubuthathaka.

4. Ububanzi bentambo yokuwelda kunye nobubanzi bokuskena:

o Ububanzi bocingo lokuwelda bukwachaphazela ububanzi bokuskena bomqadi welaser.

Intambo ecolekileyo iya kufuna ububanzi obuncinci bokuskena, nto leyo enokuba luncedo kwizicelo zokuwelda ngokuchanekileyo apho kufuneka iinkcukacha ezincinci.

o Olu lwalamano luvumela ulawulo olungcono lokufakwa kobushushu kwaye luqinisekisa ukuba i-weld igxile kwindawo efunekayo, inciphisa umonakalo onokubakho kwizinto ezingqongileyo.

Ufuna Ukwazi Iinkcukacha Ezingakumbi

Malunga nokuWelda ngeLaser?

Izinto Zangaphandle Ezichaphazela Iiparamitha Zokuwelda

Kubalulekile ukuqaphela ukuba izinto ezahlukeneyo zangaphandle, ezinje ngegesi yokukhusela kunye neemeko zokusingqongileyo, zinokuchaphazela kakhulu inkqubo yokuwelda.

Ngoko ke, kuyacetyiswa ukuba ulungise iiparameter ze-welding ngokusekelwe kwiimeko zexesha langempela.

• Igesi yokukhusela: Uhlobo kunye nesantya sokuhamba kwegesi yokukhusela zinokuchaphazela umgangatho kunye nenkangeleko yokuwelda.

Ukugqunywa kakuhle kwegesi kunokuthintela i-oxidation kwaye kuphucule ukugqitywa kwayo yonke.

• Iimeko zeNdalo: Izinto ezifana nobushushu, ukufuma, kunye nokuhamba komoya zinokuchaphazela ukusebenza komatshini wokuwelda nge-laser kunye neempawu ze-weld.

Ngaba kukho olunye ulwazi malunga ne-Laser Welder?

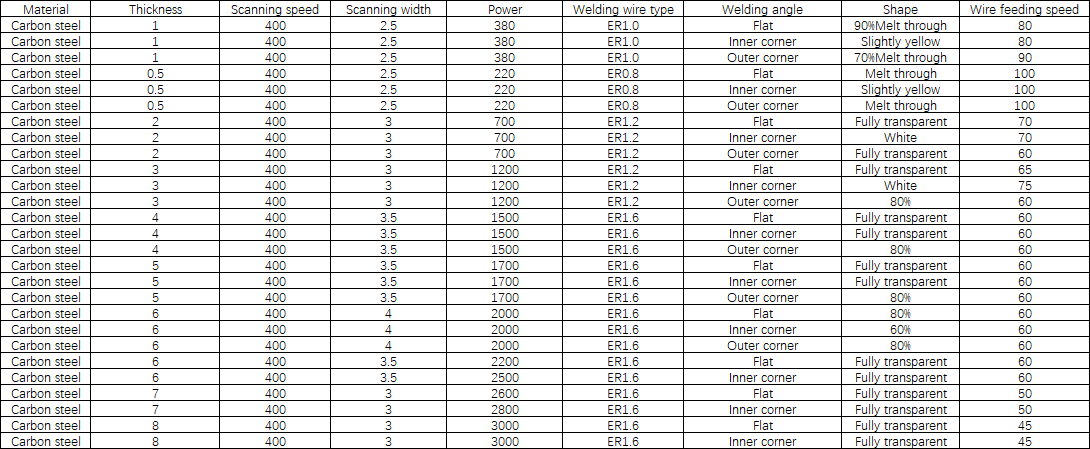

Ukuwelda ngeLaser Intsimbi yeCarbon

Qaphela: Ngenxa yempembelelo yomaleko we-zinc wephepha le-galvanized, amandla ephepha le-galvanized anokuncitshiswa ngokufanelekileyo

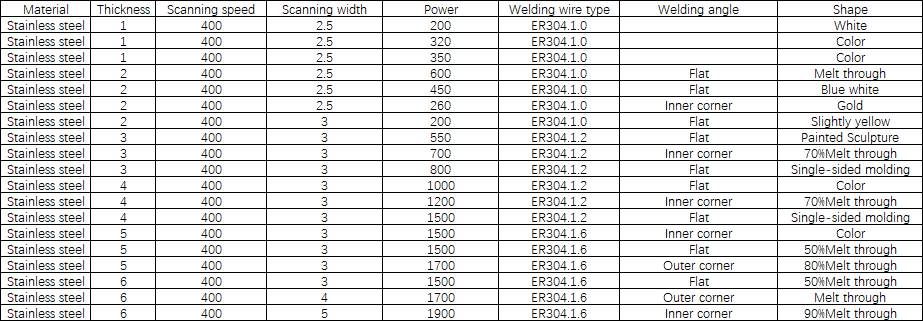

Ukuwelda kweLaser ephathwayo ngentsimbi engagqwaliyo

Amanqaku: I-3000W yentsimbi engagqwaliyo ireferensi yamandla ekhabhoni

Andazi ukuba ungayikhetha njani imashini yeLaser?

Singanceda!

Ukusuka kwiividiyo ezinomtsalane ukuya kumanqaku anika ulwazi

Indlela yokusebenzisa i-Handheld Laser Welder | Isifundo sabaqalayo

Ixesha leposi: Jan-06-2025