Indlela Yokusika I-Polyester:Izicelo, Iindlela kunye neeNgcebiso

Intshayelelo:

Izinto ezibalulekileyo ekufuneka uzazi ngaphambi kokuba ungene

I-Polyester lilaphu elisetyenziswa kakhulu kwiimpahla, kwiimpahla zokuthunga, nakwiindawo zoshishino kuba lihlala ixesha elide, lisebenziseka lula, kwaye kulula ukulinyamekela. Kodwa xa kufikwa kwiindlela yokusikai-polyester, ukusebenzisa indlela echanekileyo kwenza umahluko omkhulu. Imiphetho ecocekileyo kunye nokugqitywa kobuchwephesha kuxhomekeke kwiindlela ezifanelekileyo ezithintela ukuqhekeka nokuqinisekisa ukuchaneka.

Kule khokelo, siza kukubonisa iindlela zokusika ezidumileyo—izixhobo ezenziwe ngesandla, iinkqubo zemela ze-CNC, kunye nokusika nge-laser—ngexesha usabelana ngeengcebiso ezisebenzayo zokwenza iiprojekthi zakho zibe lula. Ngokujonga izinto ezilungileyo nezingalunganga zendlela nganye, uya kukwazi ukukhetha indlela efanela iimfuno zakho, nokuba yeyokuthunga, yokuvelisa, okanye yoyilo olwenziwe ngokwezifiso.

Iindlela ezahlukeneyo zokusetyenziswa kwePolyester

▶ Isetyenziswa Kwimveliso Yeempahla

Eyona ndlela ixhaphakileyo yokusebenzisa i-polyester ikwiimpahla. Ilaphu le-polyester lineempawu ezenza ukuba lifaneleke ukusetyenziswa njengempahla ngenxa yokuqina kwalo, ixabiso eliphantsi, kunye nokumelana nokudaya. Nangona i-polyester ingaphefumli ngokwemvelo, uphuhliso lwanamhlanje kubunjineli belaphu, olufana nobuchwepheshe bokususa umswakama kunye neendlela ezikhethekileyo zokuluka, luye lwenza ukuba lube lukhetho oludumileyo kwiimpahla ezishushu nezishushu. Ngaphezu koko, i-polyester idla ngokuxutywa nezinye iilaphu zendalo ukwandisa intuthuzelo kunye nokunciphisa ubungakanani bokukrala okuqhelekileyo kwi-polyester. Ilaphu le-polyester lelinye lamalaphu asetyenziswa kakhulu kwihlabathi.

▶ Usetyenziso lwePolyester kwiShishini

I-Polyester isetyenziswa kakhulu kwimizi-mveliso ngenxa yokuba inamandla okutsala, ukuqina kwayo, kunye nokumelana nokusoluleka kwayo.Kwiibhanti zokuhambisa impahla, ukuqinisa i-polyester kuphucula amandla, ukuqina, kunye nokugcinwa kwe-splice ngelixa kunciphisa ukungqubana. Kwiibhanti zokhuseleko, i-polyester elukiweyo ngokuxineneyo iqinisekisa ukuqina kunye nokuthembeka, ibonelela ngokhuseleko olubalulekileyo kwiinkqubo zokhuseleko lweemoto. Ezi mpawu zenza i-polyester ibe yinto ebalulekileyo kumashishini afuna ukuqinisa ilaphu okuqinileyo nokuhlala ixesha elide.

Ukuthelekiswa kweendlela zokusika iPolyester

I-Polyester yokusika ngesandla

Iingenelo:

✅Utyalo-mali oluphantsi lokuqala– Akukho mfuneko yezixhobo ezibizayo, nto leyo eyenza ukuba zifikeleleke kumashishini amancinci.

✅Iguquguquka kakhulu kwiindlela ezenziwe ngokwezifiso– Ifanelekile kwimveliso ekhethekileyo okanye encinci.

I-CNC Knife Cutting Polyester

Iingenelo:

✅Ukusebenza kakuhle okuphezulu – Ikhawuleza izihlandlo ezininzi kunendlela yokusika ngesandla, nto leyo ephucula isantya semveliso.

✅Ukusetyenziswa kakuhle kwezinto– Inciphisa inkunkuma, iphucula ukusetyenziswa kwelaphu.

I-Laser Cutting Polyester

Iingenelo:

✅Ukuchaneka okungalinganiyo – Itekhnoloji yeLaser iqinisekisa ukuchaneka okuphezulu kunye nemiphetho ecocekileyo, inciphisa iimpazamo.

✅Imveliso ekhawulezayo– Ikhawuleza kakhulu kunokusika imela ngesandla kunye ne-CNC, nto leyo eyenza ukuba ilungele ukwenziwa kwemveliso enkulu.

Iingxaki:

❌Ukusebenza kakuhle okuphantsi– Isantya sokunciphisa sixhomekeke kubasebenzi, nto leyo eyenza kube nzima ukuhlangabezana neemfuno eziphezulu zemveliso.

❌Ukuchaneka okungahambelaniyo– Impazamo yomntu ingakhokelela kwiikona ezingalinganiyo kunye nokuphambuka kwesimo, okuchaphazela umgangatho wemveliso.

❌Inkunkuma yezinto eziphathekayo– Ukusetyenziswa ngelaphu ngendlela engafanelekanga kwandisa iindleko zemveliso.

Iingxaki:

❌Kufuneka utyalo-mali lokuqala– Oomatshini banokubiza kakhulu kumashishini amancinci.

❌Ubunzima boyilo obulinganiselweyo– Unengxaki ngeenkcukacha ezintsonkothileyo kunye nokusika okuncinci kakhulu xa kuthelekiswa nokusika nge-laser.

❌Ifuna ubuchule besoftware– Abaqhubi kufuneka baqeqeshwe ekwenzeni iipateni zedijithali kunye nokuphatha oomatshini.

Iingxaki:

❌Umonakalo onokwenzeka kwilaphu – I-Polyester kunye nezinye izinto ezenziweyo zinokutsha okanye zinyibilike kancinci emaphethelweni.Nangona kunjalo, oku kungancitshiswa ngokuphucula useto lwelaser.

❌ Umoya kufuneka ungeniswe- Xa kufikwa ekusikeni nge-laser, izinto zinokuba nzima kancinci! Yiyo loo ntoukuba neinkqubo yokungenisa umoya eqinileyoendaweni yayo kubaluleke kakhulu.

●Eyona ifanelekileyo:

Imveliso encinci, eyenziwe ngokwezifiso, okanye yobugcisa.

Amashishini anotyalo-mali oluphantsi.

●Eyona ifanelekileyo:

Ukuveliswa ngobuninzi kweemveliso ezisekelwe kwilaphu ezinobunzima obuphakathi boyilo.

Amashishini afuna enye indlela yokusika ngesandla.

●Eyona ifanelekileyo:

Ukwenziwa kwempahla yamalaphu ngobuninzi.

Amashishini afuna uyilo oluchanekileyo noluntsonkothileyo

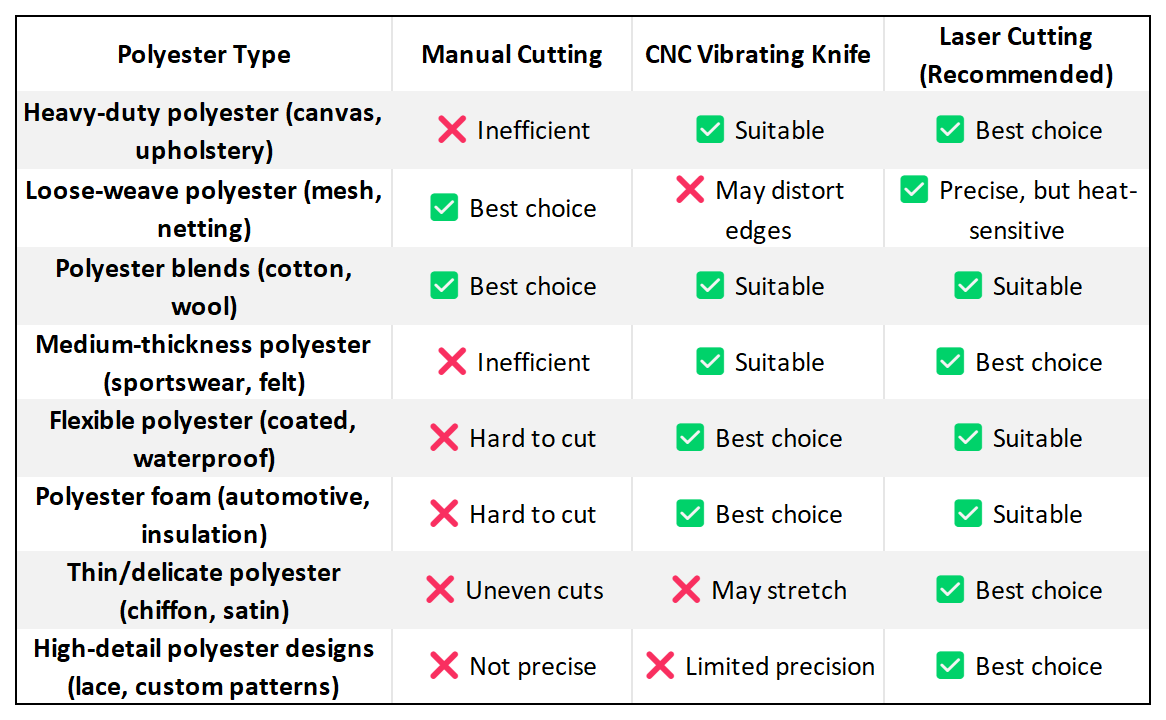

Nantsi itshathi enika umbono opheleleyo weendlela zokusika ezifanelekileyo kwiintlobo ezahlukeneyo zelaphu le-polyester. Ithelekisaukusika ngesandla, Ukusika imela engcangcazelayo ye-CNCkunyeukusika nge-laser, ikunceda ukhethe eyona ndlela ilungileyo ngokusekelwe kwimpahla ethile ye-polyester osebenza ngayo. Nokuba usika i-polyester enzima, ethambileyo, okanye eneenkcukacha eziphezulu, le tshathi iqinisekisa ukuba ukhetha eyona ndlela isebenzayo nechanekileyo yokusika ukuze ufumane iziphumo ezilungileyo.

Ukufanisa Iintlobo zePolyester Ngendlela Echanekileyo Yokusika

Naziphi na izimvo malunga neLaser Cutting Filter Laphu, Wamkelekile ukuxoxa nathi!

Ungayisika njani iLaphu lePolyester?

I-Polyester lukhetho oludumileyo lwelaphu ngenxa yokuqina kwayo kunye nokuguquguquka kwayo, kodwa ukuyisika kunokuba nzima.Ingxaki eqhelekileyo kukuqhekeka, apho imiphetho yelaphu iqhekeka khona ize idale ukugqitywa okungcolileyo.Nokuba ungumthandi we-DIY okanye ungumthungi ochwepheshileyo, ukufumana izihlangu ezicocekileyo nezingenakonakala kubalulekile ukuze ubonakale ucocekile.

▶ Kutheni Ilaphu lePolyester Liqhekeka?

Indlela Yokusika

Indlela ilaphu le-polyester elisikwa ngayo idlala indima ebalulekileyo ekuthandeni kwalo ukuqhekeka.Ukuba kusetyenziswa izikere ezibuthuntu okanye isixhobo sokusika esijikelezayo esibuthuntu, zinokwenza imiphetho engalinganiyo nejijekileyo evuleka lula. Ukuze kufezwe imiphetho ecocekileyo ngokunciphisa ukuqhekeka, izixhobo zokusika ezibukhali nezichanekileyo zibalulekile.

Ukuphatha nokusebenzisa

Ukuphathwa rhoqo kunye nokusetyenziswa rhoqo kwelaphu le-polyester kunokukhokelela ekuqhekekeni kancinci kancinci emaphethelweni.Ukungqubana kunye noxinzelelo olusebenza kwimiphetho yelaphu, ingakumbi kwiindawo ezigugileyo rhoqo, kunokubangela ukuba imicu ikhululeke kwaye iqhekeke ngokuhamba kwexesha. Le ngxaki ixhaphake kakhulu kwiimpahla nakwezinye izinto zelaphu ezisetyenziswa rhoqo.

Ukuhlamba Nokomisa

Iindlela ezingalunganga zokuhlamba nezomisa zinokubangela ukuqhekeka kwelaphu le-polyester.Ukuxinana okugqithisileyo ngexesha lokuhlamba, ingakumbi kwiimashini ezinee-agitators, kunokwenza imiphetho yelaphu ibe rhabaxa kwaye kukhokelele ekuqhekekeni. Ukongeza, ukuvezwa kubushushu obuphezulu ngexesha lokomiswa kunokwenza imicu ibe buthathaka, nto leyo eyenze ukuba iqhekeke lula.

Ukugqitywa komphetho

Indlela imiphetho yelaphu egqitywe ngayo iyayichaphazela kakhulu indlela elinokuthi liqhekeke ngayo.Imiphetho eluhlaza engenalo naluphi na unyango lokugqibela isengozini enkulu yokuqhekeka kunezo zivaliwe ngokufanelekileyo. Iindlela ezinje ngokugoba, ukuvalela ngaphezulu, okanye ukugquma imiphetho yelaphu ngokufanelekileyo, ukuthintela ukuqhekeka nokuqinisekisa ukuqina kwexesha elide.

▶ Ungayisika njani iLaphu lePolyester ngaphandle kokuliqhekeza?

1. Gqibezela ii-Raw Edges

Indlela ethembekileyo yokuthintela ukuqhekeka kukuukugqiba imiphetho eluhlaza yelaphuOku kungenziwa ngokuthunga umphetho omxinwa emacaleni, nokuba ngomatshini wokuthunga okanye ngesandla, ukuze kufakwe ilaphu eliluhlaza kwaye kubonakale kucocekile kwaye kulungiswe kakuhle. Okanye, umthungo we-overlock okanye i-serger ingasetyenziselwa ukuqinisa imiphetho, inike ukugqitywa kobuchwephesha ngelixa ithintela ngempumelelo ukuqhekeka.

2. Sebenzisa Ubushushu Ukuvala Imiphetho

Ukusebenzisa ubushushuyenye indlela esebenzayo yokwenza okuukuvala imiphetho yepolyester nokuthintela ukuqhekeka. Imela eshushu okanye intsimbi yokunyibilikisa ingasetyenziselwa ukunyibilikisa imiphetho yelaphu ngononophelo, nto leyo eyenza ukuba igqitywe kakuhle. Nangona kunjalo, ekubeni i-polyester yenziwe ngezinto zokwenziwa, ubushushu obugqithisileyo bunokubangela ukuba inyibilike ngokungalinganiyo okanye itshise, ngoko ke kufuneka uqaphele xa usebenzisa le ndlela.

3.Sebenzisa iFray Check kwi-Cut Edges

I-Fray Check sisitywini solwelo esenzelwe ukuthintela imiphetho yelaphuukusuka ekuqhekekeni. Xa isetyenziswa kwimiphetho esikiweyo yelaphu le-polyester, yoma ibe ngumqobo oguquguqukayo nocacileyo obamba imicu endaweni yayo. Faka nje inani elincinci kwimiphetho uze uyivumele yome ngokupheleleyo. I-Fray Check ifumaneka kakhulu kwiivenkile zelaphu kwaye yongezwa kakhulu kuyo nayiphi na ikhithi yokuthunga.

4. Sebenzisa iiPinking Shears xa usika

Izikere ezipinki zizikere ezikhethekileyo ezineeblade ezirhabaxa ezisika ilaphu ngendlela egosogoso.Le patheni inceda ekunciphiseni ukuqhekeka ngokunciphisa ukuqhekeka kweefayibha nokubonelela ngomphetho okhuselekileyo. Iisheya ezipinki ziluncedo ngakumbi xa usebenza ngamalaphu e-polyester alula, zibonelela ngendlela elula nesebenzayo yokuphucula ukuqina kwelaphu.

▶ Ungayisika njani iPolyester ngeLaser? | Umboniso weVidiyo

Ukufanisa Iintlobo zePolyester Ngendlela Echanekileyo Yokusika

Ivula iimfihlo zokusikwa kwempahla yezemidlalo ngokukhawuleza nangokuzenzekelayo, i-MimoWork vision laser cutter ivela njengotshintsho olukhulu kwimpahla ye-sublimated, kubandakanya impahla yezemidlalo, ii-leggings, iimpahla zokudada, nokunye. Lo matshini uphambili uzisa ixesha elitsha kwihlabathi lokuvelisa iimpahla, ngenxa yokuqaphela kwayo iipateni ngokuchanekileyo kunye nobuchule bokusika obuchanekileyo.

Zibandakanye kwizinto zemidlalo eziprintiweyo ezikumgangatho ophezulu, apho uyilo oluntsonkothileyo luphila khona ngokuchanekileyo okungenakuthelekiswa nanto. Kodwa akupheleli apho - i-MimoWork vision laser cutter yenza okungaphezulu kakhulu ngeempawu zayo zokuzondla, ukuhambisa, kunye nokusika ngokuzenzekelayo.

Umsiki weLaser weKhamera weZinxibo zemidlalo kunye neMpahla

Singena kwiindlela eziphambili nezizenzekelayo, sihlola imimangaliso yokusika amalaphu ashicilelweyo kunye neempahla ezisebenzayo. Sixhotyiswe ngekhamera yanamhlanje kunye neskena, umatshini wethu wokusika ilaser usebenza kakuhle kwaye ufikelela kwinqanaba eliphezulu. Kwividiyo yethu enomtsalane, jonga umlingo wesixhobo sokusika ilaser esisebenza ngokuzenzekelayo esilungiselelwe ihlabathi leempahla.

Iintloko ze-laser ezimbini ze-Y-axis zibonelela ngokusebenza kakuhle okungenakuthelekiswa nanto, nto leyo eyenza lo matshini wokusika i-laser wekhamera ube ngumdlali obalaseleyo kwilaphu le-sublimation lokusika i-laser, kuquka nehlabathi elintsonkothileyo lezinto zejezi. Lungela ukutshintsha indlela yakho yokusika i-laser ngokusebenza kakuhle nangesitayile!

Imibuzo Ebuzwa Rhoqo Ngokusika iPolyester

▶ Yeyiphi indlela ebalaseleyo yokusika ilaphu lePolyester?

Ukusika nge-laser yeyona ndlela isebenziseka lula, ichanekileyo, kwaye isebenzayo yokucubungula ilaphu le-polyester.Iqinisekisa imiphetho ecocekileyo, inciphisa inkunkuma yezinto eziphathekayo, kwaye ivumela uyilo oluntsonkothileyo. Nangona ukusika imela engcangcazelayo ye-CNC kuyindlela elungileyo yokusetyenziswa kwezinye iifektri, ukusika nge-laser kuseyeyona ndlela ilungileyo kwiintlobo ezininzi ze-polyester, ngakumbi kwimizi-mveliso yefashoni, yeemoto, kunye neyetekhnoloji yelaphu.

▶ Ngaba Ikhuselekile Kwi-Laser Cut Polyester?

Ewe, i-polyester yokusika nge-laser ikhuselekile ngokubanzi xa kuthathwa amanyathelo okhuseleko afanelekileyo.I-Polyester yinto eqhelekileyo yokusika nge-laserkuba inokuvelisa ukusika okuchanekileyo nokucocekileyo. Ngokwesiqhelo, kufuneka sixhobise isixhobo sokungenisa umoya esisebenza kakuhle, kwaye simisele isantya esifanelekileyo se-laser kunye namandla ngokusekelwe kubukhulu bezinto kunye nobunzima begram. Ukuze ufumane ingcebiso eneenkcukacha zokuseta i-laser, sicebisa ukuba uqhagamshelane neengcali zethu ze-laser ezinamava.

▶ Ngaba ukusika imela nge-CNC kunokutshintsha ukusika nge-laser?

Ukusika imela ye-CNC kusebenza kakuhle kwizinto ze-polyester ezityebileyo okanye eziguquguqukayo ngokunciphisa umonakalo wobushushu, kodwa ayinazo iindlela zokuzitywina ezichanekileyo kakhulu nezizivalayo ezibonelelwa kukusika nge-laser. Nangona i-CNC ingabizi kakhulu kwaye isebenza kakuhle kwizicelo ezininzi zoshishino, ukusika nge-laserihlala ingcono xa kufuneka iinkcukacha ezintsonkothileyo, ukusikwa okucocekileyo kakhulu, kunye nokuthintela ukuqhekeka, nto leyo eyenza ukuba ibe lolona khetho lukhethwayo kwiimveliso zepolyester ezithambileyo nezichanekileyo.

▶ Ungakuthintela njani ukuqhekeka komphetho wePolyester?

Ukuthintela imiphetho yepolyester ukuba ingaqhekeki, eyona ndlela ilungileyo kukwenzasebenzisa indlela yokusika evala imiphetho, njengokusika nge-laser,enyibilikisa kwaye idibanise imicu njengoko isika. Ukuba usebenzisa ezinye iindlela ezifana nemela yokungcangcazela ye-CNC okanye ukusika ngesandla, iindlela ezongezelelweyo zokugqiba—ezifana nokuvala ubushushu, ukugquma, okanye ukusebenzisa izitywina zomphetho we-adhesive—zingasetyenziswa ukuqinisa imicu nokugcina umphetho ococekileyo nohlala ixesha elide.

▶ Ngaba Ungayisika I-Polyester NgeLaser?

Ewe.Iimpawu ze-polyesteringaphuculwa kakhulu ngokucubungula nge-laser. Njengakwezinye iithermoplastics, eli laphu lenziweyo lidlula kakuhle kwiindlela zokusikwa kwelaser kunye nokugqobhoka. I-Polyester, njengezinye iiplastiki zenziweyo, ifunxa kakuhle imisebe yelaser. Kuzo zonke iithermoplastics, lelona linika iziphumo ezilungileyo zokucutshungulwa kunye nokungabikho kwenkunkuma.

Umatshini Ocetyiswayo We-Laser Cut Polyester

Ukuze ufumane iziphumo ezilungileyo xa usika i-polyester, khetha echanekileyoumatshini wokusika i-laser ye-polyesteribalulekile. I-MimoWork Laser inikezela ngoluhlu lweematshini ezifanelekileyo kakhului-polyester yokusika nge-laser, kuquka:

• Indawo Yokusebenza (W *L): 1600mm * 1200mm

• Amandla eLaser: 100W/130W/150W

• Indawo Yokusebenza (W *L): 1800mm * 1300mm

• Amandla eLaser: 100W/130W/300W

• Indawo Yokusebenza (W *L): 1800mm * 1300mm

• Amandla eLaser: 100W/130W/150W/300W

Ngaba unemibuzo malunga nomatshini wokusika iLaser wePolyester?

Ihlaziywe okokugqibela: nge-9 kaSeptemba, ngo-2025

Ixesha leposi: Feb-07-2025