Ngaba ukusika ngeLaser yeyona ndlela ilungileyo yokukhetha ilaphu lesihluzi?

Iintlobo, iiNzuzo, kunye nezicelo

Intshayelelo:

Izinto ezibalulekileyo ekufuneka uzazi ngaphambi kokuba ungene

Itekhnoloji yokusika i-laser itshintshe kakhulu indlela esetyenziswa ngayo izinto kwimizi-mveliso eyahlukeneyo. Phakathi kwezi, ukusetyenziswa kwe-laser cutting kwilaphu lesihluzo kugqamile ngokuchaneka kwalo, ukusebenza kakuhle, kunye nokuguquguquka kwalo. Ilaphu lesihluzo, elibalulekileyo kumashishini afana nonyango lwamanzi, ukuhluza umoya, amayeza, kunye nokulungiswa kokutya, lifuna iindlela zokusika ezisemgangathweni ophezulu ukuze liqhubeke nokusebenza kwalo.

Eli nqaku lihlola ukuba ukusika nge-laser kufanelekile na kwilaphu lesihluzo, lithelekise nezinye iindlela zokusika, kwaye liqaqambisa iingenelo zelaphu lesihluzo lesihluzo lesihluzo. Siza kucebisa noomatshini bokusika nge-laser ababalaseleyo abalungiselelwe iimfuno zakho.

Izinto zelaphu lesihluzi ezifana ne-polyester, i-nylon, kunye ne-polypropylene zenzelwe ukusetyenziswa apho zibamba khona amasuntswana ngelixa zivumela ulwelo okanye iigesi ukuba zidlule. Ukusika nge-laser kuyagqwesa ekucubunguleni ezi zinto kuba kubonelela:

1. Iingcango ezicocekileyo

Ilaphu lesihluzi sokusika nge-laser libonelela ngemiphetho evaliweyo, lithintela ukuqhekeka kwaye liphucula ixesha elide lamalaphu esihluzi.

2. Ubuchule obuphezulu

Umatshini wokusika ilaphu lesihluzo une-laser beam entle kodwa enamandla enokusika iimilo ezichanekileyo kunye noyilo olukhethekileyo. Ifanelekile kwizixhobo zesihluzo ezenzelwe wena okanye ezixabisa kakhulu.

3. Ukwenza ngokwezifiso

Umsiki we-laser unokusingatha uyilo oluntsonkothileyo kunye neemilo ezizodwa, ezibalulekileyo kwiimfuno zokucoca ezikhethekileyo.

4. Ukusebenza kakuhle kakhulu

Iinkqubo zokusika nge-laser ngelaphu lesihluzo zisebenza ngesantya esiphezulu, nto leyo ezenza zilungele imveliso enkulu.

5. Inkunkuma encinci yezinto eziphathekayo

Ngokungafaniyo neendlela zemveli, ukusika nge-laser kunciphisa inkunkuma yezinto ngokusebenzisa iipateni ezilungiselelweyo kunye nokusika ngokuchanekileyo.

6. Ukwenziwa kwezinto ngokuzenzekelayo okuphezulu

Inkqubo yokusika ilaphu lesihluzo kulula ukuyisebenzisa, ngenxa yenkqubo ye-CNC kunye nesoftware yokusika ilaser ekrelekrele. Umntu omnye unokulawula umatshini welaser aze afezekise imveliso eninzi ngexesha elifutshane.

Nangona ukusika nge-laser kuye kwabonakala kusebenza kakhulu kwilaphu lesihluzo, kukho ezinye iindlela ezininzi ezisetyenziswa rhoqo ekusikeni amalaphu. Makhe sizihlolisise ngokufutshane:

1. Ukusika ngoomatshini:

Izixhobo eziqhelekileyo ezifana nezicuthi ezijikelezayo zibiza kancinci kodwa zinokwaphuka imiphetho kwaye iziphumo azihambelani, ingakumbi kwiindlela ezineenkcukacha.

Iindlela zokusika zemveli ezifana nezicuku ezijikelezayo okanye iimela zelaphu zihlala zisetyenziswa ekusikeni ilaphu lesihluzo. Nangona kunjalo, ezi ndlela zinokubangela ukuqhekeka emaphethelweni, okunokuchaphazela ukuthembeka kwelaphu, ingakumbi kwizicelo ezichanekileyo ezifana nokuhluza.

2. Ukusika iidayi:

Isebenza kakuhle kwiimo ezilula neziphindaphindayo kwimveliso enkulu kodwa ayinabo ukuguquguquka kwiindlela ezenziwe ngokwezifiso okanye ezintsonkothileyo.

Ukusika nge-die kudla ngokusetyenziselwa ukuvelisa iindawo zelaphu lesihluzo ngobuninzi, ingakumbi xa kufuneka iimilo ezilula. Nangona ukusika nge-die kunokuba luncedo, akuniki nqanaba lifanayo lokuchaneka okanye ukuguquguquka njengokusika nge-laser, ingakumbi xa kusetyenzwa ngoyilo oluntsonkothileyo.

3. Ukusika nge-Ultrasonic:

Isebenza kakuhle kwimpahla ethile kodwa incinci kwizixhobo zokusika ilaphu lesihluzo, ingakumbi kwimisebenzi enzima okanye emikhulu.

Ukusika nge-ultrasonic kusebenzisa amaza esandi asebenza rhoqo ukusika izinto. Kuluncedo kwiindlela ezithile zokusetyenziswa kodwa kusenokungabi lula okanye kungasebenzi kakuhle njengokusika nge-laser kuzo zonke iintlobo zelaphu lesihluzi.

Isiphelo:

Ukusika nge-laser kugqwesa ezi ndlela ngokubonelela ngokuchanekileyo, ngokuguquguquka, nangokusebenza kakuhle, konke oku ngaphandle kokudibana ngokwasemzimbeni okanye ukuguguleka kwezixhobo.

Ukusika nge-laser kunika umphetho ochanekileyo novalekileyo othintela ukuqhekeka. Oku kubaluleke kakhulu kwizinto ezifana ne-polyester okanye i-nylon, ezinokuqhekeka ngokulula ukuba azinqunyulwanga kakuhle. Ubushushu be-laser bukwabulala iintsholongwane kwimiphetho enqunyiweyo, kunciphisa umngcipheko wongcoliseko, nto leyo ibalulekileyo kwizicelo zonyango okanye kushishino lokutya.

Nokuba ufuna ukusika iimbobo ezintsonkothileyo, iimilo ezithile, okanye uyilo olwenziwe ngokwezifiso, ukusika nge-laser kunokulungiswa ukuze kuhlangatyezwane neemfuno zakho. Ukuchaneka kuvumela ukusika okuntsonkothileyo okungenakukwazi ukuphindwa ziindlela zemveli.

Ngokungafaniyo nezicuthi zedayi okanye iiblade zoomatshini, iilaser azigugi kwaye azikrazuki. Oku kuthetha ukuba akukho mfuneko yokutshintshwa kweeblade, nto leyo enokubangela ukonga iindleko kunye nokunciphisa ixesha lokungasebenzi.

Ilaphu lokucoca ukusika nge-laserIsebenza ngokujolisa umqadi welaser onamandla aphezulu kwizinto, onyibilikisa okanye uphelise umqadi kwindawo yokudibana. Umqadi welaser ulawulwa ngokuchanekileyo okukhulu yinkqubo ye-CNC (Computer Numerical Control), evumela ukuba isike okanye ikrole izinto ezahlukeneyo zelaphu lokucoca ngokuchanekileyo okugqwesileyo.

Uhlobo ngalunye lwelaphu lesihluzo lufuna useto oluthile ukuqinisekisa iziphumo ezilungileyo zokusika. Nantsi indlela yokujongailaphu lokucoca ukusika nge-laserisebenza kwezinye zezona zinto zixhaphakileyo zelaphu lesihluzo:

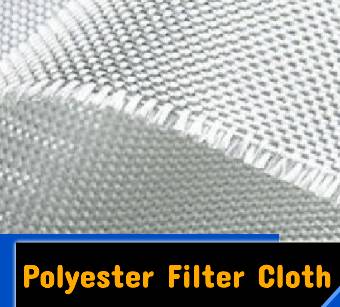

I-Polyester Esikiweyo NgeLaser:

I-Polyesterlilaphu elenziweyo elisabela kakuhle kwiilaphu lokucoca ukusika nge-laser.

I-laser iyanqumla kakuhle kwizinto, kwaye ubushushu obuvela kumqadi we-laser buvala imiphetho, buthintela nakuphi na ukuqhekeka okanye ukuqhekeka.

Oku kubaluleke kakhulu xa kusetyenzwa ukucoca apho imiphetho ecocekileyo ibalulekile ekugcineni ukuthembeka kwesihluzo.

Amalaphu angalukwanga ngeLaser Cut:

Amalaphu angalukwangazilula kwaye zithambile, nto leyo eyenza zilungele kakuhleilaphu lokucoca ukusika nge-laserI-laser ingazinqumla ngokukhawuleza ezi zinto ngaphandle kokonakalisa isakhiwo sazo, inika iziqwenga ezicocekileyo ezibalulekileyo ekuveliseni iimilo ezichanekileyo zesihluzo.Ilaphu lokucoca ukusika nge-laseriluncedo kakhulu kwilaphu elingalukwanga elisetyenziswa kwiindlela zonyango okanye zokucoca iimoto.

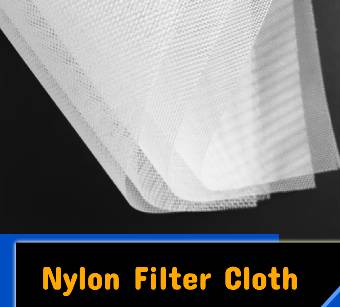

I-Nylon Esikiweyo Nge-Laser:

Inayilonisisixhobo esomeleleyo nesiguquguqukayo esifanelekileyoilaphu lokucoca ukusika nge-laserUmqadi welaser unqumla lula kwi-nylon kwaye wenze imiphetho evaliweyo negudileyo. Ukongeza,ilaphu lokucoca ukusika nge-laserayibangeli ukugqwetheka okanye ukolula, nto leyo edla ngokuba yingxaki kwiindlela zemveli zokusika. Ukuchaneka okuphezulu kweilaphu lokucoca ukusika nge-laseriqinisekisa ukuba imveliso yokugqibela igcina ukusebenza okufunekayo kokuhluza.

Igwebu Elisikiweyo NgeLaser:

IgwebuIzixhobo zokucoca nazo zifanelekileilaphu lokucoca ukusika nge-laser, ingakumbi xa kufuneka ukugqobhoka okanye ukusikwa okuchanekileyo.Ilaphu lokucoca ukusika nge-lasernjenge-foam ivumela uyilo oluntsonkothileyo kwaye iqinisekisa ukuba imiphetho ivaliwe, nto leyo ethintela i-foam ukuba yonakale okanye ilahlekelwe ziimpawu zayo zokwakha. Nangona kunjalo, kufuneka kuthathwe unonophelo ngezicwangciso ukuthintela ukwakheka kobushushu obugqithisileyo, okunokubangela ukutsha okanye ukunyibilika.

Iinkqubo zokuSika iLaser eziCetyisiweyo zeLaphu lesihluzo

Ukuze ufumane iziphumo ezilungileyo xa usika ilaphu lesihluzo, khetha elichanekileyoumatshini wokusika ilaphu lokucoca nge-laseribalulekile. I-MimoWork Laser inikezela ngoluhlu lweematshini ezifanelekileyo kakhuluilaphu lokucoca ukusika nge-laser, kuquka:

• Indawo Yokusebenza (W *L): 1000mm * 600mm

• Amandla eLaser: 60W/80W/100W

• Indawo Yokusebenza (W *L): 1300mm * 900mm

• Amandla eLaser: 100W/150W/300W

• Indawo Yokusebenza (W *L): 1800mm * 1000mm

• Amandla eLaser: 100W/150W/300W

Ukuququmbela

Ukusika nge-laser ngokungathandabuzekiyo yindlela esebenza kakhulu nefanelekileyo yokusika ilaphu lesihluzo. Ukuchaneka kwayo, isantya, kunye nokuguquguquka kwayo kwenza ukuba ibe lolona khetho luphezulu kumashishini afuna ukusika okusemgangathweni ophezulu, okwenziwe ngokwezifiso. Ukuba ufuna umatshini wokusika nge-laser othembekileyo nosebenzayo welaphu lesihluzo, uluhlu lweMimoWork loomatshini bokusika nge-laser lubonelela ngeendlela ezintle zokukhetha zombini iimfuno zemveliso ezincinci nezinkulu.

Nxibelelana nathi namhlanje ukuze ufunde okungakumbi malunga noomatshini bethu bokusika nge-laser kunye nendlela abanokuyenza ngcono ngayo inkqubo yakho yokuvelisa ilaphu lesihluzo.

A: Izinto ezifana ne-polyester, i-polypropylene, kunye ne-nylon zifanelekile. Le nkqubo ikwasebenza nakwimpahla ye-mesh kunye ne-foam.

A: Ngokuzenzekela inkqubo yokusika kunye nokubonelela ngokusika okuchanekileyo nokucocekileyo ngaphandle kokungenelela ngesandla, okukhokelela kwimijikelo yemveliso ekhawulezayo.

A: Ngokuqinisekileyo. Iinkqubo zelaser zibalasele ekudaleni iipateni ezineenkcukacha kunye neemilo ezenziwe ngokwezifiso ezingenakufezwa ziindlela zemveli.

A: Ewe, uninzi lweematshini lunesoftware esebenziseka lula kunye nokuzisebenzela ngokuzenzekelayo, nto leyo edinga uqeqesho oluncinci kubaqhubi.

Naziphi na izimvo malunga neLaser Cutting Filter Laphu, Wamkelekile ukuxoxa nathi!

Ngaba unemibuzo malunga nomatshini wokusika iLaser ngeLaphu lesihluzi?

Ihlaziywe okokugqibela: nge-9 ka-Okthobha, ngo-2025

Ixesha leposi: Novemba-18-2024