Isikhokelo Sokugqibela Selaphu Lesihluzi Sokusika NgeLaser:

Iintlobo, iiNzuzo, kunye nezicelo

Intshayelelo:

Izinto ezibalulekileyo ekufuneka uzazi ngaphambi kokuba ungene

Amalaphu okucoca adlala indima ebalulekileyo kumashishini amaninzi, ukusuka ekuhluzeni amanzi nomoya ukuya ekusetyenzisweni kwamayeza kunye nokulungiswa kokutya. Njengoko amashishini efuna ukuphucula ukusebenza kakuhle, ukuchaneka, kunye nokwenza ngokwezifiso imveliso yelaphu lokucoca, ilaphu lokucoca lokusika nge-laser liye lavela njengesisombululo esithandwayo. Ngokungafaniyo neendlela zokusika zendabuko, ilaphu lokucoca lokusika nge-laser linika izinga eliphezulu lokuchaneka, isantya, kunye nenkunkuma encinci yezinto, okwenza kube lolona khetho lufanelekileyo lokusika amalaphu okucoca enziwe ngezinto ezahlukeneyo ezifanai-polyester, i-nylonkunyeamalaphu angalukwanga.

Kweli nqaku, siza kujonga ngokusondeleyo iintlobo ezahlukeneyo zelaphu lesihluzo kunye nendlela ilaphu lesihluzo lokusika nge-laser elisebenza ngayo kwizinto ezahlukeneyo. Uza kubona ukuba kutheni liye labaisisombululo esifanelekileyo sokuvelisa umgangatho ophezulu, iimveliso zokucoca ezenzelwe wenaSiza kwabelana ngolwazi oluvela kuvavanyo lwethu lwakutshanje ngezinto ezifana ne-foam kunye ne-polyester, sikunike imizekelo yokwenyani yendlela ilaphu lesihluzo sokusika nge-laser elinokuphucula ngayo ukusebenza kakuhle kunye nokuhambelana kwemveliso.

Indlela Yokusika Ilaphu Lesihluzi NgeLaser | Umatshini Wokusika NgeLaser kwiShishini Lokucoca

Yiza kwividiyo ukuze uhlolisise inkqubo yokusika ngelaphu lesihluzo. Imfuno ephezulu yokusika ngokuchanekileyo yenze umatshini wokusika ngelaser waziwe kakhulu kwishishini lokucoca.

Iintloko ze-laser ezimbini ziphucula imveliso ngakumbi, zonyusa isantya sokusika ngelixa ziqinisekisa umgangatho.

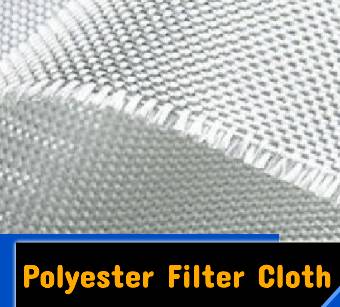

1. Ilaphu lesihluzi sePolyester:

• Ukusetyenziswa:Ilaphu lesihluzi sepolyester lelinye lawona malungiselelo asetyenziswa kakhulu ekuhluzeni ngenxa yokuqina kwalo, ukumelana neekhemikhali, kunye nokukwazi ukumelana namaqondo obushushu aphezulu.

•Izicelo:Ihlala isetyenziswa kwiinkqubo zokucoca umoya, unyango lwamanzi, kunye neenkqubo zokucoca izimboni.

•Iingenelo zokusika ngeLaser:I-Polyester ihambelana kakhulu neilaphu lokucoca ukusika nge-laserkuba ivelisa imiphetho ecocekileyo nechanekileyo. I-laser ikwavala imiphetho, ithintela ukuqhekeka kwaye yonyusa amandla elaphu iyonke.

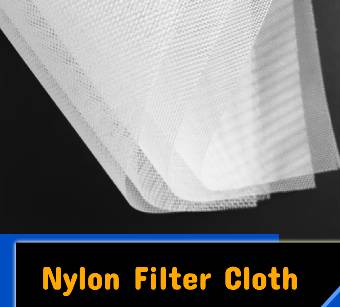

2. Ilaphu lesihluzo seNylon:

• Ukusetyenziswa:Ilaphu lesihluzo se-nylon, elaziwa ngokuba nokuguquguquka nokuqina kwalo, lilungele ukusetyenziswa ngokungxamisekileyo ekuhluzeni, njengakwimizi-mveliso yeekhemikhali okanye kwicandelo lokutya neziselo.

•Izicelo:Isetyenziswa kakhulu ekuhluzeni iikhemikhali, ekucoceni amanzi, nasekuhluzeni ukutya.

•Iingenelo zokusika ngeLaser:Amandla e-nylon kunye nokumelana nokuguguleka kwayo kuyenza ibe ngumviwa obalaseleyoilaphu lokucoca ukusika nge-laserI-laser iqinisekisa imiphetho egudileyo nevaliweyo egcina ukuqina kwezinto kunye neempawu zokuhluza.

3. Ilaphu lesihluzi sePolypropylene:

• Ukusetyenziswa:I-Polypropylene yaziwa ngokuchasana kwayo neekhemikhali ngendlela egqwesileyo, nto leyo eyenza ukuba ilungele ukuhluza iikhemikhali ezirhabaxa okanye izinto ezishushu kakhulu.

•Izicelo:Isetyenziswa ekuhluzeni amayeza, ekuhluzeni izinto ezisetyenziswa kwimizi-mveliso, nasekuhluzeni izinto ezingamanzi.

•Iingenelo zokusika ngeLaser: Ilaphu lokucoca ukusika nge-laserNjenge-polypropylene ivumela ukunqunyulwa okuchanekileyo kunye noyilo oluntsonkothileyo ngaphandle kokonakalisa izinto. Imiphetho evaliweyo ibonelela ngokuqina okungcono kwesakhiwo, okwenza ukuba ifaneleke ukusetyenziswa okubalulekileyo.

4. Ilaphu lesihluzi esingalukwanga:

• Ukusetyenziswa:Ilaphu lesihluzo elingalukwanga lilula, liguquguquka, kwaye lingabizi kakhulu. Lisetyenziswa kwiindawo apho kulula ukulisebenzisa kunye noxinzelelo oluphantsi kubalulekile.

•Izicelo:Isetyenziswa ekuhluzeni iimoto, umoya, nothuli, kunye nakwiimveliso zezihluzi ezilahlwayo.

•Iingenelo zokusika ngeLaser:Amalaphu angalukwanga anokubaukusika nge-laserngokukhawuleza nangokufanelekileyo.Ilaphu lokucoca ukusika nge-laserisebenziseka kakhulu kwiimfuno ezahlukeneyo zokuhluza, ivumela ukugqobhoka okuncinci kunye nokusikwa kwendawo enkulu.

Ilaphu lesihluzi sokusika nge-laser lisebenzisa umqadi we-laser ogxile kakhulu, onamandla aphezulu onyibilikisa okanye ophembelela ilaphu kanye kwindawo elidibana kuyo. Ikhokelwa yinkqubo ye-CNC (Computer Numerical Control), i-laser ihamba ngokuchanekileyo okumangalisayo, okwenza kube nokwenzeka ukusika okanye ukukrola iintlobo ezahlukeneyo zelaphu lesihluzi ngokuchanekileyo okugqwesileyo.

Kakade ke, ayizizo zonke izinto zelaphu lesihluzo ezifanayo. Nganye ifuna useto olucwangcisiweyo ukuze kufumaneke iziphumo ezilungileyo zokusika. Makhe sihlalutye indlela ilaphu lesihluzo lesihluzo esinqunyulwa nge-laser elisebenza ngayo kwezinye zezona zinto zisetyenziswa kakhulu.

I-Polyester Esikiweyo NgeLaser:

Ilaphu lesihluzo sepolyester lihlala ixesha elide kwaye alinakuze litsalwe, nto leyo enokwenza kube nzima ukulisika ngezixhobo zemveli. Ukusika nge-laser kubonelela ngenzuzo ecacileyo apha, njengoko kunika imiphetho egudileyo, evaliweyo ethintela ukubola ngelixa kugcinwa amandla elaphu. Oku kuchaneka kubaluleke kakhulu kumashishini afana nokucoca amanzi okanye ukucubungula ukutya, apho kufuneka ukusebenza kwesihluzo rhoqo.

Amalaphu angalukwanga ngeLaser Cut:

Amalaphu angalukwanga alula kwaye athambile, nto leyo eyenza ukuba afane kakuhle nokusika nge-laser. Ngolu buchwepheshe, izinto zingacutshungulwa ngokukhawuleza ngaphandle kokuphazamisa ulwakhiwo lwazo, nto leyo ekhokelela ekusikeni okucocekileyo nokuchanekileyo okubalulekileyo ekubumbeni izihluzi. Le ndlela ibaluleke kakhulu xa usebenza ngamalaphu angalukwanga ekuhluzeni kwezonyango okanye kweemoto, apho ukuchaneka kunye nokuhambelana kubalulekile.

I-Nylon Esikiweyo Nge-Laser:

Amalaphu enayiloni aziwa ngokuguquguquka kwawo nokuqina kwawo, kodwa kunokuba nzima ukuwaphatha ngeendlela zokusika ngoomatshini. Ukucubungula nge-laser kusombulula le ngxaki ngokuvelisa amanxeba abukhali nachanekileyo ngaphandle kokubangela ukugqwetheka. Isiphumo zizihluzi ezigcina imo yazo kwaye zinikezela ukusebenza okuthembekileyo, okubaluleke kakhulu kwiindawo ezifuna amandla angaphezulu njengezicelo zeekhemikhali okanye amayeza.

Igwebu Elisikiweyo NgeLaser:

I-Foam yinto ethambileyo nenemingxuma enokukrazula okanye ijike ngokulula xa isikiwe ngeeblade. Itekhnoloji yelaser inika isisombululo esicocekileyo nesithembekileyo ngakumbi, njengoko isika i-foam kakuhle ngaphandle kokutyumza iiseli okanye ukuphazamisa ulwakhiwo lwayo. Oku kuqinisekisa ukuba izihluzi ezenziwe nge-foam zigcina imingxunya yazo kunye nokusebenza kwazo, nto leyo eyenza zibe luncedo ngakumbi kwizicelo ezifana nokucoca umoya kunye nokuthintela umsindo.

Kutheni Ukhetha Ukusika NgeLaser Kwilaphu Lokucoca?

Ilaphu lokucoca ukusika nge-laserInika iingenelo ezininzi kuneendlela zokusika zemveli, ingakumbi kwizixhobo zelaphu lesihluzo. Nazi ezinye zeenzuzo eziphambili:

1. Ukuchaneka kunye noMda ococekileyo

Ilaphu lokucoca ukusika nge-laseriqinisekisa ukunqunyulwa okuchanekileyo okuneemiphetho ezicocekileyo nezivaliweyo, nto leyo ibalulekileyo ekugcineni ukuqina kwesakhiwo selaphu lesihluzi. Oku kubaluleke kakhulu kwiinkqubo zokucoca apho izinto kufuneka zigcine amandla azo okucoca ngokufanelekileyo.

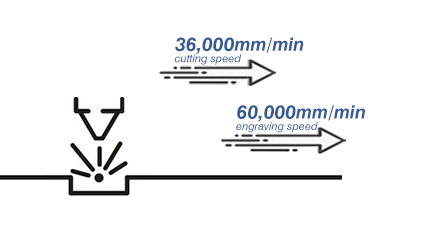

2. Isantya esikhawulezayo kunye nokusebenza kakuhle okuphezulu

Ilaphu lokucoca ukusika nge-laserIkhawuleza kwaye isebenza kakuhle kuneendlela zokusika ngoomatshini okanye zokusika ngomatshini, ingakumbi kwiindlela ezintsonkothileyo okanye ezenziwe ngokwezifiso.inkqubo yokusika ilaphu lokucoca nge-laserinokwenziwa ngokuzenzekelayo, nto leyo enciphisa isidingo sokungenelela ngesandla kwaye ikhawulezise amaxesha okuvelisa.

3. Inkunkuma encinci yezinto eziphathekayo

Iindlela zokusika zemveli zihlala zibangela inkunkuma eninzi yezinto, ingakumbi xa kunqunyulwa iimilo ezintsonkothileyo.Ilaphu lokucoca ukusika nge-laserinika ukuchaneka okuphezulu kunye nokuchithwa okuncinci kwezinto, nto leyo eyenza ukuba ibe lukhetho olungabizi kakhulu kwimveliso emincinci nekhulu.

4. Ukwenza ngokwezifiso kunye nokuguquguquka

Ilaphu lokucoca ukusika nge-laserivumela ukwenziwa ngokwezifiso ngokupheleleyo kwamalaphu esihluzo. Nokuba ufuna iimbobo ezincinci, iimilo ezithile, okanye uyilo oluneenkcukacha,ilaphu lokucoca ukusika nge-laserinokukwazi ukuhlangabezana neemfuno zakho ngokulula, ikunika ukuguquguquka kokuvelisa uluhlu olubanzi lweemveliso zelaphu lesihluzo.

5. Akukho zixhobo zokunxiba

Ngokungafaniyo nokusika ngomatshini okanye ngomatshini,ilaphu lokucoca ukusika nge-laserayibandakanyi ukudibana ngokwasemzimbeni nezinto ezisetyenzisiweyo, oko kuthetha ukuba akukho kugqwala kwiiblade okanye kwizixhobo. Oku kunciphisa iindleko zokulungisa kunye nexesha lokungasebenzi, okwenza kube sisisombululo esithembekileyo ngakumbi sexesha elide.

Iimashini Zokusika Ilaphu Le-Laser Ezicetyiswayo Zokucoca

Ukuze ufumane iziphumo ezilungileyo xa usika ilaphu lesihluzo, khetha elichanekileyoumatshini wokusika ilaphu lokucoca nge-laseribalulekile. I-MimoWork Laser inikezela ngoluhlu lweematshini ezifanelekileyo kakhuluilaphu lokucoca ukusika nge-laser, kuquka:

• Indawo Yokusebenza (W *L): 1000mm * 600mm

• Amandla eLaser: 60W/80W/100W

• Indawo Yokusebenza (W *L): 1300mm * 900mm

• Amandla eLaser: 100W/150W/300W

• Indawo Yokusebenza (W *L): 1800mm * 1000mm

• Amandla eLaser: 100W/150W/300W

Ukuququmbela

Ilaphu lokucoca ukusika nge-laserIbonakalise ukuba yindlela ebalaseleyo yokusika amalaphu okucoca, inika iingenelo ezininzi ezifana nokuchaneka, isantya, kunye nenkunkuma encinci. Nokuba usika i-polyester, i-foam, i-nylon, okanye amalaphu angalukwanga, ilaphu lokucoca lokusika nge-laser liqinisekisa iziphumo ezikumgangatho ophezulu ezinemiphetho evaliweyo kunye noyilo olwenziwe ngokwezifiso. Uluhlu lweenkqubo zokusika nge-laser zelaphu lokucoca zeMimoWork Laser zibonelela ngesisombululo esifanelekileyo kumashishini abo bonke ubungakanani afuna ukuphucula inkqubo yawo yokuvelisa amalaphu okucoca.

Qhagamshelana nathi namhlanje ukuze ufunde okungakumbi malunga nendlela yethuoomatshini bokusika ilaphu lokucoca nge-laserinokuphucula imisebenzi yakho yokusika amalaphu esihluzo kwaye iphucule umgangatho weemveliso zakho.

Xa kufikwa ekukhetheniumatshini wokusika ilaphu lokucoca nge-laser, cinga ngoku kulandelayo:

Iintlobo zeeMatshini:

Izicucu ze-laser ze-CO2 zihlala zicetyiswa xa kusikwa ilaphu lesihluzo kuba i-laser inokunqumla iimilo kunye nobukhulu obahlukeneyo. Kuya kufuneka ukhethe ubungakanani kunye namandla omatshini we-laser afanelekileyo ngokweentlobo zezinto zakho kunye neempawu. Nxibelelana nengcali ye-laser ukuze ufumane ingcebiso ye-laser yobungcali.

Uvavanyo lulokuqala:

Ngaphambi kokuba utyale imali kumatshini wokusika nge-laser, eyona ndlela ilungileyo kukwenza uvavanyo lwezinto ezibonakalayo usebenzisa i-laser. Ungasebenzisa ilaphu lesihluzo uze uzame amandla kunye nesantya se-laser esahlukileyo ukuze ubone isiphumo sokusika.

Naziphi na izimvo malunga neLaser Cutting Filter Laphu, Wamkelekile ukuxoxa nathi!

Ngaba unemibuzo malunga nomatshini wokusika iLaser kwiLaphu lesihluzi?

Ihlaziywe okokugqibela: nge-9 kaSeptemba, ngo-2025

Ixesha lokuthumela: Novemba-14-2024