Kutheni Ukhetha Umshiseli We-Laser Ophathwayo?

Umatshini wokuWelda weLaser ophathwa ngesandla - Ukhokela iShishini Umoya Omtsha

I-laser ephathwa ngesandla - ivakala ngathi sisixhobo esihle, akunjalo? Kule meko yanamhlanje yokwenziwa kwezinto ngokukhawuleza. Imfuneko yezisombululo zokuwelda ezisebenzayo nezisebenzayo ayizange ibe yeyona nto ibaluleke kangaka.

Ngoko ke, xa kuthelekiswa nomatshini wokuwelda welaser wendabuko. Yintoni eyenza umatshini wokuwelda welaser ophathwa ngesandla ubonakale uhlukile?

Mandikwaziseiingenelo zabawelda be-laser abaphathwa ngesandla xa kuthelekiswa neendlela zemveli zokuwelda.

Kwayeindlela abawelda nge-laser abaphathwa ngesandla abazisa ngayo ukukhanya okuthile.

Uluhlu Lomxholo:

Yintoni umatshini we-laser ophathwa ngesandla?

Yindlela yokuwelda esebenza kakuhle kakhulu, esemgangathweni ophezulu kwaye ixabisa kancinci.

Umatshini we-laser ophathwa ngesandla luhlobo lomsebenzi olula ophathwa ngesandla.

Umbindi wayo kukusebenzisa umqadi welaser ukwenza amanqaku angapheliyo kumphezulu wento.

Le yindlela esebenza kakuhle kakhulu, esemgangathweni ophezulu kwaye engabizi kakhulu.

Okumangalisayo kukuba, iindlela zemveli zokuwelda (ezifana ne-MIG okanye i-TIG) azilula ukuzisebenzisa.

Ngelixa umqadi we-laser ephathwayo unobubanzi obuncinci kakhulu bokugxila.

Ukuvumela ukuchaneka kokumakisha kwinqanaba le-micron ukuqinisekisa ukuba umxholo wokumakisha ucacile.

Kutshanje, bendincedisa kumzi-mveliso owenza izixhobo ezidityanisiweyo ezenziwe ngokwezifiso.

Omnye wemisebenzi enzima kakhulu esidibene nayo yayikukuba sidibanisa njani iziqwenga ezibhityileyo ze-aluminiyam phantsi kobushushu obugqithisileyo.

Xa satshintshela kwisixhobo sokuwelda nge-laser esiphathwa ngesandla.

Sifumanise ukuba ivelise ii-welds ezikumgangatho ophezulu ezingenawo ubushushu obuninzi.

Kunciphisa kakhulu umngcipheko wokugoba nokuqinisekisa ukucoceka kwe-weld ngaphandle kwesidingo sokugqitywa okubanzi emva kwe-weld.

Yinto entle kakhulu, akunjalo?

Ukuthelekisa noMatshini wokuWelda weLaser weMveli

Oomatshini bokutywina abaphathwa ngesandla bangcono kakhulu

Kwiminyaka yakutshanje, amazwe kwihlabathi liphela ebeneemfuno eziphezulu neziphezulu zokukhusela okusingqongileyo.

Ukuwelda kwe-argon arc kuya kuvelisa uthuli oluninzi kunye ne-slag.

Kuyingozi kakhulu kwindalo esingqongileyo.

Iinkampani ezingaphumeleliyo ukuhlangabezana neemfuno zokhuseleko lokusingqongileyo ziya kujongana nokujongwa ngumthetho.

Kwaye ukuwelda okubanjwe ngesandla nge-laser akunabungozi kangako kwindalo esingqongileyo.

Ingasetyenziswa kakhulu kwezinye iindawo ezingaqhelekanga nezintsonkothileyo.

Intshayelelo ye-Argon Arc Welding yendabuko

Iingenelo

1. Ukuwelda kwe-argon arc yendabuko nako kunenzuzo yokuthelekisa. Ixabiso liphantsi, ngokubanzi liqala kumawaka ambalwa ukuya kuma-20,000 ukuya kuma-30,000.

2. Nangona ukucubungula kurhabaxa, amandla anamandla kunezinye. Ifanelekile kwizakhiwo zentsimbi ezithwala umthwalo ezinesantya esicothayo sokuwelda.

Iingxaki

1. Ubukhulu bokuwelda bukhulu kakhulu, bufanelekile kwiipleyiti zokuwelda ezinobukhulu obungaphezulu kwe-4mm.

2. Ukuwelda nge-argon arc kufuna abawelda abavuthiweyo. Kwaye umvuzo wenyanga wabawelda abavuthiweyo uqala ubuncinane kwi-8K.

Intshayelelo yokuWelda ngeLaser ephathwayo

Iingenelo

1. Iseti epheleleyo yezixhobo zokuwelda ze-laser eziphathwayo zinamandla. Zenziwe ngokwe-ergonomic kwaye zifanelekile kwiindawo ezahlukeneyo zokusebenza. Zinomsebenzi wokukhusela ukhuseleko lwe-laser owahlukileyo. Kwaye zinokuqinisekisa ukhuseleko lomqhubi xa esebenza.

2. Olu sebenzi kulula ukulufunda kwaye lukhawuleza ukulusebenzisa. Kwaye umda wobuchwephesha womqhubi awuphezulu, nto leyo egcina iindleko zomsebenzi.

3. Kulula ukufunda ukuwelda ngesandla. Abaqhubi abaqhelekileyo bangaqala ngesiqingatha sosuku. Umvuzo wenyanga womntu oqhelekileyo owelda ngesandla uhlala umalunga ne-4k.

4. Isantya somatshini wokuwelda nge-laser siphindwe ka-10-20. Abasebenzi abaqhelekileyo be-laser banokuwusebenzisa ngokulula, kwaye imeko yokusebenza ikhululekile. Umvuzo womwelda omnye we-argon arc unokuqesha abaqhubi be-laser abathathu.

Khetha uhlobo olwahlukileyo lomatshini wokuwelda we-laser ophathwa ngesandla?

Singakunceda ekwenzeni isigqibo esichanekileyo ngokusekwe kwizicelo

Iingenelo ze-Laser Welders ezibanjwe ngesandla

Kukho iingenelo ezithile zokwenyani zokusebenzisa i-handheld laser welding

Imveliso yokugqibela yokuwelda nge-laser ephathwa ngesandla ayinabala kwaye ayifuni kuhlanjwa okanye kuhlengahlengiswa.

Ukuwelda okubanjwe ngesandla akupheleli nje ekufezekiseni lo mgangatho, kodwa kuyawudlula.

Inkangeleko Ephucukileyo Yobuhle

Abawelda be-laser abaphathwa ngesandla bavelisa iimveliso ezikumgangatho ophezulu wokubonwa.

Umgangatho womqadi ozinzileyo uqinisekisa ukuba imithungo ye-weld iqinile, igudileyo, kwaye inomtsalane, nto leyo enciphisa ukuguquguquka kunye namanxeba e-welding.

Oku kunciphisa isidingo sokupholisha okwesibini, konga ixesha kwaye kunciphisa iindleko zomsebenzi kubavelisi.

Isantya Esiphezulu kunye Nokusebenza Okuphuculweyo Kwemveliso

Ukuwelda nge-laser kukhawuleza kakhulu kuneendlela zemveli, ngesantya esinokufikelela kwizihlandlo ezi-5 ukuya kwezili-10 ngokukhawuleza.

Ukukwazi ukugcina ukungena nzulu kunye nesantya esiphezulu semveliso kwizinto ezahlukeneyo kuphucula imveliso.

Ukusebenza okuqhubekayo kuxhaswa ziinkqubo zokupholisa ezizinikeleyo, ezivumela ukuhamba komsebenzi iiyure ezingama-24

Ukusetyenziswa kobushushu obuphantsi

Inkqubo yokuwelda nge-laser idala indawo encinci echaphazeleka bubushushu, nto leyo enciphisa umonakalo wobushushu kwizinto ezingqongileyo.

Oku kuchaneka kuqinisekisa ukuwelda okucocekileyo kwaye kugcina ukuthembeka kwemveliso, kunciphisa umngcipheko wokugoba.

IiWelds zokucoca

Iiweld zihlala ziphuma zicocekile, zifuna ukucutshungulwa kancinci emva kokuba zisetyenzisiwe.

Kwimizi-mveliso apho ukubonakala kwemveliso yokugqibela kubaluleke njengokuqina kwayo (cinga ngeemoto okanye ngeenqwelo-moya), le yinzuzo enkulu.

Umatshini wokuwelda we-laser ophathwa ngesandla wenza kube lula

inkqubo yemveliso!

I-Handheld Laser Welder Iimeko Zokusebenza Ezisebenzayo

Ukuwelda ngeLaser ephathwa ngesandla, akunazo izinto onokuziqwalasela

Nangona iingenelo zoomatshini bokuwelda nge-laser abaphathwa ngesandla zinkulu kakhulu.

Kukwakho nezinye iindlela zokuzikhusela.

Okokuqala, izixhobo zibiza kakhulu kwaye zifuna ixesha elithile lokufunda ukuzisebenzisa nokuzigcina zisemgangathweni.

Kwakhona, abathengi abaninzi abaceba ukwazisa umatshini wokuwelda we-laser ophathwa ngesandla.

Abo banenkxalabo malunga nokusetyenziswa kwayo kunye nokusebenza kwayo.

Abanye abathengi baye bayisebenzisa ixesha elithile baza bashwankathela umxholo olandelayo.

Oomatshini bokuWelda beLaser abaphathwa ngesandla

Umatshini wokuwelda weLaser ophathwayo ufanelekile kwezi meko zilandelayo zokusebenza:

· Indawo enkulu yokuwelda ifuna ukusebenza kakuhle kokuwelda.

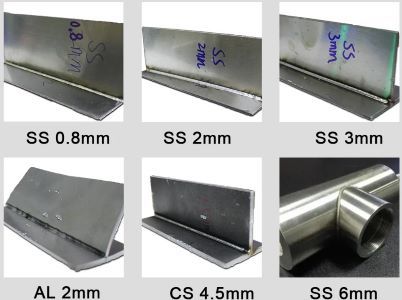

· Ubukhulu bepleyiti bungaphezulu kwe-0.5mm.

· Sombulula ingxaki yobuhle be-weld kunye nokuguqulwa kwayo.

· Yenziwe ngentsimbi engagqwaliyo, ipleyiti yesinyithi, kunye ne-aluminium.

· Kukho indawo ethile yohlahlo-lwabiwo mali.

· Ukusombulula ingxaki yabasebenzi, umthungi we-laser ophathwa ngesandla unokuqalisa ukusebenza ngaphandle kweziseko zokuthungela.

Umatshini wokuWelda weLaser unokuwelda kangakanani?

Okukhona ubukhulu bomsebenzi odibeneyo bubukhulu, kokukhona amandla omatshini wokuwelda we-laser okhethiweyo kufuneka abe makhulu.

1. Umatshini wokuwelda we-laser we-1000W: isiphumo sokuwelda silungile kwiipleyiti ezinobukhulu obungaphantsi kwe-3mm.

2. Umatshini wokuwelda we-laser we-1500W: isiphumo sokuwelda silungile kwiipleyiti ezinobukhulu obungaphantsi kwe-5mm.

3. Umatshini wokuwelda we-laser we-2000W: isiphumo sokuwelda silungile kwiipleyiti ezinobukhulu obungaphantsi kwe-8mm.

Kufuneka wazi: Indlela yokukhetha umatshini we-laser ophathwa ngesandla

Umthamo ophezulu kunye nombane osetyenziswa kwiindlela ezahlukeneyo zokuWelda

Umatshini wokuwelda we-laser ophathwa ngesandla we-2000W ubonakala ngobukhulu bomatshini obuncinci kodwa umgangatho wokuwelda oqaqambileyo.

Umthombo we-laser yefayibha ozinzileyo kunye nentambo yefayibha edibeneyo zibonelela ngokuhanjiswa komqadi we-laser okhuselekileyo nozinzileyo.

Ngamandla aphezulu, isitshixo se-laser welding sigqibelele kwaye sivumela ukuba i-welding joint iqine ngakumbi nakwintsimbi etyebileyo.

Ukuthwaleka ukuze kube lula ukuguquguquka

Njengoko ibukeka incinci kwaye incinci, umatshini wokuwelda welaser ophathwayo uxhotyiswe ngesibhamu sokuwelda selaser esiphathwayo esinokuhanjiswa esikhaphukhaphu kwaye silungele ukusetyenziswa kwe-multi-laser welding kuyo nayiphi na i-engile kunye nomphezulu.

Iindidi ezahlukeneyo zee-nozzles ze-laser welder kunye neenkqubo zokutyisa ngocingo oluzenzekelayo zenza kube lula ukusebenza kwe-laser welding kwaye oko kulungele abaqalayo.

Ukuwelda nge-laser ekhawulezayo kwandisa kakhulu ukusebenza kakuhle kwemveliso yakho kunye nemveliso ngelixa kuvumela isiphumo esihle kakhulu sokuwelda nge-laser.

Izinto Okufuneka Uzazi Ngazo: Ukuwelda Ngelaser Ephathwayo

Ukuba uyithandile le vidiyo, kutheni ungacingi ngayoubhalisela kwiChannel yethu yeYoutube?

Izicelo ezinxulumene noko onokuba nomdla kuzo:

Yonke into oyithengileyo kufuneka inolwazi oluhle

Singakunceda ngolwazi oluneenkcukacha kunye neengcebiso!

Ixesha leposi: Jan-13-2025