Igrisi Yokuhlanza Nge-Laser

Ukuhlanza nge-laser kungasusa amafutha ngempumelelo, ikakhulukazi ezisetshenziswa ezimbonini.

Imishini yokuhlanza i-laser ephathwayo ephathwayo isetshenziswaimisebe ye-laser enamandla aphezuluukuhwamukisa noma ukususa izinto ezingcolisayo

njengokugcoba, ukugqwala, nopende ovela ezindaweni.

Ingabe Ukuhlanza Nge-Laser Kususa Amafutha?

Indlela Esebenza Ngayo Nezinzuzo Zokugcoba Nge-Laser Cleaning

I-laser ikhipha amandla amuncwa amafutha

okubangela ukuthi ishise ngokushesha futhi iphele noma iphele

Ugongolo olugxilile luvumela ukuhlanzwa okunembilengaphandle kokulimazaizinto eziyisisekelo

okwenza ifaneleke ezindaweni ezahlukene.

Ngokungafani nezindlela zokuhlanza zendabuko ezingadinga amakhemikhali

ukuhlanza nge-laser kuvame ukusetshenziswaukukhanya nomoya kuphela, ukunciphisa imfucuza yamakhemikhali.

IzinzuzoUkuhlanza Nge-Laser Ukususa Amafutha

1. Ukusebenza kahle:Ukususwa okusheshayo kwezinto ezingcolisayo ngesikhathi esincane sokungasebenzi.

2. Ukuguquguquka:Isebenza kahle ezintweni ezahlukene, okuhlanganisa izinsimbi, ipulasitiki, kanye nezinto ezihlanganisiwe.

3. Ukungcola Okuncishisiwe:Imfucuza encane yesibili uma iqhathaniswa nemishini yokuhlanza yamakhemikhali.

Yini Engahlanzwa Umshini Wokuhlanza Nge-Laser?

Nasi isifinyezo esijulileyiziphi izinto ezithilele mishini ingakwaziukuhlanza ngempumelelo:

Ukuhlanza Nge-Laser:Izinsimbi

1. Ukugqwala kanye nokuvundisa:

Ama-laser angasusa ngempumelelo ukugqwala ezindaweni zensimbi

ngaphandle kokulimazainsimbi engaphansi.

2. I-Welding Spatter:

Ezindaweni zensimbi, ama-laser angakwaziqeda ukuchitheka kwe-weld,

ukubuyisela ukubukeka nobuqotho bensimbi

ngaphandle kwamakhemikhali ahlabayo.

3. Ukwemboza:

Ama-laser angasusaupende,izembozo zempuphu, kanye nokunyeukwelashwa kobusokusuka ezinsimbini.

Ukuhlanza Nge-Laser:Ukhonkolo

1. Amabala kanye ne-Graffiti:

Ukuhlanza nge-laser kuyasebenza

ukususaimidwebo namabala

kusuka ezindaweni ezikhonkolo.

2. Ukulungiswa Komphezulu:

Ingasetshenziswalungisa izindawo ezikhonkoloukubopha

ngokususa izinto ezingcolisayo

kanye nokulungisa ubuso

ngaphandle kwamathuluzi omshini.

Ukuhlanza Nge-Laser:Itshe

1. Ukuvuselelwa Kwamatshe Emvelo:

Ama-laser angakwazihlanza futhi ubuyisele esimweni sazoizindawo zemvelo zamatshe,

njengemabula negranite,

ngokususa ukungcola, uwoyela, nezinye izinsalela

ngaphandle kokuklwebha ubuso.

2. Ukhula kanye nolwelwe:

Ezindaweni zamatshe zangaphandle,

Ama-laser angasusa kahleukukhula kwezinto eziphilayo

njenge-moss kanye ne-algae

ngaphandle kokusebenzisa amakhemikhali anamandla.

Ukuhlanza Nge-Laser:Ipulasitiki

1. Ukuhlanza Okungaphezulu:

Amapulasitiki athile angahlanzwaizinto ezingcolisayo,uyinki, futhiizinsalelakusetshenziswa ama-laser.

Lokhu kuwusizo kakhulu embonini yezimoto kanye neyokupakisha.

2. Ukususwa Kokumaka:

Ama-laser angasusa futhiizimpawu ezingafunekiezindaweni zepulasitiki,

njengamalebula noma imihuzuko,

ngaphandle kokuthintaubuqotho besakhiwo sezinto.

Ukuhlanza Nge-Laser:Izinkuni

1. Ukwelashwa Okungaphezulu:

Ama-laser angakwazikuhlanzekile

futhi ulungiseleleizindawo zokhuni

ngokususa ukungcola kanye nokuqeda okudala.

Le nqubo ingakwazithuthukisaukubukeka kwezinkuni

ngenkathi kulondolozwa ukuthungwa kwayo.

2. Amamaki Okusha:Ezimweni zomonakalo womlilo,

ithini lokuhlanza le-asersusa ngempumeleloizimpawu zokusha

futhi ubuyisele ukhuni olungaphansi.

Ukuhlanza Nge-Laser:I-Ceramic

1. Ukususwa Kwamabala:

Izinto zobumba zingahlanzwaamabala aqinile

futhiizinsalelangokusebenzisa ama-laser,

okungangena ungqimba olungaphezulu

ngaphandle kokuqhekekanomaokulimazayoi-ceramic.

2. Ukubuyiselwa:

Ama-laser angakwazibuyisela ukukhanya

amathayili e-ceramic kanye nezinto zokwakha

ngokususa ukungcola kanye nokunqwabelana

izindlela zokuhlanza zendabuko ezingase zingatholakali.

Ukuhlanza Nge-Laser:Ingilazi

Ukuhlanza:Ama-laser angasusa ukungcola ezindaweni zengilazi, okuhlanganisaamafutha kanye nezinamathiselongaphandle kokulimaza impahla.

Ufuna Ukwazi NgendlelaIgrisi Yokuhlanza Nge-LaserIyasebenza?

Singasiza!

Izicelo Zokuhlanza Nge-Laser: I-Laser Cleaning Grease

Ku-umkhakha wezimoto

ochwepheshe basebenzisa ama-laser aphathwa ngesandla ukuze basuseukunqwabelana kwamafuthaezingxenyeni zenjini kanye neshasi

ukuthuthukisa izinqubo zokulungisa nokunciphisa isikhathi sokungasebenzi.

Ukukhiqizafuthi izinzuzo,

njengoba abaqhubi bengakwazi ukuhlanza amathuluzi nemishini ngokushesha,

ukuqinisekisa ukusebenza kahle kakhulu nokwandisa isikhathi sokuphila kwemishini ngaphandle kwesidingo sezincibilikisi eziqinile.

Ekucubungulweni kokudla,

ama-laser asetshenziswa ukuzegcina inhlanzekongokususa amafutha

kusuka ezindaweni nasemishinini,ukuqinisekisa ukuthobela imithethonemithethonqubo yezempilo.

Ngokufanayo, izinhlelo zokusebenza zezindiza zibona ama-laser asetshenziswayo

ku-amafutha ahlanzekilekusuka ezingxenyeni eziyinkimbinkimbi, okuthuthukisa ukuphepha nokuthembeka.

Gcoba ngaphakathiUkukhiqiza

Abakhiqizi bavame ukubhekana nenkinga yokuqongelela amafutha ezingxenyeni zemishini eziyinkimbinkimbi.

Ukuhlanzwa kwe-laser okubanjwe ngesandla kuvumela opharetha ukuthi bahlose izindawo ezithile

ngaphandle kokuthinta izingxenye ezizungezile.

Lokhu kunemba kubalulekileukugcina ubuqothoyezindlela ezibucayi

nokuqinisekisaukusebenza okuhle kakhulu.

I-Laser Cleaning Grease ku:Ukukhiqiza

Ama-laser aphathwa ngesandla angasusa amafutha ngokushesha,

kunciphisa kakhuluimishini yesikhathi ayisebenzi.

Lokhu kusebenza kahle kubalulekile ezindaweni ezikhiqiza kakhulu

lapho ukunciphisa isikhathi sokungasebenzi kuthinta ngqo inzuzo.

Ukusebenzisa ama-laser aphathwa ngesandla kunciphisa imfucuza ekhiqizwa yizinqubo zokuhlanza.

Ngokungafani nezindlela zendabuko,

okungaholela ku-ukugeleza kodaka kanye namakhemikhali, ukuhlanzwa nge-laser kukhiqiza insalela encane kakhulu.

Lokhu akugcini njekwenza kube lula ukulahlwa kwemfucuza

kodwa futhikunciphisa izindleko zokuhlanza zizonke.

Gcoba ngaphakathiIzimoto

Izinhlelo zokuhlanza nge-laser eziphathwa ngesandla ziyasebenza

kusebenza kahle kakhuluukususa amafuthakusuka ezingxenyeni zenjini,

njengezinhloko zesilinda kanye nama-crankshaft.

I-Laser Cleaning Grease ku:Izimoto

Ukunemba kwama-laser kuvumela ochwepheshe

ukuhlanza izindawo eziyinkimbinkimbi ngaphandle kokufaka engcupheni umonakalo ezingxenyeni ezibucayi.

Ama-laser aphathwa ngesandla nawo angakwaziqeda ukunqwabelana kwamafuthakuma-caliper nama-rotor amabhuleki,

ukuqinisekisa ukusebenza kahle kokubhuleka.

Lokhu kuhlanza ngokunemba kusiza ukuvimbela ukufiphala kwamabhuleki futhi kugcina ukuthembeka kohlelo lokubhuleka,

okubalulekile ekuphepheni komshayeli.

Gcoba ngaphakathiUkucubungula Ukudla

Izindawo zokucubungula ukudlakumele banamathelengemithetho eqinile yezempilo nokuphepha.

Ukuhlanzwa nge-laser okubanjwe ngesandlakusiza ukuhlangabezana nalezi zindinganisosngokuqinisekisa ukuthi zonke izindawo azinawo amafutha kanye nokungcola.

Ngokusebenzisa ama-laser, abakhiqizi bangakwazibabonise ukuzibophezela kwaboukuhlanzeka nokuthobela imithetho, kunciphisa ingozi yezifo ezibangelwa ukudla.

I-Laser Cleaning Grease ku:Ukucubungula Ukudla

Ukuthembela ezihlanzini zamakhemikhali kungenzabeka izingoziezindaweni zokucubungula ukudla,

kufaka phakathi ukungcola kanye nokukhathazeka nge-allergen.

Ukuhlanzwa nge-laser okubanjwe ngesandlakuqeda isidingongalezi zimakhemikhali,

ukuhlinzeka ngenye indlela ephephile enciphisaingozi yezinsalela zamakhemikhaliezindaweni ezithinta ukudla.

Gcoba ngaphakathiUkwakhiwa

Imishini yokwakha, njengemishini yokumba, ama-bulldozer, nama-crane,

ngokuvamileiqoqa amafutha namafuthakusukela ekusetshenzisweni okuvamile.

Ukuhlanzwa nge-laser okubanjwe ngesandla kuvumela opharetha ukuthisusa kahlelokhu kwakheka,

ukuqinisekisa ukuthi imishiniisebenza kahlefuthiukunciphisa ingoziukwehluleka kwemishini.

Ukunemba kwama-laser kwenza kube lula ukuhlanza okuqondiwe,

ukulondoloza ubuqothoyezingxenye ezibucayi.

I-Laser Cleaning Grease ku:Ukwakhiwa

Ama-laser aphathwa ngesandla alungele ukuhlanza amathuluzi ahlukahlukene kanye nezesekeli ezisetshenziswa ezindaweni zokwakha,

kufaka phakathi amathuluzi kagesi kanye ne-scaffolding.

Ngokusebenza kahleukususa amafutha kanye nokungcola,

Ama-laser asiza ukugcina ukusebenza kwamathuluzi nokwandisa isikhathi sawo sokuphila,

ekugcineni konga izindleko ezihlobene nokulungiswa nokufakwa kwezakhiwo ezintsha.

Gcoba ngaphakathiIzimboni Zamandla

Emisebenzini kawoyela negesi kwamanye amazwe,

imishini kanye nezindawo ezivezwa ezindaweni ezinzima ezingaholelaukunqwabelana okukhulu kwamafutha.

Ama-laser aphathwa ngesandla ayaphatheka futhi angasetshenziswaezimweni ezinzima,

okwenza zibe zilungele ukugcina ukuhlanzeka kwamapulatifomu

kanye nemishiningaphandle kokudinga ukuhlukaniswa okubanzi.

I-Laser Cleaning Grease ku:Izimboni Zamandla

Ama-laser aphathwa ngesandla ayakwazi ukuzivumelanisa nezimoimikhakha eyahlukene yamandla,

kusukela ku-oyela negesi yendabuko

ukufakwa kwamandla avuselelekayo njengeamapulazi omoya kanye nelanga.

Bangakwazi ukuhlanza izingxenye ngempumelelo

njengamaphaneli elanga kanye nezingxenye ze-wind turbine,

ukuqinisekisa ukusebenza kahle kanye nokusebenza kahle okuphezulu.

Ingabe Imishini Yokuhlanza Nge-Laser Iyasebenza Ngempela?

Ingabe imishini yokuhlanza nge-laser iyasebenza ngempela?Impela!

Kuyini Ukuhlanza Nge-Laser Futhi Kusebenza Kanjani?

Ukuhlanza Nge-Laser?

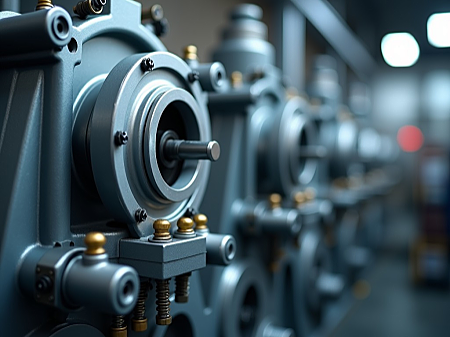

Isihlanzi Se-Laser Esicindezelwe(100W, 200W, 300W, 400W)

Kwabakhiqizi abafuna ukunakekelaamazinga aphezulukweukuhlanzekafuthiikhwalithingenkathi benza ngcono imigqa yabo yokukhiqiza, imishini yokuhlanza nge-laser inikeza ikhambi elinamandla elithuthukisa kokubiliukusebenzafuthiukusimama.

Amandla e-Laser:100-500W

Ukuguqulwa Kobude Be-Pulse:10-350ns

Ubude bekhebula le-Fiber:3-10m

Ubude bamagagasi:1064nm

Umthombo We-Laser:I-Laser Ye-Fiber Eshukunyiswayo

Isihlanzi Se-Laser Esingu-3000W(Ukuhlanzwa Kwe-Laser Yezimboni)

Ukuhlanza ngobuningi kanye nokuhlanza umzimba omkhulu njengepayipi, isikebhe semikhumbi, umkhumbi wezindiza, kanye nezingxenye zezimoto, umshini wokuhlanza i-fiber laser we-3000W ufanelekile kahleisivinini sokuhlanza nge-laser esisheshayofuthiumphumela wokuhlanza ophindaphindwayo kakhulu.

Amandla e-Laser:3000W

Isivinini Esihlanzekile:≤70㎡/ihora

Ikhebula le-Fiber:20M

Ububanzi Bokuskena:10-200nm

Isivinini Sokuskena:0-7000mm/s

Umthombo We-Laser:I-Fiber Yamagagasi Eqhubekayo