Amatafula we-Laser

Amatafula okusebenza we-Laser enzelwe izinto ezilula zondla nokuhambisa ngesikhathi sokusika i-laser, ukuqopha, okukodwa nokumaka. I-Mimowork ihlinzeka ngamatafula e-CNC laser alandelayo ukukhulisa umkhiqizo wakho. Khetha ilungiselelo elilodwa ngokwesidingo sakho, uhlelo lwakho lokusebenza, impahla kanye nemvelo yokusebenza.

Inqubo yokulayisha nokulayisha izinto ezivela etafuleni lokusika le-laser kungaba ngumsebenzi ongasebenzi kahle.

Njengoba kunikezwe itafula elilodwa lokusika, umshini kufanele umise ngokuphelele kuze kube yilapho izinqubo ziphothuliwe. Ngalesi sikhathi esingenzi lutho, uchitha isikhathi nemali eningi. Ukuze uxazulule le nkinga futhi wandise umkhiqizo ophelele, iMimowork incoma itafula le-shuttle ukuqeda isikhathi sokuphumula phakathi kokondla nokusika, ukusekela imali yonke yokusika ye-laser.

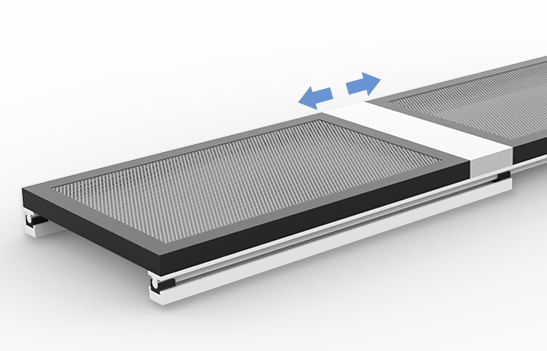

Itafula le-shuttle, elibizwa nangokuthi i-Pallet Changer, ihlelwe nge-DISTION-NGOKUQHAWULA KOKUPHAKATHI ukuze uhambise ngezindlela ezimbili ezisetshenziswayo. Ukwenza lula ukulayisha nokulayishwa kwezinto ezinganciphisa noma ukuqeda isikhathi sokuphumula futhi sahlangabezana nokusika kwakho, sakha osayizi abahlukahlukene ukuze bavumelane nawo wonke usayizi owodwa we-Mimowr Laser Cutting Machines.

Izici eziyinhloko:

Ilungele izinto eziguqukayo neziqinile

| Izinzuzo zamatafula we-shuttle | Okubi kwamatafula okudlula adlula |

| Yonke indawo yokusebenza ihlelwe ekuphakameni okufanayo, ngakho-ke akukho ukulungiswa okudingekayo e-z-axis | Ngeza esinyathelweni sohlelo lwe-Laser oluphelele ngenxa yesikhala esengeziwe esidingekayo ezinhlangothini zombili zomshini |

| Isakhiwo esizinzile, esihlala isikhathi eside futhi esithembekile, amaphutha ambalwa kunamanye amatafula ashubile | |

| Ukukhiqiza okufanayo ngentengo efinyelelekayo | |

| Ukuthutha okuqinile futhi okuzenzakalelayo okuhambisanayo | |

| Ukulayisha nokucutshungulwa kungenziwa ngasikhathi sinye |

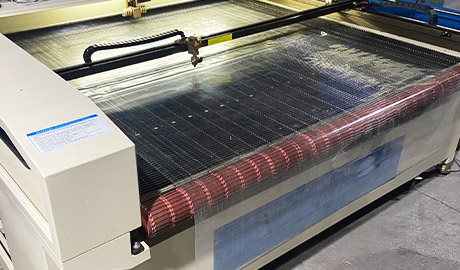

Ithebula le-conveyor lomshini wokusika we-laser

Ithebula lokuhambisa lenziwaI-Web engenasiciokulungeleIzinto ezithambile neziguquguqukayo ezifanaulwembu, into ephothiweyo yaba yingubona-isikhumba esishukiweyo. Ngohlelo lokuhambisa, ukusikwa kwe-laser okuhlala njalo sekuzenzeke. Ukusebenza kahle kwezinhlelo ze-Mimowor Laser kungandiswa ngokwengeziwe.

Izici eziyinhloko:

• Akukho ukwelula izindwangu

• Ukulawulwa kokusebenza okuzenzakalelayo

• osayizi abenziwe ngokwezifiso ukuze bahlangabezane nazo zonke izidingo, sekela ifomethi enkulu

Izinzuzo zoHlelo lweThebula lweTongerOr:

• Ukuncishiswa kwezindleko

Ngosizo lohlelo lokuhambisa, ukusika okuzenzakalelayo nokuqhubekayo ngcono kakhulu ukukhiqizwa kokukhiqiza. Lapho, kudliwa isikhathi nesikhathi esincane kanye nabezokwakha, kunciphisa izindleko zokukhiqiza.

• Ukukhiqiza okuphezulu

Ukukhiqizwa komuntu kukhawulelwe, ngakho-ke kwethula ithebula lokuhambisa esikhundleni salokho liyisilinganiso esilandelayo kuwe ekwandiseni ukukhiqizwa kwemiqulu. Ifaniswe neauto-feder, Ithebula le-Mimowork Conveyor livumela ukondla nokusika uxhumano olungenamthungo kanye ne-automation ukuze kusebenze kahle.

• ukunemba nokuphindaphinda

Njengoba isici sokuhluleka esisezingeni eliphakeme ekukhiqizeni futhi siyinto yomuntu - esikhundleni somsebenzi owenziwe nge-automate ane-automated ngethebula le-conveyor lizonikeza imiphumela ethe xaxa.

• Ukwanda kokuphepha

Ukuze wakhe indawo ephephile yokusebenza, ithebula lokuhambisa linweba isikhala esisebenza ngqo esingaboni ngaso linye noma ukuqapha ngokuphelele.

I-Honeycomb Beser Bed yomshini we-laser

Ithebula elisebenzayo liqanjwe ngenhlamvu yalo efana nejuba lezinyosi. Kwenzelwe ukuhambisana nawo wonke usayizi wemishini yokusika ye-Mimowrk Laser.Inyosi yokusika i-laser nokuqoshwa kuyatholakala.

I-Aluminium Foil ivumela ugongolo lwe-laser ukuthi ludlule ngokuhlanzeka ngokusebenzisa izinto ozicubungula futhi zehlise ukuboniswa ngaphansi kokuvutha kabusha kusuka emuva kwezinto ezibonakalayo futhi zivikele kakhulu i-laser ikhanda ekulileleni.

Umbhede we-laser honeycomb uvumela ukungena ngaphakathi komoya omncane wokushisa, uthuli nomusi ngesikhathi senqubo yokusika ye-laser.

Izici eziyinhloko:

• Ilungele izinhlelo zokusebenza ezidinga ukucatshangelwa emuva kwe-Back Reflections kanye neflethi elihle

• Ithebula eliqinile lokusebenza eliqinile, eliqinile futhi eliqinile lezinyosi lingasekela izinto ezisindayo

• Umzimba wensimbi osezingeni eliphakeme kukusiza ukulungisa izinto zakho ngoMagnets

Itafula le-Knife Strip lomshini wokusika we-laser

Itafula le-Knife Strip, elibizwa nangokuthi i-Aluminium Slat Cutting Table yakhelwe ukusekela izinto ezibonakalayo futhi zilondoloze indawo eyisicaba. Leli tafula le-laser cutter lilungele ukusika izinto ezinkulu (8 mm ubukhulu) kanye nezingxenye ezibanzi kune-100 mm.

Ngokuyinhloko ukusika ngokusebenzisa izinto ezikhudlwana lapho ungathanda ukugwema khona i-laser bounce emuva. Imigoqo emile nayo ivumela ukugeleza okuphuma phambili ngenkathi usika. Ama-Lamellas angafakwa ngawodwana, ngenxa yalokho, itafula le-laser lingashintshwa ngokuya ngohlelo lokusebenza ngalunye.

Izici eziyinhloko:

• Ukucushwa okulula, okunhlobonhlobo kwezicelo, ukusebenza okulula

• Ilungele ama-laser cut substrates njenge-acrylic, izinkuni, ipulasitiki, nezinto eziqinile eziqinile

Noma yimiphi imibuzo mayelana nosayizi wombhede we-laser cutter, izinto zokwenziwa ngamatafula we-laser nabanye

Silapha kuwe!

Amanye amatafula we-laser ajwayelekile wokusika kwe-laser nokuqoshwa

Ithebula le-Laser Vacuum

Ithebula le-laser cutter vacuum lilungisa izinto ezahlukahlukene etafuleni elisebenzayo zisebenzisa i-vacuum ekhanyayo. Lokhu kuqinisekisa ukugxila okulungile ngaphezulu kobuso bonke futhi ngenxa yalokho imiphumela evelele evelayo kuqinisekisiwe. Ihlanganiswe ne-fan eqeda amandla, ukusakazwa komoya kokumunca kungasusa izinsalela kanye nesiqephu kusuka ezintweni ezingaguquki. Ngaphezu kwalokho, kunciphisa umzamo wokuphatha okuhambisana nokufakwa kwemishini.

Ithebula le-vacuum yitafula elifanele lezinto zokwakha ezincanyana nezingasindi, ezinjengephepha, ama-foil, namafilimu ngokuvamile awafaki phansi ebusweni.

Ithebula le-ferromagnetic

Ukwakhiwa kwe-ferromagnetic kuvumela ukukhuphuka kwezinto ezincanyana ezifana nephepha, amafilimu noma ama-foil anama-magnets ukuqinisekisa indawo futhi eyisicaba. Ngisho nokusebenza kubalulekile ekufezekiseni imiphumela efanelekile yokubhangqeka kwama-laser nokumaka.

Itafula legridi yokusika ye-acrylic

Kubandakanya itafula lokusika le-laser ngegridi, igridi ekhethekile ye-laser Engraverver ivimbela ukuboniswa emuva. Ngakho-ke ilungele ukusika i-acrylics, ama-laminates, noma amafilimu epulasitiki anezingxenye ezincane kune-100 mm, ngoba lokhu kuhlala endaweni eyisicaba ngemuva kokusikwa.

Itafula lokusika le-acrylic slar

Itafula le-laser slats elinama-acrylic lamellas livimbela ukuboniswa ngesikhathi sokusika. Leli thebula lisetshenziselwa ikakhulukazi ukusika izinto ezinkulu (8 mm ubukhulu) kanye nezingxenye ezibanzi kune-100 mm. Inani lamaphoyinti okusekelayo lingancishiswa ngokususa amanye ama-lamellas ngawodwana, ngokuya ngomsebenzi.

Ukufundiswa Okungezelelwa

UMimowork uphakamisa ⇨

Ukubona umoya omncane kanye nokungcola okuqediwe, phansi noma uhlangothiI-Blower Efterzifakwe ukwenza igesi, i-fume kanye nokusalela kudlule etafuleni elisebenzayo, ukuvikela izinto ezivela konakele. Ngezinhlobo ezahlukene zomshini we-laser, ukucushwa kanye nomhlangano weIthebula Lokusebenza, I-Ventilation divayisina-I-Feume Extractorahlukile. Isiphakamiso se-laser sezazi sizokunikeza isiqinisekiso esithembekile ekukhiqizeni. I-Mimowork ilapha ukulindelela umbuzo wakho!