Ukuhlanzwa Kokushiswa Nge-Laser

Ukuhlanza Ukushiswa Kwe-Laser kuyindlela esetshenziswa ukususa ukungcola, ama-oxide, nezinye izinto ezingafuneki ebusweni be-WeldNgaphambi emvakwaInqubo Yokushisela Isiqediwe. Lokhu Kuhlanzwa Kuyisinyathelo Esibalulekile Ezicelweni Eziningi Zezimboni Nezokukhiqiza ukuzeQinisekisa Ubuqotho Nokubukekawe-Welded Joint.

Ukuhlanzwa Kwensimbi Nge-Laser

Ngesikhathi senqubo yokushisela, ukungcola okuhlukahlukene kanye nemikhiqizo elandelanayo kungafakwa ebusweni bokushisela, njengokuthiukuchitheka, ukuchitheka, kanye nokushintsha kombala.

Uma zishiywe zingahlanzekile, lezi zingakwazikuthinta kabi amandla okushisela, ukumelana nokugqwala, kanye nobuhle bokubuka.

Ukuhlanza i-laser weld kusebenzisa umsebe we-laser onamandla aphezulu ukuze kushiswe futhi kususwe lawa ma-deposit angathandeki ebusweni.ngaphandle kokulimazainsimbi engaphansi.

Izinzuzo Zokuhlanza Nge-Laser Weld

1. Ukunemba- I-laser ingaqondiswa ngqo ukuhlanza indawo yokushisela kuphela ngaphandle kokuthinta izinto ezizungezile.

2. Isivinini- Ukuhlanza nge-laser kuyinqubo esheshayo, ezenzakalelayo engahlanza ama-weld ngokushesha kakhulu kunamasu enziwe ngesandla.

3. Ukungaguquguquki- Ukuhlanza nge-laser kuveza umphumela ofanayo, ophindaphindwayo, okuqinisekisa ukuthi wonke ama-weld ahlanzwa ngezinga elifanayo eliphezulu.

4. Azikho Izinto Ezisetshenziswayo- Ukuhlanza nge-laser akudingi izinto zokukhuhla noma amakhemikhali, okunciphisa izindleko zokusebenza kanye nokuchitha.

Izicelo: Ukuhlanza i-Laser Weld

Ukuhlanza Amapuleti Ensimbi Anamandla Aphezulu Ane-Alloy Low-Alloy (HSLA) Ukushintshwa Kwe-Laser Weld

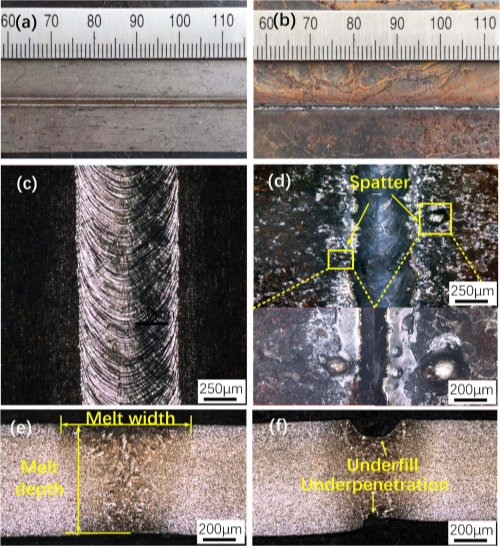

Ukubukeka Kokushintshwa Kokuhlanzwa Kwe-Laser (a, c, e) kanye Nokungahlanzwa Kokuhlanzwa Kwe-Laser (b, d, f)

Imigomo efanele yenqubo yokuhlanza nge-laser ingakwazisusaukugqwala kanye namafutha avela ebusweni bezinto zokusebenza.

Ukungena okuphezulukwabonakala kumasampula ahlanziwe uma kuqhathaniswa nalawo angahlanzwanga.

Ukwelashwa kwangaphambi kokuhlanza nge-laser kuyasiza ngempumelelogwemaukuvela kwama-pores kanye nemifantu ku-weld kanyekuyathuthukaikhwalithi yokwakheka kwe-weld.

Ukuhlanza i-Laser Weld ngaphambi kokwelashwa kunciphisa amaphutha amaningi njengemifantu kanye nemifantu ngaphakathi kwe-weld, ngaleyo ndlelaukuthuthukisaizakhiwo zokuthamba ze-weld.

Amandla okuthamba ajwayelekile esampula ngokuhlanza nge-laser ngaphambi kokwelashwa angama-510 MPa, okuyi-Phezulu ngo-30%kunalokho ngaphandle kokwelashwa kwangaphambi kokuhlanza nge-laser.

Ukunwebeka kwejoyinti yokuwelda ehlanzwe nge-laser kungu-36% okuyi-izikhathi ezingu-3lokho kwejoyinti lokushisela elingahlanzekile (12%).

Buka Iphepha Lokucwaninga Lokuqala Ngesango Locwaningo Lapha.

Ukuhlanza Ukushintshwa Kwe-Laser Weld kwe-Aluminium Yezentengiselwano 5A06

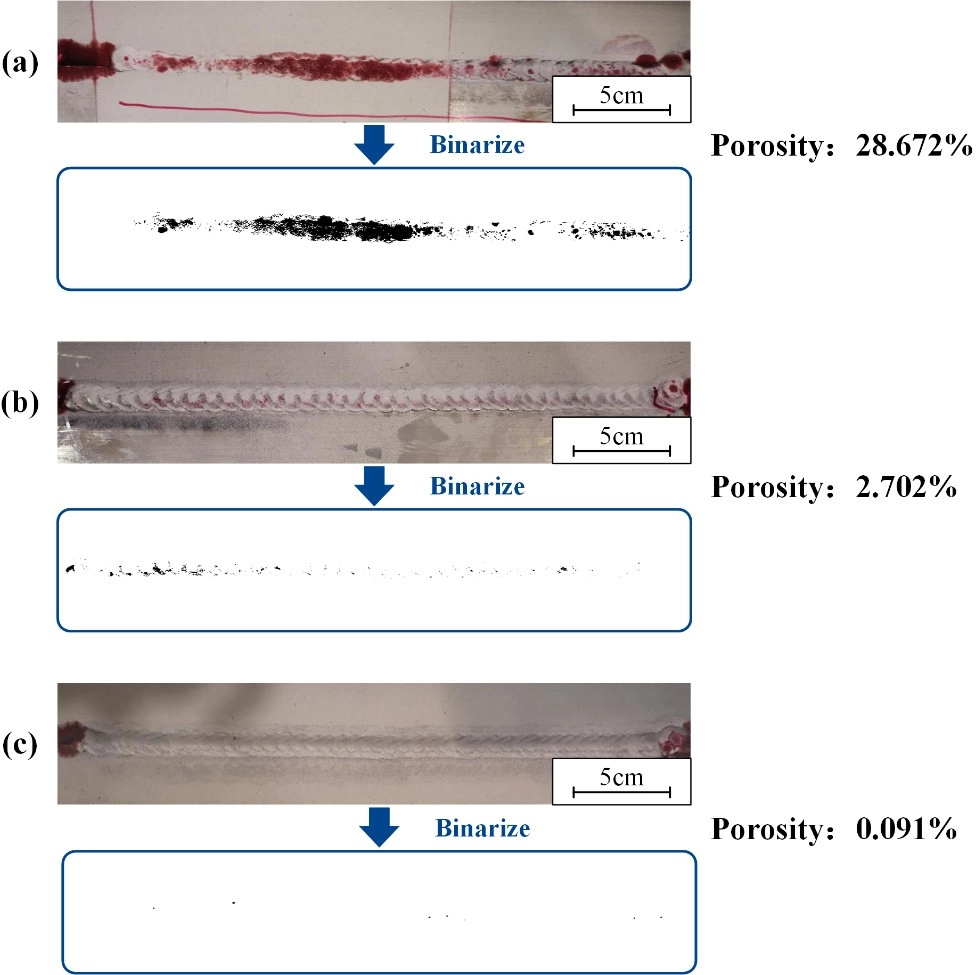

Umphumela Wokuhlolwa Kokugcwala kanye Nokugoba Kwesampula Nge: (a) Uwoyela; (b) Amanzi; (c) Ukuhlanza Nge-Laser.

Ubukhulu bengqimba ye-aluminium alloy 5A06 oxide buyi-1–2 lm, futhi ukuhlanza nge-laser kubonisaumphumela othembisayoekususweni kwe-oxide yokushisela i-TIG.

Kutholakale i-Porosityendaweni yokuhlanganiswa kwama-weld e-TIGngemuva komhlaba ojwayelekile, kanye nokufakwa okunesimo esibukhali nakho kwahlolwa.

Ngemva kokuhlanza nge-laser,akukho ukuvuleka okwakukhonaendaweni yokuhlangana.

Ngaphezu kwalokho, okuqukethwe yi-oxygenkwehle kakhulu, okuvumelana nemiphumela yangaphambilini.

Ngaphezu kwalokho, ungqimba oluncane lokuncibilika kokushisa lwenzeka ngesikhathi sokuhlanza nge-laser, okwaholelaisakhiwo esincane esicwengisisiweendaweni yokuhlangana.

Buka Iphepha Lokucwaninga Lokuqala Ngesango Locwaningo Lapha.

Noma Hlola Lesi Sihloko Esisishicilele Ku:I-Aluminium Yokuhlanza Nge-Laser (Indlela Abacwaningi Abakwenze Ngayo)

Ufuna Ukwazi Ngokuhlanzwa Kwe-Laser Weld?

Singasiza!

Yini Engingayisebenzisa Ukuhlanza Ama-Weld Ami?

Ukuhlanza Ukushintshwa Kwezinto ZokushiselaIzibopho EziqinilefuthiUkuvimbela Ukugqwala

Nazi EzinyeIzindlela ZendabukoUkuhlanza Ama-Weld:

Incazelo:Sebenzisa ibhulashi noma isondo lensimbi ukususa i-slag, i-spatter, kanye nama-oxide.

Izinzuzo:Ayibizi futhi iyasebenza ekuhlanzeni indawo.

Ububi:Kungaba nzima kakhulu futhi kungase kungafinyeleli ezindaweni eziqinile.

Incazelo:Sebenzisa umshini wokugaya ukuze ulungise ama-weld bese ususa amaphutha.

Izinzuzo:Isebenza kahle ekuhlanzeni nasekubumbeni okunzima.

Ububi:Ingashintsha iphrofayili yokushisela futhi ingase ilethe ukushisa.

Incazelo:Sebenzisa izixazululo noma izinyibilikisi ezisekelwe ku-asidi ukuze uncibilikise ukungcola.

Izinzuzo:Isebenza kahle ezinsaleleni eziqinile futhi ingasetshenziswa ezinhlotsheni ezahlukene zokusebenza.

Ububi:Kudinga izinyathelo zokuphepha kanye nokulahlwa okufanele.

Incazelo:Shayela izinto ezihudulayo ngesivinini esikhulu ukuze ususe ukungcola.

Izinzuzo:Kuyashesha futhi kusebenza kahle ezindaweni ezinkulu.

Ububi:Kungabangela ukuguguleka komhlabathi uma kungalawulwa.

Incazelo:Sebenzisa amaza omsindo avame kakhulu esixazululweni sokuhlanza ukuze ususe udoti.

Izinzuzo:Ifinyelela ezimweni eziyinkimbinkimbi futhi isusa ukungcola ngokuphelele.

Ububi:Imishini ingabiza kakhulu futhi usayizi wokuhlanza ungancishiswa.

NgobaUkususwa Kwe-Laser & Ukulungiselela Ubuso Be-Laser:

Ukususwa Kwe-Laser

Incazelo:Sebenzisa imisebe ye-laser enamandla aphezulu ukuze ushise ukungcola ngaphandle kokuthinta izinto eziyisisekelo.

Izinzuzo:Inembile, inobungani nemvelo, futhi isebenza kahle ekusetshenzisweni okubucayi.

Ububi:Imishini ingabiza kakhulu, futhi idinga ukusetshenziswa ngobuchwepheshe.

Ukulungiselela Ubuso Be-Laser

Incazelo:Sebenzisa ama-laser ukulungisa izindawo ngokususa ama-oxide kanye nokungcola ngaphambi kokushisela.

Izinzuzo:Kuthuthukisa ikhwalithi yokushisela futhi kunciphisa amaphutha.

Ububi:Imishini nayo ingabiza kakhulu, futhi idinga ukusetshenziswa ngobuchwepheshe.

Indlela Yokuhlanza Insimbi Nge-Laser?

Ukuhlanza nge-Laser kuyindlela ephumelelayo yokususa izinto ezingcolisayo

Gqoka i-PPE efanele, okuhlanganisa izibuko zokuphepha, amagilavu, kanye nezingubo zokuzivikela.

Vikela ingxenye yensimbi endaweni eqinile ukuze uvimbele ukunyakaza ngesikhathi sokuhlanza. Lungisa ikhanda le-laser libe yibanga elinconywayo ukusuka ebusweni, ngokuvamile phakathi10-30 mm.

Qapha njalo inqubo yokuhlanzaBheka izinguquko ebusweni, njengokususwa kwezinto ezingcolisayo noma yimuphi umonakalo ensimbini.

Ngemva kokuhlanza, hlola indawo yokushisela ukuze ubone ukuthi ihlanzekile yini kanye nanoma yiziphi ezinye izinto ezingcolisayo ezisele. Kuye ngokuthi isetshenziswa kanjani, cabanga ngalokhoukusebenzisa isembozo esivikelayoukuvimbela ukugqwala kwesikhathi esizayo.

Yiliphi ithuluzi elingcono kakhulu lokuhlanza ama-Welds?

Ukuhlanza Nge-Laser Kuvelele Njengenye Yamathuluzi Angcono Kakhulu Atholakalayo

Kunoma ubani ohilelekile ekwakhiweni noma ekulungisweni kwensimbi, ukuhlanza nge-laser kuyasebenza.ithuluzi eliyigugu lokuhlanza ama-weld.

Ukunemba kwayo, ukusebenza kahle kwayo, kanye nezinzuzo zemvelo kwenza kube ukukhetha okuhle kakhuluukufeza imiphumela esezingeni eliphezulungenkathi kunciphisa izingozi kanye nesikhathi sokungasebenzi.

Uma ufuna ukuthuthukisa izinqubo zakho zokuhlanza, cabanga ngokutshala imali kubuchwepheshe bokuhlanza nge-laser.

Uwenza Kanjani Ama-Welds Abukeke Ehlanzekile?

Ukuhlanzwa Nge-Laser Kusiza Ukufeza Ukushintshwa Okuhlanzekile Nokubukeka Kobungcweti

Ukulungiswa Komphezulu

Ukuhlanza Kokuqala:Ngaphambi kokushisela, qiniseka ukuthi insimbi eyisisekelo ayinazo izinto ezingcolisayo njengokugqwala, uwoyela kanye nokungcola. Lesi sinyathelo siyasebenza.kubalulekile ekufezeni ukushintshwa okuhlanzekile.

Ukuhlanza Nge-Laser:Sebenzisa uhlelo lokuhlanza nge-laser ukuze ususe ngempumelelo noma yikuphi ukungcola okungaphezulu. Indlela eqondiwe iqinisekisa ukuthi kususwa ukungcola kuphelangaphandle kokulimaza insimbi.

Ukuhlanzwa Ngemva Kokushiswa

Ukuhlanzwa Ngemva Kokushiselwa:Ngemva kokushisela, hlanza ngokushesha indawo yokushisela nge-laser ukuze ususe i-slag, i-spatter, kanye ne-oxidation engaphazamisa ukubukeka kwe-weld.

Ukungaguquguquki:Inqubo yokuhlanza nge-laser inikeza imiphumela efanayo, iqinisekisa ukuthi wonke ama-welds anokuphela okuhlanzekile nokuqhubekayo.

Imiboniso Yevidiyo: Ukuhlanza Nge-Laser Kwensimbi

Kuyini Ukuhlanza Nge-Laser Futhi Kusebenza Kanjani?

Enye yezinzuzo ezinkulu zokuhlanza nge-laser ukuthiinqubo eyomile.

Okusho ukuthi asikho isidingo sokuhlanza udoti ngemva kokuhlanza.

Mane nje uqondise umsebe we-laser endaweni ofuna ukuyihlanzangaphandle kokuthinta izinto ezingaphansi.

Izihlanzi ze-laser nazoincane futhi iyaphatheka, okuvumelaukuze kuhlanzwe kahle endaweni.

Ngokuvamile kudingaimishini yokuzivikela eyisisekelo kuphela, njengezibuko zokuphepha kanye nemishini yokuphefumula.

Ukususwa kwe-Laser Kungcono Ekuhlanzeni Ukugqwala

Ukuqhumisa isihlabathi kungadalauthuli oluningi futhi kudinga ukuhlanzwa okukhulu.

Ukuhlanza iqhwa okomile kuyintookungabiza kakhulu futhi okungafaneleki kakhulu emisebenzini emikhulu.

Ukuhlanza ngamakhemikhali kungahlekuhilela izinto eziyingozi kanye nezinkinga zokulahlwa kwazo.

Ngokungqubuzanayo,Ukuhlanza nge-laser kuvela njengenketho evelele.

Iguquguquka kakhulu, iphatha uhla lwezinto ezingcolisayo ngokunemba

Le nqubo iyonga imali ngokuhamba kwesikhathi ngenxanoukusetshenziswa kwezinto ezibonakalayo kanye nezidingo zokunakekelwa okuphansi.

Umshini Wokuhlanza I-Laser Ophathwa Ngesandla: Ukuhlanza I-Laser Weld

Isihlanzi Se-Laser Esicindezelwe(100W, 200W, 300W, 400W)

Izihlanzi ze-laser ezine-fiber ezivuvukile zilungele kakhulu ukuhlanzauthambile,ukuzwelanomausengozini yokushisaizindawo, lapho uhlobo oluqondile nolulawulwayo lwe-laser eshayayo lubalulekile ekuhlanzeni okuphumelelayo nokungenamonakalo.

Amandla e-Laser:100-500W

Ukuguqulwa Kobude Be-Pulse:10-350ns

Ubude bekhebula le-Fiber:3-10m

Ubude bamagagasi:1064nm

Umthombo We-Laser:I-Laser Ye-Fiber Eshukunyiswayo

Umshini Wokususa Ukugqwala Nge-Laser(Ukuhlanzwa Kwe-Laser Ngaphambi Nangemva Kokushiswa)

Ukuhlanza nge-laser weld kusetshenziswa kabanzi ezimbonini ezifanaizindiza,izimoto,ukwakha imikhumbi, futhiukukhiqizwa kwezinto zikagesikuphiukushintshwa kwekhwalithi ephezulu, okungenasicizibalulekile ekuphepheni, ekusebenzeni kahle, nasekubukekeni.

Amandla e-Laser:100-3000W

Imvamisa Yokushaya Kwe-Laser Elungisekayo:Kufika ku-1000KHz

Ubude bekhebula le-Fiber:3-20m

Ubude bamagagasi:1064nm, 1070nm

UsekeloOkuhlukahlukeneIzilimi