Uma kukhulunywa ngokusika nokuqopha i-acrylic, ama-router e-CNC nama-laser avame ukuqhathaniswa. Yikuphi okungcono? Iqiniso liwukuthi, ahlukile kodwa ayaphelelisana ngokudlala izindima ezihlukile emikhakheni ehlukene. Yimiphi le mehluko? Futhi kufanele ukhethe kanjani? Funda kabanzi ngalesi sihloko bese usitshela impendulo yakho.

Isebenza Kanjani? Ukusika kwe-CNC Acrylic

I-CNC router iyithuluzi lokusika lendabuko nelisetshenziswa kabanzi. Izinhlobo ezahlukene zama-bits zingaphatha ukusika nokuqopha i-acrylic ekujuleni nasekuqondeni okuhlukile. Ama-CNC routers angasika amashidi e-acrylic afinyelela ku-50mm ubukhulu, okuyinto enhle kakhulu ezincwadini zokukhangisa kanye nezimpawu ze-3D. Kodwa-ke, i-CNC-cut acrylic idinga ukupholishwa ngemva kwalokho. Njengoba omunye uchwepheshe we-CNC eshilo, 'Umzuzu owodwa wokusika, imizuzu eyisithupha yokupholishwa.' Lokhu kuthatha isikhathi. Ngaphezu kwalokho, ukufaka ama-bits esikhundleni nokubeka amapharamitha ahlukahlukene njenge-RPM, i-IPM, kanye nesilinganiso sokudla kukhulisa izindleko zokufunda nezabasebenzi. Ingxenye embi kakhulu uthuli kanye nemfucumfucu yonke indawo, okungaba yingozi uma kuphefumulwa.

Ngokuphambene nalokho, i-acrylic yokusika nge-laser ihlanzekile futhi iphephile.

Isebenza Kanjani? Ukusika Nge-Laser Acrylic

Ngaphandle kokusika okuhlanzekile nendawo yokusebenza ephephile, abasiki be-laser banikeza ukunemba okuphezulu kokusika nokuqopha ngomqamelo omncane njengo-0.3mm, i-CNC engenakukwazi ukuwufanisa. Akukho ukupholisha noma ukushintsha kancane okudingekayo, futhi ngokuhlanza okuncane, ukusika nge-laser kuthatha kuphela i-1/3 yesikhathi sokugaya i-CNC. Kodwa-ke, ukusika nge-laser kunemikhawulo yobukhulu. Ngokuvamile, sincoma ukusika i-acrylic ngaphakathi kwama-20mm ukuze kufinyelelwe ikhwalithi engcono kakhulu.

Ngakho-ke, ubani okufanele akhethe umshini wokusika nge-laser? Futhi ubani okufanele akhethe i-CNC?

Ubani Okufanele Akhethe I-CNC Router?

• I-Mechanics Geek

Uma unolwazi kwezobunjiniyela bemishini futhi ungakwazi ukusingatha amapharamitha ayinkimbinkimbi njenge-RPM, izinga lokuphakelwa, ama-flute, kanye nokwakheka kwe-tip (ukugqwayiza kwe-CNC router okuzungezwe amagama obuchwepheshe anokubukeka 'okuthosiwe engqondweni'), i-CNC router iyisinqumo esihle.

• Ukusika Izinto Ezijiyile

Ilungele ukusika i-acrylic ejiyile, engaphezu kuka-20mm, okwenza ifaneleke kakhulu ezinhlamvini ze-3D noma amaphaneli e-aquarium ajiyile.

• Kokuqopha Okujulile

I-CNC router iyazigqaja ngemisebenzi yokuqopha ejulile, njengokuqopha izitembu, ngenxa yokugaya kwayo okunamandla kwemishini.

Ubani Okufanele Akhethe I-Laser Router?

• Ngemisebenzi Eqondile

Kuhle kakhulu emisebenzini edinga ukunemba okuphezulu. Kumabhodi e-acrylic die, izingxenye zezokwelapha, amadeshibhodi ezimoto nezindiza, kanye ne-LGP, umsiki we-laser ungafinyelela ukunemba okungu-0.3mm.

• Kudingeka Ukucaca Okuphezulu

Kumaphrojekthi ecacile e-acrylic afana nama-lightbox, amaphaneli okubonisa e-LED, namadeshibhodi, ama-laser aqinisekisa ukucaca okungenakuqhathaniswa kanye nokucaca.

• Qalisa

Kumabhizinisi agxile ezintweni ezincane, ezinenani eliphezulu njengobucwebe, izingcezu zobuciko, noma izindebe, umshini wokusika nge-laser unikeza ubulula kanye nokuguquguquka kokwenza ngokwezifiso, okudala imininingwane ecebile nenhle.

Kunemishini emibili yokusika nge-laser ejwayelekile ongayenza: Abaqophi be-laser abancane be-acrylic (bokusika nokuqopha) kanye nemishini yokusika i-laser yeshidi le-acrylic enkulu (engasika i-acrylic ejiyile efika ku-20mm).

1. Umsiki we-Laser Omncane we-Acrylic kanye ne-Engaraver

• Indawo Yokusebenza (W * L): 1300mm * 900mm (51.2” * 35.4”)

• Amandla e-Laser: 100W/150W/300W

• Umthombo we-Laser: I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube

• Isivinini Esiphezulu Sokusika: 400mm/s

• Isivinini Esiphezulu Sokuqopha: 2000mm/s

Iumsiki we-laser oyisicaba 130ilungele ukusika nokuqopha izinto ezincane, njenge-keychain, imihlobiso. Kulula ukuyisebenzisa futhi ilungele ukwakheka okuyinkimbinkimbi.

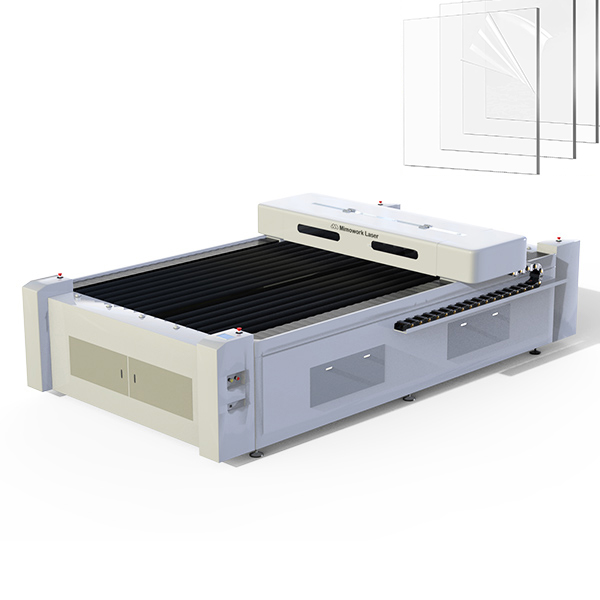

2. Umsiki Omkhulu We-Laser Weshidi Le-Acrylic

• Indawo Yokusebenza (W * L): 1300mm * 2500mm (51” * 98.4”)

• Amandla e-Laser: 150W/300W/450W

• Umthombo we-Laser: I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube

• Isivinini Esiphezulu Sokusika: 600mm/s

• Ukunemba Kwesikhundla: ≤±0.05mm

Iumsiki we-laser oyisicaba ongu-130Lilungele ishidi le-acrylic elikhulu noma i-acrylic ejiyile. Inhle ekuphatheni izimpawu zokukhangisa, ukubonisa. Usayizi omkhulu wokusebenza, kodwa ukusika okuhlanzekile nokunembile.

Uma unezidingo ezikhethekile njengokuqopha ezintweni ezisilinda, ama-sprue okusika, noma izingxenye ezikhethekile zezimoto,xhumana nathiukuze uthole iseluleko sochwepheshe nge-laser. Silapha ukuzokusiza!

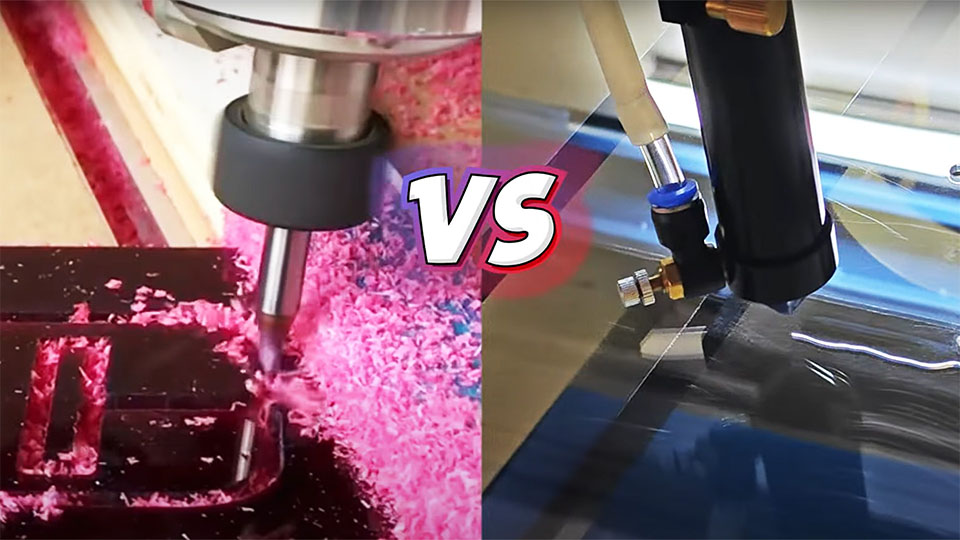

Incazelo Yevidiyo: I-CNC Router VS Laser Cutter

Ngamafuphi, ama-router e-CNC angaphatha i-acrylic ejiyile, kufika ku-50mm, futhi anikeze ukuguquguquka ngama-bits ahlukene kodwa adinga ukupholisha ngemva kokusikwa futhi akhiqize uthuli. Izicucu ze-laser zinikeza ukusika okuhlanzekile nokunembe kakhulu, asikho isidingo sokushintsha ithuluzi, futhi akukho ukuguguleka kwamathuluzi. Kodwa, uma udinga ukusika i-acrylic ejiyile kuno-25mm, ama-laser ngeke akusize.

Ngakho-ke, i-CNC Vs. Laser, iyiphi engcono kakhulu ekukhiqizeni kwakho i-acrylic? Yabelana nathi ngemibono yakho!

1. Uyini umehluko phakathi kokusika kwe-acrylic ye-CNC nokusika nge-laser?

Ama-router e-CNC asebenzisa ithuluzi lokusika elijikelezayo ukuze asuse izinto ezibonakalayo, ezifanele i-acrylic ejiyile (kufika ku-50mm) kodwa ngokuvamile zidinga ukupholishwa. Abasiki be-laser basebenzisa umsebe we-laser ukuncibilikisa noma ukufudumeza izinto, okunikeza ukunemba okuphezulu kanye nemiphetho ehlanzekile ngaphandle kwesidingo sokupholishwa, okungcono kakhulu i-acrylic encane (kufika ku-20-25mm).

2. Ingabe ukusika nge-laser kungcono kune-CNC?

Izicucu ze-laser kanye nama-router e-CNC asebenza kahle ezindaweni ezahlukene. Izicucu ze-laser zinikeza ukunemba okuphezulu kanye nokusika okuhlanzekile, okulungele imiklamo eyinkimbinkimbi kanye nemininingwane emincane. Ama-router e-CNC angaphatha izinto ezijiyile futhi angcono kumaphrojekthi okuqopha okujulile kanye ne-3D. Ukukhetha kwakho kuncike ezidingweni zakho ezithile.

3. Kusho ukuthini i-CNC ekusikeni nge-laser?

Ekusikeni nge-laser, i-CNC imele "Ukulawula Izinombolo Zekhompyutha." Ibhekisela ekulawuleni okuzenzakalelayo kwesisiki se-laser sisebenzisa ikhompyutha, eqondisa ngokunembile ukunyakaza nokusebenza komsebe we-laser ukusika noma ukuqopha izinto.

4. I-CNC ishesha kangakanani uma iqhathaniswa ne-laser?

Ama-router e-CNC avame ukusika izinto ezijiyile ngokushesha kunezisiki ze-laser. Kodwa-ke, izisiki ze-laser zishesha kakhulu ekwakhiweni okunemininingwane nokuyinkimbinkimbi ezintweni ezincane, njengoba zingadingi ukushintshwa kwamathuluzi futhi zinikeza ukusika okuhlanzekile okunezicucu ezincane ngemuva kokucutshungulwa.

5. Kungani i-acrylic ingakwazi ukusika i-acrylic nge-laser?

Ama-laser e-diode angabhekana nobunzima ne-acrylic ngenxa yezinkinga ze-wavelength, ikakhulukazi ngezinto ezicacile noma ezinombala okhanyayo ezingamunci kahle ukukhanya kwe-laser. Uma uzama ukusika noma ukuqopha i-acrylic nge-laser ye-diode, kungcono ukuhlola kuqala bese ulungele ukwehluleka okungenzeka, njengoba ukuthola izilungiselelo ezifanele kungaba yinselele. Ngokuqopha, ungase uzame ukufafaza ungqimba lopende noma ukufaka ifilimu ebusweni be-acrylic, kodwa jikelele, ngincoma ukusebenzisa i-laser ye-CO2 ukuze uthole imiphumela emihle kakhulu.

Ngaphezu kwalokho, ama-laser e-diode angasika i-acrylic emnyama, engacacile. Kodwa-ke, awakwazi ukusika noma ukuqopha i-acrylic ecacile ngoba izinto azimunci kahle umsebe we-laser. Ngokukhethekile, i-laser ye-diode ekhanyayo eluhlaza okwesibhakabhaka ayikwazi ukusika noma ukuqopha i-acrylic eluhlaza okwesibhakabhaka ngesizathu esifanayo: umbala ofanayo uvimbela ukumuncwa okufanele.

6. Yimuphi umshini we-laser ongcono kakhulu wokusika i-acrylic?

I-laser engcono kakhulu yokusika i-acrylic yi-laser ye-CO2. Ihlinzeka ngokusika okuhlanzekile nokunembile futhi iyakwazi ukusika ubukhulu obuhlukahlukene be-acrylic ngempumelelo. Ama-laser e-CO2 asebenza kahle kakhulu futhi afaneleka kokubili i-acrylic ecacile nenemibala, okwenza kube ukukhetha okuthandwayo kokusika nokuqopha kwe-acrylic okuchwepheshile nokusezingeni eliphezulu.

Khetha umshini ofanele ukukhiqizwa kwe-acrylic yakho! Uma unemibuzo, xhumana nathi!

Isikhathi sokuthunyelwe: Julayi-27-2024