Ungakwazi Yini Ukusika I-Plywood Nge-Laser?

umshini wokusika nge-laser we-Plywood

I-Plywood ingenye yezinkuni ezivamile ezisetshenziswa efenisha, ezimpawini, emihlobisoni, emikhunjini, kumamodeli, njll. I-plywood iqukethe ama-veneer amaningi futhi ibonakala ngokukhanya kwayo nokuqina kwayo. I-Plywood isetshenziswa kabanzi futhi isebenza kahle kakhulu, kodwa ungase udideke ne-plywood esikiwe nge-laser, ngenxa yeglue yayo phakathi kwama-veneer e-plywood. Ingabe i-plywood ingasikwa nge-laser?

Ngokuvamile, i-laser ingasika i-plywood futhi umphumela wokusika uhlanzekile futhi uqinile, kodwa udinga ukukhetha izinhlobo ze-laser ezifanele kanye nemingcele ye-laser efanele njengamandla, isivinini, kanye nosizo lomoya. Futhi into eyodwa okudingeka uyiqaphele imayelana nezinhlobo ze-plywood. Kulesi sihloko, sizokwethula imishini ye-plywood efanelekile yokusika i-laser, indlela yokukhetha i-plywood, kanye nendlela yokusika i-plywood nge-laser ukuze uthole umphumela omuhle kakhulu wokusika. Ngaphezu kwalokho, i-plywood eqoshwe nge-laser ithandwa ngokudala umbhalo oyingqayizivele, amaphethini, nama-logo emikhiqizo ye-plywood efana namathegi egama, izipho, kanye nezimpawu zomkhiqizo.

Silandele ukuze uhlole amaphrojekthi e-laser cut plywood athakazelisayo. Uma unesithakazelo komunye wemishini yokusika i-laser plywood, xoxa nathi ngezintandokazi zakho nezidingo zakho.

Ungakwazi Yini Ukusika I-Plywood Nge-Laser?

Ngempela, i-plywood yokusika nge-laser iyindlela ethandwayo nephumelelayo yokwenza imiklamo enembile neyinkimbinkimbi.

Ngomshini wokusika we-laser ofanele kanye ne-plywood efanelekile, ungafinyelela imiphetho ehlanzekile kanye nokusika okunemininingwane, okwenza kube ukukhetha okuthandwayo kwamaphrojekthi nemiklamo ehlukahlukene ye-plywood.

Ungayikhetha kanjani i-Plywood yokusika nokuqopha nge-laser?

Manje sesiyazi ukuthi i-plywood ifanelekela ukusika nge-laser, kodwa i-plywood ehlukile ingaveza imiphumela yokusika ehlukene, ngakho-ke kunezici ezithile okudingeka uzicabangele lapho ukhetha i-plywood ye-laser:

1. I-Plywood Resin:

Okuqukethwe kwe-resin ku-plywood kunomthelela emphumeleni wokusika nokuqopha. Okuqukethwe kwe-resin okuphezulu, kusho amamaki amnyama asele onqenqemeni noma ebusweni bokhuni. Ngakho-ke ngaphandle kokuthi unolwazi oluningi lokulungisa amaphutha emishinini ye-laser nokusetha amapharamitha e-laser, asincomi ukukhetha i-plywood enokuqukethwe kwe-resin okuphezulu.

2. Ubuso bePlywood:

Uma ukhetha i-plywood, cabangela umthunzi wayo, okusanhlamvu, nombala wayo. Ukusikwa nokuqoshwa nge-laser kungashiya amabala amnyama, ngakho-ke khetha ukuqeda i-plywood okuhambisana nezidingo zomkhiqizo wakho kanye nesitayela. Isibonelo, uma uhlela ukuqopha umbhalo noma imikhonzo nge-laser, qiniseka ukuthi okusanhlamvu ngeke kuphazamise amamaki okuqoshwa namaphethini.

3. Ubukhulu bePlywood:

Ngokuvamile, ukuqinisekisa ikhwalithi yokusika, sincoma ukuthi ubukhulu obukhulu bokhuni obungasikwa yi-laser bungaphakathi kwama-20mm. Ubukhulu obuhlukene be-plywood, budinga amandla ahlukene e-laser. Uma uthenga umshini wokusika we-laser we-plywood, xhumana nomhlinzeki wakho we-laser ukuze uthole amandla afanele e-laser tube kanye namandla okusika.

4. Izinhlobo zePlywood:

Kunezinhlobo ezithile ze-plywood ezivamile ezifanelekela i-laser ongazibhekisela kuzo: i-bamboo plywood, i-brich plywood, i-hoop pine plywood, i-basswood plywood, kanye ne-beech plywood.

Kuyini i-Laser Cutting Plywood?

I-laser igxilisa amandla okushisa amakhulu endaweni encane ye-plywood, iyifudumale kuze kube yilapho i-sublimation iqiniswa. Ngakho-ke kusele imfucumfucu nezingcezu ezincane. Indawo yokusika nendawo ezungezile ihlanzekile.

Ngenxa yamandla aqinile, i-plywood izonqunywa ngqo lapho i-laser idlula khona.

Izinhlobo Ezifanele Ze-Laser Zokusika I-Plywood

I-CO2 Laser kanye ne-Diode Laser yizinhlobo ezimbili eziyinhloko ze-laser zokucubungula i-plywood.

1. I-laser ye-CO2inamandla futhi inamandla kangangokuthi ingasika ngokushesha i-plywood ejiyile, ishiye unqenqema oluqinile nolubushelelezi. Futhi nge-plywood engraving nge-laser, i-laser ye-CO2 ivumela amaphethini, izimo nama-logo enziwe ngokwezifiso. Ngakho-ke uma utshala umshini we-laser wokukhiqiza i-plywood, ukusika nokuqopha okusheshayo, umshini we-laser we-CO2 uyafaneleka.

2. I-Diode laserAyinamandla kangako okusika i-plywood ngenxa yamandla ayo aphansi. Kodwa ifaneleka ukuqopha nokumaka ebusweni be-plywood. Yenziwe ngokwezifiso futhi iguquguquka.

I-plywood yokusika nge-laser iyashesha, ikakhulukazi kwi-laser ye-CO2. Njengoba i-automation ephezulu ifana ne-auto-focus, itafula lokusika nge-laser eliphakamisa ngokuzenzakalelayo, isofthiwe yokusika nge-laser yedijithali, nokuningi, inqubo yokusika nge-laser ye-plywood inomsebenzi omncane kanye nekhwalithi yokusika ephezulu.

I-plywood yokusika nge-laser ihilela ukusebenzisa i-laser enamandla amakhulu ukusika ngokunembile impahla. Ugongolo lwe-laser luqondiswe ku-plywood, lunciphise impahla emugqeni wokusika futhi ludale unqenqema olubushelelezi.

I-Laser isebenziseka ngezindlela eziningi ekusikeni nasekuqopheni imiklamo eyenziwe ngokwezifiso njengemihlobiso kaKhisimusi, amathegi esipho, imisebenzi yezandla, kanye namamodeli.

Sisebenzise ucezu lwe-plywood ukwenza ezinyeImihlobiso kaKhisimusi eqoshiwe nge-laser, kuhle futhi kuyinkimbinkimbi. Unentshisekelo kulokho, bheka ividiyo.

◆Ukuzivumelanisa nezimo

Ama-laser angasika izinhlobo eziningi zezimo namaphethini, okuvumela imiklamo yokudala neyinkimbinkimbi.

◆ Ukunemba Okuphezulu

Abasiki be-laser bangafinyelela ukusika okunemininingwane eminingi nokunembile kakhulu ku-plywood. Ungaklama futhi udale imiklamo eyinkimbinkimbi neyinkimbinkimbi efana namaphethini angenalutho, umsiki we-laser uzowenza ngenxa yemisebe yawo ye-laser emincane kakhulu.

◆Umphetho Obushelelezi

Ugongolo lwe-laser lukhiqiza imiphetho ehlanzekile nebushelelezi ngaphandle kwesidingo sokuqeda okwengeziwe.

◆Kusebenza Kakhulu

Ukusika nge-laser kuvame ukushesha kunezindlela zokusika zendabuko, okwandisa umkhiqizo.

◆Akukho Ukugqoka Okungokomzimba

Ngokungafani nama-blade e-saw, i-laser ayithinti i-plywood ngokoqobo, okusho ukuthi akukho ukuguguleka kwethuluzi lokusika.

◆Ukusetshenziswa Okuphezulu Kwezinto Ezibalulekile

Ukunemba kokusika nge-laser kunciphisa imfucuza yezinto ezibonakalayo, okwenza kube okonga kakhulu.

1. Amamodeli Ezakhiwo:Ugongolo lwe-laser olunembile kanye nokusika kwe-laser okuguquguqukayo kuletha amamodeli e-plywood ayinkimbinkimbi futhi anemininingwane eningiliziwe, amamodeli okwakha kanye nama-prototype.

2. Izimpawu:Umshini wokusika nge-laser we-plywood unamandla kangangokuthi ungasika i-plywood ejiyile ngenkathi unomphetho wokusika ohlanzekile futhi obushelelezi. Izimpawu ze-plywood ezisikiwe nge-laser zilungele ukudala izimpawu ezenziwe ngokwezifiso ezinemiklamo eyinkimbinkimbi kanye nezinhlamvu.

3. Ifenisha:Ifenisha ye-plywood esikwe nge-laser iletha ukuguquguquka okwengeziwe komklamo kumklami wefenisha kanye nomuntu othanda izinto zokuzijabulisa. Ngokunemba okuphezulu, i-plywood esikwe nge-laser ingakha i-living hinge enhle kakhulu (ebizwa nangokuthiukhuni oluguquguqukayo), okuthuthukisa ukubukeka kanye nokuhluka kwefenisha kanye nemisebenzi yobuciko.

4. Imihlobiso Nemisebenzi Yezandla:Ukukhiqiza izinto zokuhlobisa ezifana nobuciko bodonga, imihlobiso, kanye nemihlobiso yasekhaya.

Ngaphandle kwalokho, i-plywood yokusika nge-laser ithandwa kakhulu phakathiukusika ngokhuni oluguquguqukayo nge-laser, iphazili yokusika izinkuni nge-laser, ibhokisi lokukhanyisa ukhuni lokusika nge-laser, umsebenzi wobuciko wokusika nge-laser.

Thola umsiki we-laser, khulula ubuhlakani bakho, yenza imikhiqizo yakho ye-plywood!

Noma yimiphi imibono mayelana ne-Laser Cutting Plywood, Siyakwamukela ukuzoxoxa nathi!

I-CO2 Laser iwumthombo we-laser ofaneleka kakhulu wokusika amabhodi e-plywood, ngokulandelayo, sizokwethula uMshini Wokusika we-CO2 Laser odumile nojwayelekile we-plywood.

Ezinye Izinto Okufanele Uzicabangele

Uma ukhetha umshini wokusika we-laser we-plywood, izici eziningana kufanele zicatshangelwe ukuqinisekisa ukuthi uthola imiphumela emihle kakhulu yamaphrojekthi akho:

1. Usayizi Womshini (ifomethi yokusebenza):

Usayizi womshini unquma usayizi omkhulu wamashidi e-plywood namaphethini ongawasika. Uma udala imihlobiso emincane, imisebenzi yezandla, noma imisebenzi yobuciko yokuzilibazisa, indawo yokusebenza ye1300mm * 900mmkufanelekile. Kumaphrojekthi amakhulu njengezimpawu noma ifenisha, umshini omkhulu wokusika nge-laser onefomethi ebanzi onendawo yokusebenza1300mm * 2500mm kuyinto ekahle kakhulu.

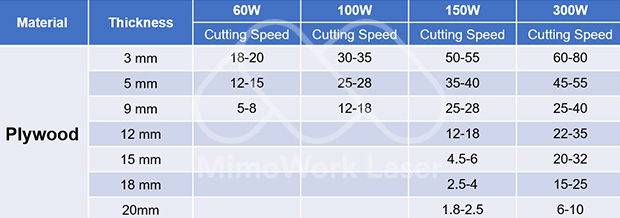

2. Amandla eThubhu yeLaser:

Amandla eshubhu le-laser anquma amandla e-laser beam kanye nobukhulu be-plywood ongayisika. Ishubhu le-laser elingu-150W livamile futhi lihlangabezana nezidingo eziningi zokusika i-plywood. Ukuze uthole i-plywood ejiyile efika ku-20mm, ungadinga ishubhu le-laser elingu-300W noma ngisho ne-450W. Uma udinga ukusika i-plywood ejiyile kuno-30mm, i-router ye-CNC ingase ifaneleke kakhulu kune-laser cutter.

Ulwazi Oluhlobene Ne-Laser:Indlela yokwandisa impilo yenkonzo ye-laser tube >

3. Ithebula Lokusika Nge-Laser:

Ukuze usike izinto zokhuni ezifana ne-plywood, i-MDF, noma ukhuni oluqinile, kunconywa itafula lokusika nge-laser elinomucu wommese. Leli thebula liqukethe ama-blade amaningi e-aluminium asekela izinto ngenkathi egcina ukuthintana okuncane, okuqinisekisa indawo ehlanzekile kanye nomkhawulo wokusika. Ukuze usike i-plywood ejiyile, ungase ucabangele nokusebenzisa itafula lokusebenza ngephini.Ulwazi olwengeziwe mayelana netafula lokusika nge-laser >

4. Ukusika Ukusebenza Kahle:

Hlola izidingo zakho zokukhiqiza ze-plywood, njengesivuno sansuku zonke ofuna ukusifinyelela, bese uxoxa ngazo nochwepheshe we-laser onolwazi. Siklame amakhanda amaningi e-laser noma amandla aphezulu omshini ukuze sihlangabezane nemigomo yakho yokukhiqiza. Ezinye izinto ezintsha ematafuleni okusika nge-laser, njengetafula lokusika nge-laser eliphakamisa ngokuzenzakalelayo, itafula lokushintshanisa, namadivayisi ajikelezayo, zingathuthukisa kakhulu ukusika nokuqopha kwe-plywood. Ngaphezu kwalokho, ezinye izilungiselelo ezifana nama-servo motors namadivayisi okudlulisa amagiya kanye ne-rack zingathinta ukusebenza kahle kokusika. Ukubonisana nomhlinzeki wakho we-laser kuzokusiza ukuthola izilungiselelo ze-laser ezifanele izidingo zakho.

Awunawo umbono wokuthi ungayikhetha kanjani i-Laser Machine? Khuluma nochwepheshe wethu we-Laser!

Umshini Wokusika we-Laser we-Plywood Odumile

• Indawo Yokusebenza: 1300mm * 900mm (51.2” * 35.4”)

• Amandla e-Laser: 100W/150W/300W

• Isivinini Esiphezulu Sokusika: 400mm/s

• Isivinini Esiphezulu Sokuqopha: 2000mm/s

• Uhlelo Lokulawula Okwenziwa Ngemishini: Ukulawula Ibhande Lemoto Yezinyathelo

• Indawo Yokusebenza: 1300mm * 2500mm (51” * 98.4”)

• Amandla e-Laser: 150W/300W/450W

• Isivinini Esiphezulu Sokusika: 600mm/s

• Ukunemba Kwesikhundla: ≤±0.05mm

• Uhlelo Lokulawula Oomatshini: I-Ball Screw & Servo Motor Drive

Imibuzo Evame Ukubuzwa ye-Laser Cutting Plywood

1. I-laser ingasika i-plywood engakanani ubukhulu?

Siyazi ukuthi i-laser ye-CO2 iwuhlobo lwe-laser olufanele kakhulu lokusika i-plywood. Ubukhulu obukhulu bokusika esibuphakamisayo bungu-20mm, okunganelisa umphumela omuhle wokusika kanye nesivinini sokusika. Sivivinye ubukhulu obuhlukene bokhuni lokusika i-laser futhi senze ividiyo yokuyibonisa. Hlola lokhu.

2. Ungayithola kanjani indawo efanele yokugxila kwe-plywood yokusika nge-laser?

Ukuze kulungiswe ubude bokugxila bokusika nge-laser, i-MimoWork yaklama idivayisi yokugxila ngokuzenzakalela kanye netafula lokusika nge-laser eliphakamisa ngokuzenzakalela, ukuze ikusize uthole ubude bokugxila obufanele kakhulu bezinto okufanele zisikwe.

Ngaphandle kwalokho, senze ividiyo yokufundisa isinyathelo ngesinyathelo ukuthi unganquma kanjani ukugxila. Hlola lokhu.

3. I-laser idinga amandla angakanani ukusika i-plywood?

Ukuthi udinga amandla e-laser angakanani kuncike ekujikeni kwe-plywood ozoyisika. I-150W ingamandla e-laser avamile okusika i-plywood eningi kusukela ekujikeni okungu-3mm kuya ekujikeni okungu-20mm. Udinga nje ukulungisa iphesenti lamandla esiqeshini se-scrap, ukuze uthole amapharamitha okusika afanele.

Siphakamisa ukusebenzisa umshini we-laser kungabi ngaphezu kuka-80%-90% wamandla aphezulu we-laser, ukuze kwandiswe isikhathi sokuphila kweshubhu ye-laser.

Funda Okwengeziwe Nge-Laser Cutting Plywood Noma Olunye Ukhuni

Izindaba Ezihlobene

Iphayini, Izinkuni Ezilahliwe, I-Beech, I-Cherry, Izinkuni Ze-Coniferous, I-Mahogany, I-Multiplex, Izinkuni Zemvelo, I-Oak, I-Obeche, I-Teak, I-Walnut nokuningi.

Cishe zonke izinkuni zingasikwa nge-laser futhi umphumela wokusika izinkuni nge-laser muhle kakhulu.

Kodwa uma ukhuni lwakho oluzonqunywa lunamathele efilimini noma kupende onobuthi, kubalulekile ukuqaphela ukuphepha ngesikhathi usika nge-laser.

Uma ungaqiniseki,buzanochwepheshe we-laser kungcono kakhulu.

Uma kukhulunywa ngokusika nokuqopha i-acrylic, ama-router e-CNC nama-laser avame ukuqhathaniswa.

Yikuphi okungcono?

Iqiniso liwukuthi, bahlukile kodwa bayaphelelisana ngokudlala izindima ezihlukile emikhakheni ehlukene.

Yimiphi le mehluko? Futhi kufanele ukhethe kanjani? Funda isihloko bese usitshela impendulo yakho.

Ubulokhu uzama ukuthola indlela yokudala iphazili yangokwezifiso? Uma kudingeka ukunemba okuphezulu kakhulu nokunemba, abasiki be-laser cishe njalo bayindlela engcono kakhulu.

Lena inqubo yokusika izinto ngomsebe we-laser, njengoba igama lisikisela. Lokhu kungenziwa ukuze kuncishiswe izinto noma kusize ekuzisikeni zibe izinhlobo eziyinkimbinkimbi okungaba nzima ukuthi ama-drill endabuko aziphathe. Ngaphandle kokusika, abasiki be-laser bangase futhi baklame i-raster noma i-etch ezintweni zokusebenza ngokushisa ubuso bento yokusebenza bese bebhoboza ungqimba oluphezulu lwezinto ukuze bashintshe ukubukeka lapho umsebenzi we-raster uqediwe khona.

Unemibuzo mayelana ne-Laser Cut Plywood?

Kugcine ukubuyekezwa: Okthoba 27, 2025

Isikhathi sokuthunyelwe: Agasti-08-2024