Indlela Yokusika Iphepha Lesandpaper: Izindlela Ezilula Zokulinganisa Ngokunembile

umshini wokusika i-sandpaper

Ufuna ukwazi kahle indlela yokusika i-sandpaper njengochwepheshe? Kungakhathaliseki ukuthi wenza umsebenzi wobuciko onembile noma u-sanding wezimboni, ukuthola ukusika okuhlanzekile kubalulekile. Sizokukhombisa indlela ehlakaniphile yokusika amashidi nokushaya imigodi yothuli - kanye namathuluzi amahle kakhulu omsebenzi wokusika ngesandla noma ngomshini.

Izinhlobo Eziyinhloko Zokugoba

Iphepha lokusanta liza ngezinhlobo ezahlukene zamatshe (ezinobuthi), ngayinye yenzelwe ukusetshenziswa okuthile. Izinhlobo ezivame kakhulu zifaka i-aluminium oxide, i-silicon carbide, i-ceramic, kanye nephepha lokusanta le-garnet. Uhlobo ngalunye lunezakhiwo ezihlukile ezifanele imisebenzi ehlukene:

• I-Aluminium Oxide: Ihlala isikhathi eside futhi isebenziseka ngezindlela eziningi, ilungele ukusantiwa ngokhuni nangensimbi.

•I-Silicon Carbide: Ibukhali futhi iqinile, ilungele ukusika izinto eziqinile njengengilazi nepulasitiki.

•I-Ceramic: Ihlala isikhathi eside kakhulu futhi isebenza kahle ekusikeni nasekugayeni okunzima.

•I-Garnet: Ithambile futhi iguquguquka kakhudlwana, ivame ukusetshenziselwa ukwenza ukhuni oluhle.

Yiziphi izinhlobo ezintathu zephepha lokusantisa?

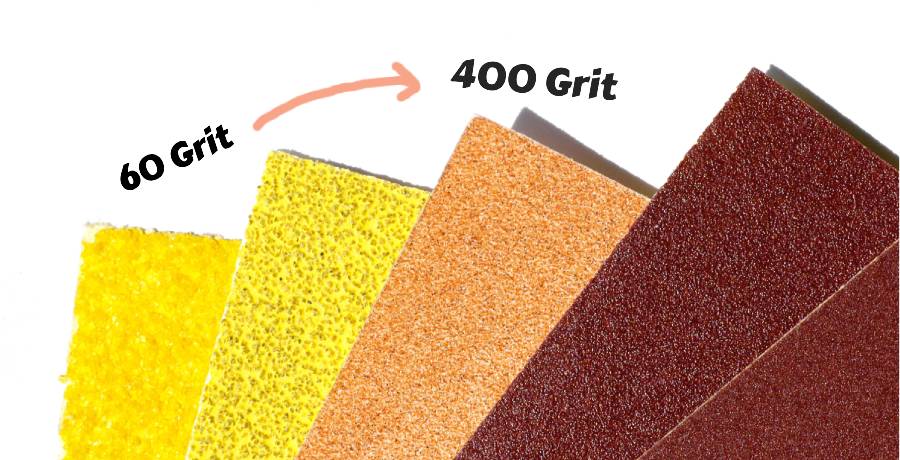

I-sandpaper ihlukaniswe ngama-grade afana nama-grade amancane, ama-coarse kanye nama-medium futhi ngalinye lala ma-grade liqukethe amazinga ahlukene achazwa yilokho okwaziwa ngokuthi i-grit.

•Okumahhadla: Ukuze uhlanze futhi ukhiphe inhlabathi kakhulu, udinga i-grit ye-sandpaper eqinile enobukhulu obungama-grit angu-40 kuya kwangu-60.

•Okuphakathi:Ukuze ulungise izindawo ezibushelelezi futhi ususe amaphutha amancane, khetha iphepha lesihlabathi eliphakathi nendawo kusukela kuphepha lesihlabathi elinama-grit angu-80 kuya kwangu-120.

•Kulungile:Ukuze uqedele izindawo kahle, sebenzisa iphepha lokusanta elihle kakhulu elinama-grit angu-400 kuya kwangu-600.

Iphepha lokusanta lisetshenziswa emikhakheni eminingi ehlanganisa ukusebenza ngokhuni, izimoto, ukusebenza ngensimbi kanye nokwakha.

Kubalulekile emisebenzini efana nokushelela izindawo, ukususa upende noma ukugqwala, nokulungiselela izinto zokuqeda.

▶ Ummese Wokusetshenziswa

Ukuze usike ngesandla, ummese owusizo one-straightedge uyindlela elula kodwa ephumelelayo.

Kuvame ukusetshenziswa ezindaweni zokusebenzela ezincane lapho ukunemba kokusika kanye nevolumu kungalawuleka khona ngesandla.

▶ Ithuluzi le-Dremel

Ithuluzi le-Dremel elinomshini wokusika lingasetshenziswa ekusikeni okuncane nokunemininingwane.

Ifaneleka kakhulu kubantu abathanda ukuzilibazisa noma abakhiqiza ngezinga elincane lapho kudingeka khona ukuguquguquka.

▶ Umsiki Wephepha Ojikelezayo

Izicucu zephepha ezijikelezayo ziwusizo ekwenzeni izicucu eziqondile kumashidi e-sandpaper.

Njengesicubunguli sephepha, isebenzisa i-blade ejikelezayo ukusika i-sandpaper.

Njengethuluzi lokusika ngesandla, umsiki wephepha ojikelezayo awukwazi ukuqinisekisa ukunemba nokusheshisa kokusika.

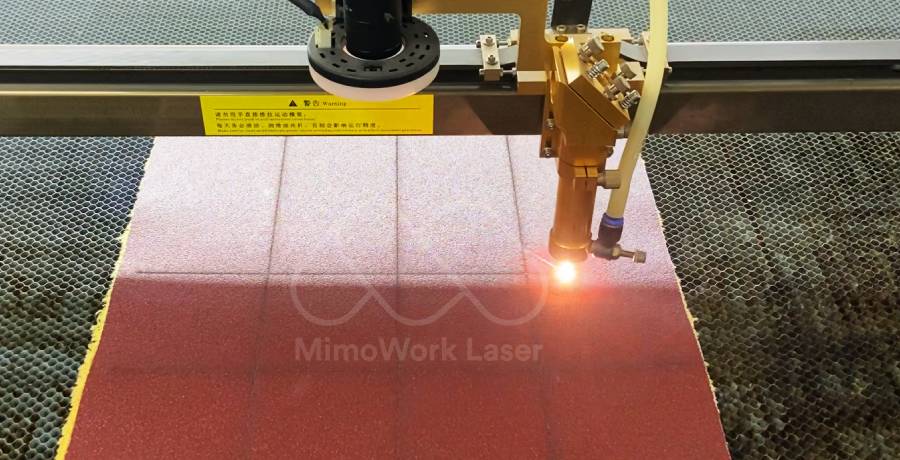

Umsiki We-Laser

Izicucu ze-laser zinembile kakhulu, okwenza zilungele izimo ezenziwe ngokwezifiso kanye nemiklamo eyinkimbinkimbi.

Basebenzisa ukukhanya okugxilile ukusika iphepha lokusanta, ukuqinisekisa ukuthi imiphetho ihlanzekile ngaphandle kokuqhekeka.

I-laser cutter iyakwazi ukusika izimbobo ezincane futhi inqume ngezimo nobukhulu obuhlukahlukene.

Ngenxa yohlelo lwe-CNC kanye nokucushwa komshini okuthuthukisiwe, ikhwalithi yokusika i-sandpaper kanye nokusebenza kahle kokusika kungabonakala emshinini owodwa.

Umsiki Wedayi

Abasiki bedayi basebenzisa idayisi elibunjwe ngaphambilini ukuze bakhiphe izimo ezithile emaphepheni noma emiqulwini yesandpaper.

Zisebenza kahle ekukhiqizeni okuningi lapho ukufana kubalulekile khona.

Umkhawulo womshini wokusika idayisi ukuguga nokudabuka kwamathuluzi ahlukumezayo. Uma sifuna ukusika izimo ezintsha kanye nemiklamo emisha yephepha lokusanta, sidinga ukuthenga amadayi amasha. Lokho kuyabiza.

Kudinga Ukunemba Okuphezulu Nokwenza Ngokwezifiso:

Uma ukhathazekile ngokunemba kokusika nokuthi kungenziwa ngezifiso yini, i-Laser Cutter iyisinqumo sakho esifanele.

Iphepha lokusika nge-laser linikeza ukunemba okungenakuqhathaniswa, ukuguquguquka, kanye nokusebenza kahle.

Ilungele kokubili ukukhiqizwa kwezinga elincane nelikhulu lapho kudingeka khona imiklamo eyinkimbinkimbi nesezingeni eliphezulu.

Ukutshalwa kwezimali kokuqala kuphakeme, kodwa izinzuzo mayelana nokunemba nokuguquguquka zenza kube yinto ewusizo.

Ukukhathazeka Ngokusebenza Kahle Kakhulu Nomphumela Wokukhiqiza

Uma sikhuluma ngokusebenza kahle kokusika,Umsiki wedayi nguyena ophumelele ngoba usike iphepha lokusanta ngamadayi akhiwe ngaphambilini.

Uma unomklamo kanye nephethini efanayo, umshini wokusika idayi ungaqeda ngokushesha ukusika. Lokho kufaneleka ekukhiqizweni okukhulu komklamo ofanayo we-sandpaper.

Kodwa uma unezidingo ezahlukahlukene zezimo ze-sandpaper, ubukhulu, namaphethini okuklama, i-die cutter ayiyona engcono kakhulu uma iqhathaniswa ne-laser cutter.

Umklamo omusha udinga idayisi entsha, okuthatha isikhathi futhi kuyabiza ukusika idayisi. Ngokuphambene nalokho,umsiki we-laser angahlangabezana nokusika okunezifiso nokuhlukahlukene emshinini owodwa.

Kokusebenza okubhekelela isabelomali

Uma ubheka izindleko zomshini,Amathuluzi enziwe ngesandla njenge-rotary cutter kanye ne-Dremel ayonga kakhulu izindleko, futhi anokuguquguquka okuthile kokusebenza.

Zifanele imisebenzi emincane noma lapho ukulinganiselwa kwesabelomali kuyisici esibalulekile.

Nakuba incwadi yesandla ingenakho ukunemba nokusebenza kahle kwemishini yokusika nge-laser, iyatholakala kalula futhi ingabizi kakhulu emisebenzini elula.

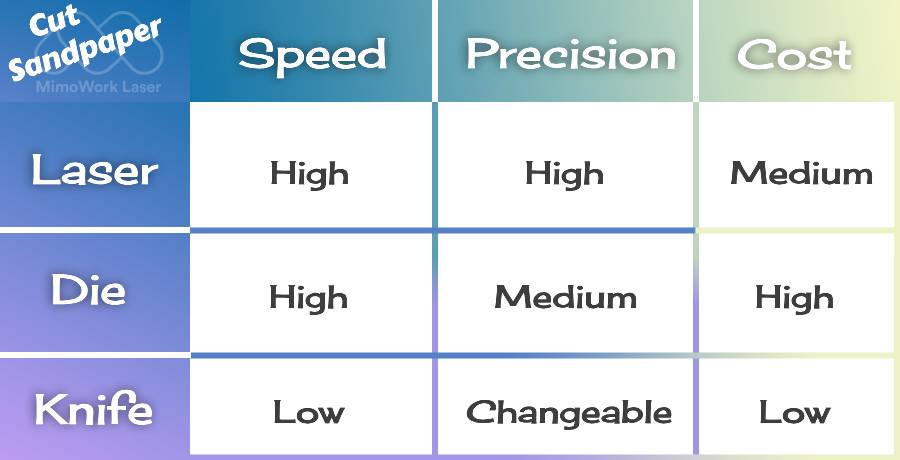

Ukuqhathaniswa Kwamathuluzi Amathathu

Ukukhetha ithuluzi kuncike kakhulu ezidingweni ezithile zomsebenzi wokusika i-sandpaper.

Izisiki ze-laser zivelele njengokukhetha okungcono kakhulu ngokunemba kwazo, ukuguquguquka kwazo, kanye nokusebenza kahle, ikakhulukazi lapho zisebenza ngemiklamo eyinkimbinkimbi kanye nama-oda enziwe ngokwezifiso.

Izicucu zedayi ziyasebenza ekukhiqizeni okunomthamo omkhulu nokuqhubekayo.

Nakuba izicucu ezijikelezayo zinikeza inketho engabizi kakhulu yemisebenzi emincane neyinkimbinkimbi.

Ngokuhlola izidingo zakho ezithile kanye nesilinganiso sokukhiqiza, ungakhetha ithuluzi elifanele kakhulu ukuze uthole imiphumela emihle ekusikeni iphepha lokusila.

Iphepha Lesandpaper Elinomumo Owenziwe Ngokwezifiso Lamathuluzi Akhethekile

Amandla Sanders: Ukusikwa nge-laser kuvumela ukudalwa kwephepha lokusanta elifanele izimo ezithile ze-power sander, njenge-orbital, ibhande, kanye ne-disc sanders. Lokhu kuqinisekisa ukusebenza kahle kanye nokusebenza kahle.

Imininingwane uSanders: Izimo ezenziwe ngokwezifiso zingasikwa ukuze zilingane nezinsimbi zokusika ezisetshenziswa emisebenzini yokhuni eyinkimbinkimbi noma yokuqeda.

Iphepha Lokucwenga Elisikwe Ngokunembile Lokusetshenziswa Ezimbonini

Imboni Yezimoto: Iphepha lokusanta elisikwe nge-laserisetshenziselwa ukuqeda nokupholisha izingxenye zezimoto, lapho izimo nobukhulu obuqondile bubalulekile khona ukuze kube nemiphumela ehambisanayo.

Imboni Yezindiza: Imboni yezindiza idinga ukunemba okuphezulu kokulungiselela ubuso nokuqedela. Iphepha lokusanta elisikwe nge-laser lihlangabezana nalezi zindinganiso eziqinile.

Amaphrojekthi Emisebenzi Yobuciko Nokuzilibazisa

Amaphrojekthi e-DIY: Abathandi bokuzilibazisa kanye nabathandi be-DIY bayazuza ngephepha lokusanta elisikwe nge-laser ukuze bathole umsebenzi oningiliziwe ezintweni ezahlukahlukene, okuhlanganisa ukhuni, insimbi, kanye nepulasitiki.

Ukwenza Amamodeli: Iphepha lokusika eliqondile lilungele abenzi bamamodeli abadinga izingcezu ezincane, ezibunjwe ngendlela eyinkimbinkimbi ukuze benze imisebenzi yokusila kahle.

Ifenisha kanye Nokusebenza Ngokhuni

Ukuvuselelwa Kwefenisha: Iphepha lokusanta elisikwe nge-laser lingalungiswa ukuze livumelane nemidwebo ethile kanye nezimo zezingcezu zefenisha, okuvumela umsebenzi wokulungisa onemininingwane.

Ukubaza: Abasebenza ngokhuni bangasebenzisa iphepha lokusanta elenziwe ngendlela oyifisayo ukuze bahlanze ngokuningiliziwe izinto eziqoshiwe, imiphetho, kanye namalunga.

Izicelo Zezokwelapha Nezamazinyo

Ukusikwa Kwamathambo: Iphepha lesihlabathi elenziwe ngendlela oyifisayo lisetshenziswa emkhakheni wezokwelapha ukulungiselela amadivayisi amathambo kanye ne-prosthetics.

Amathuluzi Amazinyo: Iphepha lokusanta elisikwe kahle lisetshenziswa emikhubeni yamazinyo yokupholisha nokuqeda izitho zokufakelwa zamazinyo kanye nezinto zikagesi.

Iphepha Lokushelela Elinezimbobo Ezikhethekile

Izinhlelo Zokukhipha Uthuli: Ukusikwa nge-laser kuvumela ukufakwa okunembile kwemigodi ephepheni lokusanti ukuze kuhambisane nezinhlelo zokukhipha uthuli, okuthuthukisa ukusebenza kahle kanye nokuhlanzeka ngesikhathi sokusantisa.

Ukusebenza Okuthuthukisiwe: Amaphethini emigodi enziwe ngokwezifiso angathuthukisa ukusebenza kwephepha lokusandpaper ngokunciphisa ukuvaleka nokwandisa isikhathi salo sokuphila.

Ubuciko Nokuklama

Amaphrojekthi Okudala: Abaculi nabaklami basebenzisa iphepha lokusanta elisikwe nge-laser emisebenzini yobuciko eyingqayizivele, lapho kudingeka khona ukunemba kanye nemiklamo eyinkimbinkimbi.

Izindawo Ezinobunono: Ukuthungwa ngokwezifiso namaphethini kungadalwa ephepheni lokusanti ukuze kube nemiphumela ethile yobuciko.

Izinsimbi Zomculo Nezemidlalo

Ithuluzi Lomculo:Iphepha lokusanta elisikwe nge-laser lisetshenziswa ekukhiqizeni amagitare ukuze kushelele futhi kuqedwe umzimba, intamo, kanye nebhodi le-fretboard. Lokhu kuqinisekisa ukuqeda kwekhwalithi ephezulu kanye nokudlala okukhululekile.

Izimpahla Zezemidlalo:Isibonelo, ama-skateboard avame ukudinga ukuthi i-sandpaper, eyaziwa ngokuthi i-grip tape, ifakwe edekhini ukuze kuthuthukiswe ukubamba nokulawula.

Ilungele ukusika, ukubhoboza, ukuqopha

Umsiki we-Laser we-Sandpaper

| Indawo Yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 100W/150W/300W |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma ishubhu ye-CO2 RF Metal Laser |

| Uhlelo Lokulawula Okwenziwa Ngemishini | Ukulawula Ibhande Lemoto Yesinyathelo |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Honey Comb noma Ithebula Lokusebenza Le-Knife Strip |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Usayizi Wephakheji | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Isisindo | 620kg |

| Indawo Yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3”) |

| Indawo Yokuqoqela (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 100W / 150W / 300W |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma ishubhu ye-CO2 RF Metal Laser |

| Uhlelo Lokulawula Okwenziwa Ngemishini | I-Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Ithebula Lokusebenza | Ithebula Lokusebenza Lomthuthi |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Indawo Yokusebenza (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Ukulethwa Kwemishayo | I-Galvanometer ye-3D |

| Amandla e-Laser | 180W/250W/500W |

| Umthombo We-Laser | I-CO2 RF Metal Laser Tube |

| Uhlelo Lwemishini | I-Servo Driven, I-Belt Driven |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Honey Comb |

| Isivinini Sokusika Esiphezulu | 1 ~ 1000mm/s |

| Isivinini Sokumaka Esiphezulu | 1 ~ 10,000mm/s |

Funda kabanzi mayelana ne-sandpaper yokusika nge-laser

Unemibuzo mayelana ne-Laser Cut Sandpaper?

Isikhathi sokuthunyelwe: Julayi-02-2024