Umhlahlandlela Ophelele Wendwangu Yesihlungi Sokusika Nge-Laser:

Izinhlobo, Izinzuzo, kanye Nezicelo

Isingeniso:

Izinto Ezibalulekile Okufanele Uzazi Ngaphambi Kokungena

Izindwangu zokuhlunga zidlala indima ebalulekile ezimbonini eziningi ezahlukene, kusukela ekuhlungeni amanzi nomoya kuya ekucubungulweni kwemithi nokudla. Njengoba amabhizinisi efuna ukuthuthukisa ukusebenza kahle, ukunemba, kanye nokwenza ngokwezifiso ekukhiqizweni kwezindwangu zokuhlunga, indwangu yokuhlunga yokusika nge-laser ivele njengesixazululo esithandwayo. Ngokungafani nezindlela zokusika zendabuko, indwangu yokuhlunga yokusika nge-laser inikeza izinga eliphezulu lokunemba, isivinini, kanye nokuchithwa kwezinto ezincane, okwenza kube ukukhetha okuhle kokusika izindwangu zokuhlunga ezenziwe ngezinto ezahlukene ezifanai-polyester, inayiloni, futhiizindwangu ezingezona ezilukiwe.

Kulesi sihloko, sizobheka kabanzi izinhlobo ezahlukene zendwangu yokuhlunga kanye nendlela indwangu yokuhlunga yokusika nge-laser esebenza ngayo ezintweni ezahlukahlukene. Uzobona ukuthi kungani isibeikhambi elisetshenziswa kakhulu lokukhiqiza ikhwalithi ephezulu, imikhiqizo yokuhlunga eyenziwe ngokwezifisoSizophinde sabelane ngemininingwane evela ezivivinyweni zethu zakamuva ngezinto ezifana ne-foam ne-polyester, sikunikeze izibonelo zangempela zendlela indwangu yesihlungi yokusika nge-laser engathuthukisa ngayo ukusebenza kahle kanye nokungaguquguquki ekukhiqizeni.

Indlela Yokusika Indwangu Yesihlungi Se-Laser | Umshini Wokusika I-Laser Wemboni Yokuhlunga

Woza kuvidiyo ukuze uhlole inqubo yokusika nge-laser yendwangu yokuhlunga. Isidingo esikhulu sokunemba kokusika senza umshini wokusika nge-laser waziwe embonini yokuhlunga.

Amakhanda e-laser amabili athuthukisa umkhiqizo ngokwengeziwe, akhuphule isivinini sokusika ngenkathi eqinisekisa ikhwalithi.

1. Indwangu Yokuhlunga Ye-Polyester:

• Ukusetshenziswa:Indwangu yokuhlunga ye-polyester ingenye yezinto ezisetshenziswa kakhulu ekuhlungeni ngenxa yokuqina kwayo, ukumelana namakhemikhali, kanye nekhono lokubekezelela amazinga okushisa aphezulu.

•Izicelo:Ivame ukusetshenziswa ezinhlelweni zokuhlunga umoya, ukwelashwa kwamanzi, kanye nezinhlelo zokuhlunga zezimboni.

•Izinzuzo Zokusika Nge-Laser:I-Polyester ihambisana kakhulu ne-indwangu yokuhlunga yokusika nge-laserngoba ikhiqiza imiphetho ehlanzekile neqondile. I-laser ivala nemiphetho, ivimbele ukuqhekeka futhi ithuthukise amandla endwangu iyonke.

2. Indwangu Yokuhlunga Inayiloni:

• Ukusetshenziswa:Yaziwa ngokuguquguquka kwayo nokuqina kwayo, indwangu yokuhlunga ye-nylon ilungele ukusetshenziswa kokuhlunga okudinga amandla, njengasezimbonini zamakhemikhali noma emkhakheni wokudla neziphuzo.

•Izicelo:Ivame ukusetshenziswa ekuhlungeni ngamakhemikhali, ekuhlanzweni kwamanzi, nasekuhlungeni ukudla.

•Izinzuzo Zokusika Nge-Laser:Amandla e-nylon kanye nokumelana nokuguguleka kwenza kube yinto enhle kakhuluindwangu yokuhlunga yokusika nge-laserI-laser iqinisekisa imiphetho ebushelelezi, evaliwe egcina ukuqina kwezinto kanye nezakhiwo zokuhlunga.

3. Indwangu Yokuhlunga Ye-Polypropylene:

• Ukusetshenziswa:I-Polypropylene yaziwa ngokumelana kwayo namakhemikhali okuhle kakhulu, okwenza ibe yindawo ekahle kakhulu yokuhlunga amakhemikhali anolaka noma izinto ezishisa kakhulu.

•Izicelo:Isetshenziswa ekuhlungeni imithi, ekuhlungeni kwezimboni, nasekuhlungeni uketshezi.

•Izinzuzo Zokusika Nge-Laser: Indwangu yokuhlunga yokusika nge-lasernjenge-polypropylene ivumela ukusikwa okunembile kanye nemiklamo eyinkimbinkimbi ngaphandle kokulimaza impahla. Imiphetho evaliwe inikeza ubuqotho besakhiwo obungcono, okwenza ifaneleke ukusetshenziswa okubalulekile.

4. Indwangu Yokuhlunga Engalukiwe:

• Ukusetshenziswa:Indwangu yokuhlunga engalukiwe ilula, iyaguquguquka, futhi iyabiza kancane. Isetshenziswa ezindaweni lapho kulula ukuyisebenzisa kanye nokucindezela okuphansi kubalulekile khona.

•Izicelo:Kusetshenziswa ekuhlungeni izimoto, umoya, nothuli, kanye nasemikhiqizweni yokuhlunga elahlwayo.

•Izinzuzo Zokusika Nge-Laser:Izindwangu ezingalukiwe zingabaukusika nge-laserngokushesha nangendlela ephumelelayo.Indwangu yokuhlunga yokusika nge-laserisebenziseka kakhulu ezidingweni ezahlukene zokuhlunga, okuvumela kokubili ukubhoboka okuncane kanye nokusikwa kwendawo enkulu.

Indwangu yokuhlunga yokusika nge-laser isebenzisa umsebe we-laser ogxile, onamandla aphezulu oncibilikisa noma uphefumise indwangu khona kanye lapho ithintana khona. Iqondiswa uhlelo lwe-CNC (Computer Numerical Control), i-laser ihamba ngokunemba okumangalisayo, okwenza kube nokwenzeka ukusika noma ngisho nokuqopha izinhlobo ezahlukene zendwangu yokuhlunga ngokunemba okuvelele.

Vele, akuzona zonke izinto zendwangu yokuhlunga ezifanayo. Ngayinye idinga izilungiselelo ezilungisiwe kahle ukuze kutholakale imiphumela emihle kakhulu yokusika. Ake sihlaziye ukuthi indwangu yokuhlunga yokusika nge-laser isebenza kanjani kwezinye zezinto ezisetshenziswa kakhulu.

I-Laser Cut Polyester:

Indwangu yesihlungi se-polyester ihlala isikhathi eside futhi imelana nokunwebeka, okungenza kube nzima ukuyisika ngamathuluzi endabuko. Ukusika nge-laser kunikeza inzuzo ecacile lapha, njengoba kunikeza imiphetho ebushelelezi, evaliwe evimbela ukuqhekeka ngenkathi kugcinwa amandla endwangu. Lokhu kunemba kubaluleke kakhulu ezimbonini ezifana nokwelashwa kwamanzi noma ukucubungula ukudla, lapho kudingeka khona ukusebenza kwesihlungi okulinganayo.

Izindwangu Ezingalukiwe Ezisikiwe Nge-Laser:

Izindwangu ezingezona ezilukiwe zilula futhi zithambile, okwenza zifane kahle kakhulu nokusika nge-laser. Ngalobu buchwepheshe, izinto zingacutshungulwa ngokushesha ngaphandle kokuphazamisa isakhiwo sazo, okuholela ekusikeni okuhlanzekile nokunembile okubalulekile ekubumbeni izihlungi. Le ndlela ibaluleke kakhulu lapho usebenza ngezindwangu ezingezona ezilukiwe ekuhlungeni kwezokwelapha noma kwezimoto, lapho ukunemba kanye nokuvumelana kubalulekile khona.

Inayiloni Esikiwe Nge-Laser:

Izindwangu zenayiloni zaziwa ngokuguquguquka kwazo nokuqina kwazo, kodwa kungaba nzima ukuzisingatha ngezindlela zokusika ngomshini. Ukucubungula nge-laser kuxazulula le nselele ngokukhiqiza ukusika okubukhali nokunembile ngaphandle kokubangela ukuphambuka. Umphumela uba izihlungi ezigcina isimo sazo futhi zilethe ukusebenza okuthembekile, okubalulekile ezindaweni ezidinga amandla njengokusetshenziswa kwamakhemikhali noma kwemithi.

Igwebu Elisikiwe Nge-Laser:

Igwebu liyinto ethambile futhi enezimbobo engadabula noma iguquguquke kalula uma isikwa ngama-blades. Ubuchwepheshe be-laser bunikeza ikhambi elihlanzekile nelithembekile, njengoba lisika igwebu kahle ngaphandle kokuchoboza amaseli noma ukuphazamisa isakhiwo salo. Lokhu kuqinisekisa ukuthi izihlungi ezenziwe ngegwebu zigcina izimbobo nokusebenza kwazo, okwenza zibe usizo kakhulu ekusetshenzisweni okufana nokuhlanzwa komoya kanye nokufakwa kwe-acoustic.

Kungani Kufanele Ukhethe Ukusika Nge-Laser Kwendwangu Yokuhlunga?

Indwangu yokuhlunga yokusika nge-laserinikeza izinzuzo eziningi kunezindlela zokusika zendabuko, ikakhulukazi zezinto zokuhlunga indwangu. Nazi ezinye zezinzuzo ezibalulekile:

1. Ukunemba Nokuhlanzeka Komphetho

Indwangu yokuhlunga yokusika nge-laserkuqinisekisa ukunqunywa okunembile okunemiphetho ehlanzekile, evaliwe, okubalulekile ekugcineni ubuqotho besakhiwo sendwangu yokuhlunga. Lokhu kubaluleke kakhulu ezinhlelweni zokuhlunga lapho izinto kufanele zigcine khona ikhono lazo lokuhlunga kahle.

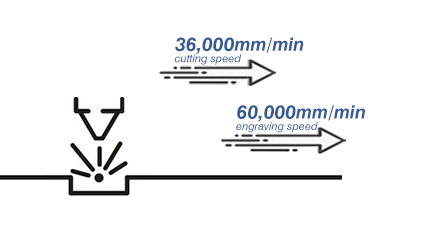

2. Isivinini Esisheshayo Nokusebenza Kahle Kakhulu

Indwangu yokuhlunga yokusika nge-laserishesha futhi isebenza kahle kunezindlela zokusika ngomshini noma ngomshini, ikakhulukazi ezidizayini eziyinkimbinkimbi noma ezenziwe ngokwezifiso.uhlelo lokusika lwe-laser lwendwangu yokuhlungakungenziwa futhi ngokuzenzakalelayo, kunciphisa isidingo sokungenelela ngesandla futhi kusheshiswe izikhathi zokukhiqiza.

3. Imfucuza Encane Yezinto Ezibalulekile

Izindlela zokusika zendabuko zivame ukudala imfucuza yezinto ezibonakalayo eziningi, ikakhulukazi lapho kunqunywa izimo eziyinkimbinkimbi.Indwangu yokuhlunga yokusika nge-laserinikeza ukunemba okuphezulu kanye nokuchithwa okuncane kwezinto zokwakha, okwenza kube inketho engabizi kakhulu kokubili ekukhiqizeni okuncane kanye nokukhulu.

4. Ukwenza ngokwezifiso kanye nokuguquguquka

Indwangu yokuhlunga yokusika nge-laserivumela ukwenza ngokwezifiso okuphelele kwezindwangu zokuhlunga. Kungakhathaliseki ukuthi udinga izimbobo ezincane, izimo ezithile, noma imiklamo enemininingwane,indwangu yokuhlunga yokusika nge-laseringahlangabezana kalula nezidingo zakho, ikunikeze ukuguquguquka kokukhiqiza imikhiqizo eminingi yendwangu yokuhlunga.

5. Akukho Ukugqoka Amathuluzi

Ngokungafani nokusika ngodayi noma ukusika ngomshini,indwangu yokuhlunga yokusika nge-laserakuhileli ukuthintana ngokomzimba nezinto zokwakha, okusho ukuthi akukho ukuguguleka kwamalambu noma amathuluzi. Lokhu kunciphisa izindleko zokulungisa kanye nesikhathi sokungasebenzi, okwenza kube yisisombululo esithembeke kakhulu sesikhathi eside.

Imishini Yokusika I-Laser Yendwangu Yokuhlunga Enconyiwe

Ukuze uthole imiphumela emihle kakhulu lapho usika indwangu yokuhlunga, ukhetha okulungileumshini wokusika indwangu yokuhlunga nge-laserkubalulekile. I-MimoWork Laser inikeza uhla lwemishini efaneleka kakhuluindwangu yokuhlunga yokusika nge-laser, kufaka phakathi:

• Indawo Yokusebenza (W *L): 1000mm * 600mm

• Amandla e-Laser: 60W/80W/100W

• Indawo Yokusebenza (W *L): 1300mm * 900mm

• Amandla e-Laser: 100W/150W/300W

• Indawo Yokusebenza (W *L): 1800mm * 1000mm

• Amandla e-Laser: 100W/150W/300W

Ekuphetheni

Indwangu yokuhlunga yokusika nge-laserKuye kwabonakala kuyindlela enhle kakhulu yokusika izindwangu zokuhlunga, okunikeza izinzuzo eziningi njengokunemba, isivinini, kanye nokuchitha okuncane. Kungakhathaliseki ukuthi usika izindwangu ze-polyester, i-foam, i-nylon, noma ezingezona ezilukiwe, indwangu yokuhlunga yokusika nge-laser iqinisekisa imiphumela esezingeni eliphezulu enemiphetho evaliwe kanye nemiklamo eyenziwe ngokwezifiso. Uhla lwezinhlelo zokusika nge-laser zendwangu yokuhlunga ye-MimoWork Laser lunikeza ikhambi elifanele amabhizinisi abo bonke osayizi abafuna ukwenza ngcono inqubo yabo yokukhiqiza izindwangu zokuhlunga.

Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nendlela yethuimishini yokusika nge-laser yendwangu yokuhlungaingathuthukisa imisebenzi yakho yokusika indwangu yokuhlunga futhi ithuthukise ikhwalithi yemikhiqizo yakho.

Uma kukhulunywa ngokukhethaumshini wokusika indwangu yokuhlunga nge-laser, cabanga ngalokhu okulandelayo:

Izinhlobo Zemishini:

Izisiki ze-laser ze-CO2 zivame ukunconywa ekusikeni indwangu yokuhlunga ngoba i-laser ingasika izimo nobukhulu obuhlukahlukene. Udinga ukukhetha usayizi namandla omshini we-laser ofanele ngokwezinhlobo zezinto zakho nezici. Xhumana nochwepheshe we-laser ukuze uthole iseluleko se-laser sochwepheshe.

Ukuhlolwa Okokuqala:

Ngaphambi kokuthi utshale imali emshinini wokusika nge-laser, indlela engcono kakhulu ukwenza isivivinyo sezinto ezibonakalayo usebenzisa i-laser. Ungasebenzisa indwangu yokuhlunga bese uzama amandla nesivinini se-laser ehlukene ukuze uhlole umphumela wokusika.

Noma yimiphi imibono mayelana nendwangu yesihlungi sokusika nge-laser, Siyakwamukela ukuzoxoxa nathi!

Unemibuzo mayelana nomshini wokusika we-laser wendwangu yokuhlunga?

Kugcine ukubuyekezwa: 9 Septhemba 2025

Isikhathi sokuthunyelwe: Novemba-14-2024