Kungani Ukhetha I-Laser Welder Ephathwayo?

Umshini Wokushisela We-Laser Ophathwa Ngesandla - Ohola Imboni Umoya Omusha

I-laser ephathwa ngesandla - izwakala njengethuluzi elihle, akunjalo? Esimweni sokukhiqiza esisheshayo sanamuhla. Isidingo sezixazululo zokushisela ezisebenza kahle nezisebenzayo asikaze sibe yinto ebaluleke kangaka.

Ngakho-ke, uma kuqhathaniswa nomshini wokushisela we-laser wendabuko. Yini eyenza umshini wokushisela we-laser ophathwa ngesandla uvelele?

Ake ngikwethule ku-izinzuzo zabashiseli be-laser abaphathwa ngesandla uma kuqhathaniswa nezindlela zokushisela zendabuko.

Futhiindlela abashiseli be-laser abaphathwa ngesandla abaletha ngayo ukukhanyiselwa okuthile.

Uhlu Lokuqukethwe:

Uyini Umshini We-Laser Ophathwa Ngesandla?

Kuyindlela yokushisela esebenza kahle kakhulu, ikhwalithi enhle kakhulu futhi ishibhile.

Umshini we-laser ophathwa ngesandla uwuhlobo lokusebenza olulula oluphathwa ngesandla.

Ingqikithi yayo ukusebenzisa umsebe we-laser ukwenza amamaki ahlala njalo ebusweni bento.

Lena indlela esebenza kahle kakhulu, esezingeni eliphezulu futhi engabizi kakhulu.

Ngokumangalisayo, izindlela zokushisela zendabuko (njenge-MIG noma i-TIG) zinzima ukuzisebenzisa.

Ngenkathi umsebe we-laser ephathwayo unobubanzi obuncane kakhulu bokugxila.

Ukunika amandla ukunemba kokumaka kwezinga le-micron ukuqinisekisa ukuthi okuqukethwe kokumaka kucacile.

Muva nje, bengisiza efektri eyayenza izingxenye ezishiselwe ngokwezifiso.

Omunye wemisebenzi eyinselele kakhulu esihlangabezane nayo kwakuwukuhlanganisa izingcezu ezincane ze-aluminiyamu ndawonye ngaphansi kokushisa okukhulu.

Ngesikhathi sishintshela kumshini wokushisela we-laser ophathwa ngesandla.

Sithole ukuthi ikhiqize ama-weld asezingeni eliphezulu ane-thermal shock encane.

Kunciphisa kakhulu ingozi yokugoba nokuqinisekisa ukuhlanzeka kwe-weld ngaphandle kwesidingo sokuqedwa okukhulu ngemva kokugoba.

Kuyinto enhle impela, akunjalo?

Ukuqhathanisa Nomshini Wokushisela We-Laser Wendabuko

Imishini yokushisela ephathwa ngesandla ingcono kakhulu

Eminyakeni yamuva nje, amazwe emhlabeni wonke abe nezidingo eziphakeme kakhulu zokuvikelwa kwemvelo.

Ukushisela i-argon arc kuzokhiqiza inani elikhulu lothuli kanye ne-slag yokushisela.

Kuyingozi kakhulu emvelweni.

Izinkampani ezihluleka ukuhlangabezana nezimfuneko zokuvikelwa kwemvelo zizobhekana nokubhekwa kwemithetho.

Futhi ukushisela okubanjwe ngesandla nge-laser akunangozi kangako emvelweni.

Ingasetshenziswa kabanzi kwezinye izimboni ezingajwayelekile neziyinkimbinkimbi.

Isingeniso Sokushisela I-Argon Arc Yendabuko

Izinzuzo

1. Ukushisela i-argon arc yendabuko nakho kunezinzuzo ezifanayo. Intengo iphansi, ngokuvamile isukela ezinkulungwaneni ezimbalwa kuya ku-20,000 kuya ku-30,000.

2. Nakuba ukucubungula kuqinile, amandla anamandla kunezinye. Kufanelekile ezakhiweni zensimbi ezithwala umthwalo ezinejubane lokushisela elihamba kancane.

Ukungalungi

1. Ubukhulu bokushisela bukhulu kakhulu, bufanelekela amapuleti okushisela amakhulu angaphezu kuka-4mm.

2. Ukushisela i-argon arc kudinga abashiseli abavuthiwe. Futhi umholo wanyanga zonke wabashiseli abavuthiwe uqala okungenani u-8K.

Isingeniso Sokushisela Nge-Laser Esiphathwa Ngesandla

Izinzuzo

1. Isethi ephelele yemishini yokushisela ye-laser ephathwayo inamandla. Yakhelwe ngendlela ye-ergonomic futhi ifanelekela izindawo ezahlukene zokusebenza. Inomsebenzi ohlukile wokuvikela ukusebenza kokuphepha kwe-laser. Futhi ingaqinisekisa ukuphepha komqhubi lapho esebenza.

2. Lo msebenzi kulula ukuwufunda futhi uyashesha ukuwusebenzisa. Futhi umkhawulo wobuchwepheshe womqhubi awuphezulu, okusindisa izindleko zabasebenzi.

3. Kulula ukufunda ukushisela okubanjwe ngesandla. Abasebenzi abavamile bangaqala ngesigamu sosuku. Umholo wenyanga womshiseli ojwayelekile ophathwa ngesandla ngokuvamile ucishe ube yi-4k.

4. Ijubane lomshini wokushisela nge-laser liphindwe izikhathi eziyi-10-20. Izisebenzi ezivamile ze-laser zingawusebenzisa kalula, futhi indawo yokusebenza ikhululekile. Umholo womshini wokushisela we-argon arc owodwa ungaqasha opharetha be-laser abathathu.

Khetha uhlobo oluhlukile lomshini wokushisela we-laser ophathwa ngesandla?

Singasiza Ekuthatheni Isinqumo Esifanele Ngokusekelwe Ezicelweni

Izinzuzo Zokushisela Nge-Laser Ezibanjwe Ngesandla

Kunezinzuzo Ezithile Zangempela Zokusebenzisa Ukushisela Nge-Laser Ephathwayo

Umkhiqizo wokugcina wokushisela nge-laser obanjwe ngesandla awunasici futhi awudingi ukusandwa noma ukushintshwa.

Ukushisela okubanjwe ngesandla akugcini nje ngokuhlangabezana naleli zinga, kodwa futhi kuyalidlula.

Ukubukeka Okuthuthukisiwe Kobuhle

Abashiseli be-laser abaphathwa ngesandla bakhiqiza imikhiqizo enekhwalithi ephezulu yokubuka.

Ikhwalithi yogongolo oluzinzile iqinisekisa imithungo yokushisela eqinile, ebushelelezi, nekhangayo, okunciphisa ukuguguleka kanye nezibazi zokushisela.

Lokhu kunciphisa isidingo sokupholisha okwesibili, konga isikhathi futhi kunciphisa izindleko zomsebenzi zabakhiqizi.

Isivinini Esiphezulu Nokusebenza Kahle Kokukhiqiza Okukhuphukile

Ukushisela nge-laser kushesha kakhulu kunezindlela zendabuko, ngesivinini esingafinyelela izikhathi ezi-5 kuya kweziyi-10 ngokushesha.

Ikhono lokugcina ukungena okujulile kanye nesilinganiso sokuvunwa okuphezulu ezintweni ezahlukene kuthuthukisa umkhiqizo.

Ukusebenza okuqhubekayo kusekelwa izinhlelo zokupholisa ezizinikele, okuvumela ukuhamba komsebenzi kwamahora angama-24

Ukusetshenziswa Kokushisa Okuphansi

Inqubo yokushisela nge-laser idala indawo encane ethintekile ekushiseni, okunciphisa umonakalo wokushisa ezintweni ezizungezile.

Lokhu kunemba kuqinisekisa ukushintshwa okuhlanzekile futhi kugcina ubuqotho bomkhiqizo, kunciphisa ingozi yokugoba.

Ukushintshwa Okuhlanzekile

Ama-weld ngokuvamile aphuma ehlanzekile, adinga ukucutshungulwa okuncane ngemva kokusetshenziswa.

Ezimbonini lapho ukubonakala komkhiqizo wokugcina kubaluleke njengamandla awo (cabanga ngezimoto noma izindiza), lokhu kuyinzuzo enkulu.

Umshini wokushisela we-laser ophathwa ngesandla wenza kube lula

inqubo yokukhiqiza!

I-Laser Welder Ephathwayo Izimo Zokusebenza Ezisebenzayo

Ukushisela Nge-Laser Okubanjwe Ngesandla Kuyizinto Ezibalulekile

Nakuba izinzuzo zemishini yokushisela nge-laser ephathwayo zinkulu kakhulu.

Kukhona futhi ezinye izinyathelo zokuphepha.

Okokuqala, imishini ibiza kakhulu futhi idinga isikhathi esithile sokufunda ukuze isetshenziswe futhi inakekelwe kahle.

Futhi, amakhasimende amaningi ahlose ukwethula umshini wokushisela we-laser ophathwa ngesandla.

Abanezinkinga ngokusetshenziswa kwayo kanye nokusebenza kwayo.

Amanye amakhasimende ayisebenzise isikhathi esithile futhi afingqa okuqukethwe okulandelayo.

Imishini Yokushisela Ye-Laser Ephathwayo

Umshini Wokushisela We-Laser Ophathwayo Ufanelekela Lezi Zimo Zokusebenza Ezilandelayo:

· Indawo enkulu yokushisela idinga ukusebenza kahle kakhulu kokushisela.

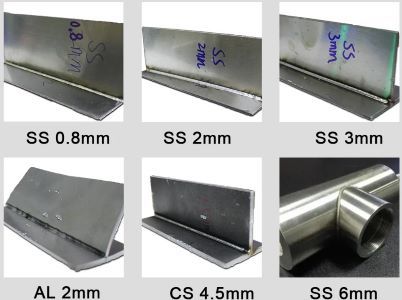

· Ubukhulu bepuleti bungaphezu kuka-0.5mm.

· Xazulula inkinga yobuhle bokushisela kanye nokuguqulwa.

· Yenziwe kakhulu ngensimbi engagqwali, ipuleti lensimbi, kanye ne-aluminium.

· Kukhona inani elithile lesikhala sesabelomali.

· Ukuze kuxazululwe inkinga yomsebenzi, umshini wokushisela we-laser ophathwa ngesandla ungaqala ukusebenza ngaphandle kwezisekelo zokushisela.

Umshini Wokushisela We-Laser Ungashisela Kangakanani?

Uma ubukhulu bomsebenzi ohlanganisiwe bubukhulu, amandla omshini wokuwelda we-laser okhethiwe kufanele abe makhulu.

1. Umshini wokushisela we-laser ongu-1000W: umphumela wokushisela ulungele amapuleti anobukhulu obungaphansi kuka-3mm.

2. Umshini wokushisela we-laser ongu-1500W: umphumela wokushisela ulungele amapuleti anobukhulu obungaphansi kuka-5mm.

3. Umshini wokushisela we-laser ongu-2000W: umphumela wokushisela ulungele amapuleti anobukhulu obungaphansi kuka-8mm.

Udinga ukwazi: Indlela yokukhetha umshini we-laser ophathwa ngesandla

Amandla aphezulu kanye ne-Wattage yezicelo ezahlukahlukene zokushisela

Umshini wokushisela we-laser ophathwa ngesandla ongu-2000W ubonakala ngobukhulu bomshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-laser yefayibha ozinzile kanye nekhebula lefayibha elixhunyiwe linikeza ukulethwa kwe-laser beam okuphephile nokuzinzile.

Ngamandla aphezulu, imbobo yokhiye yokushisela ye-laser iphelele futhi ivumela ijoyinti lokushisela ukuthi liqine ngisho nasensimbini ejiyile.

Ukuthwaleka Kokuguquguquka

Njengoba ibukeka incane futhi incane ngomshini, umshini wokushisela we-laser ophathwayo ufakwe isibhamu sokushisela se-laser esiphathwa ngesandla esinyakaziswayo esilula futhi esilungele ukusetshenziswa kokushisela kwe-laser eminingi kunoma iyiphi i-engeli kanye nobuso.

Izinhlobo ezahlukene zokuzikhethela zama-nozzle okushisela nge-laser kanye nezinhlelo zokuphakela ngocingo okuzenzakalelayo zenza ukusebenza kokushisela nge-laser kube lula futhi lokho kuyabasiza abaqalayo.

Ukushisela nge-laser okusheshayo kukhulisa kakhulu ukusebenza kahle kokukhiqiza kwakho kanye nomphumela ngenkathi kuvumela umphumela omuhle kakhulu wokushisela nge-laser.

Izinto Okufanele Uzazi Ngazo: Ukushisela Nge-Laser Ephathwa Ngesandla

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisele isiteshi sethu se-Youtube?

Izicelo Ezihlobene Ongase Ube Nentshisekelo Kuzo:

Konke Ukuthenga Kufanele Kube Nolwazi Oluhle

Singasiza ngolwazi oluningiliziwe kanye nokubonisana!

Isikhathi sokuthunyelwe: Jan-13-2025