Na'urar Laser Mai Hannu

Sanya walda ta Laser a cikin Samfurin ku

Yadda ake zaɓar ƙarfin laser mai dacewa don ƙarfe mai walda?

Kauri na Weld na gefe ɗaya don Ƙarfin Daban-daban

| 500W | 1000W | 1500W | 2000W | |

| Aluminum | ✘ | 1.2mm | 1.5mm | 2.5mm |

| Bakin Karfe | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Karfe na Carbon | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Takardar Galvanized | 0.8mm | 1.2mm | 1.5mm | 2.5mm |

Me yasa ake amfani da Laser Welding?

1. Ingantaccen Aiki

▶ Sau 2 - 10Ingancin walda idan aka kwatanta da walda ta gargajiya ◀

2. Inganci Mai Kyau

▶ Ci gaba da walda ta laser na iya haifar dahaɗin walda masu ƙarfi da leburba tare da porosity ba ◀

3. Ƙarancin Kudin Gudanarwa

▶Ajiye kashi 80% na kudin gudanarwaakan wutar lantarki idan aka kwatanta da walda ta baka ◀

4. Tsawon Rayuwar Aiki

▶ Tushen laser mai ƙarfi yana da tsawon rai na matsakaicinSa'o'in aiki 100,000, ana buƙatar ƙarancin kulawa ◀

Ingantaccen Inganci & Kyakkyawan Dinkin Walda

Bayani dalla-dalla - Na'urar walda ta Laser ta hannu 1500W

| Yanayin aiki | Ci gaba ko daidaitawa |

| Tsawon Laser | 1064NM |

| Ingancin katako | M2 <1.2 |

| Janar Power | ≤7KW |

| Tsarin sanyaya | Injin sanyaya ruwa na masana'antu |

| Tsawon zare | 5M-10MCAna iya gyarawa |

| Kauri na walda | Dogara da kayan aiki |

| Bukatun kabu na walda | <0.2mm |

| Gudun walda | 0~120 mm/s |

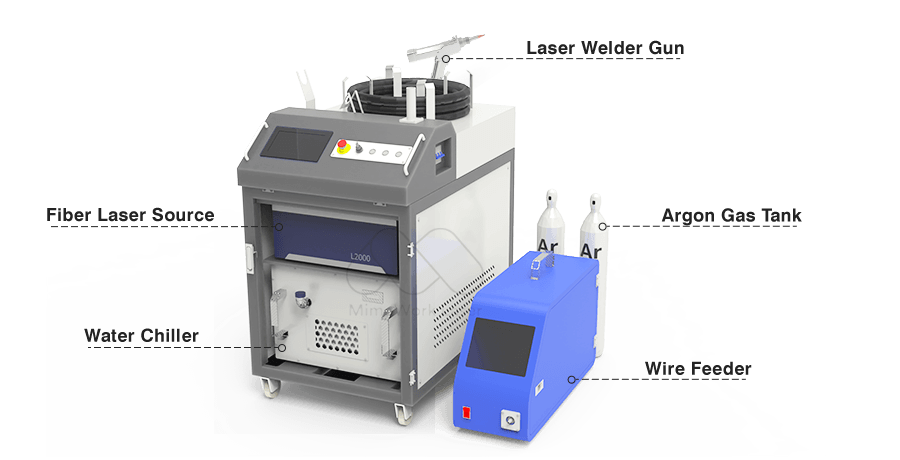

Cikakkun Bayanan Tsarin - Na'urar Walda ta Laser

◼ Tsarin mai sauƙi da ƙanƙanta, yana mamaye ƙaramin sarari

◼ An saka kura, mai sauƙin motsawa

◼ Kebul ɗin zare mai tsawon mita 5/mita 10, an yi shi da sauƙi

▷ Matakai 3 An Gama

Aiki Mai Sauƙi - Na'urar walda ta Laser

Mataki na 1:Kunna na'urar taya

Mataki na 2:Saita sigogin walda na laser (yanayi, ƙarfi, gudu)

Mataki na 3:Ɗauki bindigar walda ta laser sannan ka fara walda ta laser

Kwatanta: walda ta laser VS walda ta baka

| Walda ta Laser | Walda ta Arc | |

| Amfani da Makamashi | Ƙasa | Babban |

| Yankin da Zafi Ya Shafa | Mafi ƙaranci | Babba |

| Canzawar Kayan Aiki | Kusan ko babu nakasa | Sauƙin canza tsari |

| Wurin Walda | Kyakkyawan walda da kuma daidaitacce | Babban Wuri |

| Sakamakon walda | Tsaftace gefen walda ba tare da buƙatar ƙarin aiki ba | Ana buƙatar ƙarin aikin gogewa |

| Lokacin Aiwatarwa | Lokacin walda kaɗan | Mai ɗaukar lokaci |

| Tsaron Mai Aiki | Hasken hasken rana ba tare da wata illa ba | Hasken ultraviolet mai ƙarfi tare da hasken rana |

| Tasirin Muhalli | Mai da hankali kan muhalli | Ozone da nitrogen oxides (masu cutarwa) |

| Ana Bukatar Iskar Kariya | Argon | Argon |

Me yasa za a zaɓi MimoWork

✔Shekaru 20+ na ƙwarewar laser

✔Takardar shaidar CE da FDA

✔Fasahar Laser 100+ da haƙƙin mallaka na software

✔Manufar sabis na abokin ciniki

✔Ƙirƙirar da bincike na Laser mai ƙirƙira

Koyarwar Bidiyo

Walda ta Laser da sauri!

Menene Na'urar Laser Mai Hannu?

Yadda ake amfani da na'urar walda ta Laser ta hannu?

Walda ta Laser vs TIG: Wanne ya fi kyau?

Abubuwa 5 Game da Walda ta Laser (Da Ka Rasa)

Tambayoyin da ake yawan yi akai-akai

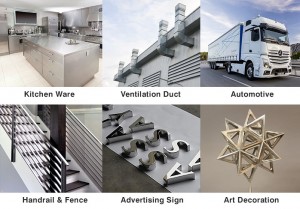

Yana aiki da kyau da aluminum, bakin karfe, carbon steel, da kuma galvanized sheets. Kauri mai sauƙin walda ya bambanta dangane da kayan aiki da ƙarfin laser (misali, 2000W yana iya sarrafa bakin karfe 3mm). Ya dace da yawancin karafa da ake samarwa a masana'antu.

Da sauri sosai. Tare da matakai 3 masu sauƙi (kunnawa, saita sigogi, fara walda), har ma sabbin masu amfani za su iya ƙwarewa a cikin sa'o'i. Ba a buƙatar horo mai rikitarwa, wanda ke adana lokaci akan lanƙwasa koyon mai aiki.

Ana buƙatar kulawa kaɗan. Tushen laser ɗin fiber yana da tsawon rai na awanni 100,000, kuma ƙaramin tsarin tare da sassa masu ɗorewa yana rage buƙatun kulawa, yana rage farashi na dogon lokaci.