Laser Yankan Zafi Canja wurin Vinyl

Teburin Abubuwan da ke Ciki:

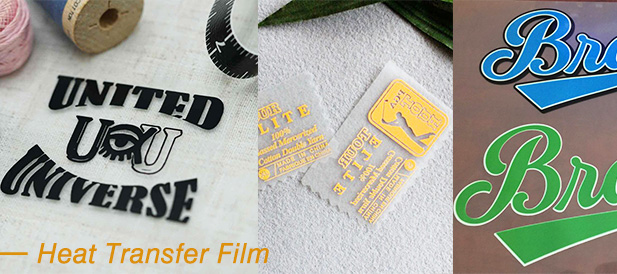

Fim ɗin canja wurin zafi na Laser (wanda kuma ake kira da laser engraving heat transfer vinyl) wata hanya ce mai shahara a masana'antar tufafi da talla.

Saboda aikin da ba a taɓawa ba da kuma zane mai kyau, zaku iya samun HTV mai kyau tare da gefen da ya dace da kuma tsabta.

Tare da tallafin kan laser na FlyGalvo, saurin yankewa da alamar laser na canja wurin zafi zai ninka wanda ke da fa'ida ga ingancin samarwa da fitarwa.

Menene Vinyl Canja wurin Zafi & Yadda ake Yankewa?

Gabaɗaya, fim ɗin buga hotuna yana amfani da bugun ɗigo (tare da ƙudurin har zuwa 300dpi). Fim ɗin yana ɗauke da tsarin ƙira mai layuka da yawa da launuka masu haske, wanda aka riga aka buga a samansa. Injin matse hotuna yana yin zafi sosai kuma yana matsa lamba don manna fim ɗin da aka buga a saman samfurin ta amfani da kan tambari mai zafi. Fasahar canja wurin zafi tana da kwafi sosai kuma tana iya biyan buƙatun masu ƙira, don haka ta sa ta dace da manyan samarwa.

Fim ɗin canja wurin zafi yawanci yana da layuka 3-5, waɗanda suka ƙunshi layin tushe, layin kariya, layin bugawa, layin manne, da layin foda mai narkewa mai zafi. Tsarin fim ɗin na iya bambanta dangane da yadda aka yi niyya. Ana amfani da fim ɗin vinyl mai canja wurin zafi a masana'antu kamar tufafi, talla, bugawa, takalma, da jakunkuna don manufar sanya tambari, alamu, haruffa, da lambobi ta amfani da tambari mai zafi. Dangane da kayan, ana iya amfani da vinyl mai canza zafi ga masaku kamar auduga, polyester, lycra, fata, da sauransu. Ana amfani da injunan yanke laser don yanke fim ɗin zana zafi na PU da kuma don tambari mai zafi a aikace-aikacen tufafi. A yau, za mu tattauna wannan tsari na musamman.

Me yasa Laser Engraving Canja wurin Film?

Tsaftataccen gefen yankewa

Mai sauƙin tsagawa

Daidaitacce & yanke mai kyau

✔A sumbaci fim ɗin ba tare da lalata layin kariya ba (takardar ɗaukar kaya mai sanyi)

✔Babban abu mai kyau akan haruffa masu faɗi

✔Mai sauƙin cire sharar gida

✔Samarwa Mai Sauƙi

Zafi Canja wurin roba Laser Cutter

FlyGalvo130

• Wurin Aiki: 1300mm * 1300mm

• Ƙarfin Laser: 130W

• Wurin Aiki: 1000mm * 600mm (An keɓance shi)

• Ƙarfin Laser: 40W/60W/80W/100W

Nunin Bidiyo - Yadda ake Yanke Zafi ta Laser akan Vinyl

(Yadda za a guji ƙone gefuna)

Wasu Nasihu - Jagorar Laser Canja wurin Zafi

1. Saita rage ƙarfin laser tare da matsakaicin gudu

2. Daidaita injin hura iska don mataimakin yankan

3. Kunna fankar shaye-shaye

Shin Mai Zane-zanen Laser Zai Iya Yanke Vinyl?

Mafi saurin zanen Galvo Laser Engraver wanda aka tsara don Laser Engraving Heat Transfer Vinyl yana tabbatar da babban haɓaka yawan aiki! Wannan zanen laser yana ba da babban gudu, daidaiton yankewa mai kyau, da kuma dacewa da kayan aiki daban-daban.

Ko dai fim ɗin canza zafi na laser ne, ƙirƙirar zane-zane na musamman, da sitika, ko aiki da fim mai haske, wannan injin sassaka laser na CO2 galvo shine mafi dacewa don cimma tasirin yanke vinyl mara aibi. Gwada ingantaccen aiki yayin da dukkan tsarin yanke laser don canja wurin zafi ke ɗaukar daƙiƙa 45 kawai tare da wannan injin da aka inganta, yana kafa kansa a matsayin shugaba mafi kyau a yanke laser ɗin sitika na vinyl.

Kayan Fim ɗin Canja Zafi Na Kowa

• Fim ɗin TPU

Ana amfani da lakabin TPU a matsayin lakabin tufafi don suturar da ta dace ko kuma ta aiki. Wannan saboda wannan kayan roba yana da laushi sosai har ba ya shiga cikin fata. Sinadarin sinadaran TPU yana ba shi damar jure yanayin zafi mai tsanani, kuma yana iya jure babban tasiri.

• Fim ɗin Dabbobin Gida

PET tana nufin polyethylene terephthalate. Fim ɗin PET polyester ne mai thermoplastic wanda za a iya yanke shi da laser, a yi masa alama, sannan a zana shi da laser mai tsawon micron 9.3 ko 10.6-micron CO2. Ana amfani da Fim ɗin PET mai canja wurin zafi a matsayin Layer mai kariya.

Fim ɗin PU, Fim ɗin PVC, Membrane Mai Tunani, Fim ɗin Mai Nuni, Fim ɗin Mai Zafi, Fim ɗin Mai Zafi, Fim ɗin Vinyl Mai Ƙarfe, Fim ɗin Wasiƙa, da sauransu.

Manhajoji na Musamman: Alamar Kayan Tufafi, Talla, Sicker, Decal, Tambarin Mota, Badge da ƙari.

Yadda ake yin Layer ɗin Canja wurin Zafi akan Tufafi

Mataki na 1. Zana tsarin

Ƙirƙiri ƙirarka ta amfani da CorelDraw ko wata manhajar ƙira. Ka tuna ka raba ƙirar Layer ɗin da aka yanke da kuma ƙirar Layer ɗin da aka yanke.

Mataki na 2. Saita siga

Loda fayil ɗin ƙira akan MimoWork Laser Cutting Software, kuma saita kashi biyu daban-daban na wutar lantarki da saurin yankewa akan layin sumba da layin die-cut tare da shawarar ƙwararrun laser na MimoWork. Kunna famfon iska don samun gefen yankewa mai tsabta sannan fara yanke laser.

Mataki na 3. Canja wurin Zafi

Yi amfani da na'urar matse zafi don canja wurin fim ɗin zuwa yadi. Canja wurin fim ɗin na tsawon daƙiƙa 17 a 165°C / 329°F. Cire layin idan kayan ya yi sanyi gaba ɗaya.