I-Laser Cutting Heat Transfer Vinyl

Uhlu Lokuqukethwe:

Ifilimu yokusika i-laser yokudlulisa ukushisa (ebizwa nangokuthi i-laser engraving heat transfer vinyl) iyindlela edumile embonini yezimpahla zokugqoka nezokukhangisa.

Ngenxa yokucubungula kokungathintwa kanye nokuqoshwa okunembayo, ungathola i-HTV enhle kakhulu enomkhawulo ohlanzekile nonembile.

Ngokusekelwa kwekhanda le-laser ye-FlyGalvo, ukusika kwe-laser yokudlulisa ukushisa kanye nesivinini sokumaka kuzophindwa kabili okunenzuzo ekusebenzeni kahle kokukhiqiza kanye nokuphumayo.

Iyini I-Vinyl Yokudlulisa Ukushisa & Indlela Yokusika?

Ngokuvamile, ifilimu yokuphrinta yokudlulisa isebenzisa ukuphrinta kwamachashazi (okunokulungiswa okufika kokungu-300dpi).Ifilimu iqukethe iphethini yokuklama enezendlalelo eziningi kanye nama-hues agqamile, aphrintiwe ngaphambili ebusweni bayo.Umshini wokucindezela ukushisa ushisa kakhulu futhi usebenzise ingcindezi yokunamathisela ifilimu ephrintiwe phezu komkhiqizo usebenzisa inhloko yokugxiviza eshisayo.Ubuchwepheshe bokudlulisa ukushisa buyaphindaphindeka ngendlela emangalisayo futhi buyakwazi ukuhlangabezana nezidingo zabaklami, ngaleyo ndlela bufanelekele ukukhiqizwa kwenani elikhulu.

Ifilimu yokudlulisa ukushisa ngokuvamile yenziwe ngezingqimba ezingu-3-5, ezihlanganisa isendlalelo sesisekelo, isendlalelo esivikelayo, isendlalelo sokuphrinta, isendlalelo sokunamathisela, kanye nesendlalelo se-adhesive adhesive eshisayo eshisayo.Isakhiwo sefilimu singahluka kuye ngokusetshenziswa okuhlosiwe.Ifilimu ye-vinyl yokudlulisa ukushisa isetshenziswa ngokuyinhloko ezimbonini ezifana nezingubo, ukukhangisa, ukuphrinta, izicathulo, nezikhwama ngenjongo yokusebenzisa amalogo, amaphethini, izinhlamvu, nezinombolo kusetshenziswa isitembu esishisayo.Ngokwezinto ezibonakalayo, i-vinyl yokudlulisa ukushisa ingasetshenziswa ezindwangu ezifana nekotini, i-polyester, i-lycra, isikhumba, nokunye.Imishini yokusika i-laser ivame ukusetshenziselwa ukusika ifilimu eqophayo yokudlulisa ukushisa kwe-PU kanye nokugxiviza okushisayo ezimpahleni zokugqoka.Namuhla, sizoxoxa ngale nqubo ethile.

Kungani Laser Engraving Dlulisa Film?

Hlanza onqenqemeni lokusika

Kulula ukudabula

Ukusika okuqondile nokucolekile

✔Kiss-sika ifilimu ngaphandle kokulimaza isendlalelo esivikelayo (ishidi lenkampani yenethiwekhi eliqandisiwe)

✔Unqenqema oluhlanzekile lwezinhlamvu eziyinkimbinkimbi

✔Kulula ukususa isendlalelo semfucuza

✔Ukukhiqiza Okuguquguqukayo

Ukushisa Ukudlulisa I-Vinyl Laser Cutter

I-FlyGalvo130

• Indawo yokusebenza: 1300mm * 1300mm

• Amandla eLaser: 130W

• Indawo yokusebenza: 1000mm * 600mm (Eyenziwe ngokwezifiso)

• Amandla eLaser: 40W/60W/80W/100W

Isibonisi Sevidiyo - Indlela Yokusika I-Laser Yokudlulisa Ukushisa I-Vinyl

(Ungagwema kanjani ukuvutha imiphetho)

Amanye Amathiphu - I-Heat Transfer Laser Guide

1. Setha amandla e-laser abe phansi ngesivinini esimaphakathi

2. Lungisa isiphephetha-moya sokusika umsizi

3. Vula isiphephetha-moya se-exhaust

Ingabe Umqophi We-Laser Angakwazi Ukusika I-Vinyl?

I-Galvo Laser Engraver eshesha kakhulu eyenzelwe i-Laser Engraving Heat Transfer Vinyl iqinisekisa ukuthuthukiswa okuphawulekayo kokukhiqiza!Lo mqophi we-laser unikeza isivinini esikhulu, ukunemba kokusika okungenakuqhathaniswa, nokuhambisana nezinto ezihlukahlukene.

Kungakhathaliseki ukuthi ifilimu yokudlulisa ukushisa esika i-laser, ukwenza amadecal angokwezifiso, nezitikha, noma ukusebenza ngefilimu ekhanyayo, lo mshini wokuqopha nge-CO2 galvo laser ufanelana kahle kakhulu nokuzuza umphumela we-vinyl wokusika ongenasici.Zizwa ukusebenza kahle okumangazayo njengoba yonke inqubo yokusika i-laser yokudlulisa ukushisa i-vinyl ithatha imizuzwana engama-45 kuphela ngalo mshini othuthukisiwe, uzibonakalisa njengomphathi omkhulu ekusikeni kwe-laser sticker ye-vinyl.

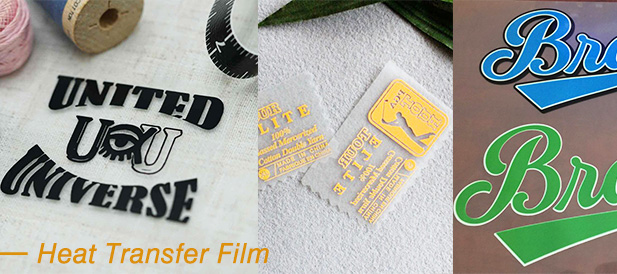

I-Common Heat Transfer Film Material

• Ifilimu ye-TPU

Amalebula e-TPU asetshenziswa kakhulu njengamalebula ezingubo zokugqokwa okusondelene noma ukugqokwa okusebenzayo.Lokhu kungenxa yokuthi le nto yerabha ithambile ngokwanele ukuthi ayimbi esikhumbeni.Ukwakheka kwamakhemikhali kwe-TPU kuyivumela ukuthi ibambe izinga lokushisa elidlulele, futhi ekwazi ukumelana nomthelela omkhulu.

• Ifilimu ye-PET

I-PET ibhekisela ku-polyethylene terephthalate.Ifilimu ye-PET i-thermoplastic polyester engasikwa nge-laser, imakwe, futhi iqoshwe ngelaser engu-9.3 noma engu-10.6-micron wavelength CO2.Ifilimu ye-PET yokudlulisa ukushisa ihlala isetshenziswa njengesendlalelo sokuvikela.

Ifilimu ye-PU, Ifilimu ye-PVC, I-Refelctive Membrane, Ifilimu Ekhombisayo, I-Heat Trasfer Pyrograph, i-Iron-on Vinyl, i-Lettering Film, njll.

Izinhlelo zokusebenza ezijwayelekile: Uphawu Lwezinsiza Zezingubo, Ukukhangisa, I-Sicker, Decal, Ilogo Ezenzakalelayo, Ibheji nokuningi.

Indlela Yokwendlalela Ifilimu Yokudlulisa Ukushisa Ku-Apparel

Isinyathelo 1. Yakha iphethini

Dala umklamo wakho nge-CorelDraw noma enye isofthiwe yokuklama.Khumbula ukuhlukanisa isendlalelo se-kiss-cut kanye ne-die-cut layer design.

Isinyathelo sesi-2. Setha ipharamitha

Layisha ifayela lokuklama ku-MimoWork Laser Cutting Software, futhi usethe amaphesenti amabili ahlukene amandla kanye nesivinini sokusika kungqimba yokusikwa kokuqabula kanye nesendlalelo sokusika ngokufa ngesincomo esivela ochwepheshe belaser be-MimoWork.Vula iphampu yomoya ukuze uthole unqenqema oluhlanzekile bese uqala ukusika nge-laser.

Isinyathelo sesi-3. Ukudlulisa Ukushisa

Sebenzisa umshini wokushisa ukushisa ukuze udlulisele ifilimu ezindwangu.Dlulisa ifilimu imizuzwana engu-17 ku-165°C / 329°F.Susa i-liner lapho impahla ibanda ngokuphelele.