Yanke Laser Polyester

Polyester ɗin yanke laser yana da shahara kuma ya zama ruwan dare.Wannan ba wai kawai saboda dacewa da laser CO2 ba (wanda kayan polyester ke sha sosai) amma kuma godiya ga babban matakin sarrafa kansa na injin yanke laser.

Mun san cewa masana'anta ta polyester tana da kyawawan halaye wajen cire danshi, bushewa da sauri, juriya ga wrinkles da kuma dorewa. Waɗannan sun sa polyester ya zama muhimmin sashi na kayan wasanni, kayan yau da kullun, kayan gida da kayan waje. Don dacewa da haɓakar abubuwan polyester, ana inganta injin yanke laser na masana'anta kuma an inganta shi.

Akwai nau'ikan kayan yanke laser polyester guda biyu masu mahimmanci waɗanda aka tsara don na'urorin ku.Yadin polyester mai ƙarfi da yadin polyester mai launin fentiBaya ga masana'anta mai yanke laser polyester, laser CO2 yana da kyakkyawan aiki a fim ɗin polyester mai yanke laser da kuma jifa mai yanke laser polyester. Yanzu ku biyo mu, ku binciki duniyar polyester mai yanke laser.

Teburin Abubuwan da ke Ciki:

◼ Sarrafa Laser Don Polyester

1. Yanke Laser Polyester

Za a iya yanke polyester ba tare da ya yi laushi ba? Amsar daga na'urar yanke laser ita ce EH!

Ana amfani da polyester na yanke laser musamman ma polyester sosai. Tare da kyakkyawan wurin laser da kuma hanyar yanke laser daidai, injin yanke laser zai iya yanke masana'antar polyester daidai zuwa guntu da ake amfani da su a tufafi, kayan wasanni, ko tutoci.

Daidaiton polyester na yanke laser yana kawo kyakkyawan gefen da santsi. Zafin da ke fitowa daga laser na CO2 yana iya rufe gefen nan take, yana kawar da shi bayan an gama aiki.

Injin yanke laser, musamman ma, yana cikin wurin da za a iya taɓawa da yanke polyester ɗin. Shi ya sa babu wani iyaka a yanke siffofi, alamu, da girma dabam-dabam. Kuna iya amfani da injin yanke laser na polyester don ƙirƙirar ƙira da aka ƙera musamman, tare da tasirin yankewa mai kyau.

2. Rage Laser a cikin Polyester

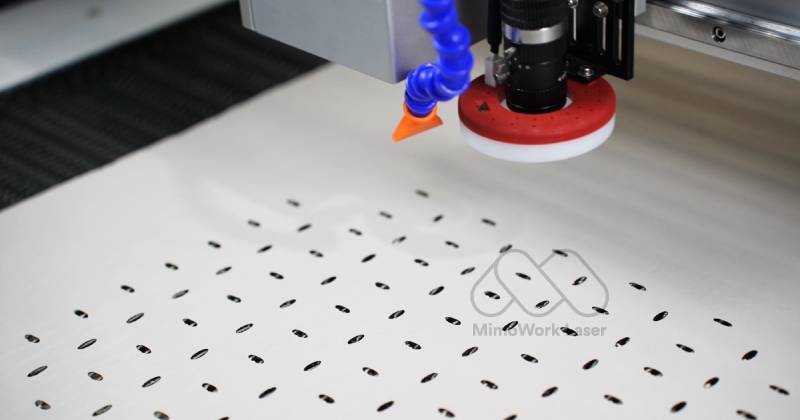

Hudawar Laser kamar polyester ɗin yanke laser ne, amma bambancin shine yanke ƙananan ramuka a cikin polyester ta laser.Mun san cewa wurin laser ɗin siriri ne sosai wanda zai iya kaiwa 0.3mm, wanda ke nufin ƙananan ramukan yanke laser yana yiwuwa.

Za ka iya keɓance siffofi da girman ramukan, gami da sarari tsakanin ramuka daban-daban. Ana amfani da ramukan yanke laser a cikin polyester sosai a cikin kayan wasanni, don cimma kyakkyawan iska mai kyau. Bugu da ƙari, ramin laser yana da saurin gudu, wanda yake da inganci sosai don sarrafa polyester.

3. Alamar Laser akan Polyester

Alamar Laser akan polyester (wanda kuma ake kira da laser engraving polyester) fasaha ce ta musamman ta alama. Ko don sassaka a kan rigunan polyester, jakunkuna, ko tawul, injin laser zai iya yin sa. Kyakkyawan wurin laser da ingantaccen iko da sarrafa gudu, suna sa tasirin sassaka ko alamar ya zama abin mamaki. Kuna iya sassaka tambari, hoto, rubutu, suna, ko kowane ƙira akan masana'anta ko ji na polyester. Alamar dindindin ba ta lalace ko ɓacewa ba. Kuna iya ƙawata yadin gida ko sanya alamomi don gano tufafi na musamman.

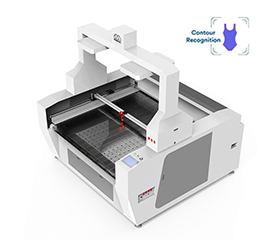

Buɗe sirrin yanke kayan wasanni na sublimation cikin sauri da atomatik,Injin yanke laser na gani na MimoWorkYa fito a matsayin babban abin da ke canza tufafi masu laushi, ciki har da kayan wasanni, wando, kayan ninkaya, da sauransu. Wannan na'urar zamani ta gabatar da sabon zamani a duniyar samar da tufafi, godiya ga ingantaccen fahimtar tsari da kuma iya yankewa daidai.

Ka nutse cikin duniyar kayan wasanni masu inganci, inda zane-zane masu rikitarwa ke bayyana a sarari ba tare da wani bambanci ba. Amma ba haka kawai ba ne - na'urar yanke laser ta MimoWork ta fi ta sauran fasahar da ke ba da damar ciyarwa ta atomatik, isarwa, da yankewa.

Kayan Yanke Laser na Kyamara don Kayan Wasanni & Tufafi

Muna zurfafa bincike kan hanyoyin zamani da na atomatik, muna binciken abubuwan al'ajabi na yadin laser da aka buga da kayan aiki. Tare da kyamarar zamani da na'urar daukar hoto, na'urar yanke laser ɗinmu tana ɗaukar inganci kuma tana da kyau har zuwa kololuwar da ba a taɓa gani ba. A cikin bidiyonmu mai kayatarwa, ku shaida sihirin na'urar yanke laser mai hangen nesa ta atomatik wacce aka tsara don duniyar tufafi.

Kawunan laser na Y-axis guda biyu suna ba da inganci mara misaltuwa, wanda hakan ya sa wannan na'urar yanke laser ta kyamara ta zama fitacciyar mai aiki a cikin yadin da aka yi amfani da su wajen yanke laser, gami da duniyar kayan jersey mai rikitarwa. Ku shirya don sauya salon aikinku na yanke laser da inganci da salo!

Yadda ake yanke Teardrop na Laser akan Sublimation

Yadda ake yanke tutocin sublimated daidai? Babban injin yanke laser na gani don masana'anta shine kayan aiki mafi sauƙi don aiwatar da samarwa ta atomatik a masana'antar tallan sublimation. Kamar tutocin hawaye, tutoci, nunin nunin faifai, bango, da sauransu.

Wannan bidiyo yana nuna yadda ake amfani da shi wajen sarrafa na'urar yanke laser ta kyamarakuma yana nuna tsarin yanke laser na alamar hawaye. Daidaitaccen yankewa tare da siffar da aka buga, da kuma saurin yankewa cikin sauri.

◼ Fa'idodi Daga Yankewar Laser Polyester

Yadda ake yanke masana'anta ta polyester cikin sauri da kuma daidai? Ta amfani da na'urar yanke laser ta polyester, zaku iya samun cikakkun kayan polyester don sublimation polyester ko polyester mai ƙarfi. Ingantaccen aiki yana zuwa tare da inganci mai kyau.

Bambance-bambanceTeburan aikikuma zaɓi neTsarin Ganewar Kwane-kwanesuna ba da gudummawa ga yankan laser na kayan masana'anta na polyester a kowane girma, kowane siffa, da kuma tsarin bugawa.

Ba wai kawai hakan ba, na'urar yanke laser za ta iyakawar da damuwa game da gurɓataccen abu da lalacewa godiya ga aikin da ba a taɓa yi ba.

Tare da tsari mai kyau da kuma yankewa daidai,Polyester Laser cutteryana taimakawa wajen inganta yawan shan giyatanadin kuɗi naalbarkatun ƙasa da sarrafawa.

Ciyarwa ta atomatik, isarwa, da yankewa na iya ƙara yawan ingancin samar da kayanka.

Gefen mai tsabta kuma lebur

Yanke zagaye na kowane kusurwa

Babban inganci & fitarwa

✔Gefuna masu tsabta da lebur kuma babu lalacewar kayan aiki

✔ Daidaitaccen yankewa tare da Tsarin Gane Kwane-kwane

✔ Babban inganci tare da ci gaba ciyarwa ta atomatik

✔ Ya dace da yankan duk wani tsari da siffar da aka buga

✔ Tsarin sarrafa atomatik na CNC, yana adana aiki da farashin lokaci

✔ Daidaito mai maimaitawa, tabbatar da daidaito mai inganci mai kyau

✔ Babu abrasion da maye gurbin kayan aiki

✔ Hanyar sarrafawa mai kyau ga muhalli

Mun san cewa masana'antar polyester tana da nau'ikan aikace-aikace iri-iri, tun daga tufafi har zuwa kayayyakin masana'antu. Aikace-aikacen masana'antar polyester daban-daban suna zuwa da halaye daban-daban na kayan aiki da buƙatun sarrafawa. Mai yanke Laser, daidai da mai yanke laser CO2, kayan aiki ne mai kyau don yanke kayayyaki daban-daban na masana'antar polyester.

Me yasa za a faɗi haka? Laser CO2 yana da fa'ida ta musamman wajen yanke masaka, saboda yawan shaƙar masaka zuwa laser CO2, gami da polyester. Haka kuma, yanke laser ba shi da iyaka ga ƙirar yankewa, don haka kowace siffa, kowace girma ana iya yanke ta da laser. Wannan yana ba da dama mai yawa don yanke laser daban-daban kayayyakin masana'anta na polyester. Kamar su kayan wasanni, jakunkuna, kyallen tacewa, tutoci, da sauransu.

◼ Aikace-aikacen Felt ɗin Yanke Laser na Polyester

Yanke Laser polyester jiyana bayar da nau'ikan aikace-aikace iri-iri.

Ya haɗa da sana'o'in hannu da ayyukan DIY, kayan adon gida kamar zane-zanen bango da coasters, kayan ado na zamani kamar huluna da jakunkuna, kayan ofis kamar masu shiryawa da linzamin kwamfuta, kayan ciki na motoci, hanyoyin hana sauti, da kayayyakin talla.

Daidaito da kuma sauƙin amfani da yanke laser ya sa ya zama manufa don ƙirƙirar ƙira masu rikitarwa da siffofi na musamman.

Amfani da laser na CO2 don yanke jigunan polyester yana da matuƙar amfani musamman saboda yana samar da gefuna masu tsabta da santsi ba tare da yankan ba.

Ingancinsa wajen yanke tsare-tsare masu rikitarwa, da kuma yanayin rashin hulɗa da shi, yana rage gurɓatar abu da kuma tabbatar da sakamako mai inganci.

◼ Aikace-aikacen Fim ɗin Yanke Laser Polyester

Ana amfani da fim ɗin polyester na yanke laser sosai a masana'antu daban-daban saboda daidaito da sauƙin amfani da shi. Aikace-aikacen sun haɗa da ƙirƙirar da'irori masu sassauƙa, stencil, buga allo, rufe kariya, kayan marufi, lakabi, da decals.

Yankewar Laser yana samar da yankewa mai tsabta da daidaito ba tare da haifar da nakasar abu ba. Wannan yana da mahimmanci don kiyaye inganci da aikin polyesterfimSamfura. Tsarin yana da inganci sosai, yana ba da damar ƙira mai rikitarwa da keɓancewa, wanda hakan ya sa ya dace da duka samfuran samfura da kuma manyan samarwa.

◼ Shawarar yanke laser na polyester

• Ƙarfin Laser: 100W/ 150W/ 3000W

• Wurin Aiki: 1800mm * 1300mm (70.87'' * 51.18'')

• Ƙarfin Laser: 100W/150W/300W

• Wurin Aiki: 1600mm*1000mm (62.9” *39.3”)

•Faɗin Yankin Tarawa: 1600mm * 500mm

• Ƙarfin Laser: 150W/300W/500W

• Wurin Aiki: 1600mm * 3000mm (62.9'' *118'')

◼ Bayanin Kayan Aiki na Laser Yankan Polyester Fabric

A matsayin kalma ta gama gari don polymer na wucin gadi, polyester (PET) yanzu ana ɗaukarsa azaman aiki mai amfani kayan roba, yana faruwa a masana'antu da kayayyakin kayayyaki. An yi shi da zare da zare na polyester, an yi shi da polyester da aka saka da kuma aka saka, wanda aka yi da polyester mai laushi da laushi.Halayen da ke tattare da juriya ga raguwa da miƙewa, juriya ga wrinkles, dorewa, sauƙin tsaftacewa, da mutuwa.

Ana ba wa polyester ƙarin halaye don haɓaka ƙwarewar saka abokan ciniki, faɗaɗa ayyukan yadi na masana'antu. Kamar auduga-polyester, ana nuna shi da ƙarfi mai yawa, juriya ga yanayi, mai numfashi da hana tsatsa, wanda hakan ya sa ya zama kayan da aka saba amfani da su a yau da kullun. tufafi da kayan wasanniHaka kuma, aikace-aikacen masana'antusuna da yawa, kamar yadin bel na jigilar kaya, bel ɗin kujera, da kuma abin da ake kira polyester.

Fasaha mai dacewa ta sarrafa kayan aiki na iya ba da cikakken amfani ga kyawawan halayen polyester.tsarin laserkoyaushe shine zaɓi na farko don sarrafa polyester, ko masana'antar tufafi ne, masana'antar yadi ta gida, kayan ado na ciki masu laushi, masana'antar kayan takalma, ko sarrafa injina, masana'antar fasaha mai inganci,yanke laser, alamar laser da kuma ramin laserakan polyester dagaMai Yanke Laser na MimoWorktaimaka wajen inganta yadda ake sarrafa kayan aiki da kuma bincika ƙarin damar yin amfani da kayan aiki da kuma keɓance su a gare ku.

◼ Tambayoyin da ake yawan yi game da Yanke Laser Polyester

# Za Ka Iya Yanke Polyester ta Laser?

Eh, ana iya yanke masana'anta ta polyester ta hanyar laser.

Ana amfani da laser na CO2 don yanke yadin polyester saboda sauƙin amfani da su da kuma ikon yanke kayan aiki iri-iri.

Ta hanyar amfani da saitunan laser da dabarun da suka dace, masana'anta na polyester za a iya yanke su yadda ya kamata ta hanyar laser don cimma daidaito da tsabta,

yana mai da shi ya dace da aikace-aikace daban-daban a masana'antar tufafi, yadi, da sauran masana'antu.

# Yadda Ake Yanke Yadi Mai Laser?

Yadin Laser kamar polyester da nailan yana da sauƙi kuma yana aiki ta atomatik.

Kawai kuna buƙatar fayil ɗin yankewa na dijital, naɗaɗɗen polyester, da kuma na'urar yanke laser ta masana'anta.

Loda fayil ɗin yankewa kuma saita sigogin laser masu dacewa, sauran aikin za a kammala shi ta hanyar mai yanke laser.

Injin yanke laser yana iya ciyar da masana'anta ta atomatik kuma yana yanke masana'anta zuwa guntu-guntu ta atomatik.

# Shin Yana Da Lafiya A Yanke Polyester Daga Laser?

Eh, polyester ɗin yanke laser gabaɗaya yana da aminci idan aka ɗauki matakan tsaro masu kyau.

Polyester abu ne da aka saba amfani da shi wajen yanke laser domin yana iya samar da yankewa masu kyau da tsafta.

Yawanci, muna buƙatar samar da na'urar samun iska mai kyau,

kuma saita saurin laser da ƙarfin da ya dace dangane da kauri da nauyin gram.

Don ƙarin bayani game da yadda ake saita laser, muna ba da shawarar ku tuntuɓi ƙwararrun laser ɗinmu waɗanda suka ƙware.