Za ku iya yanke polyester ta hanyar laser?

Polyester wani abu ne na roba wanda ake amfani da shi wajen ƙirƙirar yadi da yadi. Abu ne mai ƙarfi kuma mai ɗorewa wanda ke jure wa wrinkles, raguwa, da shimfiɗawa. Ana amfani da yadin polyester a cikin tufafi, kayan daki na gida, da sauran yadi, domin yana da amfani kuma ana iya ƙera shi da nau'ikan nauyi, laushi, da launuka iri-iri.

Yanke Laser ya zama sanannen hanyar yanke masana'anta ta polyester saboda yana ba da damar yankewa daidai kuma mai tsabta, wanda zai iya zama da wahala a cimma ta hanyar hanyoyin yankewa na gargajiya. Yanke Laser kuma yana iya ba da damar ƙirƙirar ƙira masu rikitarwa da na musamman, wanda zai iya haɓaka kyawun masana'anta ta polyester. Bugu da ƙari, yanke laser na iya inganta ingancin tsarin ƙera, saboda ana iya tsara shi don yanke yadudduka da yawa a lokaci guda, yana rage lokaci da aiki da ake buƙata don samar da kowace tufafi.

Menene polyester sublimation?

Yadin polyester abu ne mai amfani da dorewa wanda ake amfani da shi a fannoni daban-daban, kuma yanke laser na iya samar da fa'idodi da yawa dangane da daidaito, inganci, da ƙira.

Rini sublimation wata dabara ce ta bugawa wadda ke canza zane zuwa masana'anta ta amfani da zafi da matsin lamba. Ana amfani da wannan dabarar ne sau da yawa don ƙirƙirar ƙira na musamman akan masana'anta polyester. Akwai dalilai da yawa da yasa masana'anta polyester ta fi so don buga sublimation na rini:

1. Juriyar zafi:

Yadin polyester yana iya jure yanayin zafi mai yawa da ake buƙata don buga fenti ba tare da narkewa ko gurɓata ba. Wannan yana ba da damar samun sakamako mai kyau da daidaito.

2. Launuka masu haske:

Yadin polyester yana da ƙarfi da ƙarfi, wanda yake da mahimmanci don ƙirƙirar ƙira masu jan hankali.

3. Dorewa:

Yadin polyester yana da ɗorewa kuma yana jure wa raguwa, shimfiɗawa, da wrinkles, wanda hakan ya sa ya dace don ƙirƙirar samfura masu ɗorewa da inganci.

4. Shafa danshi:

Yadin polyester yana da kaddarorin da ke cire danshi, wanda ke taimakawa wajen sanya mai sa shi ya huce ya kuma bushe ta hanyar cire danshi daga fata. Wannan ya sa ya zama abin sha'awa ga kayan wasanni da sauran kayayyakin da ke buƙatar kula da danshi.

Yadda ake zaɓar injin laser don yankan polyester

Gabaɗaya, masana'anta ta polyester ita ce masana'anta da aka fi so don buga fenti saboda iyawarta ta jure yanayin zafi mai yawa, riƙe launuka masu haske, da kuma samar da juriya da kuma abubuwan da ke hana danshi shiga. Idan kuna son yin rigunan wasanni na rini, kuna buƙatar na'urar yanke laser don yanke masana'anta ta polyester da aka buga.

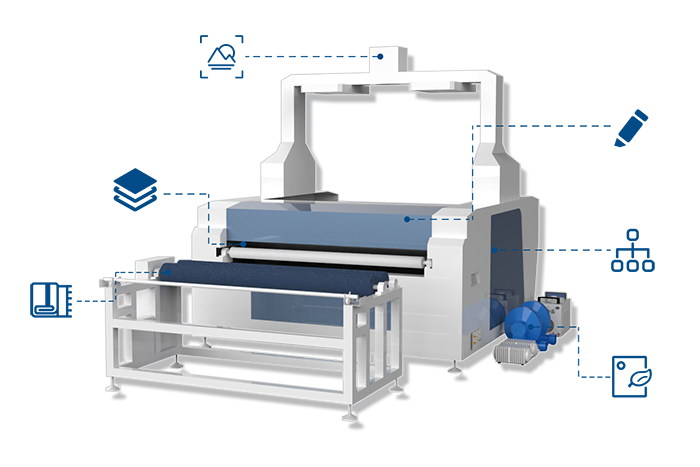

Menene abin yanka laser mai siffar kwanto (mai yanke laser na kyamara)

Mai yanke laser mai siffar lasifika, wanda kuma aka sani da mai yanke laser na kyamara, yana amfani da tsarin kyamara don gane zane-zanen yadin da aka buga sannan a yanke sassan da aka buga. An ɗora kyamarar a saman gadon yankewa kuma tana ɗaukar hoton dukkan saman yadin.

Sannan manhajar tana nazarin hoton kuma tana gano ƙirar da aka buga. Sannan tana ƙirƙirar fayil ɗin vector na ƙirar, wanda ake amfani da shi don jagorantar kan yanke laser. Fayil ɗin vector ya ƙunshi bayanai game da matsayi, girma, da siffar ƙirar, da kuma sigogin yankewa, kamar ƙarfin laser da saurin.

Fa'idodi daga kayan yanke laser na kyamara don polyester

Tsarin kyamara yana tabbatar da cewa na'urar yanke laser tana yanke daidai da siffar da aka buga, ba tare da la'akari da siffar ko sarkakiyar tsarin ba. Wannan yana tabbatar da cewa an yanke kowane yanki daidai kuma daidai, ba tare da ɓata lokaci ba.

Masu yanke laser na contour suna da amfani musamman wajen yanke masaka masu siffofi marasa tsari, domin tsarin kyamara zai iya gano siffar kowanne yanki da kuma daidaita hanyar yankewa daidai gwargwado. Wannan yana ba da damar yankewa mai inganci da kuma rage ɓarnar masaka.

Shawarar Polyester Laser Cutter

Kammalawa

Gabaɗaya, masu yanke laser na kwane-kwane suna da mashahuri zaɓi don yankan masana'anta da aka buga, saboda suna ba da daidaito da daidaito mai girma, kuma suna iya sarrafa nau'ikan ƙira da siffofi iri-iri.

Kayayyaki Masu Alaƙa & Aikace-aikace

Ƙara koyo game da yadda ake yanke masana'anta na polyester ta Laser?

Lokacin Saƙo: Afrilu-27-2023