Can you laser cut polyester?

Polyester is a synthetic polymer that is commonly used to create fabrics and textiles. It is a strong and durable material that is resistant to wrinkles, shrinking, and stretching. Polyester fabric is commonly used in clothing, home furnishings, and other textiles, as it is versatile and can be manufactured in a variety of weights, textures, and colors.

Laser cutting has become a popular method for cutting polyester fabric because it allows for precise and clean cuts, which can be difficult to achieve with traditional cutting methods. Laser cutting can also enable the creation of intricate and unique designs, which can enhance the aesthetic appeal of the polyester fabric. Additionally, laser cutting can improve the efficiency of the manufacturing process, as it can be programmed to cut multiple layers of fabric at once, reducing the time and labor required to produce each garment.

What is sublimation polyester

Polyester fabric is a versatile and durable material that is used in a wide range of applications, and laser cutting can provide many benefits in terms of precision, efficiency, and design.

Dye sublimation is a printing technique that transfers designs onto fabric using heat and pressure. This technique is commonly used to create custom designs on polyester fabric. There are several reasons why polyester fabric is the preferred fabric for dye sublimation printing:

1. Heat resistance:

Polyester fabric is able to withstand the high temperatures required for dye sublimation printing without melting or distorting. This allows for consistent and high-quality results.

2. Vibrant colors:

Polyester fabric is able to hold vibrant and bold colors, which is important for creating eye-catching designs.

3. Durability:

Polyester fabric is durable and resistant to shrinking, stretching, and wrinkles, which makes it ideal for creating long-lasting and high-quality products.

4. Moisture-wicking:

Polyester fabric has moisture-wicking properties, which helps to keep the wearer cool and dry by drawing moisture away from the skin. This makes it a popular choice for athletic wear and other products that require moisture management.

How to choose laser machine for cutting polyester

Overall, polyester fabric is the preferred fabric for dye sublimation printing due to its ability to withstand high temperatures, hold vibrant colors, and provide durability and moisture-wicking properties. If you want to make dye sublimation sportswear, you need contour laser cutter to cut the printed polyester fabric.

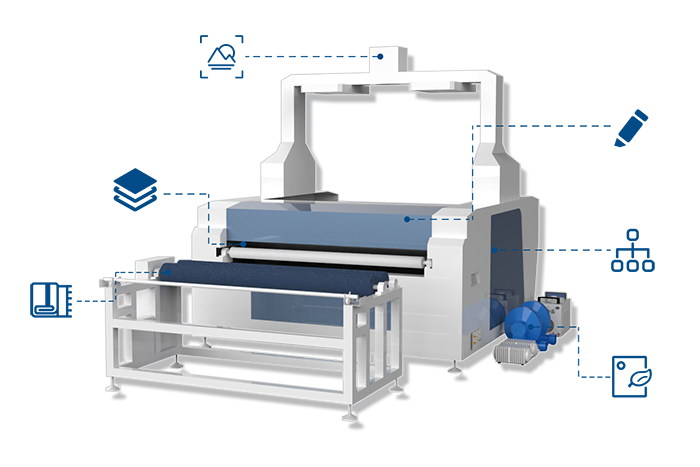

What is contour laser cutter (camera laser cutter)

A contour laser cutter, also known as a camera laser cutter, uses a camera system to recognize the outline of printed fabric and then cut out the printed pieces. The camera is mounted above the cutting bed and captures an image of the entire fabric surface.

The software then analyzes the image and identifies the printed design. It then creates a vector file of the design, which is used to guide the laser cutting head. The vector file contains information about the position, size, and shape of the design, as well as the cutting parameters, such as laser power and speed.

Benefits from camera laser cutter for polyester

The camera system ensures that the laser cutter cuts along the exact contours of the printed design, regardless of the shape or complexity of the pattern. This ensures that each piece is cut accurately and precisely, with minimal waste.

Contour laser cutters are particularly useful for cutting fabric with irregular shapes, as the camera system can identify the shape of each piece and adjust the cutting path accordingly. This allows for efficient cutting and minimizes fabric waste.

Recommended Polyester Laser Cutter

Conclusion

Overall, contour laser cutters are a popular choice for cutting printed fabric, as they offer high precision and accuracy, and can handle a wide variety of designs and shapes.

Related Materials & Applications

Learn more information about how to Laser cut polyester fabric?

Post time: Apr-27-2023