Yadda Ake Yanke Takardar Yankewa: Hanyoyi Masu Sauƙi Don Girman Daidaitacce

injin yanke takarda

Kana son sanin yadda ake yanke takarda kamar ƙwararre? Ko kana yin aikin hannu daidai ko kuma yin yashi a masana'antu, samun yankewa mai tsabta yana da mahimmanci. Za mu nuna maka hanya mai kyau ta yanke zanen gado da kuma huda ramukan ƙura - da kuma mafi kyawun kayan aiki don aikin yashi da hannu ko na'ura.

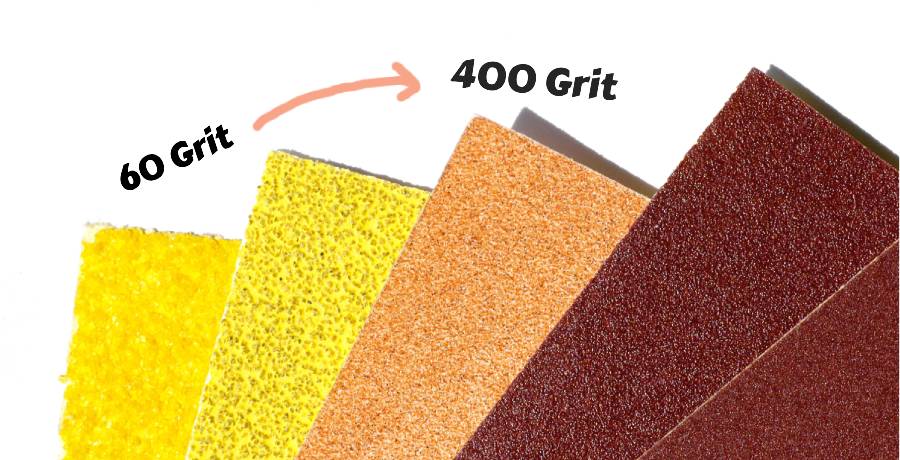

Nau'ikan Grit na Musamman

Takardar sandpaper tana zuwa da nau'ikan grit daban-daban (mai kauri), kowannensu an tsara shi ne don takamaiman aikace-aikace. Nau'ikan da aka fi sani sun haɗa da aluminum oxide, silicon carbide, yumbu, da garnet sandpaper. Kowane nau'in yana da halaye na musamman waɗanda suka dace da ayyuka daban-daban:

• Aluminum Oxide: Mai ɗorewa kuma mai sauƙin amfani, ya dace da yin yashi na itace da ƙarfe.

•Silicon Carbide: Mai kaifi da tauri, cikakke ne don yanke kayan tauri kamar gilashi da filastik.

•Yumbu: Yana da matuƙar ƙarfi kuma yana da tasiri wajen yin yashi mai nauyi da niƙa.

•Garnet: Ya fi laushi kuma ya fi sassauƙa, wanda galibi ana amfani da shi don yin katako mai kyau.

Menene maki 3 na sandpaper?

Ana raba takardar sandpaper zuwa matakai kamar su kyau, kauri da matsakaici kuma kowanne daga cikin waɗannan matakai yana ɗauke da matakai daban-daban waɗanda aka bayyana ta abin da aka sani da grit.

•Matsakaici: Don yin yashi mai yawa da cire shi, kuna buƙatar grit ɗin yashi mai kauri wanda girmansa ya kai 40 zuwa 60.

•Matsakaici:Don sassauta saman da kuma cire ƙananan kurakurai, zaɓi matsakaicin takarda mai kauri daga 80- zuwa 120-grit.

•Lafiya:Don kammala saman da kyau, yi amfani da takarda mai laushi mai laushi mai girman grit 400 zuwa 600.

Ana amfani da takardar yashi a fannoni daban-daban, ciki har da aikin katako, mota, aikin ƙarfe, da gini.

Yana da mahimmanci ga ayyuka kamar su sassauta saman, cire fenti ko tsatsa, da kuma shirya kayan da za a yi amfani da su don kammala aikin.

▶ Wukar Amfani

Don yankewa da hannu, wuka mai amfani da madauri hanya ce mai sauƙi amma mai tasiri.

Sau da yawa ana amfani da shi a ƙananan bita inda ake iya sarrafa daidaito da ƙarar yankewa da hannu.

▶ Kayan aikin Dremel

Ana iya amfani da kayan aikin Dremel tare da abin da aka haɗa don yankewa ƙananan yankewa da cikakkun bayanai.

Ya fi dacewa da masu sha'awar sha'awa ko ƙananan masana'antu inda ake buƙatar sassauci.

▶ Mai Yanke Takarda Mai Juyawa

Yankan takarda mai juyawa suna da amfani wajen yin yanke-yanke madaidaiciya a cikin zanen takarda mai yashi.

Kamar na'urar yanke takarda, tana amfani da wuka mai juyawa don yanke takardar yashi.

A matsayin kayan aikin yankewa da hannu, mai yanke takarda mai juyawa ba zai iya tabbatar da daidaito da saurin yankewa ba.

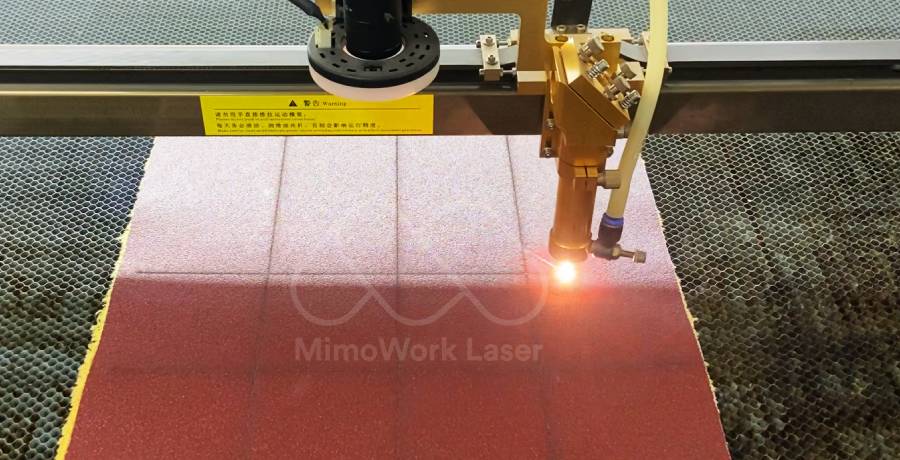

Mai Yanke Laser

Masu yanke laser suna da daidaito sosai, wanda hakan ya sa suka dace da siffofi na musamman da ƙira masu rikitarwa.

Suna amfani da hasken da aka mayar da hankali a kai don yanke takarda mai yashi, suna tabbatar da tsabtar gefuna ba tare da lalata su ba.

Injin yanke Laser yana da sauƙin amfani wajen yanke ƙananan ramuka da kuma yanke siffofi da girma dabam-dabam.

Godiya ga tsarin CNC da kuma tsarin injin ci gaba, ingancin yanke takarda da ingancin yankewa za a iya cimmawa a cikin injin guda.

Mai Yanke Mutu

Masu yanke mutu suna amfani da injin yanke mutu don fitar da takamaiman siffofi daga zanen gado ko birgima na takarda.

Suna da inganci ga yawan samar da kayayyaki inda daidaito yake da mahimmanci.

Iyakar abin yanka injin ɗin shine lalacewa da lalacewar kayan aikin gogewa. Idan muna son yanke sabbin siffofi da sabbin ƙira na takarda mai yashi, muna buƙatar siyan sabbin injinan. Wannan yana da tsada.

Bukatar Babban Daidaito da Keɓancewa:

Idan daidaiton yankewa da kuma ko za a iya keɓance shi ne damuwar ku, Laser Cutter shine zaɓin da ya dace.

Takardar yanke Laser tana ba da daidaito mara misaltuwa, versatility, da inganci.

Ya dace da ƙananan kayayyaki da manyan kayayyaki inda ake buƙatar ƙira masu inganci da rikitarwa.

Zuba jarin farko ya fi yawa, amma fa'idodin da suka shafi daidaito da sassauci sun sa ya zama mai amfani.

Damuwa Mai Inganci da Fitowar Samarwa

Da yake magana game da ingancin yankewa,mai yanke mutun shine ya yi nasara saboda ya yanke takardar sandpaper ta hanyar kayan da aka riga aka yi su.

Idan kana da tsari iri ɗaya da tsari iri ɗaya, na'urar yanke itace za ta iya kammala yankewa cikin sauri. Wannan ya dace da yawan aiki don ƙirar takarda mai kama da juna.

Amma idan kuna da buƙatu daban-daban don siffofi, girma, da kuma tsarin ƙira, mai yanke mutu ba shine mafi kyau ba idan aka kwatanta da mai yanke laser.

Sabon ƙira yana buƙatar sabon injin yanke itace, wanda ke ɗaukar lokaci kuma yana da tsada don yanke itace. Akasin haka,Laser cutter na iya haɗuwa da siffofi na musamman da na daban-daban a cikin injin guda.

Don Aikin da ya shafi kasafin kuɗi

Idan aka yi la'akari da farashin injin,Kayan aikin hannu kamar na'urar yanke rotary da Dremel sun fi adana kuɗi, kuma suna da sassaucin aiki.

Sun dace da ƙananan ayyuka ko kuma inda ƙuntatawa a kasafin kuɗi ke da mahimmanci.

Duk da cewa littafin bai da daidaito da ingancin na'urorin yanke laser, ana iya samun su kuma suna da araha don ayyuka masu sauƙi.

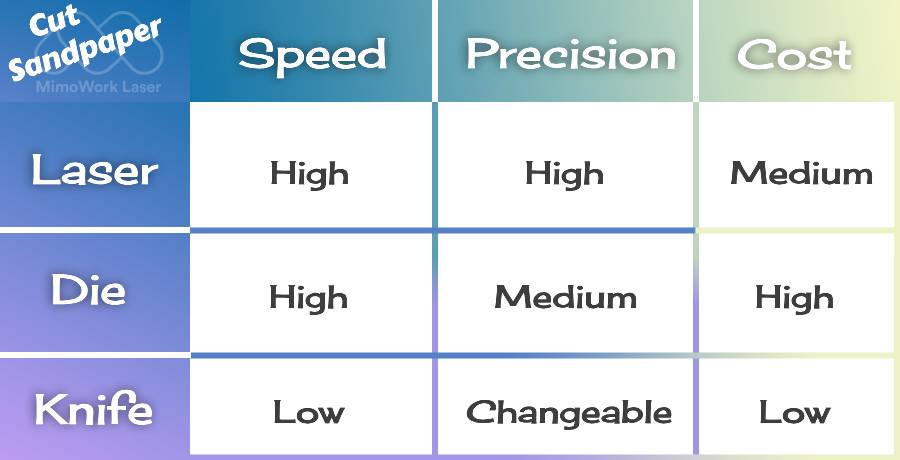

Kwatanta Kayan Aiki Uku

Don yanke takarda mai yankan, zaɓin kayan aiki ya dogara ne akan takamaiman buƙatun aikin.

Masu yanke Laser sun shahara a matsayin mafi kyawun zaɓi gabaɗaya saboda daidaito, iya aiki, da inganci, musamman lokacin da ake mu'amala da ƙira masu rikitarwa da umarni na musamman.

Masu yanke mutu suna da tasiri wajen samar da kayayyaki masu yawa da kuma daidaito.

Duk da cewa na'urorin yankewa masu juyawa suna ba da zaɓi mai araha ga ƙananan ayyuka, waɗanda ba su da rikitarwa.

Ta hanyar kimanta takamaiman buƙatunku da sikelin samarwa, zaku iya zaɓar kayan aikin da ya fi dacewa don cimma sakamako mafi kyau a cikin yanke takarda.

Takardar Sanda Mai Siffa ta Musamman don Kayan Aiki na Musamman

Power Sanders: Yankewar Laser yana ba da damar ƙirƙirar takarda mai kyau wacce ta dace da takamaiman siffofi na masu yin amfani da wutar lantarki, kamar su na orbital, bel, da masu yin amfani da faifan diski. Wannan yana tabbatar da ingantaccen aiki da inganci.

Cikakkun bayanai na Sanders: Ana iya yanke siffofi na musamman don dacewa da cikakkun kayan aikin sander da ake amfani da su a cikin ayyukan aikin katako ko kammalawa masu rikitarwa.

Takardar Yankewa Mai Daidaito Don Amfani da Masana'antu

Masana'antar Motoci: Sandpaper mai yanke laserana amfani da shi don kammalawa da goge kayan aikin mota, inda siffofi da girma dabam-dabam suke da mahimmanci don samun sakamako mai daidaito.

Masana'antar Jiragen Sama: Masana'antar sararin samaniya tana buƙatar cikakken daidaito don shirya saman da kuma kammala shi. Takardar yankan da aka yanke ta hanyar laser ta cika waɗannan ƙa'idodi masu tsauri.

Ayyukan Sana'a da Sha'awa

Ayyukan DIY: Masu sha'awar nishaɗi da masu sha'awar DIY suna amfana daga yashi mai yankewa ta hanyar laser don yin aiki dalla-dalla akan abubuwa daban-daban, gami da itace, ƙarfe, da filastik.

Yin SamfuraTakardar yashi mai kyau ta dace da masu yin samfuri waɗanda ke buƙatar ƙananan sassa masu tsari don ayyukan yashi mai kyau.

Kayan Daki da Aikin Katako

Gyaran Kayan Daki: Ana iya tsara takarda mai yanke laser don dacewa da takamaiman siffofi da siffofi na kayan daki, wanda ke ba da damar yin cikakken aikin gyarawa.

Kafinta: Masu aikin katako za su iya amfani da takarda mai siffar musamman don yin cikakken yashi na sassaka, gefuna, da haɗin gwiwa.

Aikace-aikacen Lafiya da Hakori

Sanding na Orthopedic: Ana amfani da takarda mai siffar musamman a fannin likitanci don shirya na'urorin kashin baya da na roba.

Kayan Aikin Hakori: Ana amfani da takarda mai yanke daidai a fannin kula da hakora don gogewa da kuma kammala gyaran hakora da kayan aiki.

Takardar Sand tare da Tsarin Rami na Musamman

Tsarin Cire Kura: Yankewar Laser yana ba da damar sanya ramuka daidai a cikin takarda don daidaitawa da tsarin cire ƙura, yana haɓaka inganci da tsabta yayin yin yashi.

Ingantaccen Aiki: Tsarin ramuka na musamman na iya inganta aikin takarda mai sandpaper ta hanyar rage toshewar da kuma tsawaita tsawon rayuwarsa.

Zane da Fasaha

Ayyukan Kirkire-kirkire: Masu fasaha da masu zane-zane suna amfani da takarda mai yanke laser don zane-zane na musamman, inda ake buƙatar daidaito da ƙira mai rikitarwa.

Fuskokin da aka yi wa rubutu: Ana iya ƙirƙirar zane-zane da alamu na musamman akan takarda don takamaiman tasirin fasaha.

Kayan Kayan Kida & Wasanni

Kayan aiki:Ana amfani da sandpaper mai yanke laser wajen samar da gita don yin laushi da kuma kammala jiki, wuya, da fretboard. Wannan yana tabbatar da kammalawa mai inganci da kuma sauƙin kunnawa.

Kayan Wasanni:Misali, a kan skateboards sau da yawa ana buƙatar takarda mai sandpaper, musamman da aka sani da tef ɗin riƙo, don a shafa a kan benen don inganta jan hankali da sarrafawa.

Cikakke don Yankewa, Rage Ragewa, da Zane-zane

Laser Cutter for Sandpaper

| Wurin Aiki (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Software | Manhajar Ba ta Intanet ba |

| Ƙarfin Laser | 100W/150W/300W |

| Tushen Laser | Tube na Laser na Gilashin CO2 ko Tube na Laser na Karfe na CO2 RF |

| Tsarin Kula da Inji | Kula da Bel ɗin Mota Mataki |

| Teburin Aiki | Teburin Aiki na Zuma ko Teburin Aiki na Wuka |

| Mafi girman gudu | 1~400mm/s |

| Saurin Hanzari | 1000~4000mm/s2 |

| Girman Kunshin | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Nauyi | 620kg |

| Wurin Aiki (W * L) | 1600mm * 1000mm (62.9” * 39.3”) |

| Yankin Tarawa (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Software | Manhajar Ba ta Intanet ba |

| Ƙarfin Laser | 100W / 150W / 300W |

| Tushen Laser | Tube na Laser na Gilashin CO2 ko Tube na Laser na Karfe na CO2 RF |

| Tsarin Kula da Inji | Watsa Belt & Matakin Mota Drive / Servo Motor Drive |

| Teburin Aiki | Teburin Aiki na Na'ura |

| Mafi girman gudu | 1~400mm/s |

| Saurin Hanzari | 1000~4000mm/s2 |

| Wurin Aiki (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Isar da Haske | Na'urar auna ƙarfin lantarki ta 3D |

| Ƙarfin Laser | 180W/250W/500W |

| Tushen Laser | CO2 RF Karfe Laser Tube |

| Tsarin Inji | Servo Driven, Belt Driven |

| Teburin Aiki | Teburin Aiki na Zuma tsefe |

| Matsakaicin Gudun Yankewa | 1~1000mm/s |

| Matsakaicin Saurin Alamar | 1~10,000mm/s |

Ƙara koyo game da sandpaper na yanke laser

Kuna da tambayoyi game da Sandpaper na Laser Cut?

Lokacin Saƙo: Yuli-02-2024