Zvakavanzika zveLaser Welding: Gadzirisa Matambudziko Akajairika Iye Zvino!

Nhanganyaya:

Gwaro Rakazara Rekugadzirisa Matambudziko

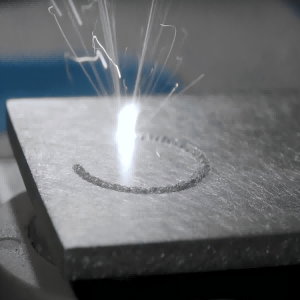

Michina Yekushongedza Nemaoko YeLaser

Muchina wekunamira we fiber laser unobatwa nemaoko wave nemukurumbira mukuru mumaindasitiri akasiyana-siyana nekuda kwekunyatsorongeka kwawo uye kushanda kwawo zvakanaka.

Zvisinei, sedzimwe nzira dzekunamira, hadzina matambudziko nematambudziko angamuka panguva yekunamira.

Izvi zvakazarakugadzirisa matambudziko e laser weldingChinangwa chayo ndechekugadzirisa matambudziko anowanzo sangana nawo nemidziyo yekucheka nelaser inobatwa nemaoko, matambudziko ane chekuita nekukwevera, uye nyaya dzine chekuita nemhando yekucheka.

Zvikanganiso & Mhinduro dzeMuchina weKushongedza Laser Usati Watanga

1. Midziyo Haigone Kutanga (Simba)

Mhinduro: Tarisa kana switch yetambo yemagetsi iri kushanda.

2. Mwenje Haungabatidzwe

Mhinduro: Tarisa bhodhi rinotanga kupiswa nemagetsi e220V kana kuti asina, tarisa bhodhi remwenje; fuse ye3A, rambi rexenon.

3. Chiedza Chabatidzwa, Hapana Laser

Mhinduro: Tarisa kuti chikamu chemuchina we laser welding chinobatwa nemaoko chiri kunze kwechiedza chakajairika. Chekutanga, tarisa kuti chikamu cheCNC chebhatani re laser chakavharwa here, kana chakavharwa, wobva wavhura bhatani re laser. Kana bhatani re laser rakajairika, vhura interface yekutarisa nhamba kuti uone kana gadziriro yechiedza chinoenderera mberi, kana chisiri, wobva wachinja kuita chiedza chinoenderera mberi.

Matambudziko & Kugadziriswa kweWelding Phase Laser Welder

Musono Weld Wakasviba

Gasi rinodzivirira harina kuvhurika, chero bedzi gasi renitrogen rakavhurika, rinogona kugadziriswa.

Kufamba kwemhepo kwegasi rinodzivirira hakuna kunaka, kufamba kwemhepo kwegasi rinodzivirira kunofanirwa kuitwa kwakatarisana nekufamba kwechinhu chebasa.

Kushaikwa kwekupinda mukati meWelding

Kushaikwa kwesimba relaser kunogona kuvandudza hupamhi hwepulse uye simba remagetsi.

Lenzi yekutarisa haisiyo huwandu hwakakodzera, yekugadzirisa huwandu hwekutarisa pedyo nenzvimbo yekutarisa.

Kupera Simba kweLaser Beam

Kana mvura inotonhodza yakasviba kana kuti isina kuchinjwa kwenguva yakareba, inogona kugadziriswa nekutsiva mvura inotonhodza uye kuchenesa chubhu yegirazi yeUV nerambi rexenon.

Diaphragm ye lenzi inotarisa kana diaphragm ye laser yakakuvara kana kusvibiswa, inofanira kutsiviwa kana kucheneswa nenguva.

Fambisa laser munzira huru yekuona, gadzirisa diaphragm yekutarisa kwese uye semi-reflection munzira huru yekuona, tarisa uye tenderera nzvimbo yacho nepepa remufananidzo.

Laser haibudi kubva mumuromo wemhangura uri pasi pemusoro wekutarisa. Gadzirisa diaphragm inoratidza madhigirii makumi mana nemashanu kuitira kuti laser ibudise kubva pakati pemuromo wegasi.

Kugadzirisa Matambudziko Emhando Yekushongedza NeLaser

1. Kusasa

Mushure mekunge laser welding yapera, zvidimbu zvakawanda zvesimbi zvinoonekwa pamusoro pechinhu chacho kana chidimbu chebasa, zvakabatana pamusoro pechinhu chacho kana chidimbu chebasa.

Chikonzero chekupfapfaidza: pamusoro pechinhu chakagadziriswa kana chidimbu chebasa hachina kuchena, pane mafuta kana kusvibiswa, zvinogonawo kukonzerwa nekuoma kwechikamu chegalvanized.

1) Nyatsocherechedza kuchenesa zvinhu kana chidimbu chebasa usati waisa laser welding;

2) Kuparadzira kwakabatana zvakananga nehuwandu hwesimba. Kuderedzwa kwakakodzera kwesimba rekuputira kunogona kuderedza kupadzira kwacho.

2. Mitswe

Kana kumhanya kwekutonhodza kwechinhu chebasa kuchikurumidza zvakanyanya, tembiricha yemvura inotonhodza inofanira kugadziriswa pachishandiso kuti tembiricha yemvura iwedzere.

Kana nzvimbo yekukwana kwechinhu chebasa yakakura zvakanyanya kana kuti paine burr, kunyatsogadzira kwakakodzera kwechinhu chebasa kunofanira kuvandudzwa.

Chishandiso hachina kucheneswa. Panyaya iyi, chishandiso chinofanira kucheneswa zvakare.

Mwero wekuyerera kwegasi rinodzivirira wakanyanya kukura, izvo zvinogona kugadziriswa nekuderedza mwero wekuyerera kwegasi rinodzivirira.

3. Pore Pamusoro Pekunamira

Zvikonzero zvekugadzirwa kwe porosity:

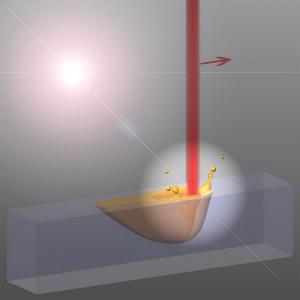

1) Dziva rakanyungudutswa reLaser welding rakadzika uye rakamanikana, uye mwero wekutonhora unokurumidza zvikuru. Gasi rinogadzirwa mudziva rakanyungudutswa ranonoka kuzara, izvo zvinogona kutungamira nyore nyore pakuumbwa kwemaburi.

2) Pamusoro pe weld hapacheneswi, kana kuti mhute ye zinc ye galvanized sheet inoshanduka kuita denga.

Chenesa pamusoro pechinhu chebasa nepamusoro peweld usati wabatanidza kuti zinc isanyanya kusimba kana yapiswa.

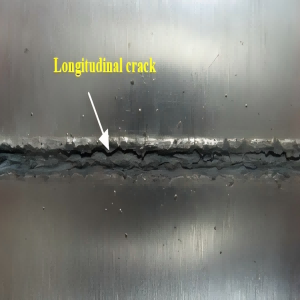

4. Kutsauka kweWelding

Simbi yakasungirirwa haizoome pakati pechimiro chejoinhi.

Chikonzero chekutsauka: Kusaiswa zvakanaka kwenzvimbo panguva yekunamira, kana nguva yekuzadza isina kururama uye kurongeka kwewaya.

Mhinduro: Gadzirisa nzvimbo yekuwedera, kana nguva yekuzadza nenzvimbo yewaya, pamwe nenzvimbo yerambi, waya uye weld.

5. Kuvharwa kweSlag Pamusoro, Kunonyanya Kuonekwa Pakati Pezvikamu

Kubatwa kwetsvina pamusoro pevhu kunokonzera:

1) Kana paine welding ine ma multi-layer multi-pass, coating iri pakati pema layer haina kuchena; kana kuti pamusoro pe weld yekare haina kutsetseka kana kuti pamusoro pe weld hahuna kuzadzisa zvinodiwa.

2) Matekiniki ekushandisa welding asina kunaka, akadai sekushandisa simba shoma re welding, kumhanya kwe welding kunokurumidza zvakanyanya.

Mhinduro: Sarudza magetsi ekuwelda anonzwisisika uye kumhanya kwekuwelda, uye chifukidziro chepakati pezvikamu chinofanira kucheneswa kana uchiwelda nezvikamu zvakawanda. Geda wobvisa weld neslag pamusoro, wobva wagadzira weld kana zvichidikanwa.

Zvimwe Zvishongedzo - Handheld Laser Welder Matambudziko Akajairika uye Mhinduro

1. Kukundikana kweChishandiso Chekudzivirira Kuchengetedzeka

Zvishandiso zvekudzivirira kuchengetedzeka zvemuchina we laser welding, zvakaita semusuwo we welding chamber, gas flow sensor, uye tembiricha sensor, zvakakosha pakushanda kwayo zvakanaka. Kukundikana kwezvishandiso izvi hakungokanganisi mashandiro enguva dzose emuchina chete asiwo kunogona kukonzera njodzi yekukuvara kumushandisi.

Kana zvikaitika kuti michina yekudzivirira yakanganisa, zvakakosha kumisa kushanda kwayo nekukasika uye kubata nyanzvi kuti dzigadziriswe nekutsiviwa.

2. Kudzvanya kweWaya

Kana paine wire feeder jam mumamiriro ezvinhu aya, chinhu chekutanga chatinofanira kuita ndechekutarisa kana muromo wepfuti wakavharwa, danho rechipiri nderekutarisa kana wire feeder yakavharwa uye kana kutenderera kwedhisiki resiriki kwakajairika.

Pfupisa

Nekunyatsorongeka, kumhanya uye kushanduka-shanduka kwezvinhu, welding yelaser tekinoroji inokosha mumaindasitiri akadai semotokari, ndege nemagetsi.

Zvisinei, zvikanganiso zvakasiyana-siyana zvinogona kuitika panguva yekunamira, zvinosanganisira kupwanyika, kutsemuka, kupwanyika, kucheka zvisina kurongeka, kutsva, kushanduka, uye oxidation.

Chikanganiso chimwe nechimwe chine chikonzero chaicho, senge marongero asina kunaka elaser, kusvibiswa kwezvinhu, magasi ekudzivirira asina kukwana, kana kuti majoini asina kumira zvakanaka.

Nekunzwisisa zvikanganiso izvi uye zvikonzero zvazvo, vagadziri vanogona kushandisa mhinduro dzakanangana, dzakadai sekugadzirisa ma parameter e laser, kuona kuti majoini akakodzera, kushandisa magasi ekudzivirira emhando yepamusoro, uye kushandisa mishonga ye pre - uye post-weld.

Kudzidziswa kwakakodzera kwemushandisi, kugadziriswa kwemidziyo yezuva nezuva uye kutarisa mashandiro acho panguva chaiyo kunowedzera kuvandudza kunaka kwekunamira uye kuderedza zvikanganiso.

Nekushandisa nzira yakakwana yekudzivirira zvikanganiso uye kugadzirisa mashandiro, laser welding inogara ichipa welds dzakasimba, dzakavimbika uye dzemhando yepamusoro dzinosangana nezvinodiwa zveindasitiri.

Hauzivi kuti ndeipi mhando yemuchina we laser welding wekusarudza?

Unofanira kuziva: Maitiro ekusarudza muchina we laser unobatwa nemaoko

Kukwanisa Kwakawanda & Wattage yeZvishandiso Zvakasiyana-siyana zveWelding

Muchina wekunamira we laser we2000W une saizi diki yemuchina asi une mhando yekunamira inopenya.

Chitubu chelaser chefiber chakagadzikana uye tambo yefiber yakabatana inopa kuendesa kwakachengeteka uye kwakagadzikana kwelaser beam.

Nesimba guru, gomba re laser welding rinokwana uye rinoita kuti welding joint irambe yakasimba kunyangwe pasimbi hombe.

Kutakurwa Kwekuti Ugone Kuchinjika

Nechitarisiko chemuchina mudiki uye mudiki, muchina we laser welder unotakurika une pfuti ye laser welder inotakurika inotakurika iyo yakareruka uye yakakodzera kushandiswa kwe multi-laser welding chero kupi zvako uye pamusoro.

Mhando dzakasiyana-siyana dzema nozzles e laser welder uye ma wire feeding systems anosarudza anoita kuti kushanda kwe laser welding kuve nyore uye izvo zvine hushamwari kune vanotanga.

Kupinza nelaser nekukurumidza kunowedzera kushanda zvakanaka kwekugadzira kwako uye kubuda kwako ukuwo zvichigonesa kushanda zvakanaka kwelaser.

Zvinhu Zvaunofanira Kuziva Nezve: Kukwesha NemaLaser Nemaoko

Kana wakafarira vhidhiyo iyi, wadii kufunga nezvayoUri kunyoresa kuYoutube Channel yedu here?

Mapurogiramu Akafanana Aungade Kufarira:

Kutenga Kwese Kunofanira Kuziviswa Zvakanaka

Tinogona Kubatsira Neruzivo Rwakadzama Uye Kubvunzana!

Nguva yekutumira: Ndira-16-2025