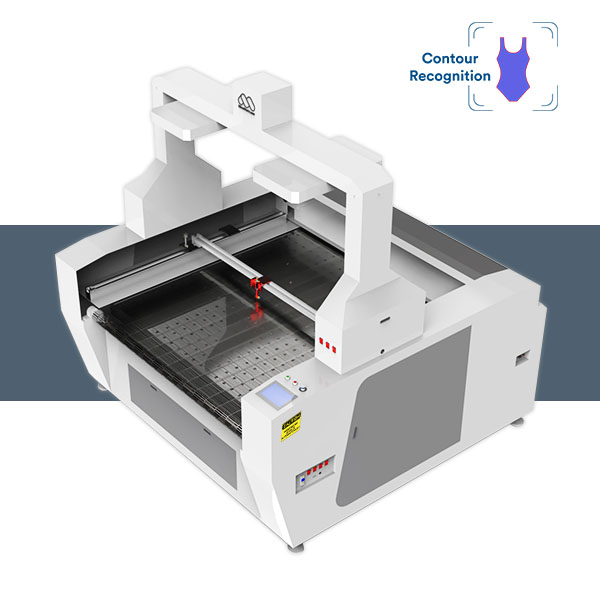

Gooyaha Laser Contour 160L

Xogta Farsamada

| Goobta Shaqada (W *L) | 1600mm * 1200mm (62.9”* 47.2”) |

| Balaadhka Walaxda ugu badan | 62.9” |

| Awoodda leysarka | 100W / 130W / 150W |

| Isha Laser | CO2 Tube Laser Glass / RF Metal tube |

| Nidaamka Xakamaynta Makaanikada | Gudbinta suunka & Servo Motor Drive |

| Shaxda Shaqada | Miiska Shaqada Qaadista Biraha Fudud |

| Xawaaraha ugu badan | 1 ~ 400mm/s |

| Xawaaraha Dardargelinta | 1000 ~ 4000mm/s2 |

* Waxaa jira laba ikhtiyaar oo madax laser ah

Xulashada Aan La Helin ee Goynta Laysarka Midabaynta Sublimation

Wax-soo-saarka aadka u wayn

◆Codsiyada ballaaran ee warshadaha sidadaabacaadda dhijitaalka ah, agabka isku dhafan, dharka iyo dunta guriga.

◆ Debecsanaan iyo dhaqsaha badan farsamada goynta laser MimoWork waxay ka caawisaa alaabtaada inay si dhakhso leh uga jawaabaan baahiyaha suuqa.

◆ Kobciyefarsamada aqoonsiga muuqaalkaiyo software awood leh ayaa bixiya tayada sare iyo kalsoonida ganacsigaaga.

◆ Quudiye toos ahwaxay bixisaaquudinta tooska ah, oggolaanshaha hawlgal aan la ilaalin oo badbaadinaya kharashka shaqada, heerka diidmada hoose (ikhtiyaar).

Goynta laysarka kamarad-goynta sublimation polyester, spandex, naylon, lycra, iwm.

R&D ee Goynta Fabric ee Dabacsan

Labada Madax-bannaan ee Madax-bannaan - Ikhtiyaarka

Mudaaharaad Video

Sidee loo gooyaa Laser Sublimation Dharka Yoga?

Sida Loo Doorto Mashiinka Laser-ka ee Dharka

Maxaad ku gooyn doontaa qalabka kamarada laser-ka?

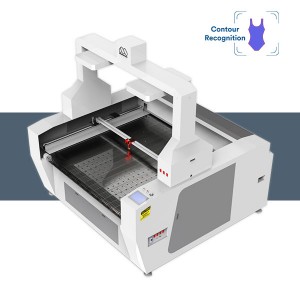

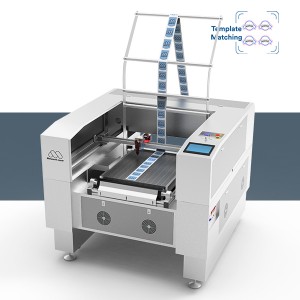

Nidaamka Aqoonsiga Aragga

✔ Tayada goynta sare, aqoonsiga hannaanka saxda ah, iyo wax soo saarka degdega ah

✔ Buuxinta baahiyaha wax soo saarka balastar yar ee kooxda isboortiga maxalliga ah

✔ Qalabka isku dhafka ah ee kulaylka kalandarka

✔ Looma baahna in la gooyo faylka

Faa'iidooyinka gaarka ah ee calaamadaha goynta laysarka & qurxinta

✔ Si weyn u dhimo wakhtiga shaqada ee dalabaadka wakhtiga gaabsan ee bixinta

✔ Meesha dhabta ah iyo cabbirka qaybta shaqada ayaa si sax ah loo aqoonsan karaa

✔ Ma jiro wax qalloocan oo ay ugu wacan tahay quudinta walxaha ka xorta ah iyo goynta xiriir la'aanta

✔ Gooye ku habboon samaynta tarabuunka, boodhadhka, hababka bandhigga, ama ilaalinta aragga

ee Contour Laser Cutter 160L

Qalabka: Dharka Polyester-ka, Spandex, Nayloon, Xariir, Velvet daabacan, Cudbi, iyo kuwo kaledunta sublimation

Codsiyada:Dharka Firfircoon ee Dharka Isboortiga (Xeebaha baaskiilka, Jerseys xeegada, Baseball Jerseys, Basketball Jerseys, Jerseys Soccer, Jerseys Lacrosse, Lacrosse Jerseys, Ringette Jerseys), Labisyada, Dharka dabaasha,Lugaha, Qalabka Sublimation(Gacmo-gacmeedyo, Gacan-gacmeedyo Lugaha, Bandanna, Xarig-madaxeed, Daboolka Wajiga, Maaskaro)