Tixgelinta ugu Sareysa ee looxa goynta Laser

Tilmaamaha Xardhista Laser-ka Alwaaxa

Alwaaxyada laysarka ee la jarjaray waxay bixiyaan saxnaan iyo kala duwanaansho aan la barbar dhigi karin, taasoo ka dhigaysa mid ku habboon wax walba laga bilaabo farshaxanka ilaa mashaariicda waaweyn. Si loo gaaro geeso nadiif ah oo looga fogaado waxyeelada, waa lagama maarmaan in la fahmo goobaha saxda ah, diyaarinta agabka, iyo talooyinka dayactirka. Tilmaamahan wuxuu la wadaagayaa tixgelinno muhiim ah si uu kaaga caawiyo inaad hesho natiijooyinka ugu fiican marka aad isticmaaleyso mashiinka jarista alwaaxa laysarka ee alwaaxa.

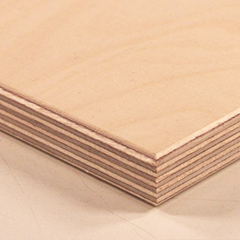

Doorashada Plywood-ka Saxda ah

Noocyada Plywood-ka ee loogu talagalay jarista Laser-ka

Doorashada alwaaxa saxda ah waa lama huraan si loo gaaro natiijooyin nadiif ah oo sax ah iyadoo la adeegsanayoAlwaax laysar ah oo la jarjaraymashaariic. Noocyada kala duwan ee alwaaxa ayaa bixiya faa'iidooyin gaar ah, doorashada saxda ahna waxay hubineysaa waxqabad wanaagsan iyo tayada dhammaystirka.

Plywood-ka Laser-ka la jaray

Plywood Birch

Hadhuudh fiican, siman oo leh madhan yar, aad ugu fiican xaraashka faahfaahsan iyo naqshadaha adag.

Plywood Poplar ah

Fudud, si fudud loo jari karo, aad ugu fiican looxyada qurxinta iyo naqshadaha waaweyn.

Plywood-Wajiga Veneer-ka ah

Dusha sare ee qurxinta alwaaxa ee loogu talagalay mashaariicda heerka sare ah, waxay bixisaa dhammaystir alwaax dabiici ah.

Plywood khafiif ah oo gaar ah

Go'yaal aad u khafiif ah oo loogu talagalay sameynta moodallada, farshaxanka, iyo mashaariicda u baahan jarista jilicsan.

MDF-Core Plywood

Cidhifyada jarista siman iyo cufnaanta joogtada ah, oo ku habboon dhammaystirka rinjiyeynta ama la dahaadhay.

Qoryaha noocee ah ayaan dooran karaa iyadoo lagu saleynayo baahiyaha jarista laysarka?

| Isticmaalka Jarida Laser-ka | Nooca Plywood-ka lagu taliyay | Qoraallo |

|---|---|---|

| Xarig Faahfaahsan oo Fiican | Birch | Hadhuudh siman iyo godad yar oo loogu talagalay geesaha qallafsan |

| Goynta Degdegga ah oo leh Faahfaahin Dhexdhexaad ah | Poplar | Fudud oo si fudud loo jari karo si loo helo hufnaan wanaagsan |

| Jarid Meel Weyn | MDF-Core | Cufnaan joogto ah oo loogu talagalay jarista isku midka ah |

| Dhammaystir Cidhif oo Tayo Sare leh ayaa Loo Baahan Yahay | Waji-Dhexdhexaad ah | Dusha sare ee qurxinta waxay u baahan tahay dejimo sax ah |

| Jarjarro khafiif ah oo jilicsan | Khafiif ah oo Khafiif ah | Aad u khafiif ah oo loogu talagalay moodooyinka iyo farshaxanka adag |

Baltic Birch Plywood

Dhumucda alwaaxda

Dhumucda alwaaxa ayaa sidoo kale saameyn karta tayada jarista laysarka alwaaxa. Alwaaxyada qaro weyn waxay u baahan yihiin awood laysar oo sare si loo jaro, taasoo sababi karta in alwaaxdu gubto ama ay gubto. Waa muhiim inaad doorato awoodda laysarka ee saxda ah iyo xawaaraha jarista ee dhumucda alwaaxa.

Talooyinka Diyaarinta Agabka

Xawaaraha Jarida

Xawaaraha jarista waa sida ugu dhakhsaha badan ee laysarka uu ugu gudbo alwaaxda. Xawaaraha jarista ee sare waxay kordhin kartaa wax soo saarka, laakiin waxay sidoo kale yareyn karaan tayada jarista. Waa muhiim in la isku dheellitiro xawaaraha jarista iyo tayada jarista ee la rabo.

Awoodda Laydhka

Awoodda laysarka ayaa go'aamisa sida ugu dhakhsaha badan ee laysarka uu u jari karo alwaaxa. Awoodda laysarka oo sareysa ayaa si dhakhso ah u jari karta alwaaxa ka dhumuc weyn marka loo eego awoodda hoose, laakiin waxay sidoo kale sababi kartaa in alwaaxdu gubto ama ay gubto. Waa muhiim inaad doorato awoodda laysarka ee saxda ah ee dhumucda alwaaxa.

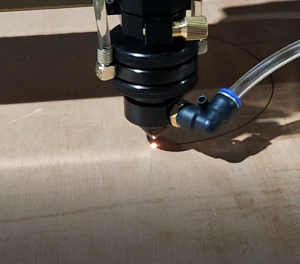

Guddiga Jarida Laser-ka Tallaabooyinka 2

Guddiga Die Wood Jarida Laser

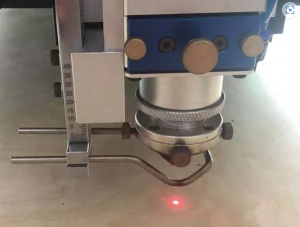

Muraayadaha Diiradda

Muraayadda diiradda saarta waxay go'aamisaa cabbirka iftiinka laysarka iyo qoto dheer ee jarista. Cabbirka alwaaxa oo yar wuxuu kuu oggolaanayaa jaritaanno sax ah, halka cabbirka alwaaxa oo weyn uu jari karo agabyo dhumuc weyn leh. Waa lagama maarmaan inaad doorato muraayadda diiradda saarta ee saxda ah ee dhumucda alwaaxa.

Caawinta Hawada

Qalabka hawada ayaa hawada ku afuufa alwaaxa laysarka jaraya, kaas oo ka caawiya in laga saaro qashinka oo ka hortagaya gubashada ama gubashada. Aad ayey muhiim u tahay jarista alwaaxa sababtoo ah alwaaxdu waxay soo saari kartaa qashin badan inta la jarayo.

Caawinta Hawada

Jihada Jarida

Jihada ay mashiinnada jarista alwaaxa ee laysarka ah ku shaqeeyaan waxay saameyn kartaa tayada jarista. Jarista hadhuudhka waxay sababi kartaa in alwaaxdu jabto ama jeexdo, halka jarista hadhuudhka ay keeni karto jaritaan nadiif ah. Waa muhiim in la tixgeliyo jihada geedka marka la naqshadaynayo jarista.

Qalabka Laser-ka ee la jarayo ee Doard 3

Muuqaalka Fiidiyowga ee Mashiinka Laysarka ee Laser Wood Cutter

Tixgelinta Naqshadeynta

Marka la naqshadeynayo jarista laysarka, waxaa muhiim ah in la tixgeliyo dhumucda alwaaxa, adkaanta naqshadda, iyo nooca isku-xidhka la isticmaalay. Naqshadaha qaarkood waxay u baahan karaan taageerooyin dheeraad ah ama tabs si loo hayo alwaaxa meesha lagu jarayo inta lagu jiro jarista, halka kuwa kalena ay u baahan karaan tixgelin gaar ah nooca isku-xidhka la isticmaalay.

Arrimaha Caadiga ah & Xallinta Dhibaatooyinka

Yaree awoodda laysarka ama kordhi xawaaraha jarista; mari cajaladda maaskarada si aad u ilaaliso dusha sare.

Kordhi awoodda laysarka ama yaree xawaaraha; hubi in barta diiradda la saaray si sax ah loo dejiyay.

Dooro alwaax leh qoyaan yar oo si adag ugu xidh sariirta laysarka.

Isticmaal awood hoose oo leh marinno badan, ama hagaaji dejimaha si aad u hesho jaritaanno nadiif ah.

Haddii aad rabto inaad isticmaasho alwaax laysar ah, dooro geed bjørk, geed basswood, ama geed maple ah oo leh dusha siman, xabag yar oo resin ah, iyo godad yar. Gooyo khafiif ah oo ku habboon xaraashka, halka go'yaal qaro weyn ay u baahan yihiin awood dheeraad ah.

Gunaanad ahaan

Jarista laysarka ee looxa alwaaxa waxay soo saari kartaa jaritaan tayo sare leh oo leh saxnaan iyo xawaare. Si kastaba ha ahaatee, waxaa jira dhowr arrimood oo muhiim ah oo ay tahay in la tixgeliyo marka la isticmaalayo jarista laysarka ee looxa alwaaxa, oo ay ku jiraan nooca looxa alwaaxa, dhumucda maaddada, xawaaraha jarista iyo awoodda laysarka, muraayadda diiradda saarta, caawinta hawada, jihada jarista, iyo tixgelinta naqshadeynta. Markaad tixgeliso arrimahan, waxaad ku gaari kartaa natiijooyinka ugu fiican jarista laysarka ee looxa alwaaxa.

Mashiinka Jarida Laser-ka Alwaaxa ee lagu taliyay

| Goobta Shaqada (W *L) | 80mm * 80mm (3.15'' * 3.15'') |

| Isha laysarka | Laysar Fiber ah |

| Awoodda Laydhka | 20W |

| Goobta Shaqada (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Isha laysarka | Tube Laser-ka CO2 ee Galaaska ama Tube Laser-ka Birta ee CO2 RF ee Galaaska |

| Awoodda Laydhka | 100W/150W/300W |

| Goobta Shaqada (W *L) | 1300mm * 2500mm (51” * 98.4”) |

| Isha laysarka | Tube Laser-ka CO2 ee Galaaska |

| Awoodda Laydhka | 150W/300W/450W |

Ma rabtaa inaad maalgashato Mashiinka Laser-ka Alwaaxa?

Waqtiga boostada: Maarso-17-2023