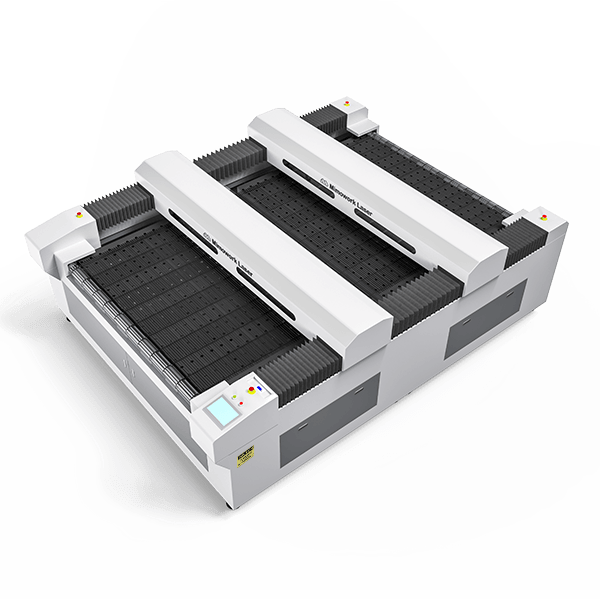

Ifomathi Enkulu Ivalwe Isisiki seLaser

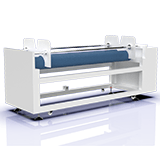

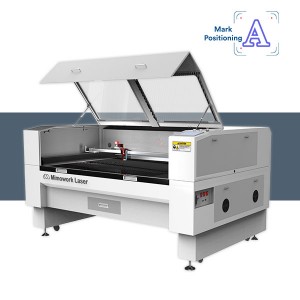

Umsiki weLaser yeFomathi enkulu,

umatshini ongcono wokusika uziva, umatshini ongcono wokusika waziva, eyona ndlela ilungileyo yokusika imvakalelo, Umatshini wokusika we-Cnc, waziva cutter, umatshini wokusika waziva, Izixhobo zokusika ezizivayo, waziva laser cut, indlela yokusika waziva, indlela yokusika izangqa ezizivayo, indlela yokusika imvakalelo enzima, laser cut waziva coasters, laser cut waziva panels, ukusika laser waziva, Umatshini wokusika weLaser waziva,

Izinto eziluncedo zeFomathi Enkulu ye-Flatbed Laser Cutter

Umtsi omkhulu kwiMveliso

Idatha yoBugcisa

| Indawo yokusebenzela (W * L) | 1600mm * 3000mm (62.9'' *118'') |

| Ubukhulu beMaterial Width | 1600mm (62.9'') |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 150W/300W/500W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | I-Rack & Pinion Transmission kunye ne-Servo Motor Driven |

| Itheyibhile yokuSebenza | Itheyibhile yokuSebenza yeConveyor |

| Isantya esiphezulu | 1-600mm/s |

| Isantya sokukhawulezisa | 1000~6000mm/s2 |

* Iiganti ezimbini ezizimeleyo zelaser ziyafumaneka ukuze uphindaphinde ukusebenza kwakho kakuhle.

I-R&D ye-Flexible Material Cutting

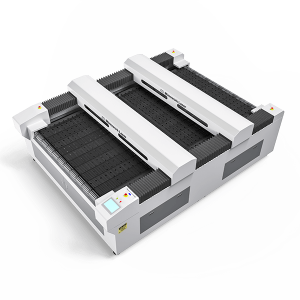

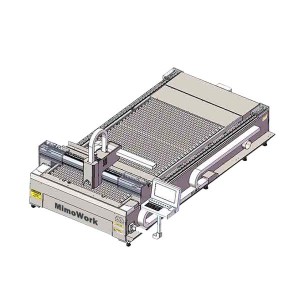

Auto Feeder

Auto Feederiyunithi yokondla eqhuba ngokuhambelana nomatshini wokusika we-laser. I-feeder iya kuhambisa izinto zomqulu kwitafile yokusika emva kokuba ubeke imiqulu kwi-feeder. Isantya sokutya sinokusetwa ngokwesantya sakho sokusika. Inzwa ixhotyiswe ukuqinisekisa ukubekwa kwezinto ngokugqibeleleyo kunye nokunciphisa iimpazamo. I-feeder iyakwazi ukudibanisa i-shaft diameters ezahlukeneyo zemiqulu. I-roller ye-pneumatic inokulungelelanisa iingubo kunye noxinzelelo kunye nobukhulu obahlukeneyo. Le yunithi ikunceda ukuba uqaphele inkqubo yokusika ngokuzenzekelayo.

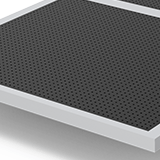

Ukufunxa iVacuum

IUkufunxa iVacuumilele phantsi kwetafile yokusika. Ngemingxuma emincinci kunye nenzulu kumphezulu wetafile yokusika, umoya 'uqinisa' izinto eziphezu kwetafile. Itheyibhile ye-vacuum ayifumani kwindlela ye-laser beam ngexesha lokusika. Ngokuchasene noko, kunye nefeni enamandla yokukhupha, yongeza umphumo womsi kunye nokuthintela uthuli ngexesha lokusika.

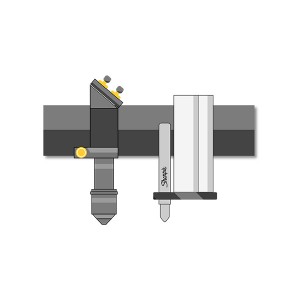

Usiba lophawu – Ukhetho

Uninzi lwabavelisi, ngakumbi ukusetyenzwa kwempahla yobugcisa, iziqwenga kufuneka zithungwe kanye emva kwenkqubo yokusika. Enkosi kwiUsiba lophawu, unokwenza amanqaku afana nenombolo ye-serial yemveliso, ubungakanani bemveliso, umhla wokwenziwa kwemveliso, njl njl ukwandisa ukusebenza kakuhle. Unokukhetha imibala eyahlukileyo ngokweemfuno zakho.

Umthombo we-CO2 RF Laser-Ukhetho

Idibanisa amandla, umgangatho ogqwesileyo we-beam, kunye ne-pulses ye-square wave (9.2 / 10.4 / 10.6μm) ekusebenzeni okuphezulu kunye nesantya. Ngommandla omncinci ochatshazelwe bubushushu, kunye ne-compact, etywinwe ngokupheleleyo, ukwakhiwa kwe-slab yokukhupha ukuthembeka okuphuculweyo. Kwamanye amalaphu akhethekileyo amashishini, i-RF Metal Laser Tube iya kuba yinto engcono.

Umboniso wevidiyo weLaser Cutting Cordura® Vest

Fumana iividiyo ezingakumbi malunga nabasiki be-laser bethuIgalari yevidiyo

Imiba yosetyenziso

Laser Cutting Izicelo Non-Metal

Iimpahla kunye neeMpahla zaseKhaya

Umphetho ococekileyo kunye ogudileyo ngonyango lwe-thermal

Umzi mveliso wokuhluza

Imfihlelo yokusika ipateni egqwesileyo

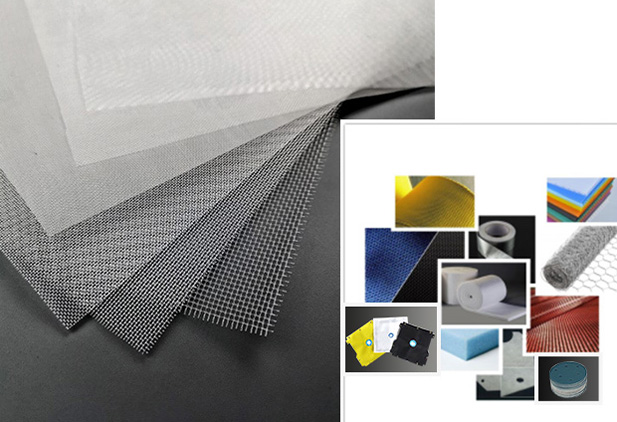

Ukukhethwa kwemidiya efanelekileyo yokucoca ithatha isigqibo somgangatho kunye noqoqosho lwenkqubo yonke yokucoca, kubandakanywa ukuhlukana okuqinileyo-olwelo kunye nokucoca umoya. I-Laser ithathwa njengeyona teknoloji ilungileyo yokusika imidiya yokucoca (Ilaphu lokuhluza,Isihluzi segwebu,Uboya begusha, Ingxowa yesihluzi, iMesh yesihluzi, kunye nezinye izicelo zokuhluza)

Izinto ezihlanganisiweyo

High Power Laser Cutting

Ukusika kweLaser kunokuhambisa ukuchaneka okuphezulu kunye neziphumo ezisemgangathweni rhoqo kunye ne-laser beam entle. Ukusetyenzwa kwe-thermal kuqinisekisa ukutywinwa kunye nemiphetho egudileyo ngaphandle kokuphazamiseka kunye nokwaphukaimathiriyeli edibeneyo.

I-Upholstery yangaphandle kunye neGear

I-laser engenamthungo yokusika ilaphu elaminethiweyo

Iimfuno zokusebenza ziphezulu kakhulu kwilaphu langaphandle. Ukukhuselwa kwelanga, ukuphefumla, ukungangeni kwamanzi, ukumelana nokunxiba, yonke le misebenzi idla ngokufuna iileya ezininzi zezinto. I-laser yethu ye-industrial cutter sesona sixhobo sifanelekileyo sokusika amalaphu anjalo.

Izinto eziqhelekileyo kunye nokusetyenziswa

yeFlatbed Laser Cutter 160L

Siye sayila iisistim zelaser ukwenzela uninzi lwabathengi

Zifake kuluhlu!

Laser Cutting Felt

Izinto ezinxulumeneyo ezizivayo zokusika kwe-laser

Uphahla oluvaliweyo, iPolyester Felt, iAkriliki evalwayo, inaliti yokuvalelwa ngenqindi, iFelt ye-Sublimation, i-Eco-fi eveziweyo, ukuvalelwa koboya

Indlela yokusika ivakale?

I-Felt lilaphu elingalukwanga elibandakanya iintsinga zendalo kunye neentsinga ezenziweyo ngenkqubo yobushushu, ukufuma, kunye nesenzo soomatshini. Xa kuthelekiswa namalaphu alukiweyo aqhelekileyo, aziva ngathi ajiyile kwaye axinene. Ngenxa yesi sizathu, ukuziva kusetyenziswe ngokubanzi ukwenza i-slippers kunye nelaphu elitsha lempahla kunye nefenitshala. Usetyenziso lwemizi-mveliso lubandakanya ukugquma, ukupakishwa, kunye nemathiriyeli yokupholisha kwiindawo zoomatshini. A bhetyebhetye kwaye ezizodwawaziva laser cutter yieyona ndlela ilungileyo yokusika imvakalelo. Yahlukile kwimveliwaziva cutter, Umatshini wokusika i-laser unomnikazi weempawu ezizodwa kunye ne-premium. Ukusika kwe-thermal kunokunyibilikisa iintambo eziqhekezayo kwaye kutywine umda wokuva. Ngokuchanekileyo ngenxa yoko, isakhiwo sangaphakathi esingenasiphelo sokuvakalelwa asiyi konakaliswa kwaye ukucubungula akuhambisani nothuli kunye nomlotha.

Ukusetyenzwa kweLaser kwimvakalelo

1. Ukusika kweLaser Ukuziva

Ukusika kwe-laser ekhawulezayo nokucocekileyo kwivakalelo kuthintela ukunamathela phakathi kwezinto, kuzisa umgangatho ophezulu ogqityiweyo ukuvaleka ngomphetho wokutywina ngelixa usika ubushushu. Ukutya okuzenzekelayo kunye nokusika kunciphisa iindleko zabasebenzi kwisidanga.

2. Ukumakishwa kweLaser kuvakala

Umahluko ophakamileyo wombala kunye ne-laser etching single-layer yevayo inokufikelela ngokusisigxina kunye neepateni zeentlobo ezingagugiyo, imifanekiso yelogo elungiselelweyo.

3. Umzobo weLaser uzivakele

Umqadi we-laser obhityileyo kunye ocolekileyo unokukrola ngoko nangoko izinto ezininzi ezizivayo ngokuseta amandla afanelekileyo elaser. Indlela yokusebenza eguquguqukayo ayinamda kwiimilo ezahlukeneyo kunye neepateni.

Ukusetyenziswa kweukusika laser waziva

Xa i-laser-cut, umatshini we-laser we-CO2 unokuvelisa iziphumo ezichanekileyo ngokumangalisayo kwii-placemats kunye neecoasters. Ukuhlobisa indlu, i-rug rug pad inokunqunyulwa ngokulula.

Umnqwazi oyivayo, Ibhegi ezivayo, into yokuncamathela ngokwakho, Ubuchule obuvakeleyo, Iphedi eveziweyo, Umatrasi oyivayo, Isihombiso esivakeleyo, Ibhodi enobumba evakeleyo, Umthi weKrisimesi ovakeleyo, ikhaphethi eveziweyo (umat)

Izibonelelo ezivela kwi-laser cutting felt panels

• Akukho mfuneko yokulungiswa kwemathiriyeli ngetafile yokufunxa

• Ukungaqhagamshelwa kunye neziqinisekiso zokuqhutywa ngamandla kwasimahla uzive uzinzo olupheleleyo

• Akukho kunxitywa kwezixhobo kunye neendleko zokutshintsha

• Imekobume yokucoca ecocekileyo

• Ukusika iphethini yasimahla, ukukrola, ukumakisha

• Indlela yokulungisa efanelekileyo ngokwesakhiwo selaphu