Ukusika ngeLaser kunye nokuGqoba iVeneer Wood

Isiqulatho

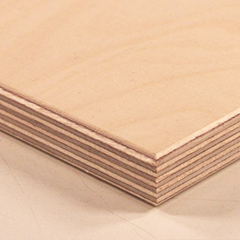

▶ Intshayelelo yeVeneer yokusika iLaser Wood

Ukusikwa kwelaser kunye nokukrola kuye kwaba yinto ebalulekileyo xa usebenza nge-veneer yomthi kuba yenza yonke inkqubo ikhawuleze, icoceke, kwaye ichaneke ngakumbi. Endaweni yokulwa namaphepha abuthathaka, abhityileyo anokuqhekeka okanye aqhekeke ngokulula, i-laser ikuvumela ukuba usike kwaye ukrole ngemiphetho egudileyo kunye neenkcukacha ebezingenakwenzeka ngesandla.

Kuye nabani na owenza ifenitshala, imihombiso, ubugcisa, okanye iziqwenga zophawu ezenziwe ngokwezifiso, iteknoloji yelaser isusa uqikelelo kwaye inike iziphumo ezihambelanayo nezibonakala zingobuchwephesha ngalo lonke ixesha. Yindlela ekrelekrele yokuzisa iingcamango zobuchule ebomini ngelixa usonga ixesha, unciphisa inkunkuma yezinto eziphathekayo, kwaye ugcine imveliso yokugqibela ibukeka icocekile kwaye ikumgangatho ophezulu.

Indalo yayo entle nengenabunzima iqinisekisa intuthuzelo kunye nokuhambahamba, iqulethe umxube ogqibeleleyo wobuthathaka kunye nobunzima.

▶ Iintlobo zeVeneer zomthi ezidumileyo kwiiprojekthi zeLaser

Iintlobo ezisixhenxe zeVeneer yoMthi

Itheyibhile yokuthelekisa iiVeneers ezisixhenxe zomthi

| Uhlobo lweVeneer yoMthi | Iimpawu | Ukusebenza kokusika/ukukrola ngeLaser | Iiprojekthi Ezifanelekileyo |

|---|---|---|---|

| I-Cherry Veneer | Iinkozo ezifudumeleyo, ezilinganayo | Ukusika okuthambileyo, ukukrola okucokisekileyo | Ifenitshala, imihombiso |

| I-Maple Veneer | Intle, inombala okhanyayo | Imiphetho ecocekileyo, umbhalo ocacileyo | Ifenitshala, iibhokisi zezipho |

| I-Oak Veneer | Ivelele, inzima | Ifuna amandla alawulwayo, ukukrola okuneeleya | Ifenitshala, imiqondiso |

| I-bamboo Veneer | Ubulukhuni obulinganayo, obuphakathi | Ukusika okugudileyo, ukukrola okucacileyo | Iiphaneli, uyilo lobuchule |

| I-Walnut Veneer | Ingqolowa emnyama, etyebileyo | Kufuneka amandla aphakathi, ukukrola okunomahluko ophezulu | Imiqondiso, ifenitshala |

| I-Birch Veneer | Intle, inombala okhanyayo | Ukusika okugudileyo, ukukrola okucacileyo | Ifenitshala, izipho |

| I-Alder Veneer | Ilungile, iguquguquka | Ukusika okugudileyo, ukukrola okucacileyo | Ifenitshala, iiphaneli zokuhombisa |

Ezi veneers zisixhenxe zomthi nganye ineempawu zayo ezikhethekileyo, ezifanelekileyo kwiiprojekthi ezahlukeneyo zokusika nokukrola nge-laser.

Itsheri kunye neMaple zinobuqhetseba obulinganayo kunye nokusika okugudileyo, zilungele ifenitshala kunye nezipho. I-oki kunye neWalnut ziqinile, zifuna amandla alawulwayo e-laser, kodwa zibonelela ngomzobo ogqwesileyo, nto leyo ezenza zilungele ifenitshala kunye neempawu. I-bamboo kunye ne-Alder zilungelelene kwaye ziguquguquka, zifanelekile kwiindlela zoyilo kunye neepaneli zokuhombisa.

Ngokubanzi, ezi veneers zisebenza kakuhle kakhulu ekwenzeni ifenitshala, ukuhombisa, kunye neeprojekthi zobuchule.

▶ Iziphumo zokusika nokukrola ngeLaser

Isikethi seLaser somthi esivela kwi-Oak Veneer

Ukukrola ngeLaser yoMthi weVeneer

Itekhnoloji yelaser kwiiveneers zomthi ivumela ulawulo oluchanekileyo lokusasazwa kobushushu namandla, nto leyo evumela ukusika nokukrola okuneenkcukacha ezininzi.

Ngexesha lokusika, umqadi welaser ugxila amandla kwindawo encinci kakhulu, uvelisa imiphetho egudileyo edla ngokufuna ukucutshungulwa okuncinci emva kokulungiswa.

Kwimifanekiso eqingqiweyo, iiparameter ze-laser zinokulungiswa ngokweenkozo zomthi kunye nobuninzi ukuze kufezekiswe iinkcukacha ezintsonkothileyo nezintsonkothileyo.

Iinkuni ezahlukeneyo zisabela ngokwahlukileyo: iinkuni ezikhaphukhaphu, ezinobunzima obufanayo (ezifana neMaple kunye neBirch) zivelisa ukukrola okucacileyo, okubukhali, ngelixa iinkuni ezimnyama okanye eziqinileyo (ezifana neWalnut kunye neOak) zifuna isantya sokusika esicothayo kunye nokulungiswa kwamandla ngononophelo, kodwa zivelisa iileya ezityebileyo zokuthungwa kunye nempembelelo ebonakalayo enamandla. Ngolawulo oluchanekileyo lweeparameter, abayili banokufikelela kwiinkcukacha zenqanaba le-micron, iziphumo ze-gradient, kunye neepateni zejometri ezintsonkothileyo kwiiveneers zomthi, zibonelela ngamava akhethekileyo okubonakalayo nokuchukumisayo kwifenitshala, izinto zokuhombisa, kunye neempawu.

▶ Iindlela Ezisebenzayo Zokusika Nokukrola NgeLaser

Ifenitshala

Iitafile, izitulo, iikhabhathi, kunye neeshelufu zeencwadi ziyazuza ekusikweni nge-laser ukuze kubekho imiphetho echanekileyo kunye namalungu acocekileyo, ngelixa ukukrola kongeza iipatheni zokuhombisa, iilogo zeempawu, okanye ubume obuneenkcukacha, nto leyo ephucula ubunzulu bokubonakala kwesi sixhobo.

Izinto zokuhombisa ezenziwe ngokwezifiso

Iibhokisi zezipho ezincinci, iifreyimu zemifanekiso, izibane, kunyeIsihombiso seKrisimesisingenziwa ngokwezifiso ngombhalo okrolwe nge-laser, iipateni, okanye uyilo lwejometri, ukugcina imvakalelo yomthi wendalo ngelixa wongeza ubuchule bobugcisa.

Iiphaneli zeMiqondiso kunye neeMboniso

Ukukrola nge-laser kuvelisa umbhalo, iilogo, kunye neepatheni ezingafaniyo kwi-veneers zomthi, okuqinisekisa ukufundeka lula kwaye kugqamisa iinkozo zendalo zomthi, ezifanelekileyo kwiimpawu zevenkile, imiboniso yeenkampani, kunye neepaneli zemiboniso.

Iiprojekthi zoBugcisa

Abayili banokudibanisa iintlobo ezahlukeneyo zomthi okanye bakrole iipateni ezintsonkothileyo ukuze benze i-gradients, uyilo lwejometri, iziphumo ezibonakalayo ezibekwe ngokwee-layered, okanye ezintsonkothileyo.Iphazili Yomthiiziqwenga, ezisetyenziswa kakhulu ekuhombiseni izinto zangaphakathi, kwimiboniso, nakwiiprojekthi zoyilo ezenziwe ngokweemfuno.

▶ Iingcebiso zeziphumo ezigqibeleleyo

Ukufezekisa iziphumo ezigqibeleleyo kwiiveneers zomthi ezisebenzisa ukusika kunye nokukrola nge-laser kufuna ulawulo olufanelekileyo lweeparameter kunye nokuphathwa kwezinto.

Ukuphepha Iimpawu Zokutsha

Lungisa amandla e-laser kunye nesantya sokusika ngokusekelwe kumbala womthi kunye noxinano ukuqinisekisa ukusasazwa kwamandla okulinganiselayo. Ukusebenzisa i-Air Assist kunceda ukukhupha ubushushu ngokukhawuleza, kunciphisa imiphetho emnyama.

Ukuthintela ukugoba

Ii-veneers ezincinci zidla ngokuwohloka xa kushushu. Ukubopha kancinci okanye ukubeka i-veneer ngokuthe tyaba etafileni yehoneycomb kunceda ukugcina uzinzo. Ukusebenzisa iindlela ezininzi zokukhanya endaweni yokusika enye enamandla aphezulu kunokunciphisa uxinzelelo lobushushu.

Ukuthintela Ukonakala Kwezinto Eziphathekayo

Iinkuni eziqinileyo ezifana ne-Oak kunye ne-Walnut zifuna isantya esicothayo kunye nokulungiswa okuchanekileyo kokugxila ukuqinisekisa ubunzulu obuhambelanayo. Iinkuni ezithambileyo zifuna amandla aphantsi ukuze kuthintelwe ukutsha kakhulu okanye ukukrola okugqithisileyo. Ngokuseta okufanelekileyo, iziqwenga zovavanyo, kunye nokulinganiswa kwezixhobo, unokuphucula kakhulu ukuchaneka komphetho kunye nokucaca kokrola.

▶ Oomatshini Abacetyiswayo

•Amandla eLaser:100W/150W/300W

•Indawo Yokusebenza:1300mm * 900mm

•Amandla eLaser:150W/300W/450W

•Indawo Yokusebenza:1300mm * 2500mm

Silungisa izisombululo zeLaser ezenzelwe wena zeMveliso

Iimfuno Zakho = Iinkcukacha Zethu

Ividiyo eNxulumeneyo:

Isifundo sokuSika nokuQoba iinkuni | Umatshini weLaser we-CO2

Iprojekthi yeLaser yoBuchule kunye neyoBuchule bokusebenza ngomthi

Sinike iingcebiso ezintle kunye nezinto ekufuneka uziqwalasele xa usebenza ngomthi. Umthi umhle kakhulu xa ucutshungulwa ngomatshini we-CO2 Laser. Abantu bebeshiya umsebenzi wabo wexesha elizeleyo ukuze baqalise ishishini lokwenza umsebenzi womthi ngenxa yendlela enenzuzo ngayo!

Kule vidiyo, sisebenzise umatshini we-CO2 Laser ukusika iiMini PhotoFrames kwiPlywood. Le yiprojekthi yeLaser Plywood ethengisa kwaye inokuba nenzuzo. Sikwakhankanye neengcebiso zokufumana iziphumo zokugqibela ezicocekileyo nezibukekayo ngeprojekthi ye-plywood laser.

▶ Imibuzo Ebuzwa Rhoqo

Uninzi lwazo, kodwa iinkuni ezimnyama, ezixineneyo, okanye ezityebileyo kwioyile zifuna uhlengahlengiso oluchanekileyo lweparameter ukuze kufumaneke imiphetho ecocekileyo kunye neziphumo zokukrola ezizinzileyo.

Iinkuni ezimnyama okanye ezixineneyo zifunxa amandla e-laser amaninzi, nto leyo eyonyusa umngcipheko wokutsha. Amandla aphantsi, isantya esiphezulu, kunye ne-Air Assist zinokunciphisa oku ngempumelelo.

Ewe. Ukugawula iinkuni kuvelisa umsi kunye nevumba elincinci lomthi otshileyo, elinokunciphisa ngeenkqubo ezifanelekileyo zokukhupha umbane okanye zokucoca.

Ngokuqinisekileyo. Ukukrola nge-laser kuvumela iinkcukacha ezinesisombululo esiphezulu, kuquka umbhalo omncinci, iilogo, iipateni zejometri, kunye neziphumo ze-gradient, nto leyo eyenza ukuba ilungele ukwenziwa ngokwezifiso okuphezulu.

Ii-veneers ezincinci zinokugoba ngenxa yobushushu. Ukuqina okuncinci, inkxaso yetafile yehoneycomb, ubushushu obuncitshisiweyo ngephasi nganye, okanye ukugqitha kokukhanya okuninzi kunokunceda ukugcina indawo ithambile.

Ewe. Ubunzulu bunokulungiswa ngokuchanekileyo ngokusebenzisa amandla, isantya, ukugxila, kunye neepasi ezininzi, ezifanelekileyo kwiingcibi ezinganzulu, ubume obunzulu, okanye uyilo oluneeleya.

Funda Ulwazi Oluthe Ngakumbi malunga neeLaser Cutters kunye neeOptions

▶ Isiphelo

Ukusikwa nokukrolwa nge-laser kubonelela ngeziphumo ezichanekileyo, ezicocekileyo, neziguquguqukayo kwiiprojekthi zefenitshala, zokuhombisa, kunye nezeempawu. Ukuze ufumane iziphumo ezilungileyo, qonda izinto zakho, lungisa isantya kunye namandla, sebenzisa iindlela ezincinci zokuvavanya, kwaye ugcine umatshini wakho ugcinwe kakuhle. Ukukhetha inkqubo ye-laser ezinzileyo nesemgangathweni kuya kukunceda usebenze ngokufanelekileyo kwaye uqinisekise iziphumo zobungcali rhoqo.