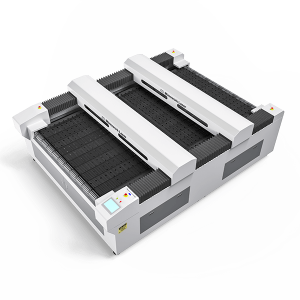

I-Laser Cutter yeBhodi yeFoam

Sinesinye sezona zixhobo zokuvelisa izinto ezintsha, iinjineli ezinamava kunye nabaqeqeshiweyo kunye nabasebenzi, baqaphela iinkqubo zokuphatha ezisemgangathweni kunye neqela elinobuhlobo elinamava okwamkela imali kwangaphambili/emva kokuthengiswa kweLaser Cutter yeBhodi yeFoam, Abasebenzi bequmrhu lethu kunye ukusetyenziswa kwetekhnoloji ye-cutting-edge kuzisa iimveliso ezikumgangatho ophezulu ezinqwenelwa kakhulu kwaye zixatyiswa ngabathengi bethu kwihlabathi liphela.

Sinesinye sezona zixhobo zivelisa izinto ezintsha, iinjineli ezinamava kunye nabaqeqeshiweyo kunye nabasebenzi, baqaphela iinkqubo zokuphatha ezisemgangathweni kunye neqela elinobuhlobo elinamava okufumana inkxaso kwangaphambili / emva kokuthengisaumsiki wesiqhelo, isiko laser cut amagwebu, i-laser yokusika amagwebu, Umsiki weLaser yogwebu, umatshini wokusika we-laser ugwebu, inkonzo yokusika i-laser foam, Laser Sika amagwebu, laser cut foam ufake, i-laser cut polyurethane foam, laser umsiki ibhodi amagwebu, laser cutter ibhodi amagwebu, Laser ukusika amagwebu, umatshini wokusika amagwebu laser, ukusika amagwebu laser, i-polyurethane foam laser ukusika, sithemba ngokunyanisekileyo ukuseka ubudlelwane beshishini elifanelekileyo kunye nexesha elide kunye nenkampani yakho ebekekileyo ngeli thuba, ngokusekelwe kukulingana, ukuxhamla kunye kunye nokuphumelela ishishini ukususela ngoku ukuya kwixesha elizayo. "Ukwaneliseka kwakho lulonwabo lwethu".

Idatha yoBugcisa

| Indawo yokusebenzela (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 100W/150W/300W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | Inyathelo Motor Belt Control |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yoBusi okanye iThayibhile yokuSebenza yeKnife Strip |

| Isantya esiphezulu | 1-400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

Ukusebenza okuninzi kumatshini omnye

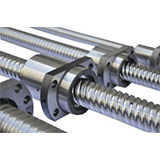

Ibhola kunye neScrew

I-ball screw yi actuator yomgca yomatshini eguqulela intshukumo ejikelezayo ukuya kwintshukumo enomda kunye nokukhuhlana okuncinci. Ishafti enemisonto ibonelela ngomdyarho wehelical weebheringi zebhola osebenza njengesikrufu esichanekileyo. Kanye nokukwazi ukufaka isicelo okanye ukumelana nemithwalo etyhalayo ephezulu, banokukwenza oko ngokrwada okuncinci kwangaphakathi. Zenziwa ukuba zivale ukunyamezela kwaye ngoko zifanelekile ukusetyenziswa kwiimeko apho ukuchaneka okuphezulu kuyadingeka. I-asembly yebhola isebenza njenge nut ngelixa i-shaft enemisonto isikrufu. Ngokuchaseneyo nezikrufu eziqhelekileyo zokukhokela, izikrufu zebhola zithande ukuba nkulu, ngenxa yesidingo sokuba nesixhobo sokujikeleza kwakhona iibhola. I-screw yebhola iqinisekisa isantya esiphezulu kunye nokuchaneka okuphezulu kwe-laser cut.

Iimoto zeServo

I-servomotor yi-servomechanism evaliweyo esebenzisa ingxelo yendawo ukulawula ukuhamba kwayo kunye nendawo yokugqibela. Igalelo kulawulo lwayo luphawu (ingaba i-analog okanye idijithali) emele indawo eyalelwe i-shaft yemveliso. I-motor idityaniswe nolunye uhlobo lwe-encoder yendawo ukunika indawo kunye nempendulo yesantya. Kwimeko elula, kuphela isikhundla silinganiswa. Indawo elinganisiweyo yemveliso ithelekiswa nendawo yomyalelo, igalelo langaphandle kumlawuli. Ukuba indawo yokuphuma iyahluka kuleyo ifunekayo, kuveliswa umqondiso wempazamo obangela ukuba imoto ijike kulo naliphi na icala, njengoko kufuneka ukuzisa ishaft yokuphuma kwindawo efanelekileyo. Njengoko izikhundla zisondela, umqondiso wephutha uyancipha ukuya kwi-zero, kwaye injini iyayeka. Iinjini ze-Servo ziqinisekisa isantya esiphezulu kunye nokuchaneka okuphezulu kokusika kwe-laser kunye nokukrola.

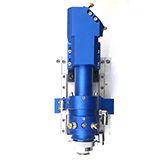

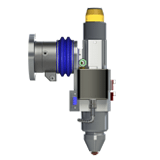

Intloko yeLaser exutyiweyo

Intloko ye-laser edibeneyo, eyaziwa ngokuba yi-metal non-metallic laser cutting head, ibaluleke kakhulu kwi-metal & non-metal edibeneyo yomshini wokusika i-laser. Ngale ntloko ye-laser yobuchwephesha, unokusika zombini isinyithi kunye nezinto ezingezizo ezentsimbi. Kukho i-Z-Axis yokudluliselwa kwenxalenye yentloko ye-laser ehamba phezulu nasezantsi ukulandelela indawo ekugxilwe kuyo. Isakhiwo sayo se-drawer esiphindwe kabini sikwenza ukuba ubeke iilensi ezimbini zokugxila ezihlukeneyo ukusika izinto zobunzima obuhlukeneyo ngaphandle kokulungelelaniswa komgama wokugxila okanye ukulungelelaniswa kwemiqadi. Yandisa ukuguquguquka kokusika kwaye yenza umsebenzi ube lula kakhulu. Unokusebenzisa igesi yokuncedisa eyahlukeneyo kwimisebenzi eyahlukeneyo yokusika.

Ugxininiso oluzenzekelayo

Isetyenziselwa ikakhulu ukusika isinyithi. Ungadinga ukuseta umgama othile wogxininiso kwisoftware xa izinto zokusika zingekho tyaba okanye ezinobunzima obahlukeneyo. Ke intloko ye-laser iya kuhla inyuka ngokuzenzekelayo, igcine ubude obufanayo kunye nomgama wokugxila ukuze utshatise nento oyibeka ngaphakathi kwesoftware ukufezekisa umgangatho wokusika ophakamileyo.

Ividiyo yeLaser Cutting Acylic (PMMA)

Ividiyo yeBhodi yeeNkuni zeLaser

Fumana iividiyo ezingakumbi malunga nabasiki be-laser bethuIgalari yevidiyo

Imiba yosetyenziso

Ukusika iLaser kwishishini lakho

Ushicilelo lweDijithali

Umphetho ococekileyo kunye ogudileyo ngonyango lwe-thermal

Intengiso & neZipho

Iinzuzo ezizodwa zeempawu zokusika i-laser kunye nemihombiso

Izinto eziqhelekileyo kunye nokusetyenziswa

yeFlatbed Laser Cutter 130

Siye sayila iisistim zelaser ukwenzela uninzi lwabathengi

Zifake kuluhlu!

Laser Cutting Foam

Ubuchwephesha kunye nabaqeqeshiweyo beLaser Cutting Solution yeFoam

Ukusetyenziswa kwimizi-mveliso ye-foam ihlaziywa rhoqo. Imarike yamagwebu yanamhlanje yenziwe ngezinto ezininzi ezahlukeneyo ezisetyenziswa kuluhlu olubanzi lwezicelo. Ukuze kuqhutywe i-foams, i-shishini liyanda ukufumana ukuba i-laser cutter ifanelekile kakhulu ukusika kunye nokukrola amagwebu enziwe nge-polyester (PES), i-polyethylene (PE) okanye i-polyurethane (PUR). Kwezinye izicelo, iilaser zinokubonelela ngenye indlela enomtsalane kwiindlela zokusetyenzwa kwemveli. Ukongeza, igwebu elicutshungulwayo lelaser likwasetyenziswa kwizicelo zobugcisa, njengezikhumbuzo okanye iifreyimu zeefoto.

Izibonelelo kwiLaser Cutting on Foam

Umphetho ococekileyo & ococekileyo

Ilungile & echanekileyo

Ukusika okuguquguqukayo kweemilo ezininzi

Xa usika i-foam yezoshishino, izibonelelo ze-laser cutter ngaphezu kwezinye izixhobo zokusika ziyabonakala. Nangona i-cutter yendabuko isebenzisa uxinzelelo oluqinileyo kwi-foam, ekhokelela kukuguqulwa kwezinto eziphathekayo kunye nemiphetho yokusika engacocekanga, i-laser inokudala i-contours egqwesileyo ngenxa yokusikwa okuchanekileyo kunye nokungadibanisi.

Xa usebenzisa ukusika ijethi yamanzi, amanzi aya kutsalwa kwi-foam efunxayo ngexesha lokwahlula. Ngaphambi kokuqhubela phambili, izinto kufuneka zomiswe, okuyinkqubo echitha ixesha. Ukusikwa kweLaser kuyayishiya le nkqubo kwaye unokuqhubeka nokulungisa izinto ngokukhawuleza. Ngokwahlukileyo koko, i-laser iqinisekisa kakhulu kwaye ngokucacileyo sisixhobo sokuqala sokusetyenzwa kwamagwebu.

Ukusetyenzwa kweLaser kwiFoam

1. Ukusika iLaser kwi-Foam

Intloko ye-laser eguquguqukayo enomqadi ocolekileyo welaser ukunyibilikisa ugwebu ngephanyazo ukunqumla ugwebu ukufezekisa imiphetho yokutywina.

2. Ukukrolwa kweLaser kwi-Foam

Umqadi ocoliweyo welaser ogcina umphezulu wegwebu ngokulinganayo ukufezekisa isiphumo sokukrola esifanelekileyo.

Izicelo eziqhelekileyo zeLaser Cutting Foam

• Igasket yogwebu

• Iphedi yogwebu

• Isigcwali sesitulo semoto

• Umgca wegwebu

• Umqamelo wesihlalo