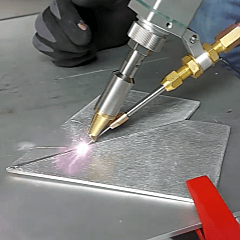

Indlela yokuWelda iiAluminiyam ngeLaser

Ukuwelda iAluminiyam Kunokuba Yingxaki

Ii-alloys ze-aluminium zahlulwe zibe ziichungechunge ngokusekelwe kwizinto zazo eziphambili zokudibanisa.

Uthotho ngalunye luneempawu ezizodwa ezichaphazela ukudityaniswa kwalo, ingakumbi xa kusetyenziswa ukudityaniswa nge-laser ephathwayo.

Apha ngezantsi kukho isishwankathelo sothotho lwe-aluminium alloy eqhelekileyo, iimpawu zazo, iigesi zokukhusela ezifanelekileyo, iintambo zokuzalisa ezifanelekileyo, kunye neengcebiso zokufikelela kwii-welds ezikumgangatho ophezulu.

Uluhlu Lomxholo:

1. IiAluminiyam eziqhelekileyo ze-Aluminiyam zokuWelda ngeLaser

Inyathelo Lokuqala Lokufumana I-Weld Elungileyo: Ukuqonda

Ii-Aluminium ze-Aluminium ze-1000 Series

Ulwakhiwo:Iqulethe i-aluminium engama-99.00% nangaphezulu.

Iipropati:Ilula kwaye ithambile kakhulu, okwenza kube lula ukusebenza ngayo.

Igesi yokukhusela:I-Argon eyi-100% iyacetyiswa ukuthintela i-oxidation.

Ucingo lokuzalisa:Sebenzisa ucingo lwe-filler oluyi-4047 okanye i-4045 ukuze ulungelelane ngcono.

Iingcebiso zokuWelda:Qinisekisa ukuba umphezulu ucocekile kwaye awunazo ii-oxides. Ukufudumeza akunyanzelekanga ngenxa yokuba kuthambile kakhulu.

Ii-Aluminium Alloys zothotho luka-2000

Ulwakhiwo:Ixutywe kakhulu ngekopolo (2-10%).

Iipropati:Amandla aphezulu kodwa ukuguguleka okuphantsi; kulula ukuqhekeka ngexesha lokuwelda.

Igesi yokukhusela:I-Argon enepesenti encinci yeHelium inokunceda ukuphucula ukungena kwamanzi.

Ucingo lokuzalisa:Sebenzisa ucingo lwe-filler oluyi-4047 okanye i-2319, oluyilelwe ii-alloys ezinobhedu oluninzi.

Iingcebiso zokuWelda:Fudumeza izinto ukuze unciphise umngcipheko wokuqhekeka. Lawula ubushushu ngononophelo ukuze uphephe uxinzelelo olugqithisileyo lobushushu.

Ii-Aluminium Alloys ze-3000 Series

Ulwakhiwo:Ixutywe ne-manganese.

Iipropati:Ukumelana nokugqwala kakuhle kunye namandla; igcina amandla kumaqondo obushushu aphezulu.

Igesi yokukhusela:I-Argon eyi-100% iyasebenza.

Ucingo lokuzalisa:Ucingo lokugcwalisa oluyi-4045 okanye i-4047 lufanelekile.

Iingcebiso zokuWelda:Coca umphezulu kakuhle ukuze ususe naziphi na izinto ezingcolisayo. Gcina isantya sokuhamba sizinzile ukuqinisekisa ukuba ubushushu busasazeka ngokulinganayo.

Ii-Aluminium Alloys ze-4000 Series

Ulwakhiwo:Iqulethe i-silicon, ehlisa iqondo lokunyibilika.

Iipropati:Ukwanda kokuguquguquka kunye nokugqwesa kakhuluukuphosa ngoxinzeleloayinyangeki ngobushushu.

Igesi yokukhusela:I-Argon ikhethwa kakhulu.

Ucingo lokuzalisa:Sebenzisa ucingo lwe-filler lwe-4047 ukuze ufumane iziphumo ezilungileyo.

Iingcebiso zokuWelda:Ukufudumeza kunokunceda ekungeneni. Jonga ubushushu ngokusondeleyo ukuze uphephe ukugoba.

Ii-Aluminium Alloys ze-5000 Series

Ulwakhiwo:Ixutywe ne-magnesium.

Iipropati:Amandla aphezulu kunye nokumelana nokugqwala okugqwesileyo; ifanelekile kwiishiti kunye neepleyiti.

Igesi yokukhusela:I-Argon eyi-100% iyacetyiswa.

Ucingo lokuzalisa:Sebenzisa ucingo lwe-filler lwe-5356 ukuze uhambelane ngcono.

Iingcebiso zokuWelda:Ukufudumeza kuluncedo kwiindawo ezityebileyo. Sebenzisa indlela yokutyhala ukuphucula indlela yokucoca nokunciphisa ungcoliseko.

Ii-aluminium ze-aluminium ze-6000 Series

Ulwakhiwo:Iqulethe zombini i-magnesium kunye ne-silicon.

Iipropati:Iyakwazi ukuguguleka kakuhle kwaye inyangwa kubushushu; ilungele ukusetyenziswa kwezinto eziphumayo.

Igesi yokukhusela:I-Argon okanye umxube we-Argon kunye ne-Helium.

Ucingo lokuzalisa:Ucingo lokugcwalisa oluyi-4045 okanye i-5356 lufanelekile.

Iingcebiso zokuWelda:Qinisekisa ukuba umphezulu ucocwa ngokufanelekileyo. Sebenzisa isantya esiphezulu sokuhamba ukuze uthintele ukugqithisa kakhulu.

Ii-aluminium ze-aluminium ze-7000 Series

Ulwakhiwo:Ngokuyintloko ixutywe ne-zinc.

Iipropati:Amandla aphezulu kodwa ngokubanzi afanelekanga kwi-fusion welding ngenxa yeengxaki zokuqhekeka.

Igesi yokukhusela:I-Argon eneHelium inokuba luncedo.

Ucingo lokuzalisa:Sebenzisa ucingo lwe-filler oluyi-7072 okanye oluyi-7005.

Iingcebiso zokuWelda:Ukufudumeza kubalulekile ukunciphisa umngcipheko wokuqhekeka. Sebenzisa ubushushu obulawulwayo kwaye uphephe isantya sokuhamba esigqithisileyo.

Ngokuphuhliswa kobuchwepheshe banamhlanje

Ixabiso lomatshini wokuwelda ngeLaser alikaze libe nexabiso eliphantsi kangaka!

2. Iingcebiso eziqhelekileyo zokuWelda i-Aluminiyam ngeLaser

Ukuze ufumane iziphumo ezilungileyo zokuWelda, nazi ezinye iingongoma eziphambili:

Ukulungiswa komphezulu

Soloko ucoca umphezulu we-aluminiyam ukuze ususe ii-oxides kunye nezinto ezingcolisayo.

Ulawulo lobushushu

Jonga ngononophelo igalelo lobushushu ukuze uphephe ukugoba nokuphambuka, ingakumbi kwizinto ezincinci.

Isantya Sokuhamba

Lungisa isantya sokuhamba ngokwesixa sezinto ukuze ulungelelanise ukungena kunye nokufakwa kobushushu.

Uhlengahlengiso lweNqanaba eliPhambili

Gxila i-laser kancinci ngaphantsi komphezulu ukuze ungene ngcono kwaye unciphise ukubonakaliswa kwayo.

Ukukhetha Phakathi Kweentlobo Ezahlukeneyo Zomatshini Wokuwelda NgeLaser?

Singakunceda ekwenzeni isigqibo esichanekileyo ngokusekwe kwizicelo

3. Indlela Yokufumana I-Weld Elungileyo Ngee-Aluminium Alloys

Ukuqonda izinto zakho kuphakathi kwendlela

Ukuqonda uthotho lwe-common aluminium alloy kubalulekile ekufezekiseni i-weld elungileyo nge-handheld laser welder ngezizathu ezahlukeneyo:

Iipropati zezinto ezibonakalayo

Uthotho ngalunye lwe-aluminium alloy luneempawu ezizodwa, kuquka amandla, ukuguquguquka, kunye nendawo yokunyibilika.

Ukwazi ezi mpawu kunceda ekukhetheni iiparameter ezifanelekileyo zokuwelda, ezinje ngoseto lwamandla kunye nesantya sokuhamba, ukuqinisekisa ukuwelda okuqinileyo nokusebenzayo.

Imingeni yokuWelda

Uthotho lwee-alloy ezahlukeneyo luzisa imingeni ethile ngexesha lokuwelda.

Umzekelo, ii-alloys zochungechunge lwe-2000 zinokwaphuka lula, ngelixa ii-alloys zochungechunge lwe-4000 zinokuhamba lula kakhulu.

Ukuqonda ezi ngxaki kwenza abawelda bakwazi ukusebenzisa iindlela zokunciphisa iingxaki, ezinje ngokufudumeza okanye ukulungisa izinto zokuzalisa.

Ukuhambelana kwezinto ezizalisa

Ii-alloys ezahlukeneyo ze-aluminium zifuna izixhobo zokuzalisa ezihambelanayo ukuqinisekisa ukubopha okuqinileyo.

Umzekelo, ukusebenzisa ucingo olufanelekileyo lokugcwalisa kunokuthintela iingxaki ezifana nokuqhekeka okanye ukudibana okunganelanga.

Ulwazi ngoluhlu lwe-alloy lunceda ekukhetheni ucingo oluchanekileyo lokugcwalisa ukuphucula umgangatho we-weld.

Ukukhethwa kweGesi yokukhusela

Ukukhethwa kwegesi yokukhusela kunokuchaphazela kakhulu umgangatho we-weld.

Uthotho ngalunye lwe-alloy lungadinga iigesi ezithile zokukhusela ukuthintela i-oxidation kunye nokuphucula ukungena.

Ukuqonda ukwakheka kwe-alloy kunceda abawelda ukuba bakhethe igesi yokukhusela efanelekileyo ukuze bafumane iziphumo ezilungileyo.

Ulawulo lobushushu

Ii-alloys ezahlukeneyo zisabela ngokwahlukileyo kubushushu.

Ezinye zisenokufuna ukufudunyezwa kwangaphambili okanye unyango emva kokushiselwa ukuze kuncitshiswe uxinezeleko.

Ukuqonda uthotho lwe-alloy kuvumela abawelda ukuba balawule ubushushu ngendlela efanelekileyo, benciphisa umngcipheko wokugoba okanye ukuqhekeka.

Ukufaneleka kwesicelo

Ii-alloys ezithile ze-aluminium zilungele ngcono ukusetyenziswa okuthile, njenge-aerospace okanye i-automotive.

Ukwazi iimpawu zoluhlu ngalunye kunceda ekukhetheni i-alloy efanelekileyo yomsebenzi, ukuqinisekisa ukuba imveliso yokugqibela iyahlangabezana nemigangatho yokusebenza kunye nokhuseleko.

Ukusebenza kakuhle kweendleko

Ukusebenzisa iiparameter ezifanelekileyo ze-alloy kunye ne-welding kunokukhokelela kwiinkqubo zokuwelda ezisebenzayo ngakumbi, ukunciphisa inkunkuma yezinto kunye nokuhlaziya.

Ukuqonda iipropati ze-alloy kunceda ekucwangcisweni nasekusetyenzisweni ngcono, ekugqibeleni konga ixesha kunye neendleko.

Ukuqinisekisa umgangatho

Ukwazi uluhlu olwahlukeneyo lwe-aluminiyam kunceda ekusekeni amanyathelo okulawula umgangatho.

Abawelda banokusebenzisa iindlela ezithile kunye nemigangatho ngokusekelwe kuhlobo lwe-alloy, nto leyo ekhokelela kwiiwelda ezihambelanayo nezisemgangathweni ophezulu.

Ukuwelda i-Aluminiyam Kunzima Xa Uwelda Ngokwesiko

Ukuwelda ngeLaser Yenza kube lula le nkqubo

Ngaba ufuna ukwazi okungakumbi malunga ne-laser Welding Aluminium?

Ukuwelda I-Aluminiyam inzima kakhulu kunekuwelda Ezinye izinto.

Kungoko ke sibhale inqaku malunga nendlela yokufumana iiWelds ezilungileyo ngeAluminiyam.

Ukusuka kwiSetingi ukuya kwiNjani.

Ngeevidiyo kunye nolunye ulwazi.

Unomdla kwi-Laser Welding Ezinye Izinto?

Ngaba ufuna ukuqala ukuwelda nge-laser ngokukhawuleza?

Ngaba ufuna ukuhlaziya ulwazi lwakho malunga nokuwelda nge-laser?

Esi sikhokelo sipheleleyo seReferensi senzelwe wena!

Umthamo ophezulu kunye nombane osetyenziswa kwiindlela ezahlukeneyo zokuWelda

Umatshini wokuwelda we-laser ophathwa ngesandla we-2000W ubonakala ngobukhulu bomatshini obuncinci kodwa umgangatho wokuwelda oqaqambileyo.

Umthombo we-laser yefayibha ozinzileyo kunye nentambo yefayibha edibeneyo zibonelela ngokuhanjiswa komqadi we-laser okhuselekileyo nozinzileyo.

Ngamandla aphezulu, isitshixo se-laser welding sigqibelele kwaye sivumela ukuba i-welding joint iqine ngakumbi nakwintsimbi etyebileyo.

Ukuthwaleka ukuze kube lula ukuguquguquka

Njengoko ibukeka incinci kwaye incinci, umatshini wokuwelda welaser ophathwayo uxhotyiswe ngesibhamu sokuwelda selaser esiphathwayo esinokuhanjiswa esikhaphukhaphu kwaye silungele ukusetyenziswa kwe-multi-laser welding kuyo nayiphi na i-engile kunye nomphezulu.

Iindidi ezahlukeneyo zee-nozzles ze-laser welder kunye neenkqubo zokutyisa ngocingo oluzenzekelayo zenza kube lula ukusebenza kwe-laser welding kwaye oko kulungele abaqalayo.

Ukuwelda nge-laser ekhawulezayo kwandisa kakhulu ukusebenza kakuhle kwemveliso yakho kunye nemveliso ngelixa kuvumela isiphumo esihle kakhulu sokuwelda nge-laser.

Izinto Okufuneka Uzazi Ngazo: Ukuwelda Ngelaser Ephathwayo

Ukuba uyithandile le vidiyo, kutheni ungacingi ngayoubhalisela kwiChannel yethu yeYoutube?

Izicelo ezinxulumene noko onokuba nomdla kuzo:

Yonke into oyithengileyo kufuneka inolwazi oluhle

Singakunceda ngolwazi oluneenkcukacha kunye neengcebiso!

Ixesha leposi: Disemba-20-2024