Ukuwelda ngeLaser vs Ukuwelda ngeTIG: Yintoni Etshintshileyo Ngo-2024

Yintoni i-Handheld Laser Welding?

Ukuwelda kweLaser ephathwayo ngentsimbi engagqwaliyo

Ukuwelda nge-laser ephathwa ngesandlaisebenzisa isixhobo selaser esiphathwayo ukudibanisa izinto, ngokuqhelekileyo iintsimbi.

Ukuwelda nge-laser ephathwayo kuvumelaenkuluukukwazi ukuhamba nokuchaneka,

Kwaye ivelisa i-weld esemgangathweni ophezulu, ecocekileyo eneubuncinciigalelo lobushushu,

Ukunciphisaukuphazamiseka kunye nesidingo sokulungiswa okubanzi emva kokuwelda.

Abaqhubi banokulungisa ngokulula amandla kunye nesantya selaser,

Iyavumelauseto olulungiselelwe wenaizixhobo ezahlukeneyo kunye nobukhulu.

Uluhlu Lomxholo:

Yintoni ukuCoca ngeLaser Weld?

Ukubaluleka kococeko ekuWelding

Ukucocwa Kwangaphambi Kokushintshwa Kwe-TIG Welding

Xa kufikwa kumba wokuwelda,

Ucoceko ludlala indima ebalulekileyo ekufezekiseniumgangatho ophezuluiziphumo.

Lo mgaqo usebenza kuzo zombini ii-TIG welding kunye nee-handheld laser welding,

Kodwa iindlela zokulungiselela izinto zahlukile kakhulu.

Nakweyiphi na inkqubo yokuwelda,

Ubukho bezinto ezingcolisayo ezifana nomhlwa, ipeyinti, kunye negrisi

I-Canukuyekelela kakhuluukuthembeka kwe-weld.

Ezi zinto zingcolileyo zinokubangela amalungu abuthathaka, ukuvuleka, kunye nezinye iziphene

Oko kuyawuthomalalisa amandla emveliso yokugqibela.

Nantsi indlela oziphatha ngayoKUFANELEKILEHlangana nezi zinto zingcolisayo:Ukucoca i-Laser Weld.

Ukuwelda ngeLaser vs Ukuwelda ngeTIG: Ukucocwa kweLaser Weld

Iindawo ezicociweyo zivelisa iiWelds ezikumgangatho ophezulu

Ukucocwa kwe-Laser Weld yokucoca nge-Laser ephathwa ngesandla

Nangona ukuwelda kwe-TIG kuxhomekekeincwadi yesandlaiindlela zokucoca ezifana nokugaywa kwe-engile kunye nokusula i-acetone,

Ukuwelda nge-laser ephathwayo kunika okungakumbikululaenye indlela enezakhono zayo zokucoca ezihlanganisiweyo.

Olu tshintsho alupheleli nje ekuphuculeni ukusebenza kakuhle

Kodwa ikwaqinisekisa ukuba inkqubo yokuwelda isebenza kakuhle kangangoko,

Ekugqibeleni kukhokelela kwiziphumo ezingcono.

Ukulungiswa kwe-TIG Welding:

Kwi-TIG (Igesi engasebenziyo yeTungsten) ukuwelda, ukulungiselela ngononophelo kubalulekile.

Ngaphambi kokuba uqale inkqubo yokuwelda,

Kuqhelekile ukusebenzisaii-engile grindersukususa umhlwa okanye iingubo kumphezulu wento leyo.

Olu kucoca ngoomatshini lunceda ekuqinisekiseni ukuba umphezulu awungcolisi.

Emva koku, sula ngokucokisekileyo ngei-acetoneidla ngokwenziwa.

I-Acetone sisinyibilikisi esinamandlaisusa ngempumelelonayiphi na igrisi okanye izinto ezingcolisayo eziseleyo,

Ukushiya umphezulu ococekileyo wokuwelda.

Le nkqubo yokucoca enamanyathelo amabini ingathatha ixesha elide,

Kodwa kubalulekile ukuze kufunyanwe i-weld eqinileyo nehlala ixesha elide.

Ukulungiselela Ukuwelda Nge-Laser Ephathwayo

Ngokwahlukileyo koko, iinkonzo zokuwelda nge-laser eziphathwa ngesandla

Okunyeindlela elungelelanisiweyoukulungiselela umphezulu.

Nge3-kwi-1Ngokwenza i-laser welder, inkqubo iba lula kakhulu.

Ezi matshini ziphucukileyo zihlala zixhotyiswe ngeii-nozzles ezitshintshanayo

Oko kuvumela ukucocwa komphezulu ngaphambi kokuba udibanise.

Ngokungafaniyo neendlela zemveli, apho kufuneka izixhobo ezahlukeneyo kunye nezinto zokucoca,

Abawelda nge-laser banokuwucoca umphezulu ngokulula nge-laser beam egxile kuyo.

Oku akugcini nje ngokusindisa ixesha kodwa kunciphisaubungakanani bezixhoboifuneka kwindawo.

Ukuwelda ngeLaser vs TIG kutshintshile ngo-2024

Qhagamshelana Nathi ukuze ufumane okungakumbi malunga neNkqubo yokuWelda yeLaser ephathwayo

Kutheni Usebenzisa Igesi Yokukhusela Kwi-Welding?

Ukukhetha iGesi yokukhusela idlala indima ebalulekileyo

Igesi yokukhusela i-TIG Welding: Argon

Xa kufikwa kumba wokuwelda,

Ukukhetha igesi yokukhusela kubalulekile ukuqinisekisa iziphumo ezisemgangathweni ophezulu.

Ngokukodwa, ukuwelda kwe-TIG kunye nokuwelda nge-laser ephathwayo kuneemfuno ezahlukeneyo kunye neendlela onokukhetha kuzo.

Xa kufikwa ekukhuseleni iigesi, okuchaphazela ukusebenza kunye neendleko.

Ukukhusela igesi ngaphakathiUkuwelda kweTIG

Kwi-TIG (Tungsten Inert Gas) ukuwelda,

Igesi yokukhusela esetyenziswayo kakhulu yileubunyulu obuphezului-argon.

Le gesi intle ikhethwe ngenxa yokukwazi kwayo okugqwesileyokhusela ichibi lokuwelda

Ukusuka ekungcolisweni komoya, ingakumbi i-oxidation.

Ukuxinana kwe-oksijini kunokukhokelelaiziphenekwi-weld, njenge-porosity kunye namalungu abuthathaka,

Yeyiphiukuvumelanaukuthembeka ngokubanzi kwesinyithi.

Ngenxa yokusebenza kwayo kakuhle,

Ukuwelda kwe-TIG kudla ngokufunaokuqhubekayoukunikezelwa kwe-argon kuyo yonke inkqubo yokuwelda.

Nangona kunjalo, i-argon ingabiza kakhulu, nto leyo ekhokelela kwiindleko eziphezulu zokusebenza,

Ingakumbi kwiiprojekthi ezifuna ukuwelda okubanzi.

Ukukhusela igesi ngaphakathiUkuwelda ngeLaser ephathwayo

Igesi yokukhusela enye indlela yokuwelda nge-laser: i-nitrogen

Kwelinye icala, ukuwelda nge-laser ephathwayo kudla ngokusebenzisa i-nitrogen njengegesi yokukhusela.

I-nitrogen ayisiyo kuphelaiyasebenzaukuthintela i-oxidation

Kodwa kukwabaluleke ngakumbiisebenza kakuhle emalinikune-argon.

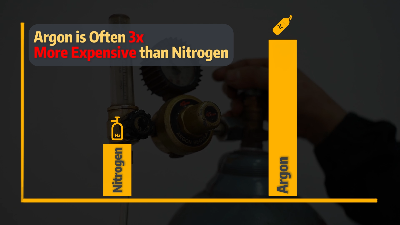

Umahluko wexabiso unokuba mkhulu kakhulu;

I-nitrogen inokuba phantse ibeamaxa amathathuixabisa kancinci kune-argon ecocekileyo kakhulu.

Oku kwenza i-nitrogen ibe lukhetho olunomtsalane kumashishini afuna ukunciphisa iindlekongaphandle kokuzincamaumgangatho.

Ukuwelda kweTIG vs Laser: Iinketho zegesi zokukhusela

Fumana Ukonga Ngelixa Ugcina Umgangatho

Ukuthelekiswa kwexabiso phakathi kweArgon kunye neNitrogen

Ukutshintshela kwi-nitrogen kwiinkonzo zokuwelda nge-laser eziphathwayoezininziiingenelo

Ukonga iindleko:

Neebalulekileyoumahluko wamaxabiso phakathi kwe-argon kunye ne-nitrogen,

Ukusebenzisa i-nitrogen kunokubangela ukonga okukhulu ekuhambeni kwexesha.

Yi leiluncedo kakhulukwiiprojekthi ezinkulu okanye amashishini

Ezo zenza imisebenzi yokuwelda rhoqo.

Ukhuseleko Olusebenzayo:

I-nitrogen inikaukhuselo olufanelekileyongokuchasene ne-oxidation,

Ukuqinisekisa ukuba i-weld ihlala ihleliicocekile kwaye yomelele.

Nangona i-argon yaziwa ngokhuseleko lwayo oluphezulu,

I-nitrogen isasebenzaukhetho olusebenzayoehlangabezana ngempumelelo neemfuno zezicelo ezininzi zokuwelda.

Thelekisa iNkqubo yokuWelda: UkuWelda ngeLaser vs TIG

Ukuqwalaselwa Ngononophelo Kwindlela Yokusebenza Kufumana Iziphumo Ezilungileyo

I-engile echanekileyo yokuWelda ngeLaser: Iidigri ezingama-45

Nje ukuba igesi yokukhusela ihambe kakuhle,

Lifikile ixesha lokugxila kwinkqubo yokwenyani yokuwelda.

Zombini ii-welding ze-TIG (Tungsten Inert Gas) kunye nee-welding ze-laser eziphathwa ngesandla

Kufunekaiindlela ezichanekileyoukuze kuzuzwe iziphumo ezisemgangathweni ophezulu,

Nangona kunjalo, zahlukile kwiimfuno zazo ezithile kunye neendlela zazo.

Ukuwelda kweTIGUbuchule

Injongo yokugcina i-electrode ikwimeko entleumgama ofanelekileyo kunye nesantyaukwenza nokukhokela ichibi lokuwelda.

Lo mgama ungahluka ngokuxhomekeke kwizinto ezidityanisiweyo kunye nobukhulu obudityanisiweyo.

Ukugcina i-engile echanekileyo, idla ngokujikelezaAmaqondo obushushu ukusuka kwi-15 ukuya kwi-20 degrees,

Inceda ekufumaneni i-weld ehambelanayo necocekileyo.

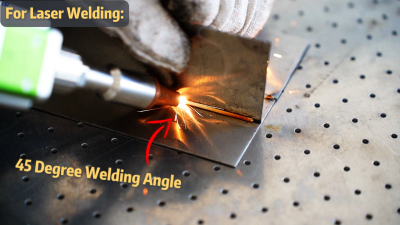

Ukuwelda ngeLaser ephathwayoUbuchule

Enye yeenzuzo zokuwelda nge-laser kukukwazi ukuseta i-engile efanayo

Ngokwesiqhelo ijikelezeIidigri ezingama-45, okuvumela ulawulo olulula lwenkqubo yokuwelda.

Nje ukuba i-engile imiselwe, gcinaisantya esizinzileyosisitshixo.

Ukuwelda nge-laser ephathwa ngesandla kudla ngokuvelisaubushushu obuncincixa kuthelekiswa nokuwelda kweTIG.

Oku kuthetha ukuba kukhoumngcipheko omncinci wokugoba okanye ukugqwetheka,

Ukwenza kube yeyona nto ifanelekileyo kumsebenzi ochanekileyo kwizinto ezincinci.

Amandla okuWelda ngeLaser vs TIG: Iintsomi ezityhila iingxaki

Ingcamango Engaqhelekanga Ngokuphathelele Ukuwelda NgeLaser

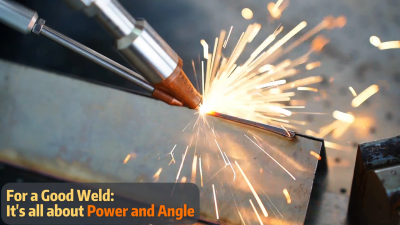

Ukuze Usebenzise I-Laser Welding Ephathwayo Elungileyo: Amandla kunye ne-Angle

Enye yezona nzuzo ziphambili zokuwelda nge-laser ephathwayo kukukwazi kwayo ukunika amandla aqinileyongokuchanekileyoapho kufuneka khona.

Neuseto lwamandla asekunenekunyei-engile efanelekileyo

Ngokwesiqhelo ijikelezeIidigri ezingama-45, ukuwelda nge-laser kunokufikelela ekungeneni nasekuqineni okugqwesileyo.

Isiphumo Samandla Esifanelekileyo

Ukuseta amandla kwe-laser welder kubaluleke kakhulu.

Umbane ophumayo uphantsi kakhulu kunokubangelaukungena ngokwaneleyo, nto leyo ekhokelela kwiintsimbi ezibuthathaka.

Ngokwahlukileyo koko, inqanaba lamandla elifanelekileyo livumela i-laser ukuba inyibilikise izinto ngokufanelekileyo, idale amalungu aqinileyo.

Ukusebenzisa izixhobo ezingasebenzisi amandla aneleyo akuyi kuvelisa iziphumo ezinqwenelekayo.

Zombini i-TIG kunye ne-Handheld Laser Welding ziyasebenza kakuhle

Ngaba ufuna ukufunda okungakumbi malunga nokuwelda nge-laser ephathwayo?

Ukuwelda ngeLaser ephathwayo: Indlela yokuGcina izixhobo

Ukunyamekela Okufanelekileyo Nokuqwalaselwa Kweenkcukacha Kuya Kuqinisekisa Imveliso Nokuthembeka

Ubusazi na ukuba zombini i-TIG (Tungsten Inert Gas) welding kunye ne-handheld laser welding zihlulwe njenge

Iindlela zokuwelda ezingasetyenziswayo?

Oku kuthetha ukuba, phantsi kweemeko ezifanelekileyo nangononophelo olufanelekileyo,

Izinto eziphambili ezisetyenziswa kwezi nkqubo zinokuhlala ixesha elide

Ngaphandle kokufuna ukutshintshwa rhoqo.

Izinto ezingasetyenziswayo

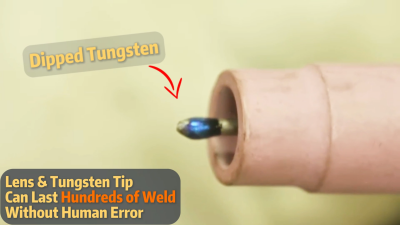

Impazamo yeTungsten edityiweyo kwi-TIG Welding

I-electrode ye-tungsten yinxalenye ebalulekileyo ekudibaniseni i-TIG.

Ngokungafaniyo nee-electrode ezisetyenziswa kwezinye iindlela zokuwelda,

ezifana nokuwelda kwe-MIG, i-electrode ye-tungstenayinyibilikingexesha lenkqubo yokuwelda.

Kunoko, igcina ingqibelelo yayo, ivumela ukusetyenziswa ixesha elide.

Nangona kunjalo, i-electrode ingangcoliswa okanye "idiphu" ukuba ifumanakufutshane kakhulu nedama lokusila elinyibilikisiweyo.

Kwiimeko ezinjalo, kufuneka inqunyulwe ize igutyulwe ukuze kubuyiselwe inqanaba layo elibukhali kunye nokusebenza kwayo okusebenzayo.

Ukugcinwa rhoqoI-electrode ye-tungsten ibalulekile ekufezekiseni ii-welds ezicocekileyo nezisemgangathweni ophezulu.

Ukulungiselela Ukuwelda Nge-Laser Ephathwayo

Ilensi yeLaser yoLondolozo lweLaser oluphathwayo

Kwi-laser welding ephathwayo, ilensi yelaser isebenza njengendawo ephambili yomqadi welaser.

Ilensi ebekwe kakuhle inokuhlala ixesha elide, inika ukusebenza okuzinzileyo.

Nangona kunjalo, ukuba ilensi iyaqhekeka ngenxa yokungabekwa kakuhle okanye ukuvezwa kubushushu obugqithisileyo

Kuya kufuneka itshintshwe.

Kubalulekile ukugcina ilensi ikwimeko entle,

Njengoko nomonakalo omncinci unokuchaphazela ukuchaneka nokusebenza kakuhle kwelaser, nto leyo ekhokelela kwiiwelds ezingaphantsi komgangatho.

Ngaba ufuna isikhokelo esipheleleyo sokubhekisa kwi-Handheld Laser Welding?

Ukuwelda nge-laser ephathwayo kunika iingenelo ezininzi,

Kodwa ikwafuna ingqalelo enzulu kwiinkqubo zokhuseleko.

Eli nqaku liza kuhlola izinto ezibalulekileyo ekufuneka ziqwalaselwe xa kusenziwa i-laser welding ngesandla.

Kunye nokubonelela ngeengcebiso malunga nokukhetha igesi yokukhusela kunye nokukhetha ucingo lokuzalisa kwiintlobo zesinyithi eziqhelekileyo.

Ngaba ukuWelda ngeLaser kunamandla njengokwelda ngeTIG?

Ukuwelda nge-laserkunye ne-TIG (Tungsten Inert Gas) welding zombini ziyaziwa ngokuchaneka kwazo kunye nomgangatho wazo ekudibaniseni isinyithi.

Kodwa bahlangana njani xa kufikwa kumandla?

Kule vidiyo, siza kungena kwiiyantlukwano eziphambili kwiukusebenza kwe-weld,ukuhambelana kwezinto ezibonakalayokunyeukuqina kwayo yonkephakathi kwe-laser kunye ne-TIG welding.

Ukuwelda ngeLaser yeFiber ephathwa ngesandla (Ukuwelda ngeLaser ephathwa ngesandla)

Ukongezwa Okuxabisekileyo Kwindawo Yokushisela I-Laser Ephathwayo

Umatshini Wokuwelda Omncinci We-Laser Wenza Ukuwelda Kube Yindleko Ephantsi Nefikelelekayo

Inembonakalo encinci nencinci yomatshini.

Umatshini wokuwelda welaser ophathwayo uxhotyiswe ngesibhamu sokuwelda selaser esiphathwayo esiphathwayo esikwaziyo ukushukuma.ilula.

Kwaye kulula kakhulu kwizicelo zokuwelda ze-laser ezininzi aphanaliphi na i-engilekwayeumphezulu.

Iindidi ezahlukeneyo zeempumlo ze-laser welder ozikhethelayo.

Inkqubo yokutya ngocingo oluzenzekelayo ekhethwayo yenza kube lula ukusebenza nge-laser welding kwaye ilungele abaqalayo.

Izinto ezi-5 malunga nokuWelda ngeLaser (Ongazikhumbulanga)

Ukuba uyithandile le vidiyo, kutheni ungacingi ngayoubhalisela kwiChannel yethu yeYoutube?

Izicelo ezinxulumene noko onokuba nomdla kuzo:

I-Laser Weld ephathwayo lukhetho oluhle kakhulu kwimisebenzi yokuWelda ngesandla

Kwaye ikamva liqala ngawe!

Ixesha leposi: Sep-14-2024