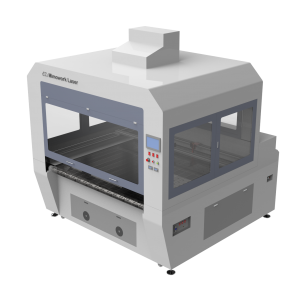

I-Lace Laser Cutting Machine ene-High Precision

| Indawo yokusebenza (W *L) | 1600mm * 1,000mm (62.9”* 39.3”) - Okujwayelekile |

| 1600mm * 1200mm (62.9” * 47.2”) - Inwetshiwe | |

| Isoftware | Isoftware Yokubhalisa ye-CCD |

| Laser Amandla | 100W / 150W / 300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Step Motor Drive & Belt Control |

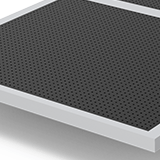

| Ithebula Lokusebenza | I-Mild Steel Conveyor Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

I-Lace Laser Cutter (Ivalwe Ngokugcwele)

| Indawo yokusebenza (W *L) | 1800mm * 1300mm (70.87'' * 51.18'') |

| Max Ububanzi Bezinto | 1800mm (70.87'') |

| Laser Amandla | 100W/ 130W/ 150W/ 300W |

| Umthombo we-Laser | CO2 Glass Laser Tube / RF Metal Tube |

| IMechanical Control System | Ukudluliswa kwebhande kanye ne-Servo Motor Drive |

| Ithebula Lokusebenza | I-Mild Steel Conveyor Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Khipha ubuciko: Ukunemba kuhlangana Nobuhle

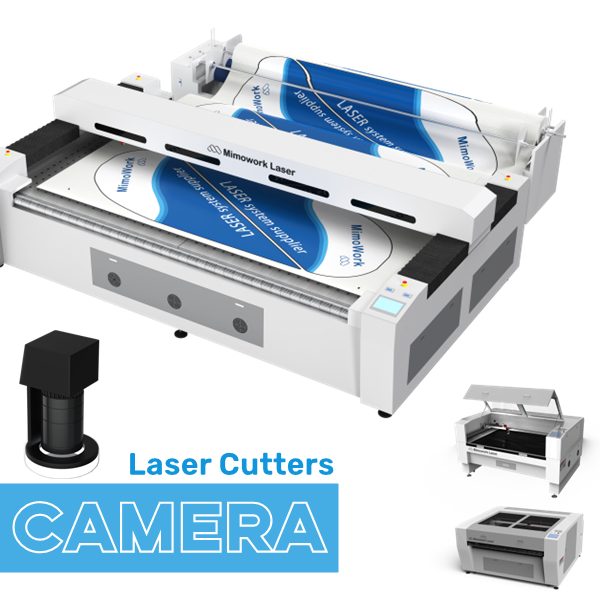

OkweLace Laser Cutter 160 & 160L (Okuvamile & Kwandisiwe):

◉Ukusika i-laser ye-sublimation yezinto eziguquguqukayo ezifanaIleyisikanye OkunyeIzesekeli Zezingubo

◉ Kuthuthukiswe amakhanda e-laser amabili, kukhulisa kakhulu ukukhiqiza kwakho (Ongakukhetha Ukuthuthukiswa)

◉I-CNC (Computer Numerical Control) kanye nedatha yekhompiyutha isekela ukucubungula okuzenzakalelayo okuphezulu kanye nokuphuma njalo okuzinzile kwekhwalithi ephezulu

◉I-MimoWork SmartI-Vision Laser Cutter Softwareilungisa ngokuzenzakalelayo ukuguquguquka nokuchezuka

◉Wide izicelo ezimbonini ezifanaUkuphrinta Kwedijithali, Izinto Ezihlanganisiwe, Izingubo Nezingubo Zasekhaya

◉ Ubuchwepheshe bokusika i-laser be-MimoWork obuguquguqukayo nobusheshayo busiza imikhiqizo yakho ukuthi iphendule ngokushesha ezidingweni zemakethe

◉ Okuphakelayo okuzenzakalelayoinikezaukudla okuzenzakalelayo, okuvumela ukusebenza okungagadiwe okonga izindleko zakho zokusebenza, kanye nezinga lokwenqatshwa eliphansi (Izithuthukisi Ongazikhethela)

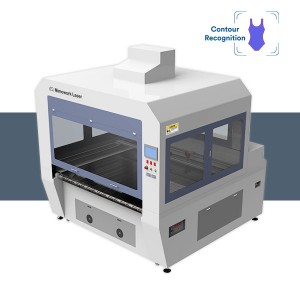

OkweLace Laser Cutter (Ivalwe Ngokugcwele):

◉Izicelo ezibanzi ezimbonini ezinjengokuphrinta kwedijithali, izinto eziyinhlanganisela, izingubo zokugqoka nezindwangu zasekhaya

◉ Iyavumelana nezimo futhi iyasheshaUbuchwepheshe bokusika i-MimoWork laser busiza imikhiqizo yakho ukuthi iphendule ngokushesha ezidingweni zemakethe

◉Ukuziphendukela kwemveloI-Visual Recognition Technologykanye nesofthiwe enamandla inikeza ikhwalithi ephezulu nokuthembeka kwebhizinisi lakho.

◉ Ukondla okuzenzakalelayoivumela ukusebenza okungagadiwe okonga izindleko zakho zokusebenza futhi kwehlise izinga lokunqatshelwa (kuyakhetheka)

◉IIsakhiwo Esivalwe Ngokugcweleyengezwa emshinini ojwayelekile wokusika i-Vision Laser.

Bangu3izindawo zokwenza ngcono ekusebenzeni kwalesi sisiki se-contour laser:

1. Ukuphepha kwe-Operator

2. Indawo yokusebenza ehlanzekile kanye nomphumela ongcono wokuqeda uthuli

3. Ikhono elingcono lokuqaphela i-optical

Amaphuzu avelele eMishini yokusika iLace Laser

IIkhamera ye-CCDifakwe eduze kwekhanda le-laser ingakwazi ukubona izimpawu zesici ukuze kutholwe amaphethini aphrintiwe, afekethisiwe, noma alukiwe futhi isofthiwe izosebenzisa ifayela lokusika iphethini yangempela ngokunemba okungu-0.001mm ukuze kuqinisekiswe umphumela wokusika oyigugu kakhulu.

II-Contour Recognition Systemithola i-contour ngokuya ngokungafani kombala phakathi kohlaka lokuphrinta nengemuva lezinto ezibonakalayo. Asikho isidingo sokusebenzisa amaphethini okuqala noma amafayela. Ngemuva kokuphakela okuzenzakalelayo, izindwangu eziphrintiwe zizotholwa ngokuqondile. Lena inqubo ezenzakalelayo ngokuphelele ngaphandle kokungenelela komuntu. Ngaphezu kwalokho, ikhamera izothatha izithombe ngemuva kokuthi indwangu idliwe endaweni yokusika. I-contour yokusika izolungiswa ukuze kuqedwe ukuchezuka, ukuguquguquka, nokujikeleza, ngaleyo ndlela, ekugcineni ungafinyelela umphumela wokusika onembe kakhulu.

Uma uzama ukusika amakhonsathi ahlanekezelwe kakhulu noma uphishekele amapheshana anembe kakhulu namalogo,Uhlelo Lokufanisa Isifanekisoifaneleka kakhulu kunokusikwa kwekhonta. Ngokufanisa izifanekiso zakho zoqobo zedizayini nezithombe ezithathwe ikhamera ye-HD, ungathola kalula i-contour efanayo naleyo ofuna ukuyisika. Futhi, ungasetha amabanga okuchezuka ngokwezidingo zakho eziqondene nawe.

Amakhanda Amabili Azimele - Ukuthuthukisa Ongakukhetha

Ukuze uthole umshini wokusika amakhanda amabili e-laser ayisisekelo, amakhanda amabili e-laser afakwe ku-gantry efanayo, ngakho-ke awakwazi ukusika amaphethini ahlukene ngesikhathi esisodwa. Kodwa-ke, ezimbonini eziningi zemfashini ezifana nezingubo ze-sublimation ezidayi, ngokwesibonelo, zingase zibe nengaphambili, ingemuva, nemikhono yejezi yokusika. Kuleli qophelo, amakhanda amabili azimele angakwazi ukuphatha izingcezu zamaphethini ahlukene ngesikhathi esisodwa. Le nketho ikhulisa ukusebenza kahle kokusika kanye nokuguquguquka kokukhiqiza ngezinga elikhulu kakhulu. Umphumela ungakhuphuka usuka ku-30% uye ku-50%.

I-Auto feederiyunithi yokudla egijima ngokuhambisana nomshini wokusika we-laser. Kuhlanganiswe neithebula lokuthutha, i-auto feeder ingadlulisela izinto zokugoqa etafuleni lokusika ngemva kokufaka ama-roll kusiphakeli. Ukuze ihambisane nefomethi ebanzi, i-MimoWork incoma i-auto-feeder enwetshiwe ekwazi ukuthwala umthwalo osindayo ngefomethi enkulu, kanye nokuqinisekisa ukudla kahle. Isivinini sokudla singasethwa ngokuya ngesivinini sakho sokusika. Inzwa ihlonyiselwe ukuqinisekisa ukuma kahle kwempahla kanye nokunciphisa amaphutha. I-feeder iyakwazi ukunamathisela amadayamitha e-shaft ahlukene emiqulu. Irola ye-pneumatic ingakwazi ukuzivumelanisa nezindwangu ngokushuba okuhlukahlukene nokuqina. Le yunithi ikusiza ukuthi ubone inqubo yokusika ezenzakalelayo ngokuphelele.

I-Y-axis Gear & X-axis Belt Drive

Umshini wokusika i-laser yekhamera une-Y-axis rack & pinion Drive kanye nokudluliswa kwebhande le-X-axis. Idizayini inikeza ikhambi eliphelele phakathi kwendawo yokusebenza yefomethi enkulu kanye nokudluliswa okubushelelezi. I-Y-axis rack & pinion iwuhlobo lwe-actuator ewumugqa ohlanganisa igiya eliyindilinga (iphinikhodi) elibamba igiya elingumugqa (irack), elisebenza ukuhumusha ukunyakaza okujikelezayo kube ukunyakaza okuqondile. I-rack ne-pinion zishayelana ngokuzenzakalelayo. Amagiya aqondile kanye ne-helical ayatholakala ku-rack & pinion. Ukudluliswa kwebhande le-X-axis kunikeza ukudluliswa okubushelelezi futhi okuqhubekayo ekhanda le-laser. Ukusika kwe-laser ngesivinini esikhulu nokunemba okuphezulu kungaqedwa.

Ukuzikhethela kwe-Servo Motor

Vula isivinini sokusika esisheshayo ngombani wesistimu yokunyakaza ye-servo motor. Phakamisa ukusebenza kwe-Sublimation Laser Cutter Machines ibe phezulu kakhulu njengoba iqopha kalula imidwebo ye-contour yangaphandle ngokunemba okungantengantengi. Yamukela amandla e-servo futhi uzwe ukuzinza nesivinini esingenakuqhathaniswa.

II-Vacuum Suctionilele ngaphansi kwetafula lokusika. Ngezimbobo ezincane nezijulile endaweni yetafula lokusika, umoya 'ubopha' izinto ezisetafuleni. Ithebula le-vacuum alingeni endleleni ye-laser beam ngenkathi isika. Ngokuphambene nalokho, kanye nefeni enamandla yokukhipha umoya, ithuthukisa umphumela wokuvimbela intuthu nothuli ngesikhathi sokusika.

Idizayini Evalekile Ngokugcwele - Ukuthuthukisa Ongakukhetha

Ngomklamo okhethekile womnyango ovalwe ngokugcwele, iI-Contour Laser Cutter Ehlanganisiweingaqinisekisa ukukhathala okungcono futhi ithuthukise ngokwengeziwe umphumela wokubonwa kwekhamera ye-HD ukuze igweme i-vignetting ethinta ukubonwa kwekhonta esimweni sezimo zokukhanya ezimbi. Umnyango kuzo zonke izinhlangothi ezine zomshini ungavulwa, ongeke uthinte ukugcinwa nokuhlanza nsuku zonke.

Indwangu ye-Laser Cutting Lace (I-Applique, i-Embroidery)

Idizayini Ebiyelwe Ngokugcwele - Umbukiso

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

ngoba Lace Laser Cutting Machines

Yamukela Ubuhle, Ukunemba Kuhlangana Nobuhlakani

✔ Ikhamera ye-CCD iwabeka ngokunembile amamaki okubhalisa

✔ Izinhloko ze-laser ezizikhethela ezimbili zingakhuphula kakhulu ukuphuma nokusebenza kahle

✔ Hlanza futhi unembile unqenqema lokusika ngaphandle kokusikwa ngemuva

✔ Sika ama-contours ngemuva kokuthola amaphuzu

✔ Ukunemba Okuphezulu phakathi kwebanga lephutha elingu-0.1 mm

✔ Umshini wokusika i-laser ulungele kokubili ukukhiqizwa okufushane kanye nama-oda wokukhiqiza ngobuningi

✔ Vula izimfihlo zokusika i-laser ze-Lace Accessories futhi uvule umhlaba wamathuba

✔ Zizwa ngokunemba okungenasici, imiklamo eyinkimbinkimbi, ubuhle obuqhakazile, nokwenza ngokwezifiso okungenamthungo

✔ Phakamisa okudaliwe kwakho kufinyelele ukuphakama okusha ngobuciko nokusebenza kahle kobuchwepheshe bokusika i-laser

✔ Ngena esikhathini esizayo sokukhiqizwa kwe-Lace Accessory futhi ubuke ubuhlakani bakho buphila ngemininingwane emangalisayo

Ukuphelela Okungenasici Nokudala Okungenamkhawulo

Perfect Fit, Njalo: Finyelela ukusikeka okungaguquki, okulungiselelwe okuqinisekisa ukulingana okuphelele, okuthuthukisa ukunethezeka nokuzethemba ezingutsheni zeleyisi.

Ukuhlanganiswa Okungenamthungo, Ukugeleza Kokusebenza Okulula: Hlanganisa ngaphandle komthungo ubuchwepheshe bokusika i-laser ezinqubweni zokukhiqiza ukuze kuthuthukiswe ukusebenza kahle nokukhiqiza.

Phakamisa ubuciko, Imininingwane Enhle: Phakamisa ubuciko bokwenza uleyisi ngokunemba nge-laser, ukugqamisa imininingwane eyinkimbinkimbi futhi uthuthukise ubuciko bubonke.

Unleash Amandla ka-Lace: Yamukela amandla okuguqula ukusika kwe-laser, ukusunduza imingcele yobungcweti beleyisi nokudala imiklamo engalibaleki, ephefumulayo.

Ukukhiqiza Okuphumelelayo, Ubuhle Obungapheli: Londoloza isikhathi nezinsiza ngenkathi ugcina ubuhle obungaphelelwa yisikhathi ngokusika kwe-laser okusheshayo, okusebenzayo kwezinto zeleyisi.

ye-Sublimation Laser Cutting Machines

Izinto zokwakha:

Twill,I-velvet, I-Velcro, Inayilonii-polyester,Ifilimu, I-Foil, nezinye Izinto Ezinephethini

Indwangu yePolyester,Spandex,Inayiloni,Usilika,I-Velvet ephrintiwe,Ukotini, nokunyeI-Sublimation Textiles

Izicelo:

Izingubo,Izesekeli Zezingubo, Ileyisi, Izindwangu Zasekhaya, Uhlaka Lwesithombe, Amalebula, Isitika, I-Applique

Izingubo Ezisebenzayo, Izingubo Zezemidlalo (Izigqoko Zebhayisikili, Amajezi eHockey, Amajezi e-Baseball, Amajezi e-Basketball, Amajezi ebhola lezinyawo, Amajezi e-Volleyball, Amajezi e-Lacrosse, Amajezi e-Ringette)

Umfaniswano, Izimpahla zokubhukuda,Ama-Leggings,Izesekeli ze-Sublimation(Imikhono Yengalo, Imikhono Yomlenze, Ibhandeshi, Ibhande Lekhanda, Ikhava Yobuso, Izifihla-buso)