Ifomethi Enkulu I-Aramid Fabric Laser Cutting

singanikeza imikhiqizo yekhwalithi ephezulu, intengo yokuncintisana kanye nenkonzo yamakhasimende engcono kakhulu.Indawo yethu ithi "Uza lapha ngobunzima futhi sikunikeza ukumamatheka okuzothatha" ukuze uthole Ifomethi Enkulu ye-Aramid Fabric Laser Cutting, Ifemu yethu yakhula ngokushesha ngosayizi nedumela ngenxa yokuzinikela kwayo ngokuphelele ekukhiqizeni okusezingeni eliphakeme, amanani entengo ezixazululo kumnandi kwamakhasimende.

singanikeza imikhiqizo yekhwalithi ephezulu, intengo yokuncintisana kanye nenkonzo yamakhasimende engcono kakhulu.Indawo yethu ithi "Uza lapha ngobunzima futhi sikunikeza ukumamatheka ozohamba nakho" ngakhoaramid izingubo laser cutting, i-aramid fabric laser cutter, ukusika i-kevlar, indwangu laser cutter, indlela yokusika i-kevlar, indlela ukusika kevlar panel, abasiki be-kevlar, amathuluzi okusika i-kevlar, laser cutting aramid fabric, laser engraving indwangu, sithembele ezinzuzweni zethu ukuze sakhe indlela yokuhweba ezuzisanayo nozakwethu bethu abasebenzisana nabo.Ngenxa yalokho, sizuze inethiwekhi yokuthengisa yomhlaba wonke efinyelela eMpumalanga Ephakathi, eTurkey, eMalaysia naseVietnam.

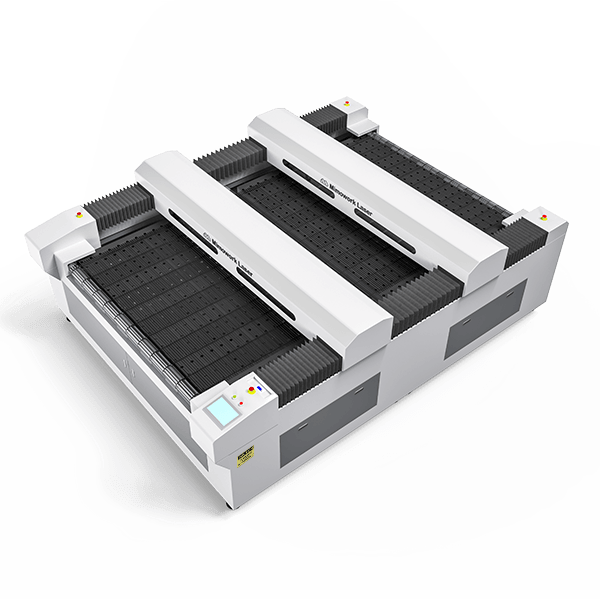

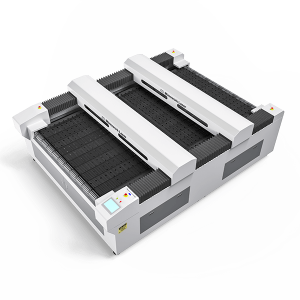

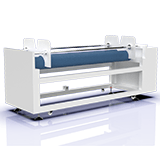

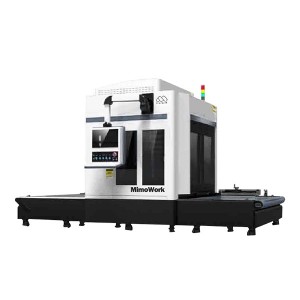

Izinzuzo Zefomethi Enkulu I-Flatbed Laser Cutter

Ukugxuma Okukhulu Ekukhiqizeni

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1600mm * 3000mm (62.9'' *118'') |

| Max Ububanzi Bezinto | 1600mm (62.9'') |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/500W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | I-Rack & Pinion Transmission kanye ne-Servo Motor Driven |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~6000mm/s2 |

* Ama-laser gantries amabili azimele ayatholakala ukuze aphinde kabili ukusebenza kahle kwakho.

I-R&D ye-Flexible Material Cutting

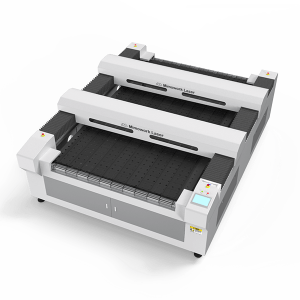

I-Auto feeder

I-Auto feederiyunithi yokudla egijima ngokuhambisana nomshini wokusika we-laser.I-feeder izodlulisela izinto zokugoqa etafuleni lokusika ngemva kokubeka ama-rolls ku-feeder.Isivinini sokudla singasethwa ngokuya ngesivinini sakho sokusika.Inzwa ihlonyiselwe ukuqinisekisa ukuma kahle kwempahla kanye nokunciphisa amaphutha.I-feeder iyakwazi ukunamathisela amadayamitha e-shaft ahlukene emiqulu.Irola ye-pneumatic ingakwazi ukuzivumelanisa nezindwangu ngokushuba okuhlukahlukene nokuqina.Le yunithi ikusiza ukuthi ubone inqubo yokusika ezenzakalelayo ngokuphelele.

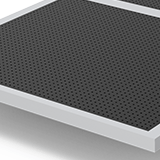

I-Vacuum Suction

II-Vacuum Suctionilele ngaphansi kwetafula lokusika.Ngezimbobo ezincane nezijulile endaweni yetafula lokusika, umoya 'ubopha' izinto ezisetafuleni.Ithebula le-vacuum alingeni endleleni ye-laser beam ngenkathi isika.Ngokuphambene nalokho, kanye nefeni enamandla yokukhipha umoya, ithuthukisa umphumela wokuvimbela intuthu nothuli ngesikhathi sokusika.

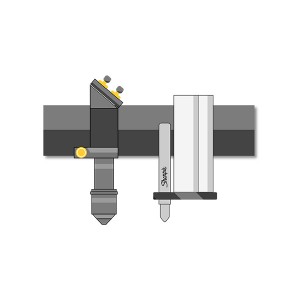

Ipeni Lomaka - Inketho

Kubakhiqizi abaningi, ikakhulukazi ukucubungula izindwangu zobuchwepheshe, izingcezu zidinga ukuthungwa ngemva kwenqubo yokusika.Siyabonga kuIpeni Lokumaka, ungenza amamaki afana nenombolo yesiriyali yomkhiqizo, usayizi womkhiqizo, idethi yokwenziwa komkhiqizo, njll ukuze kwandiswe ukusebenza kahle kukonke.Ungakhetha imibala ehlukene ngokwezidingo zakho.

Umthombo we-CO2 RF Laser - Inketho

Ihlanganisa amandla, ikhwalithi ye-beam enhle kakhulu, kanye nama-pulses amagagasi acishe abe isikwele (9.2 / 10.4 / 10.6μm) ngokusebenza kahle okuphezulu kanye nesivinini.Ngendawo encane ethinteke ekushiseni, kanye nokwakhiwa okuhlangene, okuvalwe ngokugcwele, kokukhipha ama-slab ukuze kube nokuthembeka okuthuthukisiwe.Kwezinye izindwangu ezikhethekile zezimboni, i-RF Metal Laser Tube izoba inketho engcono.

Ukuboniswa kwevidiyo kwe-Laser Cutting Cordura® Vest

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

Laser Cutting Non-Metal Izicelo

Izingubo Nezindwangu Zasekhaya

I-edge ehlanzekile futhi ebushelelezi ngokwelashwa okushisayo

Imboni yokuhlunga

Imfihlo yokusika iphethini enhle

Ukukhethwa kwesihlungi semidiya esifanele kunquma ikhwalithi nomnotho wayo yonke inqubo yokuhlunga, okuhlanganisa ukuhlukaniswa koketshezi oluqinile kanye nokuhlunga komoya.I-Laser ibhekwa njengobuchwepheshe obungcono kakhulu bokusika imidiya yokuhlunga (Hlunga Indwangu,Igwebu Lokuhlunga,Uboya, Isikhwama Sokuhlunga, I-Filter Mesh, nezinye izinhlelo zokusebenza zokuhlunga)

Izinto Ezihlanganisiwe

High Power Laser Cutting

Ukusika i-laser kungaletha ukunemba okuphezulu nemiphumela yekhwalithi engaguquki ngogongolo oluhle lwe-laser.Ukucutshungulwa kwemvelo okushisayo kuqinisekisa imiphetho evaliwe futhi ebushelelezi ngaphandle kokuphazamiseka nokuphukaizinto ezihlanganisiwe.

I-Outdoor Upholstery & Gear

Indwangu engenamthungo ye-laser yokusika i-laminated

Izidingo zokusebenza ziphakeme kakhulu ngendwangu yangaphandle.Ukuvikela ilanga, ukuphefumula, ukungangeni kwamanzi, ukumelana nokugqoka, yonke le misebenzi ivamise ukudinga izendlalelo eziningi zezinto.I-laser cutter yethu yezimboni iyithuluzi elifaneleka kakhulu lokusika izindwangu ezinjalo.

Izinto ezivamile kanye nezicelo

ye-Flatbed Laser Cutter 160L

Buka izinto zokusebenza ezengeziwe

Senze amasistimu e-laser enqwaba yamakhasimende

Zingeze ohlwini!

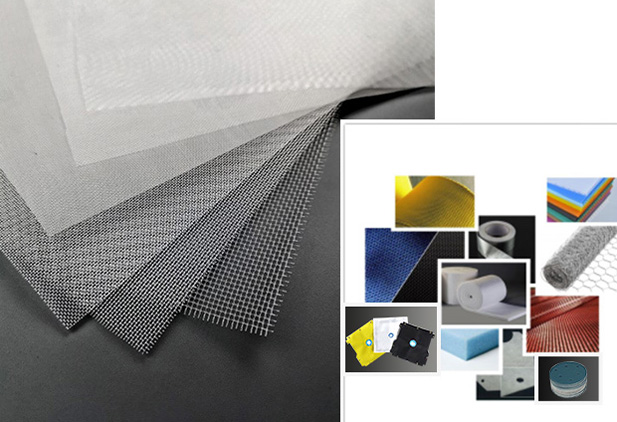

Ulwazi Material of Laser Cutting Aramid

Yasungulwa ngeminyaka yama-60s, i-Aramid kwaba i-organic fibre yokuqala enamandla anele ne-modulus futhi yathuthukiswa esikhundleni sensimbi.Ngenxa yokushisa kwayo okuhle (indawo encibilikayo ephezulu>500℃) kanye nezindawo zokufakwa kukagesi, ama-Aramid Fibers asetshenziswa kabanzi ku-aerospace, izimoto, izilungiselelo zezimboni, izakhiwo namasosha.Abakhiqizi Bezinto Zokuzivikela Zomuntu Siqu (i-PPE) bazoluka kakhulu imicu ye-aramid ibe yindwangu ukuze bathuthukise ukuphepha nokunethezeka kwabasebenzi kukho konke ukweqisa.

Amagama omkhiqizo we-Aramid ajwayelekile:

I-Kevlar®, i-Nomex®, ne-Twaron

Izinzuzo ezivela ku-Laser Cutting ku-Aramid

Amaphethelo okusika ahlanzekile futhi avalwe

✔ Ukusika okuphezulu okuguquguqukayo kuyo yonke indawo

✔ Imiphumela yokusika enemininingwane enemininingwane emihle

✔ I-automatic processing roll textiles futhi yonga imisebenzi

✔ Akukho deformation ngemva kokucubungula

Izinhlelo zokusebenza ezijwayelekile ze-Laser Cutting Aramid

• Izinto Zokuzivikela Zomuntu Siqu (PPE)

• Iyunifomu yokuzivikela ye-Ballistic efana namavesti angangenwa izinhlamvu

• Izingubo zokuzivikela ezifana namagilavu, izingubo zokuzivikela zesithuthuthu kanye nemigwaqo yokuzingela

• Amaseyili anefomethi enkulu yezikebhe nama-yachts

• Ama-gaskets wokushisa okuphezulu nokucindezela izicelo

• Izindwangu zokuhlunga umoya oshisayo