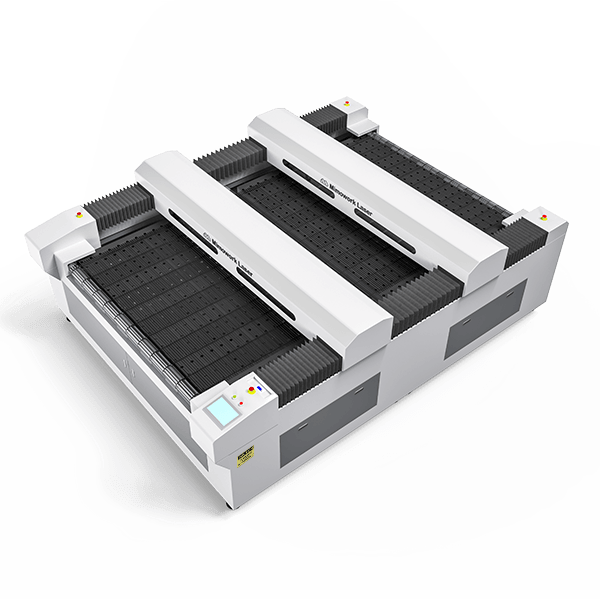

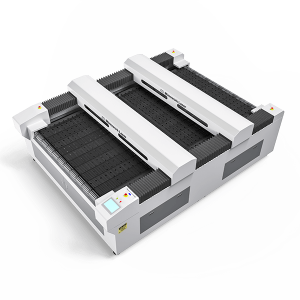

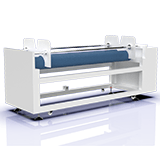

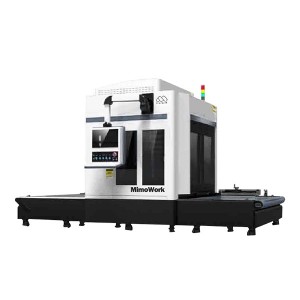

Ifomethi Enkulu Ye-Laser Cutter

Umsiki weLaser wefomethi enkulu,

umshini omuhle kakhulu wokusika wazizwa, umshini omuhle kakhulu wokusika wazizwa, indlela engcono kakhulu yokusika imizwa, Umshini wokusika we-Cnc, wazizwa umsiki, umshini wokusika wezwa, Amathuluzi okusika ezwayo, wazizwa laser cut, indlela ukusika wazizwa, indlela ukusika imibuthano wazizwa, indlela yokusika wazizwa obukhulu, ama-laser cut wezwa ama-coasters, laser cut wazizwa panel, laser cutting wazizwa, Umshini wokusika we-laser,

Izinzuzo Zefomethi Enkulu I-Flatbed Laser Cutter

Ukugxuma Okukhulu Ekukhiqizeni

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1600mm * 3000mm (62.9'' *118'') |

| Max Ububanzi Bezinto | 1600mm (62.9'') |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/500W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | I-Rack & Pinion Transmission kanye ne-Servo Motor Driven |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~6000mm/s2 |

* Ama-laser gantries amabili azimele ayatholakala ukuze aphinde kabili ukusebenza kahle kwakho.

I-R&D ye-Flexible Material Cutting

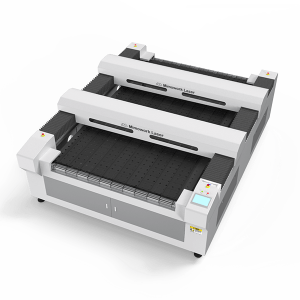

I-Auto feeder

I-Auto feederiyunithi yokudla egijima ngokuhambisana nomshini wokusika we-laser.I-feeder izodlulisela izinto zokugoqa etafuleni lokusika ngemva kokubeka ama-rolls ku-feeder.Isivinini sokudla singasethwa ngokuya ngesivinini sakho sokusika.Inzwa ihlonyiselwe ukuqinisekisa ukuma kahle kwempahla kanye nokunciphisa amaphutha.I-feeder iyakwazi ukunamathisela amadayamitha e-shaft ahlukene emiqulu.Irola ye-pneumatic ingakwazi ukuzivumelanisa nezindwangu ngokushuba okuhlukahlukene nokuqina.Le yunithi ikusiza ukuthi ubone inqubo yokusika ezenzakalelayo ngokuphelele.

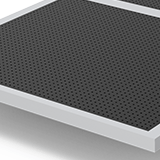

I-Vacuum Suction

II-Vacuum Suctionilele ngaphansi kwetafula lokusika.Ngezimbobo ezincane nezijulile endaweni yetafula lokusika, umoya 'ubopha' izinto ezisetafuleni.Ithebula le-vacuum alingeni endleleni ye-laser beam ngenkathi isika.Ngokuphambene nalokho, kanye nefeni enamandla yokukhipha umoya, ithuthukisa umphumela wokuvimbela intuthu nothuli ngesikhathi sokusika.

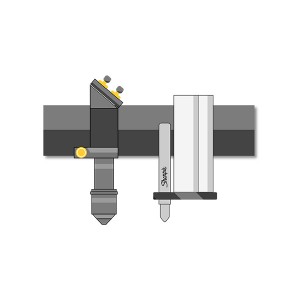

Ipeni Lomaka - Inketho

Kubakhiqizi abaningi, ikakhulukazi ukucubungula izindwangu zobuchwepheshe, izingcezu zidinga ukuthungwa ngemva kwenqubo yokusika.Siyabonga kuIpeni Lokumaka, ungenza amamaki afana nenombolo yesiriyali yomkhiqizo, usayizi womkhiqizo, idethi yokwenziwa komkhiqizo, njll ukuze kwandiswe ukusebenza kahle kukonke.Ungakhetha imibala ehlukene ngokwezidingo zakho.

Umthombo we-CO2 RF Laser - Inketho

Ihlanganisa amandla, ikhwalithi ye-beam enhle kakhulu, kanye nama-pulses amagagasi acishe abe isikwele (9.2 / 10.4 / 10.6μm) ngokusebenza kahle okuphezulu kanye nesivinini.Ngendawo encane ethinteke ekushiseni, kanye nokwakhiwa okuhlangene, okuvalwe ngokugcwele, kokukhipha ama-slab ukuze kube nokuthembeka okuthuthukisiwe.Kwezinye izindwangu ezikhethekile zezimboni, i-RF Metal Laser Tube izoba inketho engcono.

Ukuboniswa kwevidiyo kwe-Laser Cutting Cordura® Vest

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

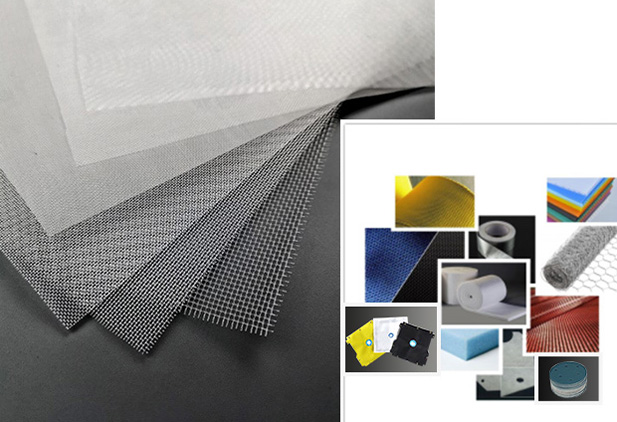

Laser Cutting Non-Metal Izicelo

Izingubo Nezindwangu Zasekhaya

I-edge ehlanzekile futhi ebushelelezi ngokwelashwa okushisayo

Imboni yokuhlunga

Imfihlo yokusika iphethini enhle

Ukukhethwa kwesihlungi semidiya esifanele kunquma ikhwalithi nomnotho wayo yonke inqubo yokuhlunga, okuhlanganisa ukuhlukaniswa koketshezi oluqinile kanye nokuhlunga komoya.I-Laser ibhekwa njengobuchwepheshe obungcono kakhulu bokusika imidiya yokuhlunga (Hlunga Indwangu,Igwebu Lokuhlunga,Uboya, Isikhwama Sokuhlunga, I-Filter Mesh, nezinye izinhlelo zokusebenza zokuhlunga)

Izinto Ezihlanganisiwe

High Power Laser Cutting

Ukusika i-laser kungaletha ukunemba okuphezulu nemiphumela yekhwalithi engaguquki ngogongolo oluhle lwe-laser.Ukucutshungulwa kwemvelo okushisayo kuqinisekisa imiphetho evaliwe futhi ebushelelezi ngaphandle kokuphazamiseka nokuphukaizinto ezihlanganisiwe.

I-Outdoor Upholstery & Gear

Indwangu engenamthungo ye-laser yokusika i-laminated

Izidingo zokusebenza ziphakeme kakhulu ngendwangu yangaphandle.Ukuvikela ilanga, ukuphefumula, ukungangeni kwamanzi, ukumelana nokugqoka, yonke le misebenzi ivamise ukudinga izendlalelo eziningi zezinto.I-laser cutter yethu yezimboni iyithuluzi elifaneleka kakhulu lokusika izindwangu ezinjalo.

Izinto ezivamile kanye nezicelo

ye-Flatbed Laser Cutter 160L

Buka izinto zokusebenza ezengeziwe

Senze amasistimu e-laser enqwaba yamakhasimende

Zingeze ohlwini!

I-Laser Cutting Felt

Izinto ezihlobene ezizwakalayo zokusika kwe-laser

I-Roofing Felt, I-Polyester Felt, Inzwa ye-Acrylic, I-Punch Yenaliti, I-Sublimation Felt, I-Eco-fi Felt, I-Wool Felt

Indlela yokusika wazizwa?

I-Felt iyindwangu engalukiwe ngokuvamile equkethe imicu yemvelo nemicu yokwenziwa ngenqubo yokushisa, umswakama, nesenzo somshini.Uma kuqhathaniswa nezindwangu ezilukiwe ezivamile, izizwa iminyene kakhulu futhi ihlangene.Ngenxa yalesi sizathu, inzwa isetshenziswa kabanzi ukwenza ama-slippers futhi njengendwangu entsha yezingubo nefenisha.Izicelo zezimboni zifaka ukufakwa kwensimbi, ukupakisha, nezinto zokupholisha zezingxenye zemishini.A nezimo futhi ezikhethekilewazizwa laser cutter yiindlela engcono kakhulu yokusika imizwa.Ihlukile kwendabukowazizwa umsiki, umshini wokusika we-laser uphethe izici eziyingqayizivele ne-premium.Ukusika okushisayo kungancibilikisa imicu eyizicucu futhi kuvale unqenqema lwemizwa.Ngokuqondile ngenxa yalokho, isakhiwo sangaphakathi esingaqinile sokuzizwa ngeke sonakaliswe futhi ukucubungula akuhambisani nothuli nomlotha.

Ukucutshungulwa kwe-laser kokuzizwa

1. Laser cutting Felt

Ukusika kwe-laser okusheshayo nokuhlanzekile kokuzwayo kugwema ukunamathela phakathi kwezinto, kuletha ikhwalithi ephezulu eqediwe ezwakalayo enqenqemeni yokuvala ngenkathi isika ukushisa.Ukondla okuzenzakalelayo nokusika kunciphisa izindleko zabasebenzi ngezinga elithile.

2. Ukumakwa kwe-laser kuzwakala

Ukugqama okuphakeme kombala nge-laser etching ungqimba olulodwa lokuzwa kungafinyelela amaphethini ezinhlobonhlobo ezihlala njalo nezingabuni, izithombe zelogo yomkhiqizo engokwezifiso.

3. Laser engraving wazizwa

I-laser izacile necolekileyo ingaqopha ngokushesha okuzwakalayo kwe-multilayer ngokusetha amandla e-laser afanelekile.Indlela yokucubungula eguquguqukayo ayinamkhawulo kumajamo namaphethini ahlukene.

Isicelo selaser cutting wazizwa

Lapho i-laser-cut, umshini we-laser we-CO2 ungaveza imiphumela enembe ngokumangalisayo kuma-placemats azwakele nama-coasters.Ngokuhlobisa indlu, i-rug rug pad ingasikwa kalula.

Isigqoko esizizwayo, Isikhwama esizwayo, Okuzwakalayo okuzinamathelayo, Ubuciko obuzwiwayo, Iphedi elizwayo, Umatilasi ozwayo, Umhlobiso ozwayo, Ibhodi lezinhlamvu ezizwayo, Isihlahla sikakhisimusi esizwakele, umata ozwayo (umata)

Izinzuzo ezivela kumaphaneli wokusika we-laser

• Asikho isidingo sokulungiswa kwempahla ngetafula elisebenza ngevacuum

• Iziqinisekiso zokungathinteki nezinamandla zamahhala zizwakala uzinzile

• Akukho ukuguga kwamathuluzi nokushintsha izindleko

• Hlanza indawo yokucubungula

• Ukusika iphethini yamahhala, ukuqopha, ukumaka

• Indlela yokucubungula efanelekile ngokuya ngesakhiwo sendwangu