Ukugcina umshini wakho wokusika nge-laser kubalulekile, kungakhathaliseki ukuthi usuvele uwusebenzisa noma ucabanga ukuwuthola.

Akukhona nje ukugcina umshini usebenza; kumayelana nokufeza lezo zicucu ezihlanzekile kanye nokuqoshwa okubukhali okufisayo, ukuqinisekisa ukuthi umshini wakho usebenza njengephupho nsuku zonke.

Kungakhathaliseki ukuthi udala imiklamo enemininingwane noma ubhekana namaphrojekthi amakhulu, ukulungiswa kahle kwe-laser cutter yakho kuyindlela eyimfihlo yokuthola imiphumela esezingeni eliphezulu.

Kulesi sihloko, sizogxila emishinini yokusika nokuqopha nge-laser ye-CO2, sabelane ngamathiphu nezindlela zokulungisa eziwusizo.

Okuqukethwe

Izinto zokuqala kuqala: umshini ohlanzekile uwumshini osebenza kahle!

Cabanga ngelensi nezibuko zesikhiphi sakho se-laser njengamehlo aso. Uma zingcolile, ukusikeka kwakho ngeke kube bukhali kangako. Uthuli, imfucumfucu, kanye nezinsalela zivame ukwakheka kulezi zindawo, okungaphazamisa kakhulu ukunemba kwakho kokusika.

Ukuze konke kuhambe kahle, kwenze kube umkhuba ukuhlanza ilensi nezibuko njalo. Ngithembe, umshini wakho uzokubonga!

Ungayihlanza kanjani ilensi nezibuko zakho? Izinyathelo ezintathu yilezi ezilandelayo:

Ukuqaqa:Khulula izibuko bese uhlukanisa amakhanda e-laser ukuze ususe ilensi ngobumnene. Beka konke endwangwini ethambile, engenalo ulwelwesi.

Lungisa Amathuluzi Akho:Thatha i-Q-tip bese uyicwilisa esixazululweni sokuhlanza ilensi. Ukuze uhlanze njalo, amanzi ahlanzekile asebenza kahle, kodwa uma ubhekene nothuli oluqinile, ikhambi elisekelwe kutshwala liyindlela engcono kakhulu.

Sula Phansi:Sebenzisa i-Q-tip ngokucophelela ukuhlanza izindawo zelensi nezibuko. Icebiso nje elisheshayo: gcina iminwe yakho kude nezindawo zelensi—thinta kuphela imiphetho!

Futhi khumbula, uma izibuko noma ilensi yakho yonakele noma igugile,kungcono ukuzishintsha ngezintshaUmshini wakho ufanelwe okungcono kakhulu!

Isifundo Sevidiyo: Ungahlanza Futhi Ufake Kanjani Ilensi Yelaser?

Uma kukhulunywa ngetafula lakho lokusika nge-laser kanye nendawo yokusebenza, ukugcina kuhlanzekile ngemva komsebenzi ngamunye kubalulekile.

Ukususa izinto ezisele kanye nemfucumfucu kuqinisekisa ukuthi akukho lutho oluphazamisa umsebe we-laser, okuvumela ukusikwa okuhlanzekile nokunembile njalo.

Ungakhohlwa nangohlelo lokungenisa umoya! Qiniseka ukuthi uhlanza lezo zihlungi namapayipi ukuze umoya ungagelezi futhi intuthu ingangeni.

Icebiso Lokuhamba Ngesikebhe Okushelelayo:Ukuhlolwa njalo kungase kuzwakale sengathi kuyinkinga, kodwa kuyazuzisa kakhulu. Ukuhlola okusheshayo emshinini wakho kungasiza ekuxazululeni izinkinga ezincane ngaphambi kokuba zibe yizinkinga ezinkulu kamuva!

2. Ukulungiswa Kwesistimu Yokupholisa

Manje, ake sixoxe ngokugcina izinto zipholile—ngokoqobo!

I-water cooler ibalulekile ekugcineni ishubhu lakho le-laser lisezingeni lokushisa elifanele.

Ukuhlola njalo izinga lamanzi kanye nekhwalithi kubalulekile.

Khetha njalo amanzi acwengekile ukuze ugweme ukuchitheka kwamaminerali okukhathazayo, futhi ungakhohlwa ukushintsha amanzi njalo ukuze uvimbele ulwelwe ukuthi lungangeni.

Ngokuvamile, kuwumqondo omuhle ukushintsha amanzi efrijini njalo ezinyangeni ezi-3 kuya kwezi-6.

Kodwa-ke, lo mugqa wesikhathi ungashintsha ngokusekelwe kwikhwalithi yamanzi akho nokuthi uwusebenzisa kangaki umshini wakho. Uma amanzi eqala ukubukeka engcolile noma enamafu, qhubeka uwashintshe ngokushesha!

Ukukhathazeka Kwasebusika? Hhayi ngala macebiso!

Uma izinga lokushisa lehla, ingozi yokuba ifriji yakho yamanzi iqine iyanda.Ukufaka i-antifreeze efrijini kungayivikela phakathi nalezo zinyanga ezibandayo.Vele uqiniseke ukuthi usebenzisa uhlobo olufanele lwe-antifreeze bese ulandela imiyalelo yomenzi ukuze uthole isilinganiso esifanele.

Uma ufuna ukwazi ukuthi ungayifaka kanjani i-antifreeze ku-water chiller ukuze uvikele umshini wakho ekuqandeni. Bheka umhlahlandlela:Amathiphu ama-3 okuvikela umshini wakho wokushisa amanzi kanye nomshini we-laser

Futhi ungakhohlwa: ukugeleza kwamanzi njalo kubalulekile. Qiniseka ukuthi iphampu isebenza kahle nokuthi azikho izithiyo. Ishubhu ye-laser eshisiwe kakhulu ingaholela ekulungisweni okubizayo, ngakho-ke ukunaka okuncane lapha kuyasiza kakhulu.

3. Ukulungiswa Kweshubhu Le-Laser

Ishubhu lakho le-laser liyinhliziyo yomshini wakho wokusika nge-laser.

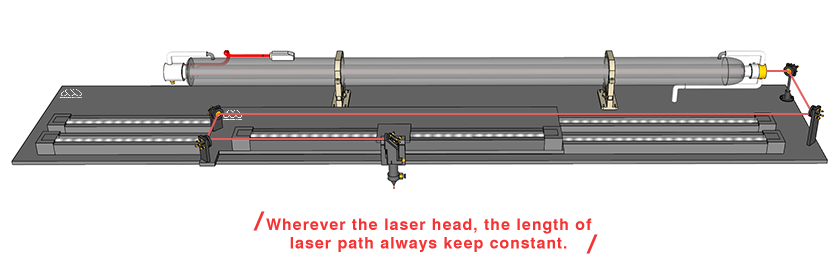

Ukugcina ukuhambisana kwayo nokusebenza kahle kubalulekile ekuqinisekiseni amandla okusika nokunemba.

Kwenze umkhuba ukuhlola njalo ukuhambisana kwezinhlangothi.

Uma ubona noma yiziphi izimpawu zokungalungi kahle—njengokunqunywa okungahambisani noma ukwehla kwamandla okukhanya—qiniseka ukuthi ulungisa kabusha ipayipi ulandela iziqondiso zomenzi.

Ukugcina konke kuqondile kuzogcina ukusika kwakho kubukhali!

Icebiso Elihle: Ungawucindezeli umshini wakho kuze kube sezingeni lawo!

Ukusebenzisa i-laser ngamandla aphezulu isikhathi eside kunganciphisa isikhathi sokuphila kwepayipi lakho. Kunalokho, lungisa izilungiselelo zamandla ngokuya ngezinto ozisikayo.

Ithubhu lakho lizokwazisa, futhi uzojabulela umshini ohlala isikhathi eside!

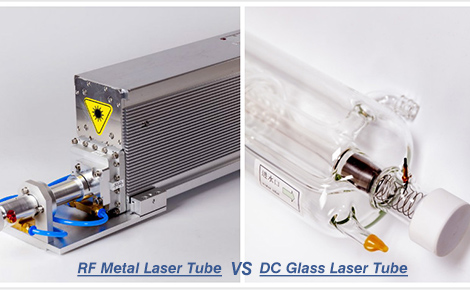

Kunezinhlobo ezimbili zamashubhu e-laser e-CO2: amashubhu e-laser e-RF namashubhu e-laser engilazi.

Amashubhu e-RF Laser:

>> Amayunithi avaliwe adinga ukulungiswa okuncane.

>> Ngokuvamile kuthatha amahora aphakathi kuka-20,000 kuya ku-50,000 okusebenza.

>> Imikhiqizo ephezulu ifaka phakathi i-Coherent ne-Synrad.

Amapayipi E-Glass Laser:

>> Isetshenziswa futhi iphathwa njengezimpahla ezidliwayo.

>> Ngokuvamile kudingeka ukushintshwa njalo eminyakeni emibili.

>> Impilo yesevisi emaphakathi ingamahora angaba ngu-3,000, kodwa amashubhu asezingeni eliphansi angahlala amahora ayi-1,000 kuya ku-2,000 kuphela.

>> Imikhiqizo ethembekile ifaka phakathi i-RECI, i-Yongli Laser, kanye ne-SPT Laser.

Uma ukhetha umshini wokusika nge-laser, xhumana nochwepheshe babo ukuze baqonde izinhlobo zamashubhu e-laser abawanikezayo!

Uma ungaqiniseki ngokuthi ungawakhetha kanjani amashubhu e-laser omshini wakho, kungani ungaqinisekikhuluma nochwepheshe wethu we-laserukuze nixoxe ngokujulile?

Xoxa Nethimba Lethu

I-MimoWork Laser

(Umkhiqizi Womshini We-Laser Ochwepheshe)

4. Amathiphu Okunakekela Ebusika

Ubusika bungaba nzima emshinini wakho, kodwa ngezinyathelo ezimbalwa ezengeziwe, ungawugcina usebenza kahle.

Uma umshini wakho wokusika nge-laser usendaweni engashisi, cabanga ukuwuhambisa endaweni efudumele.Ukushisa okubandayo kungathinta ukusebenza kwezingxenye ze-elekthronikhi futhi kuholele ekujiyeni ngaphakathi komshini.Lingakanani izinga lokushisa elifanele lomshini we-laser?Bheka ikhasi ukuze uthole okwengeziwe.

Isiqalo Esifudumele:Ngaphambi kokusika, vumela umshini wakho ufudumale. Lokhu kuvimbela ukwakheka komswakama kulensi nasezibukweni, okungaphazamisa umsebe we-laser.

Ngemva kokuba umshini usufudumale, hlola ukuthi awunazo yini izimpawu zokuminyana. Uma ubona noma yiziphi, zinike isikhathi sokuminyana ngaphambi kokusebenzisa. Sithembe, ukugwema ukuminyana kubalulekile ekuvimbeleni ama-short-circuits kanye neminye imonakalo.

5. Ukugcotshwa Kwezingxenye Ezihambayo

Gcina izinto zihamba kahle ngokugcoba njalo ama-linear rails nama-bearings. Lezi zingxenye zibalulekile ekuvumeleni ikhanda le-laser ukuthi lishelele kalula phezu kwezinto.

Nakhu okufanele ukwenze:

1. Faka i-Lubricant Ekhanyayo:Sebenzisa uwoyela womshini olula noma igrisi ukuze uvimbele ukugqwala futhi uqinisekise ukuhamba koketshezi.

2. Sula Okungaphezulu:Ngemva kokufaka, qiniseka ukuthi usula noma yikuphi ukugcotshwa okweqile. Lokhu kusiza ukuvimbela uthuli kanye nemfucumfucu ukuthi kunganqwabelani.

3. Ukulungiswa njalokuzogcina umshini wakho usebenza kahle futhi kwandise isikhathi sawo sokuphila!

Amabhande Okushayela, Nawo!Amabhande okushayela adlala indima ebalulekile ekuqinisekiseni ukuthi ikhanda le-laser lihamba kahle. Hlola njalo izimpawu zokuguguleka noma ukuxega, bese uwaqinisa noma uwashintshe njengoba kudingeka.

Ukuxhumana kukagesi emshinini wakho kufana nohlelo lwawo lwezinzwa.

1. Ukuhlolwa Okuvamile

>> Hlola Ukuguguleka: Bheka noma yiziphi izimpawu zokuguguleka, ukugqwala, noma ukuxhumeka okuxegayo.

>> Qinisa futhi Ushintshe: Qinisa noma yikuphi ukuxhumana okuxegayo bese ushintsha izintambo ezonakele ukuze konke kusebenze kahle.

2. Hlala Uvuselelwe!

Ungakhohlwa ukugcina isofthiwe yomshini wakho kanye ne-firmware kusesikhathini. Izibuyekezo ezivamile zivame ukufaka:

>> Ukuthuthukiswa Kokusebenza: Ukuthuthukiswa kokusebenza kahle.

>> Ukulungiswa kwamaphutha: Izixazululo zezinkinga ezikhona.

>> Izici Ezintsha: Amathuluzi angenza kube lula ukuhamba komsebenzi wakho.

Ukuhlala usesikhathini kuqinisekisa ukuhambisana okungcono nezinto ezintsha kanye nemiklamo, okwenza umshini wakho usebenze kahle kakhulu!

Okokugcina kodwa ngokuqinisekile okungabalulekile, ukulinganisa njalo kubalulekile ekugcineni ukunemba kokusika.

1. Isikhathi Sokulungisa Kabusha

>> Izinto Ezintsha: Njalo uma ushintshela kwenye into.

>> Ukwehla Kwekhwalithi: Uma ubona ukwehla kwekhwalithi yokusika, sekuyisikhathi sokulungisa amapharamitha okusika omshini wakho—njengejubane, amandla, kanye nokugxila.

2. Lungisa Kahle Ukuze Uphumelele

>> Lungisa i-Focus Lens: Ukulungisa njalo i-focus lens kuqinisekisa ukuthi i-laser beam ibukhali futhi igxile ngokunembile ebusweni bezinto ezibonakalayo.

>> Nquma Ubude Bokugxila: Thola ubude obufanele bokugxila bese ulinganisa ibanga ukusuka ekugxileni kuya ebusweni bezinto ezibonakalayo. Ibanga elifanele libalulekile ukuze kube nekhwalithi yokusika nokuqopha efanele.

Uma ungaqiniseki ngokugxila nge-laser noma ukuthi ungayithola kanjani ubude obufanele be-focal, qiniseka ukuthi ubheka ividiyo engezansi!

Isifundo Sevidiyo: Ungayithola Kanjani Ubude Bokugxila Obufanele?

Ukuze uthole izinyathelo zokusebenza ezinemininingwane, sicela uhlole ikhasi ukuze uthole okwengeziwe:Umhlahlandlela Welensi Yelasi Ye-CO2

Isiphetho: Umshini Wakho Ufanelwe Okungcono Kakhulu

Ngokulandela lawa macebiso okulungisa, awugcini nje ngokwandisa isikhathi sokuphila komshini wakho wokusika nge-laser we-CO2—uqinisekisa nokuthi yonke iphrojekthi ihlangabezana nezindinganiso eziphakeme kakhulu zekhwalithi.

Ukunakekelwa okufanele kunciphisa isikhathi sokungasebenzi, kunciphisa izindleko zokulungisa, futhi kwandisa umkhiqizo. Futhi khumbula, ubusika budinga ukunakekelwa okukhethekile, njengokuthiukwengeza i-antifreeze ku-water chiller yakhofuthi ufudumale umshini wakho ngaphambi kokusebenzisa.

Ulungele Okuningi?

Uma ufuna abasiki nabaqophi be-laser abasezingeni eliphezulu, sikuphathele konke.

I-Mimowork inikeza uhla lwemishini eyenzelwe izinhlelo zokusebenza ezahlukahlukene:

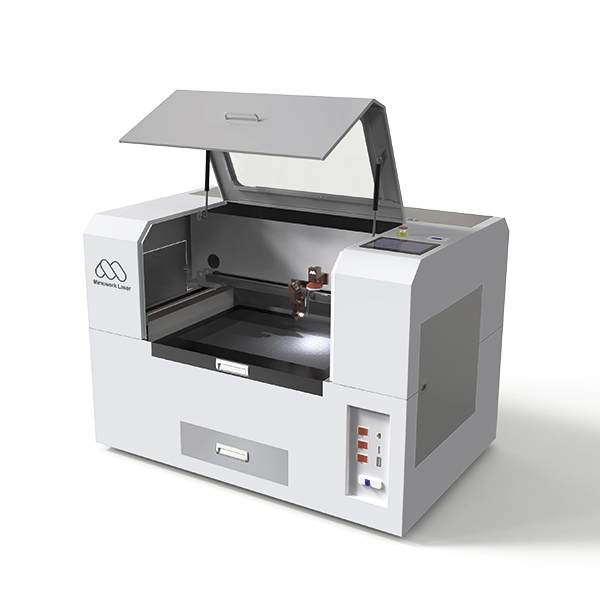

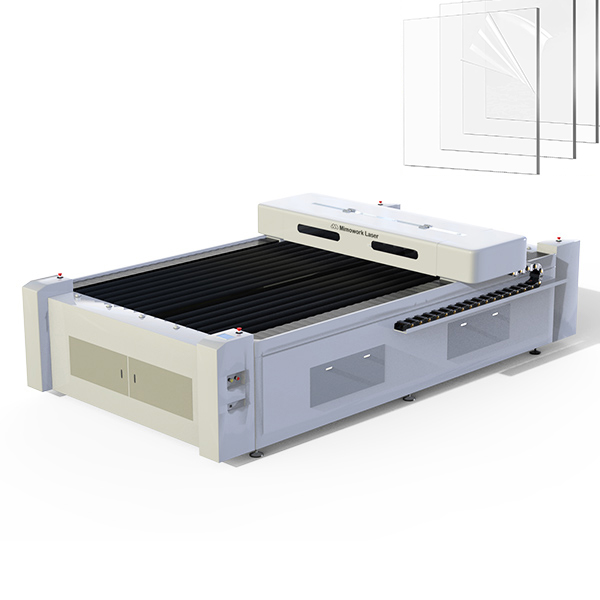

• Umsiki kanye noMqophi we-Laser we-Acrylic kanye nokhuni:

Ilungele leyo miklamo yokuqopha eyinkimbinkimbi kanye nokusika okunembile kuzo zombili izinto.

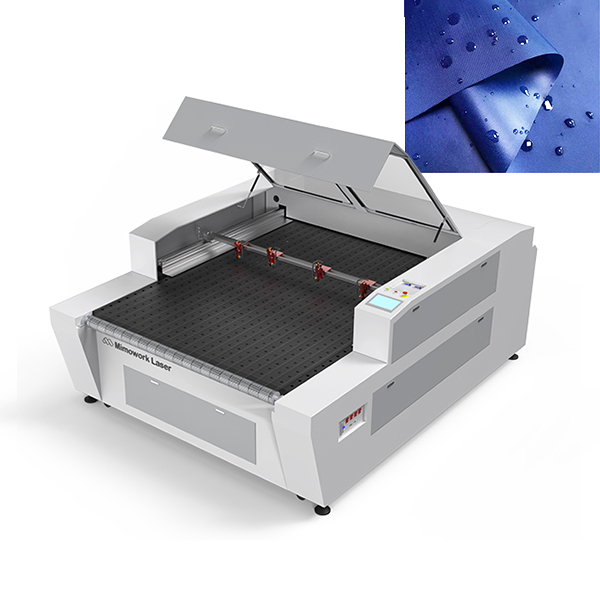

• Umshini Wokusika Nge-Laser Wendwangu Nesikhumba:

Ukuzenzakalela okuphezulu, kulungele labo abasebenza ngezindwangu, okuqinisekisa ukusikwa okubushelelezi nokuhlanzekile njalo.

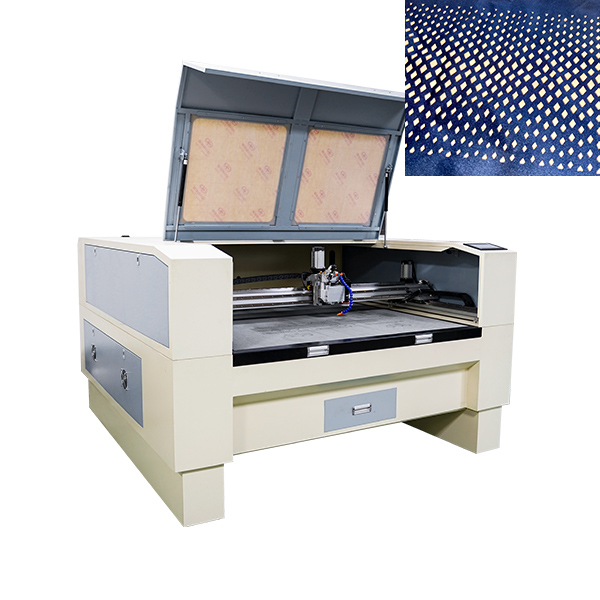

• Umshini Wokumaka we-Galvo Laser wePhepha, iDenim, nesikhumba:

Kuyashesha, kusebenza kahle, futhi kuphelele ekukhiqizweni okuphezulu ngemininingwane yokuqopha ngokwezifiso kanye namamaki.

Funda kabanzi ngomshini wokusika nge-laser, umshini wokusika nge-laser

Bheka Iqoqo Lethu Lomshini

Singobani?

I-Mimowork ingumkhiqizi we-laser ogxile emiphumeleni, oseShanghai naseDongguan, eShayina. Njengoba sineminyaka engaphezu kwengu-20 yobuchwepheshe obujulile bokusebenza, sigxile ekukhiqizeni izinhlelo ze-laser futhi sinikeze izixazululo eziphelele zokucubungula nokukhiqiza kumabhizinisi amancane naphakathi (ama-SME) kuzo zonke izimboni eziningi.

Okuhlangenwe nakho kwethu okubanzi kwezixazululo ze-laser kokubili ukucubungula izinto zensimbi nezingezona ezensimbi kusenze saba ngumlingani othembekile emhlabeni wonke, ikakhulukazi emkhakheni wezikhangiso, izimoto nezindiza, izinto zensimbi, izinhlelo zokusebenza zokufaka udayi, indwangu, kanye nemboni yezindwangu.

Ngokungafani nabanye abaningi, silawula yonke ingxenye yochungechunge lokukhiqiza, siqinisekisa ukuthi imikhiqizo yethu ihlinzeka ngokusebenza okuhle kakhulu njalo. Kungani kufanele wamukele noma yini encane uma ungathembela esixazululweni esenziwe ochwepheshe abaqonda izidingo zakho?

Ungase ube nentshisekelo

Imibono Eminye Yevidiyo >>

Ungaligcina Kanjani Futhi Ulifake Kanjani I-Laser Tube?

Ungayikhetha Kanjani Ithebula Lokusika I-Laser?

Isebenza Kanjani I-Laser Cutter?

Singumkhiqizi Womshini Wokusika I-Laser Ochwepheshe,

Yeka Ukukhathazeka Kwakho, Siyakukhathalela!

Isikhathi sokuthunyelwe: Agasti-30-2024