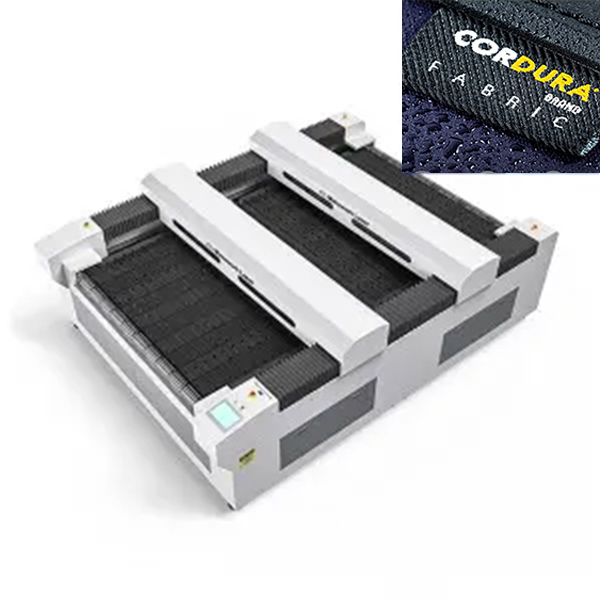

I-Industrial Laser Cutter ye-Cordura

▶ I-Fabric Cutter Enkulu: i-laser cut Cordura

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1600mm * 3000mm (62.9'' *118'') |

| Max Ububanzi Bezinto | 1600mm (62.9'') |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/450W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | I-Rack & Pinion Transmission kanye ne-Servo Motor Driven |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~6000mm/s2 |

* Ama-laser gantries amabili azimele ayatholakala ukuze aphinde kabili ukusebenza kahle kwakho.

Isakhiwo Semishini

▶ Ukusebenza Okuphezulu Nokukhipha Okuphezulu

- Ama-laser gantries amabili azimele

Ukumatanisa nethebula elisebenzayo lefomethi enkulu, isisiki se-laser yezimboni siklanywe ngamakhanda e-laser akabili ukuqedela ngokushesha ukukhiqizwa kwendwangu. Ama-laser gantries amabili azimele ahola amakhanda e-laser amabili ukusika indwangu ye-Cordura noma ezinye izindwangu ezisebenzayo ezindaweni ezihlukene. Ngokuphathelene namaphethini ahlukene, amakhanda amabili e-laser azohamba nendlela yokusika efanele ukuqinisekisa ukusika amaphethini ahlukene ngesikhathi esifushane. Ukusika nge-laser ngesikhathi esisodwa kuphinda kabili ukukhiqiza nokusebenza kahle. Inzuzo igqama kakhulu kuthebula lokusebenza lefomethi enkulu.

Kukhona indawo yokusebenza engu-1600mm * 3000mm (62.9'' *118'') ukuthwala izinto ezinkulu noma ezibanzi ngesikhathi esisodwa. Ifakwe i-auto-conveyor system kanye namakhanda e-laser amabili, umshini wokusika ifomethi enkulu ye-laser uhlanganisa ukudlulisa okuzenzakalelayo nokusika okuqhubekayo ukuze kusheshiswe inqubo yokukhiqiza.

▶ Ikhwalithi Enhle Yokusika

I-servo motor inamazinga aphezulu we-torque ngesivinini esikhulu. Ingaletha ukunemba okuphezulu ekumiseni i-gantry nekhanda le-laser kune-stepper motor.

- Amandla aphezulu

Ukuze kuhlangatshezwane nezidingo eziqinile zamafomethi amakhulu nezinto eziwugqinsi, i-Cordura laser cutter ifakwe amandla e-laser aphezulu angu-150W/300W/500W. Njengokugcwalisa i-ballistic enkulu yegiya lezempi, ulayini olungangenwa izinhlamvu zemoto, imishini yezemidlalo yangaphandle enefomethi ebanzi, amandla aphezulu angakwazi ukunqamula ngokushesha.

- Ukusika okuguquguqukayo njengephethini

Umzila wokusika oguquguqukayo ongenawo umkhawulo ejikeni nasekuqondeni. Ngokusho kwefayela lephethini elingenisiwe, ikhanda le-laser lingahamba njengendlela eklanyelwe ukubona ukusika okunembile nokuphezulu.

▶ Isakhiwo Esiphephile Futhi Esizinzile

- Ukukhanya kwesignali

Ngenxa yokucutshungulwa okuzenzakalelayo kwabasiki bethu be-laser, kuvame ukuvela ukuthi opharetha akekho emshinini. Ukukhanya kwesignali kungaba yingxenye ebalulekile engabonisa futhi ikhumbuze opharetha isimo sokusebenza somshini. Ngaphansi kwesimo esivamile sokusebenza, sibonisa isignali eluhlaza. Lapho umshini uqeda ukusebenza futhi uyama, wawuzoba phuzi. Uma ipharamitha isethwe ngendlela engavamile noma kukhona ukusebenza okungafanele, umshini uzoma bese kukhishwa ilambu elibomvu lokukhumbuza opharetha.

- Inkinobho yesimo esiphuthumayo

Uma ukusebenza okungalungile kubangela ubungozi obuthile obuvelayo ekuphepheni komuntu, le nkinobho ingaphushelwa phansi futhi inqanyulwe amandla omshini ngokushesha. Uma yonke into isicacile, ukukhipha inkinobho yesimo esiphuthumayo kuphela, bese ukukhanyisa amandla kungenza umshini uvuleke ukuze usebenze.

- Isifunda esiphephile

Izifunda ziyingxenye ebalulekile yemishini, eqinisekisa ukuphepha kwabaqhubi kanye nokusebenza okuvamile kwemishini. Zonke izakhiwo zesekethe zemishini yethu zisebenzisa imininingwane kagesi ye-CE & FDA. Uma kuba nokugcwala ngokweqile, ukujikeleza okufushane, njll., isekethe yethu ye-elekthronikhi ivimbela ukungasebenzi kahle ngokumisa ukugeleza kwamandla.

Ngaphansi kwetafula elisebenzayo lemishini yethu ye-laser, kunesistimu yokudonsa i-vacuum, exhunywe kuma-blower ethu aqeda amandla anamandla. Ngaphandle komphumela omkhulu wokuqeda intuthu, lolu hlelo luzohlinzeka ngokukhangisa okuhle kwezinto ezibekwe etafuleni lokusebenza, ngenxa yalokho, izinto ezincanyana ikakhulukazi izindwangu ziba yisicaba ngokwedlulele ngesikhathi sokusika.

I-R&D ye-Roll Cordura Laser Cutting

Umthombo we-CO2 RF Laser - Inketho

Amasampula Endwangu avela ku-Cordura Laser Cutter

Isibonisi Sevidiyo

I-Cordura Fabric Laser Cutting

- ivesti yokuzivikela

◆Ukusika ngendwangu ngesikhathi esisodwa, akukho ukunamathela

◆Azikho izinsalela zentambo, azikho i-burr

◆Ukusika okuguquguqukayo kwanoma yimuphi umumo nosayizi

Izindwangu ezilungele i-Laser:

inayiloni(inayiloni ye-ballistic),i-aramid, I-Kevlar, I-Cordura, i-fiberglass, i-polyester, indwangu eboshiwe,njll.

Izithombe Dlulisa amehlo

I-Protection Suit, I-Ballistic car flooring, I-Ballistic Ceiling yemoto, Impahla yezempi, Izindwangu zokusebenza, izingubo ezingangenwa izinhlamvu, umfaniswano we-Firefighter, ikhava yesihlalo semoto ye-Ballistic

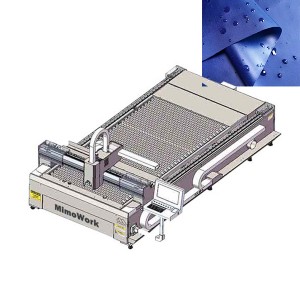

Ahlobene Indwangu Laser Cutters

• Amandla eLaser: 100W / 150W / 300W

• Indawo yokusebenza (W *L): 1600mm * 1000mm

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenza (W *L): 1800mm * 1000mm

• Amandla eLaser: 150W/300W/450W

• Indawo yokusebenza (W *L): 1600mm * 3000mm