Yebo, ungasika i-fiberglass nge-laser ngokuphelele usebenzisa umshini wokusika we-laser we-CO2 ochwepheshe!

Nakuba i-fiberglass iqinile futhi ihlala isikhathi eside, i-laser inamandla amakhulu, isika kalula izinto.

Ugongolo oluncane kodwa olunamandla luziba ngendwangu ye-fiberglass, amashidi, noma amaphaneli, okukushiya unezicucu ezihlanzekile nezinembile njalo.

I-fiberglass yokusika nge-laser ayigcini nje ngokuba yimpumelelo kodwa futhi iyindlela enhle yokuletha imiklamo yakho yokudala kanye nezimo eziyinkimbinkimbi ekuphileni ngale nto eguquguqukayo. Uzomangala ngalokho ongakudala!

Xoxa nge-Fiberglass

I-Fiberglass, evame ukubizwa ngokuthi ipulasitiki eqiniswe ngengilazi (i-GRP), iyinhlanganisela ethakazelisayo eyenziwe ngemicu yengilazi emincane elukiwe ibe yi-resin matrix.

Le ngxube ehlakaniphile ikunikeza izinto ezingagcini nje ngokuba lula kodwa futhi eziqinile futhi ezisebenziseka kalula.

Uzothola i-fiberglass kuzo zonke izinhlobo zezimboni—isetshenziselwa yonke into kusukela ezingxenyeni zesakhiwo kanye nokufakwa kokushisa kuya ezintweni zokuzivikela emasimini afana nezindiza, izimoto, ezokwakha kanye nezasolwandle.

Uma kukhulunywa ngokusika nokucubungula i-fiberglass, ukusebenzisa amathuluzi afanele kanye nezinyathelo zokuphepha kubalulekile ekwenzeni umsebenzi ngokuphepha nangokunembile.

Ukusikwa nge-laser kukhanye ngempela lapha, kukuvumela ukuthi ufinyelele kulezo zicucu ezihlanzekile neziyinkimbinkimbi ezenza umehluko omkhulu!

I-Fiberglass Yokusika Nge-Laser

I-fiberglass yokusika nge-laser imayelana nokusebenzisa umsebe we-laser onamandla amakhulu ukuncibilikisa, ukushisa, noma ukuhwamukisa impahla endleleni ethile.

Okwenza le nqubo ibe nembaba kangaka yisofthiwe yokuklama esekelwa yikhompyutha (CAD) elawula umshini wokusika nge-laser, iqinisekise ukuthi ukusika ngakunye kunembile futhi kuyahambisana.

Enye yezinto ezinhle kakhulu ngokusika nge-laser ukuthi isebenza ngaphandle kokuthintana ngokomzimba nezinto ezibonakalayo, okusho ukuthi ungafinyelela lawo madizayini ayinkimbinkimbi futhi anemininingwane kalula.

Ngesivinini sayo sokusika esisheshayo kanye nekhwalithi ephezulu, akumangalisi ukuthi ukusika nge-laser sekuyindlela esetshenziswa kakhulu yokusebenza ngendwangu ye-fiberglass, omata, nezinto zokuvikela!

Ividiyo: I-Fiberglass Embozwe Nge-Silicone Yokusika Nge-Laser

I-fiberglass embozwe nge-silicone iyisithiyo esihle kakhulu sokuvikela izinhlansi, amachaphaza, nokushisa, okwenza ibe usizo kakhulu ezimbonini ezahlukene.

Nakuba ukuyisika ngommese noma imihlathi kungaba yinselele impela, ukusika nge-laser kwenza inqubo kungabi yinto engenzeka kuphela kodwa futhi kube lula, kuletha ikhwalithi enhle kakhulu ngokusika ngakunye!

Ngokungafani namathuluzi okusika endabuko afana nama-jigsaw noma ama-Dremels, imishini yokusika nge-laser isebenzisa indlela engathintani ukuze ibhekane ne-fiberglass.

Lokhu kusho ukuthi akukho ukuguguleka kwamathuluzi futhi akukho monakalo wezinto ezibonakalayo—okwenza ukusika nge-laser kube ukukhetha okuhle kakhulu!

Kodwa yiluphi uhlobo lwe-laser okufanele ulusebenzise: i-Fiber noma i-CO₂?

Ukukhetha i-laser efanele kuyisihluthulelo sokuthola imiphumela emihle kakhulu lapho usika i-fiberglass.

Nakuba ama-laser e-CO₂ evame ukunconywa, ake sihlole ama-laser e-CO₂ kanye ne-fiber ukuze sibone izinzuzo kanye nemikhawulo yawo kulo msebenzi.

I-CO2 Laser Cutting Fiberglass

Ubude bamagagasi:

Ama-laser e-CO₂ ngokuvamile asebenza ngobude be-wavelength obungama-micrometer ayi-10.6, okusebenza kahle kakhulu ekusikeni izinto ezingezona ezensimbi, kufaka phakathi i-fiberglass.

Ukusebenza kahle:

Ubude be-CO₂ lasers bumuncwa kahle yizinto ze-fiberglass, okuvumela ukusika okuphumelelayo.

Ama-laser e-CO₂ ahlinzeka ngokusika okuhlanzekile nokunembile futhi angaphatha ubukhulu obuhlukahlukene be-fiberglass.

Izinzuzo:

1. Ukunemba okuphezulu kanye nemiphetho ehlanzekile.

2. Kufanelekela ukusika amashidi amakhulu e-fiberglass.

3. Isungulwe kahle futhi isetshenziswa kabanzi ezinhlotsheni zezimboni.

Imikhawulo:

1. Kudinga ukulungiswa okwengeziwe uma kuqhathaniswa nama-fiber laser.

2. Ngokuvamile inkulu futhi ibiza kakhulu.

Ukusika i-Fiber Laser Fiberglass

Ubude bamagagasi:

Ama-laser e-fiber asebenza ngobude be-wavelength obungaba ngu-1.06 micrometer, okufaneleka kakhulu ukusika izinsimbi futhi angasebenzi kahle ezintweni ezingezona izinsimbi njenge-fiberglass.

Kungenzeka:

Nakuba ama-fiber lasers engasika izinhlobo ezithile ze-fiberglass, ngokuvamile awasebenzi kahle kune-CO₂ lasers.

Ukumuncwa kobude be-wavelength be-fiber laser yi-fiberglass kuphansi, okuholela ekusikeni okungekuhle.

Umphumela Wokusika:

Ama-laser e-fiber angase anganikeli ukusika okuhlanzekile nokunembile ku-fiberglass njengama-laser e-CO₂.

Amaphethelo angase abe mancane, futhi kungaba nezinkinga ngokusikwa okungaphelele, ikakhulukazi ngezinto ezijiyile.

Izinzuzo:

1. Amandla aphezulu kanye nesivinini sokusika sezinsimbi.

2. Izindleko zokulungisa nezokusebenza eziphansi.

3. Incane futhi isebenza kahle.

Imikhawulo:

1. Akusebenzi kahle ezintweni ezingezona ezensimbi njenge-fiberglass.

2. Kungase kungafinyeleli ikhwalithi yokusika efiselekayo yokusetshenziswa kwe-fiberglass.

Ungayikhetha Kanjani I-Laser Yokusika I-Fiberglass?

Nakuba ama-fiber lasers ephumelela kakhulu ekusikeni izinsimbi futhi anikeza izinzuzo eziningana

Ngokuvamile akuzona izinketho ezinhle kakhulu zokusika i-fiberglass ngenxa yobude bayo besikhathi kanye nezici zokumuncwa kwezinto.

Ama-laser e-CO₂, anobude bawo obude, afaneleka kakhulu ukusika i-fiberglass, enikeza ukusika okuhlanzekile nokunembe kakhudlwana.

Uma ufuna ukusika i-fiberglass ngempumelelo nangekhwalithi ephezulu, i-CO₂ laser iyindlela enconywayo.

Uzothola ku-CO2 Laser Cutting Fiberglass:

✦Ukumuncwa Okungcono:Ubude be-CO₂ lasers bumuncwa kangcono yi-fiberglass, okuholela ekusikeni okusebenzayo nokuhlanzekile kakhudlwana.

✦ Ukuhambisana kwezinto ezibonakalayo:Ama-laser e-CO₂ aklanyelwe ngqo ukusika izinto ezingezona ezensimbi, okwenza zibe zilungele i-fiberglass.

✦ Ukuguquguquka: Ama-laser e-CO₂ angaphatha ukujiya okuhlukahlukene nezinhlobo ze-fiberglass, anikeze ukuguquguquka okwengeziwe ekukhiqizeni nasekusetshenzisweni kwezimboni.ukuvikela ukushisa, idekhi yasolwandle.

| Indawo Yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 100W/150W/300W |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma ishubhu ye-CO2 RF Metal Laser |

| Uhlelo Lokulawula Okwenziwa Ngemishini | Ukulawula Ibhande Lemoto Yesinyathelo |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Honey Comb noma Ithebula Lokusebenza Le-Knife Strip |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa i-Laser Cut Fiberglass

Ukugxila Okuzenzakalelayo

Kungase kudingeke ukuthi usethe ibanga elithile lokugxila kusofthiwe uma izinto zokusika zingasicaba noma zinobukhulu obuhlukile. Khona-ke ikhanda le-laser lizokhuphuka futhi lehle ngokuzenzakalelayo, ligcine ibanga elifanele lokugxila ebusweni bezinto ezibonakalayo.

Injini yeServo

I-servomotor iyi-servomechanism evaliwe esebenzisa impendulo yesikhundla ukulawula ukunyakaza kwayo kanye nendawo yokugcina.

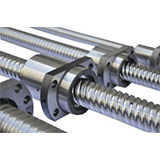

Isikulufu Sebhola

Ngokungafani nezikulufo ezijwayelekile ze-lead, izikulufo zebhola zivame ukuba zinkulu kakhulu, ngenxa yesidingo sokuba nendlela yokujikeleza kabusha amabhola. Isikulufo sebhola siqinisekisa ukusika nge-laser okusheshayo nokunembile okuphezulu.

| Indawo Yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3”) |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 100W/150W/300W |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma ishubhu ye-CO2 RF Metal Laser |

| Uhlelo Lokulawula Okwenziwa Ngemishini | I-Belt Transmission & Step Motor Drive |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Honey Comb / Ithebula Lokusebenza Le-Knife Strip / Ithebula Lokusebenza Le-Conveyor |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa i-Laser Cutting Fiberglass

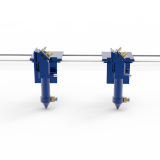

Amakhanda e-Laser Amabili

Ngendlela elula nengabizi kakhulu yokusheshisa ukusebenza kahle kokukhiqiza kwakho ukufaka amakhanda amaningi e-laser endaweni efanayo bese usika iphethini efanayo ngasikhathi sinye. Lokhu akudingi isikhala esengeziwe noma umsebenzi.

Uma uzama ukusika imiklamo eminingi ehlukene futhi ufuna ukonga izinto ngezinga elikhulu,Isofthiwe Yokwakha Izidlekekuzoba ukukhetha okuhle kuwe.

IIsiphakeli EsizenzakalelayoKuhlanganiswe neThebula Lokuthutha kuyisisombululo esifanele sochungechunge kanye nokukhiqizwa ngobuningi. Kuthutha izinto eziguquguqukayo (indwangu isikhathi esiningi) kusukela ku-roll kuya enkambisweni yokusika ohlelweni lwe-laser.

I-Laser Ingasika Kangakanani I-Fiberglass Enobukhulu Obungaka?

Ngokuvamile, i-laser ye-CO₂ ingasika amaphaneli e-fiberglass aqinile afinyelela ku-25mm kuya ku-30mm.

Njengoba amandla e-laser ahlukahlukene kusukela ku-60W kuya ku-600W, amandla aphezulu asho ikhono elikhulu lokusika izinto ezijiyile.

Kodwa akukhona nje ukujiya; uhlobo lwezinto ze-fiberglass nalo ludlala indima ebalulekile. Ukwakheka okuhlukene, izici, kanye nesisindo samagremu kungathinta kakhulu ukusebenza kanye nekhwalithi yokusika nge-laser.

Yingakho kubalulekile ukuhlola izinto zakho ngomshini wokusika we-laser ochwepheshe. Ochwepheshe bethu be-laser bazohlaziya izici ezithile ze-fiberglass yakho futhi bakusize uthole ukucushwa komshini okuphelele kanye nemingcele yokusika efanele!

Ingabe i-Laser Cut G10 Fiberglass ingakwazi ukusika?

I-fiberglass ye-G10 iyi-laminate eqinile enomfutho ophezulu eyenziwe ngokufaka izendlalelo zendwangu yengilazi ezicwiliswe ku-epoxy resin bese zicindezelwa ngaphansi komfutho ophezulu. Umphumela uba yinto eqinile neqinile eyaziwa ngezakhiwo zayo ezinhle kakhulu zokuvimbela ugesi kanye nomshini.

Uma kukhulunywa ngokusika i-fiberglass ye-G10, ama-laser e-CO₂ ayindlela engcono kakhulu yokusika, ahlinzeka ngokusika okuhlanzekile nokunembile njalo.

Ngenxa yezici zayo ezihlaba umxhwele, i-G10 fiberglass ilungele ukusetshenziswa okuhlukahlukene, kusukela ekushiseni kukagesi kuya ezingxenyeni ezisebenza kahle ngokwezifiso.

Inothi Elibalulekile: I-fiberglass ye-G10 yokusika nge-laser ingakhipha umusi onobuthi kanye nothuli olucolekile, ngakho-ke kubalulekile ukukhetha umsiki we-laser ochwepheshe onesistimu yokungenisa umoya kanye nokuhlunga eklanywe kahle.

Njalo beka phambili izinyathelo zokuphepha ezifanele, okuhlanganisa nokuphathwa komoya opholile kanye nokushisa okuphumelelayo, ukuqinisekisa imiphumela esezingeni eliphezulu kanye nendawo yokusebenza ephephile lapho usika i-fiberglass ye-G10!

Noma yimiphi imibuzo mayelana ne-Laser Cutting Fiberglass

Khuluma nochwepheshe wethu we-laser!

Unemibuzo mayelana ne-Laser Cutting Fiberglass Sheet?

Isikhathi sokuthunyelwe: Mashi-25-2025