Ungayikhetha Kanjani Ingxube Yegesi Engcono Kakhulu Yokushisela Kwakho Nge-Laser?

Izinhlobo, Izinzuzo, kanye Nezicelo

Isingeniso:

Izinto Ezibalulekile Okufanele Uzazi Ngaphambi Kokungena

Ukushisela nge-laser kuyindlela yokushisela enembayo kakhulu esebenzisa umsebe we-laser ukuncibilikisa izinto zento yokusebenza bese yakha ukushisela ngemva kokupholisa. Ekushiseleni nge-laser, igesi idlala indima ebalulekile.

Igesi evikelayo ayithinti nje kuphela ukwakheka komthungo wokushisela, ikhwalithi yomthungo wokushisela, ukungena komthungo wokushisela, kanye nobubanzi bokungena kodwa futhi ithinta ngqo ikhwalithi kanye nokusebenza kahle kokushisela nge-laser.

Yimaphi amagesi adingekayo ukuze kufakwe i-laser welding?Lesi sihloko sizobheka kabanziukubaluleka kwamagesi okushisela nge-laser, amagesi asetshenziswayo, nokuthi asebenzani.

Sizophinde sincomeumshini wokushisela we-laser omuhle kakhulungezidingo zakho.

Kungani Kudingeka Igesi Ukuze Kushiswe Nge-Laser?

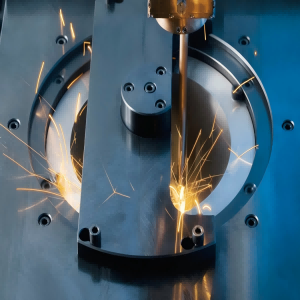

Ukushisela Ugongolo Lwelaser

Ngesikhathi senqubo yokushisela nge-laser, umsebe we-laser onamandla aphezulu ugxile endaweni yokushisela yento yokusebenza.

Kubangela ukuncibilika okusheshayo kwezinto ezingaphezulu kwento yokusebenza.

Igesi iyadingeka ngesikhathi sokushisela nge-laser ukuze kuvikelwe indawo yokushisela.

Lawula izinga lokushisa, uthuthukise ikhwalithi yokushisela, futhi uvikele uhlelo lokukhanya.

Ukukhetha uhlobo lwegesi olufanele kanye nemingcele yokuphakelwa yizinto ezibalulekile ekuqinisekiseni ukusebenza kahle.

Futhi inqubo yokushisela nge-laser ezinzile kanye nokuthola imiphumela yokushisela esezingeni eliphezulu.

1. Ukuvikelwa Kwezindawo Zokushisela

Ngesikhathi senqubo yokushisela nge-laser, indawo yokushisela ivezwa endaweni engaphandle futhi ithinteka kalula yi-oxygen kanye namanye amagesi emoyeni.

I-oksijini ibangela ukusabela kwe-oxidation okungaholela ekwehleni kwekhwalithi ye-weld, kanye nokudalwa kwama-pores kanye ne-inclusions. I-weld ingavikelwa ngempumelelo ekungcolisweni yi-oksijini ngokunikeza igesi efanele, ngokuvamile igesi engasebenzi njenge-argon, endaweni yokushisela.

2. Ukulawula Ukushisa

Ukukhethwa kanye nokutholakala kwegesi kungasiza ekulawuleni izinga lokushisa lendawo yokushisela. Ngokulungisa izinga lokugeleza kanye nohlobo lwegesi, izinga lokupholisa lendawo yokushisela lingathinteka. Lokhu kubalulekile ukulawula indawo ethintekile ekushiseni (HAZ) ngesikhathi sokushisela nokunciphisa ukuphambuka kokushisa.

3. Ikhwalithi Yokushisela Ethuthukisiwe

Amanye amagesi asizayo, njenge-oxygen noma i-nitrogen, angathuthukisa ikhwalithi kanye nokusebenza kwama-weld. Isibonelo, ukwengeza i-oxygen kungathuthukisa ukungena kwe-weld futhi kwandise isivinini sokushisela, kuyilapho kuthinta nesimo kanye nokujula kwe-weld.

4. Ukupholisa Igesi

Ekushiseni nge-laser, indawo yokushisela ivame ukuthintwa amazinga okushisa aphezulu. Ukusebenzisa uhlelo lokupholisa igesi kungasiza ekulawuleni izinga lokushisa lendawo yokushisela futhi kuvimbele ukushisa ngokweqile. Lokhu kubalulekile ekunciphiseni ukucindezeleka kokushisa endaweni yokushisela nokuthuthukisa ikhwalithi yokushisela.

Ukushisela Kwe-Laser Beam Okuzenzakalelayo

5. Ukuvikelwa Kwegesi Kwezinhlelo Zokubona

Umsebe we-laser ugxile endaweni yokushisela ngokusebenzisa uhlelo lwe-optical.

Ngesikhathi senqubo yokunamathisela, izinto ezincibilikisiwe kanye nama-aerosol akhiqizwayo kungangcolisa izingxenye zokukhanya.

Ngokufaka amagesi endaweni yokushisela, ingozi yokungcola iyancishiswa futhi isikhathi sokuphila kwesistimu yokukhanya siyandiswa.

Yimaphi Amagesi Asetshenziswa Ekushiseni Nge-Laser?

Ekushiseni nge-laser, igesi ingahlukanisa umoya epuletini lokushisela futhi iwuvimbele ukuthi ungahlangani nomoya. Ngale ndlela, ubuso bokushisela bepuleti lensimbi buzoba mhlophe futhi bube buhle kakhulu. Ukusebenzisa igesi kuvikela namalensi othulini lokushisela. Ngokuvamile, kusetshenziswa amagesi alandelayo:

1. Igesi Evikelayo:

Amagesi okuvikela, ngezinye izikhathi abizwa ngokuthi “amagesi angasebenzi,” adlala indima ebalulekile enqubweni yokushisela nge-laser. Izinqubo zokushisela nge-laser zivame ukusebenzisa amagesi angasebenzi ukuvikela ichibi lokushisela. Amagesi okuvikela asetshenziswa kakhulu ekushiseleni nge-laser afaka phakathi i-argon ne-neon. Izakhiwo zawo zomzimba nezamakhemikhali zihlukile, ngakho-ke imiphumela yawo ekushiseleni nayo ihlukile.

Igesi Evikelayo:I-Argon

I-Argon ingenye yamagesi angasebenzi kahle asetshenziswa kakhulu.

Inezinga eliphezulu le-ionization ngaphansi kwesenzo se-laser, okungasizi ukulawula ukwakheka kwamafu e-plasma, okuzoba nomthelela othile ekusetshenzisweni kahle kwama-laser.

Ukungangeni kahle kwe-argon kuyigcina ingangeni enkambisweni yokugoqa, kuyilapho futhi ikhipha ukushisa kahle, okusiza ukulawula izinga lokushisa endaweni yokugoqa.

Igesi Evikelayo:I-Neon

I-Neon ivame ukusetshenziswa njengegesi engasebenzi, efana ne-argon, futhi isetshenziswa kakhulu ukuvikela indawo yokushisela emoyeni nakwezinye izinto ezingcolisayo endaweni engaphandle.

Kubalulekile ukuqaphela ukuthi i-neon ayifaneleki kuzo zonke izinhlelo zokushisela nge-laser.

Isetshenziswa kakhulu kweminye imisebenzi ekhethekile yokushisela, njengokushisela izinto ezijiyile noma lapho kudingeka imithungo yokushisela ejulile.

2. Igesi Elisizayo:

Ngesikhathi senqubo yokushisela nge-laser, ngaphezu kwegesi eyinhloko evikelayo, amagesi asizayo angasetshenziswa futhi ukuthuthukisa ukusebenza kanye nekhwalithi yokushisela. Okulandelayo amanye amagesi asizayo avamile asetshenziswa ekushiseleni nge-laser.

Igesi Elisizayo:I-oxygen

I-oksijini ivame ukusetshenziswa njengegesi yokusiza futhi ingasetshenziswa ukwandisa ukushisa nokujula kokushisela ngesikhathi sokushisela.

Ukwengeza umoya-mpilo kungandisa isivinini sokushisela kanye nokungena, kodwa kudinga ukulawulwa ngokucophelela ukuze kugwenywe umoya-mpilo owengeziwe obangela izinkinga zokushiswa.

Igesi Elisizayo:Ingxube ye-Hydrogen/Hydrogen

I-hydrogen ithuthukisa ikhwalithi yama-welds futhi inciphisa ukwakheka kwama-porosity.

Izingxube ze-argon ne-hydrogen zisetshenziswa kwezinye izinhlelo ezikhethekile, njengokushisela insimbi engagqwali. Okuqukethwe kwe-hydrogen kule ngxube kuvame ukuba phakathi kuka-2% no-15%.

Igesi Evikelayo:I-nitrogen

I-nitrogen ivame ukusetshenziswa njengegesi elisizayo ekushiseni nge-laser.

Amandla e-ionization e-nitrogen aphakathi nendawo, aphezulu kune-argon futhi aphansi kune-hydrogen.

Izinga le-ionization ngokuvamile lingaphansi kwesenzo se-laser. Linganciphisa kangcono ukwakheka kwamafu e-plasma, linikeze ama-welds asezingeni eliphezulu kanye nokubukeka, futhi linciphise umthelela womoya-mpilo kuma-welds.

I-nitrogen ingasetshenziswa futhi ukulawula izinga lokushisa lendawo yokushisela nokunciphisa ukwakheka kwamabhamuza nama-pores.

Igesi Evikelayo:I-Helium

I-Helium ivame ukusetshenziselwa ukushisela nge-laser enamandla amakhulu ngoba ine-conductivity ephansi yokushisa futhi ayishintshi kalula i-ion, okuvumela i-laser ukuthi idlule kahle kanye namandla okukhanya afinyelele endaweni yokusebenza ngaphandle kwezithiyo.

Ilungele ukushisela okunamandla aphezulu. I-Helium ingasetshenziswa futhi ukuthuthukisa ikhwalithi yokushisela nokulawula amazinga okushisa okushisela. Lena igesi yokuvikela ephumelela kakhulu esetshenziswa ekushiseleni nge-laser, kodwa ibiza kakhulu.

3. Igesi Yokupholisa:

Igesi yokupholisa ivame ukusetshenziswa ngesikhathi sokushisela nge-laser ukulawula izinga lokushisa lendawo yokushisela, ukuvimbela ukushisa ngokweqile, nokugcina ikhwalithi yokushisela. Okulandelayo amanye amagesi okupholisa asetshenziswa kakhulu:

Igesi Epholisayo/ Ephakathi:Amanzi

Amanzi ayindlela evamile yokupholisa evame ukusetshenziselwa ukupholisa amajeneretha e-laser kanye nezinhlelo zokukhanya zokushisela nge-laser.

Izinhlelo zokupholisa amanzi zingasiza ekugcineni izinga lokushisa elizinzile lejeneretha ye-laser kanye nezingxenye ze-optical ukuqinisekisa ukuzinza nokusebenza kahle kwemisebe ye-laser.

Igesi Epholisayo/ Ephakathi:Amagesi Omoya

Kwezinye izinqubo zokushisela nge-laser, amagesi asemoyeni angasetshenziswa ukupholisa.

Isibonelo, ohlelweni lwe-optical lwe-laser generator, igesi ezungezile yomkhathi inganikeza umphumela wokupholisa.

Igesi Epholisayo/ Ephakathi:Amagesi Angasebenzi

Amagesi angasebenzi njenge-argon ne-nitrogen nawo angasetshenziswa njengamagesi okupholisa.

Zine-conductivity ephansi yokushisa futhi zingasetshenziswa ukulawula izinga lokushisa lendawo yokushisela nokunciphisa indawo ethinteke ekushiseni (HAZ).

Igesi Epholisayo/ Ephakathi:I-Nitrogen Ewuketshezi

I-nitrogen ewuketshezi iyindlela yokupholisa ephansi kakhulu engasetshenziswa ekushiseni nge-laser enamandla amakhulu kakhulu.

Inikeza umphumela wokupholisa osebenza kahle kakhulu futhi iqinisekisa ukulawulwa kwezinga lokushisa endaweni yokushisela.

4. Igesi Exubile:

Izingxube zegesi zivame ukusetshenziswa ekushiseleni ukuze kuthuthukiswe izici ezahlukahlukene zenqubo, njengesivinini sokushisela, ukujula kokungena, kanye nokuqina kwe-arc. Kunezinhlobo ezimbili eziyinhloko zezingxube zegesi: izingxube ezimbili kanye nezingxube ezintathu.

Izingxube Zegesi Ezimbili:I-Argon + I-Oxygen

Ukwengeza inani elincane le-oxygen ku-argon kuthuthukisa ukuzinza kwe-arc, kucwengisisa ichibi lokushisela, futhi kwandisa isivinini sokushisela. Le ngxube ivame ukusetshenziswa ekushiseleni insimbi yekhabhoni, insimbi engena-alloy ephansi, kanye nensimbi engagqwali.

Izingxube Zegesi Ezimbili:I-Argon + I-Carbon Dioxide

Ukwengezwa kwe-CO₂ ku-argon kwandisa amandla okushisela kanye nokumelana nokugqwala ngenkathi kunciphisa ukuchitheka. Le ngxube ivame ukusetshenziselwa ukushisela insimbi yekhabhoni kanye nensimbi engagqwali.

Izingxube Zegesi Ezimbili:I-Argon + i-Hydrogen

I-hydrogen inyusa izinga lokushisa le-arc, ithuthukisa isivinini sokushisela, futhi inciphisa amaphutha okushisela. Iwusizo kakhulu ekushiseleni ama-alloy asekelwe ku-nickel kanye nensimbi engagqwali.

Izingxube Zegesi Eziyi-Ternary:I-Argon + I-Oxygen + I-Carbon Dioxide

Le ngxube ihlanganisa izinzuzo zombili izingxube ze-argon-oxygen kanye ne-argon-CO₂. Inciphisa ukuchitheka, ithuthukisa ukugeleza kwamanzi echibini lokushisela, futhi ithuthukisa ikhwalithi yokushisela. Isetshenziswa kabanzi ekushiseleni ubukhulu obuhlukahlukene bensimbi yekhabhoni, insimbi engenangxube eningi, kanye nensimbi engagqwali.

Izingxube Zegesi Eziyi-Ternary:I-Argon + i-Helium + i-Carbon Dioxide

Le ngxube isiza ekuthuthukiseni ukuzinza kwe-arc, yandisa izinga lokushisa lechibi lokushisela, futhi ithuthukisa isivinini sokushisela. Isetshenziswa ekushiseleni kwe-arc okwenziwa nge-short-circuit kanye nasekushiseleni okunzima, okunikeza ukulawula okungcono kokushisela.

Ukukhethwa Kwegesi Ezinhlelweni Ezihlukene

Ukushisela Nge-Laser Ephathwa Ngesandla

Ezindleleni ezahlukene zokushisela nge-laser, ukukhetha igesi efanele kubalulekile, ngoba inhlanganisela yegesi ehlukene ingakhiqiza ikhwalithi, isivinini kanye nokusebenza kahle okuhlukile kokushisela. Nazi ezinye iziqondiso zokukusiza ukhethe igesi efanele isicelo sakho esithile:

Uhlobo Lwezinto Zokushisela:

Insimbi engagqwalingokuvamile isebenzisaIngxube ye-Argon noma i-Argon/i-Hydrogen.

Ama-Aluminium nama-Aluminium Alloyskuvame ukusetshenziswaI-Argon Emsulwa.

Ama-alloy e-Titaniumkuvame ukusetshenziswaI-nitrogen.

Izinsimbi Ezinekhabhoni Eningikuvame ukusetshenziswaI-oksijini njengegesi elisizayo.

Isivinini Sokushisela Nokungena:

Uma kudingeka isivinini esiphezulu sokushisela noma ukungena okujulile kokushisela, inhlanganisela yegesi ingalungiswa. Ukwengeza i-oxygen kuvame ukuthuthukisa isivinini kanye nokungena, kodwa kudinga ukulawulwa ngokucophelela ukuze kugwenywe izinkinga zokushisela.

Ukulawulwa Kwendawo Ethintekile Ekushiseni (HAZ):

Kuye ngokuthi izinto ezihlanzwayo zihlanzwa kanjani, imfucuza eyingozi edinga izinqubo ezikhethekile zokuphatha ingadalwa ngesikhathi senqubo yokuhlanza. Lokhu kunganezela ezindlekweni eziphelele zenqubo yokuhlanza nge-laser.

Ikhwalithi Yokushisela:

Ezinye izinhlanganisela zegesi zingathuthukisa ikhwalithi kanye nokubukeka kwama-weld. Isibonelo, i-nitrogen inganikeza ukubukeka okungcono kanye nekhwalithi yobuso.

Ukulawula Ama-Pore kanye nama-Bubble:

Ngezinhlelo zokusebenza ezidinga ukushintshwa kwekhwalithi ephezulu kakhulu, kudingeka kuqashelwe ngokukhethekile ukwakheka kwama-pores nama-bubble. Ukukhetha igesi ngendlela efanele kunganciphisa ingozi yalezi ziphazamiso.

Izinto Zokusebenza Nezindleko Zokucatshangelwa:

Ukukhethwa kwegesi nakho kuthonywa uhlobo lwemishini kanye nezindleko. Amanye amagesi angadinga izinhlelo ezikhethekile zokuphakelwa noma izindleko eziphakeme.

Ngezinhlelo zokusebenza ezithile, kunconywa ukuthi usebenze nonjiniyela wokushisela noma umenzi wemishini yokushisela we-laser ochwepheshe ukuze uthole iseluleko sochwepheshe futhi uthuthukise inqubo yokushisela.

Ukuhlolwa okuthile kanye nokwenza ngcono ngokuvamile kuyadingeka ngaphambi kokuba kukhethwe inhlanganisela yokugcina yegesi.

Kuye ngesicelo esithile, inhlanganisela yegesi ehlukene kanye namapharamitha kungazanywa ukuthola izimo zokushisela ezifanele kakhulu.

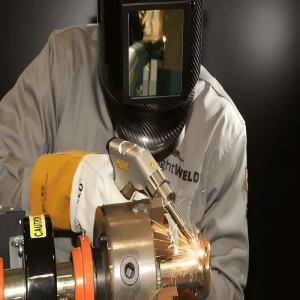

Izinto Okufanele Uzazi Ngazo: Ukushisela Nge-Laser Ephathwa Ngesandla

Umshini Wokushisela We-Laser Onconyiwe

Ukuze wenze ngcono imisebenzi yakho yokusebenza ngensimbi kanye nokucubungula izinto, ukukhetha imishini efanele kubalulekile. I-MimoWork Laser itusa ukuthiUmshini Wokushisela We-Laser Ophathwa Ngesandlaukuze kuhlanganiswe insimbi ngendlela enembile nephumelelayo.

Amandla aphezulu kanye ne-Wattage yezicelo ezahlukahlukene zokushisela

Umshini wokushisela we-laser ophathwa ngesandla ongu-2000W ubonakala ngobukhulu bomshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-laser yefayibha ozinzile kanye nekhebula lefayibha elixhunyiwe linikeza ukulethwa kwe-laser beam okuphephile nokuzinzile.

Ngamandla aphezulu, imbobo yokhiye yokushisela ye-laser iphelele futhi ivumela ijoyinti lokushisela ukuthi liqine ngisho nasensimbini ejiyile.

Njengoba ibukeka incane futhi incane ngomshini, umshini wokushisela we-laser ophathwayo ufakwe isibhamu sokushisela se-laser esiphathwa ngesandla esinyakaziswayo esilula futhi esilungele ukusetshenziswa kokushisela kwe-laser eminingi kunoma iyiphi i-engeli kanye nobuso.

Izinhlobo ezahlukene zokuzikhethela zama-nozzle okushisela nge-laser kanye nezinhlelo zokuphakela ngocingo okuzenzakalelayo zenza ukusebenza kokushisela nge-laser kube lula futhi lokho kuyabasiza abaqalayo.

Ukushisela nge-laser okusheshayo kukhulisa kakhulu ukusebenza kahle kokukhiqiza kwakho kanye nomphumela ngenkathi kuvumela umphumela omuhle kakhulu wokushisela nge-laser.

Fingqa

Ngamafuphi, ukushisela nge-laser kudinga ukusebenzisa igesi ukuvikela izindawo zokushisela, ukulawula izinga lokushisa, ukuthuthukisa ikhwalithi yokushisela, nokuvikela izinhlelo zokukhanya. Ukukhetha izinhlobo zegesi ezifanele kanye nemingcele yokuhlinzeka kuyisici esibalulekile ekuqinisekiseni inqubo yokushisela nge-laser esebenza kahle futhi ezinzile kanye nokuthola imiphumela yokushisela esezingeni eliphezulu. Izinto zokwakha kanye nezinhlelo zokusebenza ezahlukene kungadinga izinhlobo ezahlukene kanye nezilinganiso ezixubile ukuze kuhlangatshezwane nezidingo ezithile zokushisela.

Xhumana nathi namuhlaukuze ufunde kabanzi mayelana nabasiki bethu be-laser nokuthi bangayithuthukisa kanjani inqubo yakho yokukhiqiza ukusika.

Izixhumanisi Ezihlobene

Ingabe Unayo Imibono Ngemishini Yokushisela Nge-Laser?

Isikhathi sokuthunyelwe: Jan-13-2025